Professional Documents

Culture Documents

Design of Steel I-Section (BS5950)

Uploaded by

Rachelle C. AbanesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Steel I-Section (BS5950)

Uploaded by

Rachelle C. AbanesCopyright:

Available Formats

E. B.

NALDOZA Engineering Design

Registered in Dublin, Ireland (with Branch Office in Cavite, Philippines) Eddie Naldoza, BSc MIES MPICE E: eddienaldoza@engineer.com W: www.eddienaldoza.com

Project Irish Cement Ltd. - Kiln 3 Cement Mill-Silos Structure Subject Design of Steel Beam at EL 56.40 Beam No. 192-195, 47 Calculated Checked Date E. Naldoza E. Naldoza 26/09/07

Ref. No. PB9729

Page of

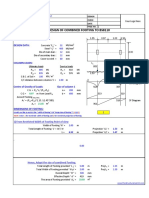

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216 Gridlines : 6 / C-E

www.eddienaldoza.com)

Limited to Plastic Section & Major Axis Bending only)

(Developed by: Eddie Naldoza, BSc MIES MPICE

Code / 1. Loadings : (Ultimate Loads) Clause Maximum Moment, Mx = 2 kN-m BS5950 Maximum Shear at Support,Fv = 3 kN Part 1 : Total Span, L = 700 mm 2000 / Load factor for Imposed Loads, f i = 1.5 2. Member Checks : 2.1 Trial Section

Point Load, P

Distance of point load from nearer support, ae

= = =

2 350 2

kN mm kN

Maximum Shear at Point Load or at Point of Maximum Moment, Fvc

127x76x13

UB

Steel Grade = S 275

From Member Capacity Tables (Blue Book) Moment Capacity, Mc = 0.00 kN-m 2.2 Section Properties : D = 127.0 mm b B = 76.00 mm d t = 4.00 mm Sx T = 7.60 mm Zx

= 38 mm = 96.60 mm 3 = 84 cm 3 = 75 cm

r = 7.60 mm Local Buckling Ratios : 2 E = 2.05E+05 N/mm b/T = 5.00 cm4 Ix = 473 d/t = 24.10 ry = 18.4 mm x = 16.3

2.3 Section Classification :

3.1.1 T < 16 mm 275 = 275 = 2 Table 9 Therefore; py = 275 N/mm py 275 3.5.2 For Rolled Section; Outstand Element of Compression Flange Table 11

= 1.00

Flange is Class 1 Plastic For Flange : b/T = 9 = 9 x 1.0 = 9.0 ; Actual b/T = 5.00 < 9.0 Web of an I-, H- or Box Section; Neutral Axis at Mid-depth For Web : d/t = 80 = 80 x 1.0 = 80.0 ; Actual d/t = 24.10 < 80.0 Web is Class 1 Plastic Therefore : Section is Class 1 Plastic 2.4 Check For Shear Buckling if : d/t > 70 70 = 70 x 1.00 = 70.0 ; Actual d/t = 24.10 < 70.0

(3.5.2-Table 11 b )

4.2.3

No need to check for Shear Buckling

4.2.3

2.5 Check For Shear Capacity : Fv or Fvc Pv 2 mm2 py = 275 N/mm ; Av = t D = 4.0 x 127.0 = 508 2 Pv = 0.6 py Av ; Pv = 0.6 x 275 N/mm x 508 mm2 = 83820

84 kN > 3.0 kN ; Adequate for Shear

4.2.5 2.6 Check For Moment Capacity : Mx Mcx 4.2.5.2/ Check for High/Low Shear (at point of Maximum Moment, Fvm) 4.2.5.3 Shear at point of Maximum Moment ; Fvc = 2 kN

Limiting Shear, Fve = 0.60 x Pv = 0.60 x

84

kN = 50.3 kN >

kN

Low Shear

For Low Shear (for Class 1 Plastic or Class 2 Compact cross-sections) Mcx = py Sx = 275 N/mm x 84 cm = 23.2 kN-m >

2.0

kN-m ; Adequate for Flexure

4.2.5.1

2.7 Check Limit To Avoid Irreversible Deformation Under Serviceability Loads : For simply supported beam : Mcx 1.2 py Zx 2 3 Mcx = 1.2 x 275 N/mm x 75 cm 23.2 < 24.618 kN-m ; Adequate for Flexure

E. B. NALDOZA Engineering Design

Registered in Dublin, Ireland (with Branch Office in Cavite, Philippines) Eddie Naldoza, BSc MIES MPICE E: eddienaldoza@engineer.com W: www.eddienaldoza.com

Project Irish Cement Ltd. - Kiln 3 Cement Mill-Silos Structure Subject Design of Steel Beam at EL 56.40 Beam No. 192-195, 47 Calculated Checked Date E. Naldoza E. Naldoza 26/09/07

Ref. No. PB9729

Page of

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216 Gridlines : 6 / C-E

www.eddienaldoza.com)

Limited to Plastic Section & Major Axis Bending only)

(Developed by: Eddie Naldoza, BSc MIES MPICE

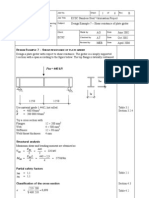

Part 1 : 2.8 Web Bearing and Buckling Under the Point Load :

2000 /

4.5.2.1

2.8.1 Bearing capacity of the unstiffened web : P Pb w ; Pb w = (b 1 + n k ) t py w b1 = t + 1.6r + 2T

; py w

= 275

N/mm2

= 31.4 mm ; n = 5 (not at the end of the member) ; k = T+r = 15.2 mm Pbw = [ 31.4 + ( 5 x 15.2 ) ] 4.0 x 275 = 118.1 kN > 2 kN

; Therefore Bearing Capacity of the unstiffened web under the point load is adequate

4.5.3.1

2.8.2 Buckling resistance of the unstiffened web : P P x ; Check if ; a e 0.7d ; a e is the distance from the load to the nearer end of the member = 350 mm 350 0.7 x 96.60 ; 350 > 67.6 mm ; Therefore 25 T 25 x 1.0 x 7.6 x 118.1 Px= Pbw ; P x= (b1 + nk ) d ( 31 + 5 x 15.2 ) x 96.60 P x = 220.33 kN > 2 kN

; Therefore Buckling Resistance of the unstiffened web under the point load is adequate

4.5.2.1

2.9 Web Bearing and Buckling at the Support : 2.9.1 Bearing capacity of the unstiffened web : Fv Pb w ; Pb w = (b 1 + n k ) t py w b1 = t + T + 0.8r - g

; py w

= 275

N/mm2

= 4.0 + 7.6 + 0.8 x 7.6 - 10 = 7.68 mm (properties of the supporting element ) n = 2 + 0.6b e /k 5 ; b e is the distance to the nearer end of the member from the end of the stiff bearing = 0 mm n = 2 + 0.6 x 0 / 15.2 = 2.0 < 5 ; Therefore use n = 2.0 ; k = T+r = 54.1 + 30.0 = 84.1 mm Pbw = [ 7.7 + ( 2.0 x 15.2 ) ] 4.0 x 275 = 41.9 kN > 3.0 kN

; Therefore Bearing Capacity of the unstiffened web at the support is adequate 4.5.3.1

2.9.2 Buckling resistance of the unstiffened web : Fv P x ; Check if ; a e 0.7d ; a e is the distance from the reaction to the nearer end of the member = 25 mm 25 0.7 x 96.60 ; 25 < 67.6 mm ; Therefore ae + 0.7d 25 T 25 x 1.0 x 7.6 x 41.9 25 + 67.6 x Px= Pbw ; P x= x 1.40 x 96.60 (b1 + nk ) d ( 7.7 + 2 x 84.1 ) x 96.60 1.4 d P x = 61.059 kN x > 3.0 kN 0.68 = 41.8 kN

; Therefore Buckling Resistance of the unstiffened web at the support is adequate 2.5.2

2.10 Serviceabilty Limit States : Deflection Check

The serviceability Loads are taken as unfactored imposed loads. In this case, as only ultimate loads are the available data, the unfactored imposed loads will be taken as Mc or P / f i conservatively, for simplicity; f i to be the load factor = 1.5

From Maximum Moment, Mc; wi = Unfactored Distributed Load wi Le2 8x 2 kN-m 8 Mc Mc = 1.5 ; wi = = = 2 1.5 Le2 8 1.5 x 0.7 m From Point Load P; W i = Unfactored Point Load P 2.1 P = 1.5 W i ; Wi = = = 1.4 kN 1.5 1.5 The total deflection is given by: Wi Le 5 wi Le4 = + 384 E I 48 EI 5 x 21.8 x 0.7 4 1.4 x 0.7 3 = + 384 x 2.E+05 x 473 48 x 2.E+05 x 473 ; Adequate for deflection = 0.081 mm < 3.89 mm

21.8

kN/m

Limits for calculated deflection (2.5.2 Table 8) for : Cantilever Allowable deflection, a Le 700 a = = = 180 180

3.89

mm

Therefore : 127x76x13

is Adequate, Adopt Section

UB

E. B. NALDOZA Engineering Design

Registered in Dublin, Ireland (with Branch Office in Cavite, Philippines) Eddie Naldoza, BSc MIES MPICE E: eddienaldoza@engineer.com W: www.eddienaldoza.com

Project Irish Cement Ltd. - Kiln 3 Cement Mill-Silos Structure Subject Design of Steel Beam at EL 56.40 Beam No. 192-195, 47 Calculated Checked Date E. Naldoza E. Naldoza 26/09/07

Ref. No. PB9729

Page of

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216

4.3.0

Gridlines :

C-E

www.eddienaldoza.com)

Limited to Plastic Section & Major Axis Bending only)

(Developed by: Eddie Naldoza, BSc MIES MPICE

2.11 Lateral Torsional Buckling : Mx Mb/m LT ;

Maximum Major axis Moment in the segment, Mx = Effective Length of the segment, L E

= 700 mm

2 38

kN-m ; /x = 38.0 / 16.3 = 2.3 ; = 0.5 (Equal flange) ; ; W = 1.0 LO ; v = 0.93 (Table 19)

4.3.6.7 4.3.6.8

=LE/ry = 700 / 18.4 = u = 0.9

(for Rolled I of Equal flange-4.3.6.8 )

(for Class 1 Plastic or Class 2 Compact Sections-4.3.6.9 )

Equivalent Slenderness

; LT = uvw

Limiting equivalent slenderness

LT = 0.9 x 0.93 x 38.0 x 1.0 = 32

B.2.2 Perry factor & Robertson constant

0.5 ; LO = 0.4( E /py) 0.5 = 0.4 x ( x 2.05E+05 / 275 ) = 34.31

LT

B.2.1

= 7.0 x ( 32 -

; LT = a LT(LT-LO)/1000 ; a LT = 7.0 34.31 )/ 1000 = -0 ; LT = p y +( LT +1)p E 2 = = 275 + ( -0 2

2

p E = E/ LT2 = x 2.05E+05 / 32

Bending Strength,

+ 1 ) 1980

pb =

= 1980 pE py

= 1111 N/mm2

1980 x 275 1111 + ( 1111 84200 - 1980 x 275 )

0.5

LT +( LT 2 -p E p y ) Mb = p b Sx

0.5

= 280

4.3.6.4

Buckling Resistance Moment;

= 280 x

= 23.606 kN-m

Uniform Moment Factor for Lateral Torsional Buckling (General case); m LT Moments at quarter points Moments at mid point

M2 = M4 =

Table 18

2 2

kN-m kN-m

M3 =

kN-m

m LT = 0.2 +

0.15M 2+0.5M 3+0.15M 4 0.15 x = 0.2 + Mx 24 kN-m > 2 kN-m

+ 0.50 x 2

+ 0.15 x

= 1.00

4.3.6.2

Mb

m LT

23.606 = 1.00

; Therefore Buckling Resistance Moment is Adequate

PB9729

r Axis Bending only)

kN quate for Shear

PB9729

r Axis Bending only)

N/mm2

N/mm2

mm

PB9729

r Axis Bending only)

(Table 19)

N/mm2

You might also like

- DESIGN CALCULATION SHEET FOR SUPPORTING BEAMDocument29 pagesDESIGN CALCULATION SHEET FOR SUPPORTING BEAMTamkwokkwong86% (7)

- Plinth BeamDesignDocument1 pagePlinth BeamDesignsabahpm0% (1)

- Design of Steel Beam EC3Document5 pagesDesign of Steel Beam EC3myutilities71% (7)

- Design of PurlinsDocument2 pagesDesign of PurlinsFeri Noviantoro57% (7)

- Steel Beam DesignDocument32 pagesSteel Beam DesignNaveen Parthasarathy88% (8)

- Design of Base Plate For BS5950Document2 pagesDesign of Base Plate For BS5950dantevarias89% (19)

- BASE PLATE DESIGNDocument4 pagesBASE PLATE DESIGNvinujohnpanickerNo ratings yet

- Purlins DesignDocument1 pagePurlins Designzhuan89100% (9)

- Steel DesignDocument14 pagesSteel DesignNordin AhmadNo ratings yet

- Wind Load Bs CodeDocument36 pagesWind Load Bs CodeFranklyn Genove100% (1)

- Design of Roof TrussDocument25 pagesDesign of Roof TrusshemanatuNo ratings yet

- Design of Roof (Pratt) TrussDocument17 pagesDesign of Roof (Pratt) TrussD.V.Srinivasa Rao100% (4)

- Design Strip FootingDocument12 pagesDesign Strip FootingHenra HalimNo ratings yet

- Steel Design SpreadsheetDocument53 pagesSteel Design SpreadsheetJan Alexis Monsalud100% (3)

- PULL-OUT CAPACITY OF HOLDING DOWN BOLTS CALCULATIONSDocument1 pagePULL-OUT CAPACITY OF HOLDING DOWN BOLTS CALCULATIONSatokku100% (2)

- 10.0design of Baseplate and Anchor BoltsDocument7 pages10.0design of Baseplate and Anchor BoltsklynchelleNo ratings yet

- Design of RCC SlabDocument8 pagesDesign of RCC Slabrajseema_n2180% (5)

- Design of Composite Steel BeamDocument4 pagesDesign of Composite Steel BeamDodoo AhmedNo ratings yet

- Design CalculationDocument20 pagesDesign CalculationSơn Nguyễn-Lê100% (1)

- Isolated & Combined Footing Design Bs8110.1985Document6 pagesIsolated & Combined Footing Design Bs8110.1985EdwinNo ratings yet

- Shear Connection - Beam - Steel Column - Fin PlateDocument30 pagesShear Connection - Beam - Steel Column - Fin Platekalpanaadhi100% (3)

- Design of circular water tank reinforcementDocument20 pagesDesign of circular water tank reinforcementSourav Chandra83% (6)

- 10m R.C BEAM DESIGNDocument3 pages10m R.C BEAM DESIGNchris100% (1)

- Base Plate With Moment & Axial CompressionDocument2 pagesBase Plate With Moment & Axial CompressionAnonymous b3NKZUb100% (3)

- BS5950 End Plate DesignDocument4 pagesBS5950 End Plate DesignSimon Lsm67% (3)

- Monolithic Staircase DesignDocument5 pagesMonolithic Staircase DesignAzraiAzizNo ratings yet

- Raft DesignDocument28 pagesRaft DesignMkh Engcivil75% (4)

- STRAP FOOTING DESIGNDocument23 pagesSTRAP FOOTING DESIGNAyazAkram100% (6)

- Combined Footing DesignDocument3 pagesCombined Footing DesignThe Structural WorldNo ratings yet

- Design of Base PlateDocument4 pagesDesign of Base PlateBenjun Balbin100% (5)

- Purlin Design ReportDocument12 pagesPurlin Design Reportarif_rubin100% (1)

- Isolated Footing Design by SefianDocument6 pagesIsolated Footing Design by SefianManoj Kumar Pal80% (5)

- TCC11 Element Design - Xls of Slab and BeamDocument12 pagesTCC11 Element Design - Xls of Slab and BeamAmadu Farrow100% (1)

- Design of Beams To BS 8110Document14 pagesDesign of Beams To BS 8110Kasun Karunaratne99% (76)

- Base PlateDocument12 pagesBase PlateD SRINIVAS100% (1)

- Baseplate Design Input DataDocument166 pagesBaseplate Design Input DataAnonymous ciKyr0t86% (7)

- Design of roof truss and purlin for Thermax LtdDocument9 pagesDesign of roof truss and purlin for Thermax LtdManju BirjeNo ratings yet

- RC water tank design and reinforcement calculationDocument10 pagesRC water tank design and reinforcement calculationChhour CE100% (1)

- Underground Water Tank DesignDocument23 pagesUnderground Water Tank Designfawad_jawaid570072% (36)

- Wind Load CalculationsDocument2 pagesWind Load CalculationsMoumita Sit100% (3)

- StaircaseDocument2 pagesStaircaseMAGED MOHMMED AHMED QASEMNo ratings yet

- Design of Steel I Section BS5950Document6 pagesDesign of Steel I Section BS5950amachmouchi100% (1)

- Design of Steel I Section BS5950Document6 pagesDesign of Steel I Section BS5950Haffizul SaidNo ratings yet

- Design of Steel I-Section (BS5950)Document3 pagesDesign of Steel I-Section (BS5950)gertjaniNo ratings yet

- Structural Designsteel BeamDocument7 pagesStructural Designsteel BeamAtienza Design StudioNo ratings yet

- Steel Column BeamDocument6 pagesSteel Column Beamdharul khairNo ratings yet

- SEO-Optimized Beam Design CalculationDocument169 pagesSEO-Optimized Beam Design CalculationabuzahrauNo ratings yet

- Pile Cap Design 1Document6 pagesPile Cap Design 1kjpatel2100% (2)

- Design of Plate GirderDocument9 pagesDesign of Plate GirdermunnaiitrNo ratings yet

- Steel Beam DesignDocument26 pagesSteel Beam DesignWazini D. Izani100% (1)

- Tutorial 7 - Connections - Part ADocument28 pagesTutorial 7 - Connections - Part ACyrus HongNo ratings yet

- Design Manual For Structural Stainless Steel Design Example 7 enDocument6 pagesDesign Manual For Structural Stainless Steel Design Example 7 enAl7amdlellah100% (1)

- Plate Girder DesignDocument8 pagesPlate Girder Designkalpanaadhi100% (1)

- Moment Connection - Flush End Plate-19.01.06Document48 pagesMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- CSE 362 Design of Steel Structures Section Properties and CapacitiesDocument19 pagesCSE 362 Design of Steel Structures Section Properties and CapacitiesRufus ChengNo ratings yet

- Ec9 Ex61 Shear No StiffenersDocument3 pagesEc9 Ex61 Shear No StiffenersimotalpNo ratings yet

- Steel Structure - Solutions - Batch AbDocument7 pagesSteel Structure - Solutions - Batch AbAvinash ChoudharyNo ratings yet

- Method of Design Cantilever ErectionDocument62 pagesMethod of Design Cantilever Erectionzieq72No ratings yet

- Roof - Semi-D (Idp)Document117 pagesRoof - Semi-D (Idp)Amalina Idris AlphonsoNo ratings yet

- 03 1 Weynand Moment Resistant JointsDocument71 pages03 1 Weynand Moment Resistant Jointsdeepak_dce_meNo ratings yet

- Ra 544 - Ce LawDocument17 pagesRa 544 - Ce LawRachelle C. Abanes100% (22)

- Proposed Geometric DesignDocument1 pageProposed Geometric DesignRachelle C. AbanesNo ratings yet

- Project Management For Engineers - 0Document2 pagesProject Management For Engineers - 0Rachelle C. AbanesNo ratings yet

- REVISED DPWH Standard SpecificationDocument203 pagesREVISED DPWH Standard SpecificationCaSas JeCca100% (1)

- Traffic Data AnalysisDocument4 pagesTraffic Data AnalysisRachelle C. AbanesNo ratings yet

- m6l35 Lesson 35 Indeterminate Trusses and Industrial FramesDocument28 pagesm6l35 Lesson 35 Indeterminate Trusses and Industrial FramesVitor ValeNo ratings yet

- Soils and Foundations 3rd Ed, Cheng Liu & Jack EvettDocument475 pagesSoils and Foundations 3rd Ed, Cheng Liu & Jack EvettRachelle C. Abanes83% (12)

- Acopos User's ManualDocument171 pagesAcopos User's ManualKonstantin Gavrilov100% (1)

- Aerodrome Controller (ADC) ExamDocument5 pagesAerodrome Controller (ADC) ExamaxnpicturesNo ratings yet

- Insulation Coordination 52 kV SystemDocument5 pagesInsulation Coordination 52 kV SystemSahil BhagatNo ratings yet

- Capitulos 10 y 11Document34 pagesCapitulos 10 y 11mlpz188669No ratings yet

- Diesel Engine: Service Parts List ForDocument49 pagesDiesel Engine: Service Parts List ForIgnacio OsorioNo ratings yet

- Chapter 1 XXXDocument8 pagesChapter 1 XXXChristelle Mary Sabile SabanalNo ratings yet

- History of JS: From Netscape to Modern WebDocument2 pagesHistory of JS: From Netscape to Modern WebJerraldNo ratings yet

- Micom p343Document66 pagesMicom p343kjfenNo ratings yet

- Billing No. 4 Accomplishement ReportDocument1 pageBilling No. 4 Accomplishement ReportGOB ConstructionNo ratings yet

- Elsa CableDocument2 pagesElsa CableJay WangNo ratings yet

- Proposed Rule: Airworthiness Directives: Cirrus Design Corp. Models SR20 and SR22 AirplanesDocument2 pagesProposed Rule: Airworthiness Directives: Cirrus Design Corp. Models SR20 and SR22 AirplanesJustia.comNo ratings yet

- Indigo Assessment - Cynthia Nieto VargasDocument14 pagesIndigo Assessment - Cynthia Nieto Vargasapi-506651646No ratings yet

- Grade CalculatorDocument1 pageGrade CalculatorKHENN ALDIANONo ratings yet

- HVDC Grid Feasibility StudyDocument189 pagesHVDC Grid Feasibility StudyDeoudrafNo ratings yet

- Çimsa Eco White TDS (EN)Document1 pageÇimsa Eco White TDS (EN)Babu NysemereNo ratings yet

- Evaporation: (I) Vapour PressureDocument15 pagesEvaporation: (I) Vapour Pressurevenka07No ratings yet

- Autodesk 2010 Product Key PDFDocument6 pagesAutodesk 2010 Product Key PDFDragon NestNo ratings yet

- Rocket Icluster V8.1Document16 pagesRocket Icluster V8.1Felipe Cervantes EspinosaNo ratings yet

- GE Con Perkins Más StamfordDocument2 pagesGE Con Perkins Más Stamfordjim perdigonNo ratings yet

- Improved M16A2 - A3 - A4 Zero TargetDocument6 pagesImproved M16A2 - A3 - A4 Zero Targetbeetho1990No ratings yet

- DDNS Management System User's Manual V1.0 - 20120301Document7 pagesDDNS Management System User's Manual V1.0 - 20120301judapiesNo ratings yet

- IPTC 12029 Selection Criteria For Artificial Lift Technique in Bokor FieldDocument13 pagesIPTC 12029 Selection Criteria For Artificial Lift Technique in Bokor FieldJean Carlos100% (1)

- ZI-Manual en PDFDocument56 pagesZI-Manual en PDFhaphapNo ratings yet

- Technical Information HANSA-FLEX Hose ConnectionsDocument75 pagesTechnical Information HANSA-FLEX Hose ConnectionshorsanicuNo ratings yet

- 7 Inch Liner Cementing ProgramDocument44 pages7 Inch Liner Cementing ProgramMarvin OmañaNo ratings yet

- Kali Linux For BeginnersDocument13 pagesKali Linux For Beginnersnihal0% (1)

- Python Question Paper Mumbai UnivercityDocument5 pagesPython Question Paper Mumbai UnivercityRahul PawarNo ratings yet

- Cloud Radio Access Network Architecture Towards 5G NetworkDocument171 pagesCloud Radio Access Network Architecture Towards 5G NetworkwobblegobbleNo ratings yet

- BMS for EVs: Why Battery Management is Critical for Electric Vehicle Performance and SafetyDocument24 pagesBMS for EVs: Why Battery Management is Critical for Electric Vehicle Performance and SafetyChaudhari JainishNo ratings yet

- Computer Science & Engineering Department ElectivesDocument13 pagesComputer Science & Engineering Department Electivesnitro gtnaNo ratings yet