Professional Documents

Culture Documents

Volvo 850 ODB A1 Automatic Transmission Diagnostic

Uploaded by

Bartłomiej KilianOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Volvo 850 ODB A1 Automatic Transmission Diagnostic

Uploaded by

Bartłomiej KilianCopyright:

Available Formats

"VCC-022644 EN 2001-08-13"

Diagnostic functions

Overview

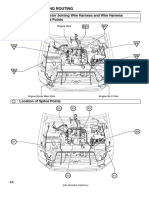

The transmission control module (TCM) (1) has onboard diagnostics (Volvo On-board Diagnostic system) which continuously monitors the TCM input and output signals. A fault in the system will result in the TCM storing a Diagnostic Trouble Code (DTC) and the warning lamp in the combined instrument (3) will begin flashing. (There are exceptions however, refer to "Diagnostic trouble codes DTC" ). Information on possible faults and other information as well can be read off from the system in the following ways: Volvo diagnostics: By reading off the output from the Data Link Connector (DLC) (2). OBD II: Using a faulttracing instrument attached to the OBD II socket (6) on the bracket in front of the gear shift (only certain markets, USA and Canada).

Volvo diagnostics

Communication with the system is via the Data Link Connector (DLC) A1. Information can be displayed in three ways: - Flashing LED combinations and pressing buttons on the DLC (2) - Volvo Scan Tool (Diagnostic Key) (5) - Volvo Scan Tool (System Tester) (4) with cassette memory for text readouts (only certain markets, USA and Canada) Using Volvo Diagnostics the following Diagnostic Test Modes (DTMs) can be utilized: DTM 1: Display and erase stored Diagnostic Trouble Codes (DTC) DTM 2: Receive confirmation that certain system components are operating. DTM 3: Activate system components following a routine of tests. DTM 4: Activate the same components as in DTM 3 but activation takes place component by component, as requested by the operator. DTM 5: Continuous readings from certain sensors in the system. DTM 6: Enter information in the transmission's control system.

General

DTM 1

Stored Diagnostic Trouble Codes (DTCs) can be read off and erased in DTM 1. A short press on the button on the DLC will start the DTC read-off procedure. If the control module replies by flashing code 111 no faults have been registered, so no DTCs have been stored. If the control module replies using any other flashing code sequence it is a DTC that has been stored. Use "Diagnostic trouble codes DTC" to identify the reason for the DTC being set. The control module can store a maximum of five DTCs. The fault must be corrected and the DTC erased before further DTCs can be stored in the

"VCC-022644 EN 2001-08-13"

transmission control module.

Erasing DTCs

It is only possible to clear the data link connector (DLC) of codes after reading off all the codes at least once and the first code stored at least twice. The procedure for erasing stored DTCs is as follows: - Ignition ON - Press the button and hold down for more than five seconds. Release the button. - Wait for the LED to light. - Press the button again and hold down for more than five seconds. Release the button. - Make sure that the DTC's have been cleared by reading off the DTCs again.

Diagnostic Test Mode 2

General

Using DTM 2 it is possible to verify whether certain system components are operating. The test is carried out by activating the components one by one. The control module responds with an acknowledgement code to confirm the activation of a component. In addition to checking the operation of the individual components, this also verifies whether there are breaks or shortcircuits in cables or connectors on the component circuitry. DTM 2 is activated with two short presses on the DLC button.

Activation of DTM 2

- Ignition ON - Move the gear selector to position R and set the mode selector to mode S. - Press twice on the DLC button. The LED starts to blink. - Activate the components in the order shown in the table below. Note! Certain models: The stop (brake) light switch also sends a signal to the control module. Use "SHIFTLOCK OVERRIDE" to move the gear shift selector from the P to the R position at operation 2 in the table below.

"VCC-022644 EN 2001-08-13"

Procedure

Pos R to pos P Pos P to pos R Pos R to pos N Pos N to pos D Pos D to pos 3 Pos 3 to pos L

Component tested Response Code

242 144 241 214 224 234 243

Press W for one 324 second Press E 244 Press S 314 Depress brake pedal 334 for one sec. Fully depress 341 accelerator pedal (AP) to kickdown position

Gear selector in pos P OK Gear selector in pos R OK Gear selector in pos N OK Gear selector in pos D OK Gear selector in pos 3 OK Gear selector in pos L OK Gear selector faulty in this lever position Winter mode OK Economy mode OK Sport mode OK Stop (brake) light switch OK Kickdown switch OK

Diagnostic Test Mode 3

General

DTM 3 enables the system components/functions to be activated in a set order. The testing is performed in a cycle in which each component/function is activated 6 times, with a short interval between each activation. Before each activation there is a short pause. The test cycle is repeated 3 times and then terminates automatically. DTM 3 is activated with three short presses on the DLC button. Note! On cars with Turbo and/or OBD II. When activating operation 6 and 7, according to the

Activating Diagnostic Test Mode 3

"VCC-022644 EN 2001-08-13"

table below, no change/symptom is indicated on the engine, transmission or combined instrument. To check these functions proceed as follows before activating DTM 3: - Ignition OFF - Connect testbox - Connect a voltmeter to the terminal indicated in the table below. Check the voltmeter reading when function is activated. - Ignition ON - Move the gear selector to position P or N. - Engine idling Note! The gear selector must be in position P or N and the car's speed should 0 km/h. - Press the diagnosis button three times. The LED will flash as the components are activated. Use a stethoscope to listen for solenoid clicks. The following components/functions can be activated:

Operation Component

1 Solenoid S1 2 3 4

5 6*

7**

Clicking noise in transmission Solenoid S2 Clicking noise in transmission Solenoid SL Clicking noise in transmission Solenoid STH Clicking noise in transmission. The solenoid only clicks twice, when stopping and when starting. So listen carefully. Warning light in Light blinks combined instrument OBD II Connect a voltmeter malfunction between #20 (#A20) and signal. MILR #45 (#B15). When the component is activated the voltmeter will give a reading that oscillates between 0 V and battery voltage. Torque limit Connect a voltmeter

Function

"VCC-022644 EN 2001-08-13"

8 9 10

between #20 (#A20) and #31 (#B1). When the component is activated the voltmeter will give a reading that oscillates between 0 V and battery voltage. Drive Engine is varying idle compensation at engine speed idle Torque limit Engine is varying idle signal TC2 at idle engine speed Torque limit Engine is varying idle signal TC1 at idle engine speed

signal, Turbo, TCT

*) Certain markets only, USA, Canada **) Only cars with Turbo engines

General

DTM 4

Activating Diagnostic Test Mode 4

DTM 4 activates the same components/functions activated in DTM 3 but activation takes place component by component, only as requested by the operator. The component/function is activated six times in sequence. In DTM 4 the rate of code transmission between the transmission control module TCM and the DLC can be changed from two to ten times the standard rate. After testing, the OBD system automatically exits test function 4. This means that to perform another test, the entire procedure must be repeated from the beginning. DTM 4 is activated with four short presses on the DLC button.

Note! On cars with Turbo and/or OBD II. When activating DTCs 431 and 432 no change/sympton is indicated on the engine, transmission or combined instrument. To check these functions proceed as follows before activating DTM 4: - Ignition OFF - Connect testbox - Connect a voltmeter to the terminals indicated in the table below Note! Check the voltmeter reading when function is activated. - Ignition ON - Move the gear selector to position P or N. - Engine idling (applies to activating DTCs 414, 422 and 423). Note! The gear selector must be in position P or N and the car's speed should be 0 km/h. - Press the DLC button four times. - Enter the selected code. Enter one digit each time the LED comes on. LED begins flashing when the component/function is activated. Use a stethoscope to listen for solenoid clicks. The following components/functions can be

"VCC-022644 EN 2001-08-13"

activated:

311 312 313 342 343 411 412 414 422 423 431

DTC

Standard speed Double standard speed 10x standard speed Solenoid S1 Solenoid S2 Solenoid STH Warning light in combined instrument Drive compensation at idle Torque limit signal TC2 at idle Torque limit signal TC1 at idle, Request for lighting the Malfunction Indicator Lamp (MILR), Torque limit signal, Turbo, TCT,

Component

Normal transmission speed Double transmission speed Ten times normal transmission speed Clicking noise in transmission Clicking noise in transmission Clicking noise in transmission. The solenoid only clicks twice, when stopping and when starting. So listen carefully. Light blinks Engine is varying idle engine speed Engine is varying idle engine speed Engine is varying idle engine speed Connect a voltmeter between #20 (#A20) and #45 (#B15). When the component is activated the voltmeter will give a reading that oscillates between 0 V and battery voltage. Connect a voltmeter between #20 (#A20) and #31 (#B1). When the component is activated the voltmeter will give a reading that oscillates between 0 V and battery voltage.

*) Certain markets only, USA, Canada **) Only cars with Turbo engines

Function

432

Diagnostic Test Mode 5

General

Test function 5 continuously reads off values for oil temperature, speed, transmission rpm, transmission and throttle position. The values are continuously updated and shown as flashing codes. These cannot be understood without using the table on the next page. Use the table to convert the code blinks to an reading. The status of the control module's control of the TP

"VCC-022644 EN 2001-08-13"

Activating Diagnostic Test Mode 5

signal and slippage time can also be displayed. The status is read directly from the response codes. Note! The adaptive slippage time function is not yet available as a transmission control module (TCM) function. This will be available in the future. DTM 5 is activated with five short presses on the DLC button.

- Ignition ON - Push the DLC button five times. - Enter the selected code. Enter one digit each time the LED comes on. The LEDs will respond with a flashing code. Use the conversion table to obtain the status readout."Conversion tables"

Code Function

11 5 12 5 13 5

Oil temperature Oil temperature in "Conversion tables" Throttle signal 145 Unadjusted 215 status Adapted Shifting speed 155 Normal 225 status (Not Adjusted available in TCM) 42 Speed Speed in "Conversion 4 tables" . Only when driving 43 Transmission Speed in "Conversion 4 speed rpm tables" . Only when driving 44 Throttle position Throttle opening in 4 "Conversion tables" .

Response

Diagnostic Test Mode 6

General

DTM 6 can be used to enter data in the tranmission control system. The adaptive (selfadjusting) throttle signal and shiftingspeed adjustment functions can be reset. The shifting speed must be reset when the transmission is replaced. Note! DTM 6 has not yet been integrated into the transmission control system. This will be available in the future. It is however possilbe to follow the

"VCC-022644 EN 2001-08-13"

Activating Diagnostic Test Mode 6

method described in this DTM. The operation of the transmission will not be affected. Diagnostic Test Mode 6 is activated by pressing the DLC button six times in quick succession after DTM 5 has been activated.

Activation is in two stages: Reading in DTM 5 and resetting in DTM 6. - Ignition ON - Activate DTM 5 - Select the adaptive function that is to be reset. - Enter the selected code according to the table below. Enter one digit each time the LED comes on. The LEDs will respond with a flashing code. Use the conversion table below to obtain the status readout.

Throttle signal 145 Unadjusted 2 status 15 Adapted 135 Shifting speed 155 Normal 225 status (Not Adjusted available in TCM) - Make a note of the code for the response in DTM 5. - Activate DTM 6 by pressing the DLC button six times within 30 seconds of the response being given. When the LED lights enter the selected code for resetting according to the table below.

Code

125

Function

Response

"VCC-022644 EN 2001-08-13"

125 Throttle signal status 135 Status for shifting speed Once the selected code has been entered, the adaptive value has been reset to its normal value.

Code

Function

OnBoard Diagnostics II (OBD II)

(Only certain markets, USA and Canada) OBD II is a diagnostics system designed to meet legal requirements. Instruments for faulttracing can be plugged in to the OBD II socket in order to access DTCs and system parameters. OBD II contains only DTCs and parameters for emissions and cannot as such provide the comprehensive range of information available from the Volvo Onboard diagnostics systems. Refer to "OBD II-codes" .

You might also like

- 2008 Chevrolet HHR DTCDocument6 pages2008 Chevrolet HHR DTCTal Benyamin100% (1)

- Avalon XL 2009Document257 pagesAvalon XL 2009Luis PerezNo ratings yet

- Diagnose P0778 Code for Electronic Controlled Automatic TransmissionDocument3 pagesDiagnose P0778 Code for Electronic Controlled Automatic TransmissionCaislanteNo ratings yet

- Hybrid Battery Control: HV Battery: Charging 2010 My Ls600h (11:2009 - )Document15 pagesHybrid Battery Control: HV Battery: Charging 2010 My Ls600h (11:2009 - )Duc TruongNo ratings yet

- Engine Unit Exploded View With Torque Specifications (1 of 7)Document7 pagesEngine Unit Exploded View With Torque Specifications (1 of 7)miguel100% (1)

- Instruction Manual: P/N 30-2860 B Series COP Conversion KitDocument22 pagesInstruction Manual: P/N 30-2860 B Series COP Conversion KitWhiro Opo Arief100% (1)

- Supplemental Restraint System (SRS) PDFDocument64 pagesSupplemental Restraint System (SRS) PDFruanm_1No ratings yet

- SPFRDDocument2 pagesSPFRDSebastianus Ari YudhantoNo ratings yet

- Electro-Pneumatic Positioner/Smart Positioner: (Lever Type/rotary Type)Document25 pagesElectro-Pneumatic Positioner/Smart Positioner: (Lever Type/rotary Type)Anonymous 144EsBNo ratings yet

- Ford Technology Newsletter 102010Document3 pagesFord Technology Newsletter 102010fordfiesta_myNo ratings yet

- Re4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresDocument3 pagesRe4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresfulltransmissionNo ratings yet

- MIL ON DTC P2820 2014 - 2017 Corolla Transmission(s) CVT 2017 Im Transmission(s) CVTDocument10 pagesMIL ON DTC P2820 2014 - 2017 Corolla Transmission(s) CVT 2017 Im Transmission(s) CVTSajjad HussainNo ratings yet

- Can Communication System: PrecautionDocument106 pagesCan Communication System: PrecautionRicardo Watson100% (1)

- Seat Alhambra 2.0 TDi 2005-2010Document11 pagesSeat Alhambra 2.0 TDi 2005-2010marquin84No ratings yet

- TS TR 0075 D PDFDocument2 pagesTS TR 0075 D PDFromanjcNo ratings yet

- RC4A-EL Manual OEMDocument207 pagesRC4A-EL Manual OEMcarlosNo ratings yet

- DSB 240LHDocument96 pagesDSB 240LHGuillermo HernandezNo ratings yet

- Peugeot 308 Specifications Brochure PDFDocument12 pagesPeugeot 308 Specifications Brochure PDFLuis PanaoNo ratings yet

- Service Bulletin: Area Application: Europe Model Name: Corolla, Corolla Verso Model Code: ZNR11#, NDE120#Document8 pagesService Bulletin: Area Application: Europe Model Name: Corolla, Corolla Verso Model Code: ZNR11#, NDE120#Jou Power100% (1)

- Bando TototaDocument55 pagesBando TototagaelNo ratings yet

- Automatic Transmission PDFDocument334 pagesAutomatic Transmission PDFAriel MercochaNo ratings yet

- Group Models Listed Excessive Oil ConsumptionDocument20 pagesGroup Models Listed Excessive Oil Consumptionkomodo30No ratings yet

- DI102Document6 pagesDI102Erln LimaNo ratings yet

- ZF 4HP16 OptraDocument5 pagesZF 4HP16 OptraGERARDO CESSANo ratings yet

- A340h TransferDocument5 pagesA340h TransferPushkar NathNo ratings yet

- A Report On Industrial Work ExperienceDocument20 pagesA Report On Industrial Work ExperienceAgusiobo Anthony ChukwudiNo ratings yet

- AL4 Pressure Regulation FaultDocument3 pagesAL4 Pressure Regulation Faultsirajmy100% (1)

- Diagrama A Honda Civid Hybrid 2009Document1 pageDiagrama A Honda Civid Hybrid 2009enio romeroNo ratings yet

- Hybrid2009 SKBDocument6 pagesHybrid2009 SKBsovon adhikaryNo ratings yet

- G Electrical Wiring Routing: Position of Parts in Engine CompartmentDocument8 pagesG Electrical Wiring Routing: Position of Parts in Engine CompartmentTec RomeroNo ratings yet

- A760E Auto Trans - InstallationDocument7 pagesA760E Auto Trans - InstallationJohn Locke100% (1)

- ToYOTA MMT Diagnosis SummaryDocument6 pagesToYOTA MMT Diagnosis SummaryBrais Gutierrez RodriguezNo ratings yet

- PCM Codes For MitsubishiDocument6 pagesPCM Codes For MitsubishiahmednallaNo ratings yet

- Land Rover Help!: How To Change The Fuel Pump On Your Land Rover LR2Document11 pagesLand Rover Help!: How To Change The Fuel Pump On Your Land Rover LR2Salif NdiayeNo ratings yet

- Typical LED SymbolDocument4 pagesTypical LED Symbolthy thy thyNo ratings yet

- Electrically Controlled Shift Lock SystemDocument3 pagesElectrically Controlled Shift Lock SystemMayobanex Moya MartinezNo ratings yet

- ToyodaDocument4 pagesToyodaCloud SkyNo ratings yet

- G4a El FallasDocument8 pagesG4a El FallasLogam Lopez100% (1)

- YarisworldDocument150 pagesYarisworldapi-3706132No ratings yet

- Z4 E85 Hardtop Retrofit KitDocument11 pagesZ4 E85 Hardtop Retrofit KitChristian MariNo ratings yet

- Engine Mechanical PDFDocument193 pagesEngine Mechanical PDFDean BNo ratings yet

- Technical Service BULLETINDocument328 pagesTechnical Service BULLETINCarlos E. FuentesNo ratings yet

- CIRCUIT DIAGRAMDocument40 pagesCIRCUIT DIAGRAMYannick de WalqueNo ratings yet

- BOR Hemi Installation GuideDocument43 pagesBOR Hemi Installation GuideBryan100% (2)

- Toyota ReparacionDocument12 pagesToyota ReparacionCibernetica pasin Alta tecnologiaNo ratings yet

- Engine Compartment Fuse Box (Type 2) : 1 - 2 Head (RH) 10 Right Hand Headlight 3 Head (LH) 10 Left Hand HeadlightDocument7 pagesEngine Compartment Fuse Box (Type 2) : 1 - 2 Head (RH) 10 Right Hand Headlight 3 Head (LH) 10 Left Hand HeadlightCarlos Alberto LopezNo ratings yet

- Idle Air Volume Learning Procedure GuideDocument2 pagesIdle Air Volume Learning Procedure GuideGala Sn100% (1)

- Technical Service Information 12-58Document3 pagesTechnical Service Information 12-58Planta Damiana2100% (1)

- Mitsubishi: Front Wheel Drive Automatic Transmission (E-W) Workshop ManualDocument4 pagesMitsubishi: Front Wheel Drive Automatic Transmission (E-W) Workshop ManualRamon AcostaNo ratings yet

- Almera N16 TechDocument4 pagesAlmera N16 TechSpiros FousasNo ratings yet

- Engine Control System 1. General: 37 Engine-4A-Fe and 7A-Fe EnginesDocument10 pagesEngine Control System 1. General: 37 Engine-4A-Fe and 7A-Fe EnginesDavid R PaucaraNo ratings yet

- 32d05 Control of ECTDocument12 pages32d05 Control of ECTMelvin MhdsNo ratings yet

- Eee 1Document3 pagesEee 1Gordo FragosoNo ratings yet

- How To Use Electrical Wiring Diagram: Section 1Document3 pagesHow To Use Electrical Wiring Diagram: Section 1benjie187100% (1)

- ToyotaDocument12 pagesToyotaZarate CruzNo ratings yet

- If Your Vehicle Needs To Be Towed: 5-1. Essential InformationDocument7 pagesIf Your Vehicle Needs To Be Towed: 5-1. Essential InformationxsmartieNo ratings yet

- Technical Service Bulletin: Automatic Transmission DTC P0880/P088000Document11 pagesTechnical Service Bulletin: Automatic Transmission DTC P0880/P088000anoNo ratings yet

- Plug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideFrom EverandPlug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideNo ratings yet

- Turbo H5M-RDocument50 pagesTurbo H5M-RBartłomiej KilianNo ratings yet

- BMW - zf6 6r60 Zip inDocument11 pagesBMW - zf6 6r60 Zip inBartłomiej Kilian100% (1)

- 05 07 30 023Document8 pages05 07 30 023meteoro666No ratings yet

- Viewfile 0 EabDocument9 pagesViewfile 0 EabBartłomiej KilianNo ratings yet

- GM 6L50 80 90Document42 pagesGM 6L50 80 90Tony Holmes100% (10)

- 5R55S Troubleshooting & ElectricDocument186 pages5R55S Troubleshooting & ElectricBartłomiej Kilian100% (3)

- 087 VW Audi PorsheDocument306 pages087 VW Audi PorsheBartłomiej Kilian100% (1)

- BTRDocument100 pagesBTRBartłomiej Kilian100% (1)

- 3biegi VWDocument30 pages3biegi VWBartłomiej KilianNo ratings yet

- BW 35 NiedomaganiaDocument23 pagesBW 35 NiedomaganiaBartłomiej KilianNo ratings yet

- Tecumseh Basic Troubleshooting & Service InformationDocument21 pagesTecumseh Basic Troubleshooting & Service Information"Rufus"82% (17)

- Tecumseh Service ManualDocument123 pagesTecumseh Service Manualmasterviking82% (85)

- Reaming InstructionDocument5 pagesReaming InstructionBartłomiej KilianNo ratings yet

- 5R55NWS ReamerDocument4 pages5R55NWS ReamerBartłomiej KilianNo ratings yet

- BW 35 TransmissionDocument84 pagesBW 35 TransmissionBartłomiej KilianNo ratings yet

- BW Users ManualDocument14 pagesBW Users ManualBartłomiej KilianNo ratings yet

- Ford Overdrive Transmissions 101Document54 pagesFord Overdrive Transmissions 101Ian Foreman73% (11)

- Automatic Transmission Specifications and Tightening TorquesDocument63 pagesAutomatic Transmission Specifications and Tightening TorquesBartłomiej Kilian100% (3)

- Ford Overdrive Transmissions 101Document54 pagesFord Overdrive Transmissions 101Ian Foreman73% (11)

- Jf506e Gearbox OverviewDocument8 pagesJf506e Gearbox OverviewRoberto Volo100% (5)

- 6 Speed Auto 09G ATF Fluid Change and Filter DIYDocument6 pages6 Speed Auto 09G ATF Fluid Change and Filter DIYBartłomiej KilianNo ratings yet

- 6HP19 Manual CompletoDocument15 pages6HP19 Manual CompletoMaría Martz De García92% (12)

- 722.6 Adaptation ProcedureDocument3 pages722.6 Adaptation ProcedureBartłomiej Kilian80% (5)

- Ford Transmission AnniversaryDocument20 pagesFord Transmission Anniversarysava88100% (1)

- Automatavalto - PDF CD4EDocument7 pagesAutomatavalto - PDF CD4EDan JurekNo ratings yet

- Chapter 1-Musculoskeletal SystemDocument113 pagesChapter 1-Musculoskeletal SystemWang Ming YaNo ratings yet

- Kit TransmisionDocument45 pagesKit TransmisionJose Carlos Troncoso SarachoNo ratings yet

- 4320 Tractor IntroductionDocument9 pages4320 Tractor Introductionodali batista0% (1)

- D3G, D4G, and D5G HYSTAT Track-Type Tractors Hydraulic SystemDocument2 pagesD3G, D4G, and D5G HYSTAT Track-Type Tractors Hydraulic SystemNidya Wardah JuhanaNo ratings yet

- Hyper Acc Dragon PDFDocument387 pagesHyper Acc Dragon PDFmikheil darsavelidze100% (1)

- "Luigi" Amigurumi Pattern: by Andrea LealDocument10 pages"Luigi" Amigurumi Pattern: by Andrea LealSandra SouzaNo ratings yet

- Homebrew 5e RacesDocument8 pagesHomebrew 5e RacesMarc AndréNo ratings yet

- Arcanist - Level 4Document2 pagesArcanist - Level 4АндрейПраздниковNo ratings yet

- MATERIAL BALANCE TITLEDocument46 pagesMATERIAL BALANCE TITLEG Vamsee KrishnaNo ratings yet

- Hand Lasting ProcessDocument8 pagesHand Lasting ProcessmanojNo ratings yet

- A1 - A2 - Calling Customer ServiceDocument8 pagesA1 - A2 - Calling Customer ServiceAnderson MoraesNo ratings yet

- League of Legends Game PresentationDocument10 pagesLeague of Legends Game PresentationFlavia IanofschiNo ratings yet

- Yury Markushin - Chess Statistics - Top 10 Best Openings For White and BlackDocument4 pagesYury Markushin - Chess Statistics - Top 10 Best Openings For White and Blackchezzter25No ratings yet

- Gautam Research ReportDocument81 pagesGautam Research ReportDeep ChoudharyNo ratings yet

- Bowflex Sport ManualDocument78 pagesBowflex Sport ManualBalloonpopper100% (1)

- BVB11 Scoresheet Electronic 2021-22Document2 pagesBVB11 Scoresheet Electronic 2021-22Petter LauraHuamanNo ratings yet

- James Smith - Applied Sprint TrainingDocument184 pagesJames Smith - Applied Sprint Training張凱奇95% (22)

- TFG FinalDocument72 pagesTFG FinalValentina AntuñaNo ratings yet

- Planos Electricos T-6Document26 pagesPlanos Electricos T-6jrgonzales24No ratings yet

- Philippine Folk Dance StepsDocument10 pagesPhilippine Folk Dance StepsKersey BadocdocNo ratings yet

- Barbarian Tower Level 20-30 PDFDocument16 pagesBarbarian Tower Level 20-30 PDFIqbal BaihaqiNo ratings yet

- Kickboxing ManualDocument5 pagesKickboxing ManualBoky DjordjevicNo ratings yet

- Nexgen Fabrics Catalogue-2Document62 pagesNexgen Fabrics Catalogue-2Bala VishnuNo ratings yet

- Ford 7.3L 94-03 DiagnosticsDocument9 pagesFord 7.3L 94-03 DiagnosticsColoray Borthwick75% (8)

- Hemi Tech ArticleDocument4 pagesHemi Tech ArticleBen WineNo ratings yet

- GI A2PLUS U3 Grammar StandardDocument1 pageGI A2PLUS U3 Grammar StandardjohanaNo ratings yet

- Freebitco - in Script Fast Multiply - 2020Document3 pagesFreebitco - in Script Fast Multiply - 2020Mohammadreza EmamiNo ratings yet

- Choose the Correct Answer for English Test QuestionsDocument11 pagesChoose the Correct Answer for English Test Questionsmuhammad azzamNo ratings yet

- 163 Automan March Issue 2015Document84 pages163 Automan March Issue 2015Automan MagazineNo ratings yet