Professional Documents

Culture Documents

CS Pipe Fab & Erect Costs

Uploaded by

wally55bearOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CS Pipe Fab & Erect Costs

Uploaded by

wally55bearCopyright:

Available Formats

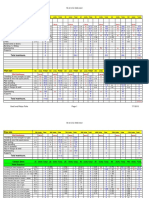

St-st & Cs field erect

Stainless 304L & 316

15

Units

Total

20

0

0

0

0

0

0

0

0

0

0

0

0

0

0.49

Units

Total

25

Units

0

0

0

0

0

0

0

0

0

0

0

0

0

0.52

20

0.92

11

0.18

Total

40

Units Total

50

Units

Total

80

Units

185

196

12.5

0

57.6

0

0

0

0

0

50

0

0

0.72

400

1.12

359

0.34

75

Total

100

Units

288

402

25.5

0

91.2

0

0

0

0

0

83

0

0

0.79

600

1.21

352

0.38

95

Total

Stainless Steel Erection Hours

Wall thickness

Field handling pipework..

Handle & erect fab spool pieces.

Pipe cutting

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

Socket weld

O'lets

Install vents or drains

Bending 1 x 90deg

Hydrotesting

Supports

1.5m/m

0.39

0.79

0.16

0.12

0.62

0.73

0.75

2.16

Total manhours.

1.5m/m

0.82

0.16

0.12

0.65

0.74

0.75

2.46

1.5m/m

0.14

0.73

0.84

0.82

3.06

1.5m/m

10.4 0.59

10.1 0.94

0.72 0.22

0

0.18

2.92 0.85

0

1.15

0

1.02

0

4.14

0

0

4

1

0

0

80

48

10

12

12

28.2

2m/m

47.2 0.66

45.1 0.98

2.2 0.26

0

0.2

10.2 1.2

0

1.36

0

1.15

0

5.76

0

0

12

1

0

0

281

200

48

48

50

117

2m/m

0.26

1.52

60

2.05

1.6

7.8

83

502

2m/m

0.32

1.78

70

2.57

0

9.96

120

890

474

425.9

36.1

0

124.6

0

0

0

0

0

120

0

0

1181

1536.2

Pipe size

Wall thickness

Handling & erect straight run pipe.

Handle & erect fab spool pieces.

Pipe cutting

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

O'lets

Hydrotesting

Supports

Total manhours.

150

Units

Total

200

356

402

64.4

20.4

217

0

0

100

0

0

1.05

200

1.64

109

1.08

30

0.88

15

3.75

30

2m/m

0.89

400

1.31

307

0.92

70

0.68

30

3.1

70

3.65

12.72

1

100

Units

Total

250

210

179

32.4

13.2

113

0

0

0

0

0

1.31

30

2.03

16

2m/m

1160

5.17

13.56

50

Units

Total

300

39.3

32.5

4.8

2.08

18.2

0

0

10

0

0

1.57

100

2.36

36

1.76

13

1.4

13

2m/m

546.86

1.2

1.04

4.56

6.45

1

10

Units

Total

350

157

85

22.9

8.4

65

0

0

36

0

0

1.8

30

2.69

2m/m

106.9

7.56

1

36

Units

Total

400

54

24.2

6

1.7

17.6

0

0

10

0

0

2.13

80

2.95

34

3.1

11

2.4

6.8

11

2.5m/m

374.2

1.7

5.86

8.85

1

10

Units

Total

450

170

100

34.1

12

74.8

0

0

40

0

0

2.46

3m/m

113.49

9.36

1

40

Units

Total

3m/m

0

0

0

0

0

0

0

0

0

0

3.61

4

3.2

8.7

10.02

431.6

0

2733.06

Geoff and Robyn Poile

Page 1

7/7/2013

St-st & Cs field erect

Pipe size

500 Units Total

Wall thickness

Handling & erect straight run pipe.

Handle & erect fab spool pieces.

Pipe cutting

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

Hydrotesting

Supports

600 Units Total

5m/m

2.79

4.13

5.6

4.4

11.3

Total manhours.

700 Units

5m/m

0

0

0

0

0

0

0

0

3.28

4.76

7.6

12.5

12

Total

900 Units Total

5m/m

19.7

23.8

15.2

6

25

0

12

0

3.65

100

5.2

61

8.3

16

7.4

10

13.8

16

100

101.68

1200 Units

6m/m

Total

1500 Units

6m/m

Total

1700 Units Total

6m/m

6m/m

365

317

133

74

221

0

100

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1209.8

0

1311.48

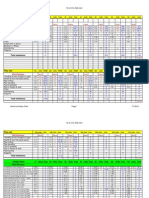

Carbon Steel

15

Units Total

20 Units Total

25

Units Total

40 Units Total

50

Units Total

80

Units Total

100 Units Total

Field Erection

Handling & erect straight run

Handling & erect fab spools sch 10-60.

Handling & erect fab spools sch 80-100.

Handling & erect fab spools sch 120-160.

Make on screw fittings & valves.

Field handling valves & install. < 600#

Field erection bolt ups < 600#

Attaching flanges screw type.

Attaching flanges slip on type.

Attaching flanges weld neck.

Man B/W Tig root run sched 40 pipe.

Man B/W Tig root run sched 80 pipe.

Man B/W Tig root run sched 160 pipe.

Man B/W Tig root run sched 160 pipe.

Man B/W Tig root run sched 160 pipe.

Olet type welds.

Mark cut & bevel < 80.

Threading pipe including cut.

Bending

Pressure test 10% of piping manhours.

Total manhours.

Geoff and Robyn Poile

0.52

0.6

0.75

0.85

0.1

0.2

0.7

1.2

0.9

1.5

0.7

0.9

1.2

1.5

0.1

0.23

1.4

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.55

0.7

0.8

0.9

0.1

0.2

0.7

1.2

0.9

1.5

0.98

1.1

1.6

1.8

0.1

0.23

1.5

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.59

0.73

0.85

1

0.2

0.3

0.7

1.2

0.9

1.5

1.09

1.33

1.83

2.1

0.17

0.23

1.6

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Page 2

0.62

0.81

0.93

1.12

0.3

0.4

0.7

1.2

1

1.5

1.36

1.71

2.37

2.9

0.17

0.26

2

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.65

0.88

1.02

1.26

0.3

0.5

0.7

1.2

1.3

1.5

1.47

1.87

2.76

3.9

0.21

0.3

2.3

1

20

11

13

9.68

0

0

0

0

0

0

0

0

5.88

0

0

0

0

0

0.84

0

0

4

0

33.4

0.75

1.02

1.26

1.56

0.4

1.2

0.8

1.4

1.8

2.5

2.25

2.83

4.04

5.3

0.27

0.39

3.1

1

70

41

16

12

12

52.5

41.8

0

0

0

0

0

0

0

0

36

0

0

0

0

0

3.24

0

0

12

0

146

0.82

1.05

1.33

1.6

0.5

1.75

1.2

1.7

2.4

3.2

2.86

3.66

4.88

5.3

10

7

0.4

0.42

4.4

1

60

39

13

12

49.2

40.95

0

0

0

0

0

0

0

0

37.18

0

0

0

0

0

3.2

0

0

12

0

142.5

321.5

7/7/2013

St-st & Cs field erect

Pipe size

150 Units Total 200 Units Total

Handling & erect straight run pipe.

0.91 100 91 1.11 40 44.4

Handling & erect fab spools sch 10-60. 1.16 58 67.3 1.33 37 49.2

Handling & erect fab spools sch 80-100. 1.58

0

1.79

0

Handling & erect fab spools sch 120-160. 1.96

0

2.16

0

Field handling valves & install. < 600# 2.31

0

2.94

0

Bolt ups < 300#

1.5

0

2.1

0

Attaching flanges slip on type.

3.6

0

5.1

0

Attaching flanges weld neck.

4.2

0

5.4

0

Man B/W Tig root run sched 40 pipe. 3.6

22 79.2 4.59 11 50.5

Man B/W Tig root run sched 80 pipe. 4.8

0

6.15

0

Man B/W Tig root run >> sched 160 pipe.

11

0

0

Mark cut & bevel < 80.

0.55 12

6.6 0.82 6

4.92

Pressure test 10% of piping manhours. 1

24

24

1

14

14

Install supports at approx 4mtr centres. 4

0

4.5

0

0

0

Total manhours.

268

163

Pipe size

500 Units Total 600 Units Total

Handling & erect straight run pipe.

3.37

0

3.77 40

151

Handling & erect fab spools sch 10-60. 3.68

0

4.76 13 61.9

Handling & erect fab spools sch 80-100.4.42

0

5.16

0

Handling & erect fab spools sch 120-160.5.23

0

6

0

Handling & erect fab spools sch >160.

0

0

Field handling valves & install. < 600# 5.67

0

6.3

0

Bolt ups < 300#

5.5

0

6.6

0

Attaching flanges slip on type.

14.6

0

18.3

0

Attaching flanges weld neck.

13.3

0

17.6

0

Man B/W Tig root run sched 40 pipe. 11

0

12.5 6

74.9

Man B/W Tig root run sched 80 pipe. 15.5

0

17.9

0

Mark cut & bevel < 80.

2.9

0

3.3

4

13.2

Pressure test 10% of piping manhours. 1

0

1

21

21

Install supports at approx 4mtr centres. 9

0

10

0

Total manhours.

0

322

Geoff and Robyn Poile

250 Units Total 300 Units Total

1.41

0

1.7

20

34

1.7

0

1.74 12 20.9

2.21

0

2.28

0

3

0

3.15

0

3.1

0

3.6

0

2.7

0

3.4

0

7.56

0

9.24

0

6.7

0

7.3

0

5.45

0

6.62

5 33.1

7.48

0

9.24

0

0

45.5

0

1.1

0

1.4

2

2.8

1

0

1

9

9

5.3

0

6

0

0

0

0

99.8

350 Units Total 400 Units Total 450 Units Total

2.09

30 62.7 2.46

12 29.5 2.88

0

1.93

18 34.7 2.61

3

7.83 3.05

0

2.78

0

3.18

0

3.75

0

3.56

0

4.15

0

4.76

0

3.85

0

4.55

0

5.2

0

3.8

0

4.4

0

4.8

0

10.8

0

12.6

0

14.64

0

8.8

0

9.6

0

12

0

7.56

7

52.9

8.6

2

17.2 10.05

0

10.6

0

11.97

0

13.94

0

0

52

0

0

1.6

3

4.8

2

1

2

2.5

0

1

15

15

1

6

6

1

0

6.5

0

7

0

7.5

0

0

0

0

170

62.6

0

763.6

750 Units Total 800 Units Total 950 Units Total 1400 Units Total 1500 Units Total

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

7.2

0

7.6

0

0

0

0

0

0

0

0

0

7.5

0

0

15.7

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

3.7

0

4

0

0

0

0

0

0

0

0

0

16

0

16

0

0

0

0

0

0

0

0

321.8

1407

Page 3

7/7/2013

Cabon St- shop fab S 40,80.30.

Carbon steel sch-40

15

Units

Total

20

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.1

Units

Total

25

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.1

Units

Total

40

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.012

Units

Total

50

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.13

Units

Total

80

0

0

0

6.6

0

0

0

0

0

0

0

0

0

0

0.26

Units

Total

100

0

0

0

23

0

0

0

0

0

0

0

0

0

0

0.35

Units

Total

Workshop Spooling

Wall thickness

Shop handling pipe for fabrication.

Mark & Cut

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

90 deg nozzle ( un reinforced )

90 deg nozzle ( reinforced )

45 deg nozzle ( un reinforced )

45 deg nozzle ( reinforced )

Socket weld

O'lets

Install vents or drains

Bending 1 x 90deg

Thread pipe including cut.

Total manhours.

2.77

0.1

0.85

0.6

0

0

0

0.56

1.45

3.5

1.9

0.23

2.87

0.85

0.6

0

0

0

0.56

1.79

3.6

1.9

0.23

3.38

0.85

0.75

0

0

0

0.6

2.02

3.73

1.9

0.23

3.68

0.065

0.04

0.9

0.8

0

0

0

0.7

2.79

2.38

0.23

3.91

0.1

0.046

1.1

1.12

2.48

6.41

3.38

6.6

0.75

3.81

2.73

0.23

5.49

0.13

0.053

1.44

16

1.48

3.26

7.36

4.2

8.36

1.48

5.73

3.84

0.35

6.6

6.02

0.175

0.0693

1.78

16

1.87

3.77

8.15

4.95

10.2

7.27

5.65

0.52

23.04

0

0

0

28.48

0

0

0

0

0

0

0

0

0

0

28.48

58.12

Carbon steel sch-40

150

Wall thickness

Shop handling pipe for fabrication.

Mark & Cut

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

90 deg nozzle ( un reinforced )

90 deg nozzle ( reinforced )

45 deg nozzle ( un reinforced )

45 deg nozzle ( reinforced )

O'lets

Total manhours.

Units

Total

200

40

4.68

1.8

66.3

13.4

9.72

0

0

0

8.82

144.7

0.46

7.11

0.4

100

0.312

15

0.15

12

2.55

26

2.68

4.86

9.48

6.05

11.74

8.82

Units

Total

250

0

0

0

37.08

0

0

0

0

0

0

0.67

8.18

0.416

0.185

3.09

3.24

5.99

11.85

7.59

14.35

9.78

12

Units

Total

9.27

37.08

0.52

0.277

3.23

3.81

7.4

14.5

8.91

15.79

13.8

0

0

0

0

0

0

0

0

0

0

0

300

Units

Std-Wt

9.53

0.83

0.624

0.323

4.64

5.08

8.8

16.25

10.25

19.37

21.08

Total

350

0

0

0

23.2

0

0

0

0

0

0

0.88

Units

Total

400

0

0

0

37.44

0

0

0

0

0

0

1.01

9.53

23.2

0.728

0.37

4.68

5.2

9.79

18.7

12.66

Units

Total

450

0

0

0

15.6

0

0

0

0

0

0

1.13

9.53

37.44

0.832

0.41

5.2

5.9

11.36

22.96

15.68

Units

Total

9.5

0

0

1

0

0

0

0

0

0

0

0.936

0.461

6.1

6.88

14.59

15.6

259.04

Geoff and Robyn Poile

Page 4

7/7/2013

Cabon St- shop fab S 40,80.30.

Carbon steel sch-40

500

Wall thickness

Shop handling pipe for fabrication.

Mark & Cut

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

90 deg nozzle ( un reinforced )

90 deg nozzle ( reinforced )

45 deg nozzle ( un reinforced )

45 deg nozzle ( reinforced )

Total manhours.

Units

Total

600

9.53

0.512

6.8

7.87

16.35

Total

700

9.5

0

0

0

0

0

0

0

0

0

1.2

1.04

Units

1.35

1.248

0.615

8.84

20.84

Units

Total

750

9.5

0

0

0

64

0

0

0

0

0

1.5

0.72

9.2

10.2

29

64

Total

900

9.5

0

0

0

0

0

0

0

0

0

1.58

Units

0.769

10

11

30.5

Total

1050

0

0

0

2.16

Units

Total

1700

Units

Total

9.5

0

0

0

0

0

0

0

0

0

1.67

1.547

Units

2

1.85

0.922

2.4

1.077

12

14

13

15

37.5

44

0

0

0

0

0

0

64

302

Carbon steel sch-80

15

Workshop Spooling

Wall thickness

Shop handling pipe for fabrication.

Mark & Cut

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

90 deg nozzle ( un reinforced )

90 deg nozzle ( reinforced )

45 deg nozzle ( un reinforced )

45 deg nozzle ( reinforced )

Socket weld

O'lets

Install vents or drains

Bending 1 x 90deg

Thread pipe including cut.

Total manhours.

Geoff and Robyn Poile

Units

Total

20

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.1

3.73

0.1

0.7

0.75

0

0

0

0.56

2.18

3.5

1.9

0.23

Units

Total

25

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.14

3.91

0.75

0.8

0

0

0

0.56

2.68

3.6

1.9

0.23

Units

Total

40

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.16

4.55

0.075

0.033

0.8

0.85

0

0

0

0.6

3.02

3.73

1.9

0.23

Units

Total

50

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.18

5.08

Page 5

0.095

0.042

0.95

1

0

0

0

0.7

4.19

2.38

0.23

Units

Total

80

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.34

5.54

0.105

0.048

1

1.1

3.92

7.45

4.29

9.32

0.75

5.71

2.73

0.23

Units

Total

100

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.35

7.62

0.1365

0.0556

1.59

1.62

4.95

9.81

5.45

11.69

1.48

8.59

3.84

0.35

Units

Total

8.56

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.1838

0.0728

1.99

2.05

5.61

10.75

6.49

13.79

10.9

5.65

0.52

7/7/2013

Cabon St- shop fab S 40,80.30.

Carbon steel sch-80

Wall thickness

Shop handling pipe for fabrication.

Mark & Cut

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

90 deg nozzle ( un reinforced )

90 deg nozzle ( reinforced )

45 deg nozzle ( un reinforced )

45 deg nozzle ( reinforced )

O'lets

Total manhours.

Carbon steel sch-80

150

Geoff and Robyn Poile

Total

200

10.97

0.158

2.85

3.14

7.54

12.75

7.26

14.89

13.22

500

Units

1.092

0.538

12.3

11.9

21.81

Total

250

0.1943

3.52

3.8

8.64

17.15

10.4

21.86

14.67

600

0

0

0

0

0

0

0

0

0

1.84

Units

Total

30.96

1.31

0.646

17.73

15

27.8

Total

300

0.291

4.75

4.9

9.37

19.25

12.65

25.9

23.46

Units

Units

S 30

15.88

350

0.3392

6.27

6.1

10.92

21.9

14.55

29.87

35.84

Total

Units

Units

400

0.389

7.62

7.4

13.49

25.5

16.96

34.8

Total

15.88

Units

Units

450

0.431

8.96

9.05

15.68

29.5

19.77

40.24

Total

16

Units

Total

23.83

0

0

0

0

0

0

0

0

0

0

1.35

0.8736

900

Total

21.44

0

0

0

0

0

0

0

0

0

0

1.13

0.764

750

Total

19.05

0

0

0

0

0

0

0

0

0

0

1.02

0.6552

700

Total

17.48

0

0

0

0

0

0

0

0

0

0

0.94

0.546

Total

Units

15.09

0

0

0

0

0

0

0

0

0

0

0.61

0.4368

26.19

1.65

Units

12.7

0

0

0

0

0

0

0

0

0

0

0

0.55

0.328

Wall thickness

Shop handling pipe for fabrication.

Mark & Cut

Pipe bevelling

Tack & buttweld

Slip on flanges & weld

90 deg nozzle ( un reinforced )

90 deg nozzle ( reinforced )

45 deg nozzle ( un reinforced )

45 deg nozzle ( reinforced )

Total manhours.

Units

0

0

0

0

0

0

0

0

0

0

1.52

0.9828

0.4841

10.94

10.5

18.2

1050

Units

Total

1700

Units

Total

12.7

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Page 6

7/7/2013

You might also like

- SS Pipe Fab & Erect CostsDocument5 pagesSS Pipe Fab & Erect Costswally55bear67% (3)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisFrom EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisRating: 5 out of 5 stars5/5 (1)

- Piping ManhoursDocument32 pagesPiping ManhoursNejat Ababay75% (16)

- Estimate Piping LabourDocument5 pagesEstimate Piping Labourandy100% (7)

- 54 - Process Plant Piping Estimate DetailDocument57 pages54 - Process Plant Piping Estimate Detailstefax2010100% (3)

- Piping Works EstimationDocument3 pagesPiping Works Estimationakg20041100% (5)

- Piping Manhours (Weight)Document25 pagesPiping Manhours (Weight)Nejat AbabayNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Industrial Piping (Process Plant) Productivity StandardsDocument30 pagesIndustrial Piping (Process Plant) Productivity Standardsburerey100% (4)

- Manhour StandardsDocument6 pagesManhour StandardsNaing Lin Cho56% (18)

- Piping EstimationDocument19 pagesPiping EstimationTitoFernandez86% (7)

- Technical Calculation and Estimators Man-Hour ManualDocument238 pagesTechnical Calculation and Estimators Man-Hour ManualN P Srinivasarao33% (12)

- Piping Manhour Costing Estimate SampleDocument24 pagesPiping Manhour Costing Estimate SampleMethosalem Haincadto85% (34)

- Cost Estimating Manual for Pipelines and Marine Structures: New Printing 1999From EverandCost Estimating Manual for Pipelines and Marine Structures: New Printing 1999Rating: 5 out of 5 stars5/5 (2)

- Standard Manhour Estimation: Fabrication & WeldingDocument3 pagesStandard Manhour Estimation: Fabrication & WeldingPratik Desai100% (7)

- Technical Calculation and Estimator's Man-Hour Manual - Erection of Process or Chemical PlantsDocument241 pagesTechnical Calculation and Estimator's Man-Hour Manual - Erection of Process or Chemical PlantsJOHN67% (15)

- Estimation Man HourDocument241 pagesEstimation Man HourAnonymous ynJByUs52% (42)

- Cost Centers Vs ManhoursDocument166 pagesCost Centers Vs Manhoursguy88100% (1)

- Thumb RuleDocument27 pagesThumb Ruleavinashudupa67% (6)

- 1 Piping CostingDocument33 pages1 Piping Costingamoldhole97% (34)

- Planner's and Estimator's HandbookDocument295 pagesPlanner's and Estimator's Handbooknabeeltp92% (12)

- Commercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsFrom EverandCommercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsNo ratings yet

- 37° Flared Tube Fitting GuideDocument13 pages37° Flared Tube Fitting GuidehernychtNo ratings yet

- Square Air Core Inductors: 1515SQ 2222SQ 2929SQDocument3 pagesSquare Air Core Inductors: 1515SQ 2222SQ 2929SQvidhya.dpi5566No ratings yet

- Plumbing PIpe SizingDocument12 pagesPlumbing PIpe SizingAwokeNo ratings yet

- Reinforced Concrete DesignDocument28 pagesReinforced Concrete DesignJefNo ratings yet

- ReportDocument29 pagesReportAzri AhmedNo ratings yet

- Concrete Design-UDocument28 pagesConcrete Design-UKhải TrươngNo ratings yet

- Friction Losses in Pipe Fittings Resistance Coefficient K (Use in Formula H KV /2g)Document12 pagesFriction Losses in Pipe Fittings Resistance Coefficient K (Use in Formula H KV /2g)Alvin KimNo ratings yet

- تصميم كل العناصر الأنشائيةDocument26 pagesتصميم كل العناصر الأنشائيةMohamed ElbahnsyNo ratings yet

- Fluke 1650B Series: Multifunction Installation TestersDocument10 pagesFluke 1650B Series: Multifunction Installation TestersWasinchai KanjanapanNo ratings yet

- Cs Pipe Fab Amp Erect CostsDocument6 pagesCs Pipe Fab Amp Erect CostsBudi SantonyNo ratings yet

- FRP Composite ComparisonDocument2 pagesFRP Composite Comparisonyanuar_adhiNo ratings yet

- External Sewege DesignDocument3 pagesExternal Sewege DesigngvgbabuNo ratings yet

- Labor Units Manual: Electrical Contractor'sDocument14 pagesLabor Units Manual: Electrical Contractor'sBNo ratings yet

- Practice Exercises # 3 Fall 2023Document6 pagesPractice Exercises # 3 Fall 2023Nidhi ShettyNo ratings yet

- Hs Bolt SpecificationDocument6 pagesHs Bolt SpecificationncristiNo ratings yet

- RTWALLDocument18 pagesRTWALLJomar CerdaNo ratings yet

- BoqDocument30 pagesBoqPrashant Singh Chauhan100% (1)

- Chiller Selection MethodDocument9 pagesChiller Selection MethodAbdullah.N FAAliNo ratings yet

- S CurveDocument25 pagesS CurveHarold EscalonaNo ratings yet

- Electrical Panel Load Calculation (22.8.12)Document28 pagesElectrical Panel Load Calculation (22.8.12)Erfan AhmedNo ratings yet

- Ferraz Shawmut High Voltage Fuses CatalogueDocument93 pagesFerraz Shawmut High Voltage Fuses CataloguerocketvtNo ratings yet

- Watermain Testing and Commissioning ProceduresDocument6 pagesWatermain Testing and Commissioning ProceduresLaurence BeltranNo ratings yet

- 12NDF100Document2 pages12NDF100DisetiaNo ratings yet

- Hume Pipe BOQ For QuoteDocument4 pagesHume Pipe BOQ For Quotebsenthil78No ratings yet

- 5_6251188031605178888Document10 pages5_6251188031605178888ganeshemmadi1987No ratings yet

- Hard Alloy Tube CapabilitiesDocument7 pagesHard Alloy Tube CapabilitiesJM SVNo ratings yet

- Working of Breather Valve Working On TanksDocument4 pagesWorking of Breather Valve Working On Tanks54045114No ratings yet

- Derive 12 hr UHG ordinates from 4 hr UHG using S curve methodDocument8 pagesDerive 12 hr UHG ordinates from 4 hr UHG using S curve methodPiyush BhandariNo ratings yet

- Carbon Hollow Bar ST 52Document2 pagesCarbon Hollow Bar ST 52JeganeswaranNo ratings yet

- H.Q Lamps manufacturing co. Daily Inventory Report 15-Jul-15/TITLEDocument35 pagesH.Q Lamps manufacturing co. Daily Inventory Report 15-Jul-15/TITLEharishNo ratings yet

- الدليل الانشائي لحساب الاحمال الزلزاليةDocument42 pagesالدليل الانشائي لحساب الاحمال الزلزاليةTarek AbulailNo ratings yet

- Cocurrent No. Sample T2 ( C) T3 ( C) T4 ( C) Pump Setting (%) Valve Setting (%) Thot ( C) T1 ( C)Document10 pagesCocurrent No. Sample T2 ( C) T3 ( C) T4 ( C) Pump Setting (%) Valve Setting (%) Thot ( C) T1 ( C)IkhsanSolikhuddinNo ratings yet

- Hydraulics CalculationDocument10 pagesHydraulics Calculationali khosravinarNo ratings yet

- Hydraulics CalculationDocument4 pagesHydraulics Calculationali khosravinarNo ratings yet

- DBR ChecklistDocument9 pagesDBR ChecklistJai ThakkarNo ratings yet

- Aluminium AW 6063 T6 AngleDocument4 pagesAluminium AW 6063 T6 Angledoshi78No ratings yet

- Chempro & UPVCDocument28 pagesChempro & UPVCcsdcw fqefqfNo ratings yet

- Coldformed SectionsDocument56 pagesColdformed SectionsSwapnil ToraskarNo ratings yet

- Coldformed SectionsDocument56 pagesColdformed SectionsSwapnil ToraskarNo ratings yet

- D-2N Brake DrawingDocument1 pageD-2N Brake Drawingwally55bearNo ratings yet

- 4 Internal FlowDocument40 pages4 Internal FlowMarilaine ColnagoNo ratings yet

- Heathrow T3 MapDocument6 pagesHeathrow T3 Mapwally55bearNo ratings yet

- Atlas Technical Handbook of SS Rev Aug 2013Document49 pagesAtlas Technical Handbook of SS Rev Aug 2013timparker01No ratings yet

- Ebsray pumps V series model V40 technical brochureDocument8 pagesEbsray pumps V series model V40 technical brochurewally55bearNo ratings yet

- Heathrow Airport Terminal 2 GuideDocument7 pagesHeathrow Airport Terminal 2 Guidewally55bearNo ratings yet

- Cleveland SI Impact VibratorDocument4 pagesCleveland SI Impact Vibratorwally55bearNo ratings yet

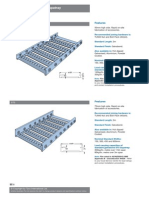

- 3F1 - Cable Ladder SCL Shaped AccessoriesDocument1 page3F1 - Cable Ladder SCL Shaped Accessorieswally55bearNo ratings yet

- Cable Tray - Supatray SectionDocument3 pagesCable Tray - Supatray Sectionwally55bearNo ratings yet

- 3J1 - Cable Ladder Accessory SupportsDocument1 page3J1 - Cable Ladder Accessory Supportswally55bearNo ratings yet

- Cable Tray - Supatray SectionDocument3 pagesCable Tray - Supatray Sectionwally55bearNo ratings yet

- Tram Network Mapp TV A 4Document1 pageTram Network Mapp TV A 4Jason HoNo ratings yet

- Mass CalcDocument3 pagesMass Calcwally55bear0% (1)

- Tram Network Mapp TV A 4Document1 pageTram Network Mapp TV A 4Jason HoNo ratings yet

- CS Pipe Fab & Erect CostsDocument6 pagesCS Pipe Fab & Erect Costswally55bear69% (16)

- Steel Pipe DimensionsDocument7 pagesSteel Pipe Dimensionswally55bearNo ratings yet

- HSSC English Model PaperDocument32 pagesHSSC English Model PaperMaryam Abdus SalamNo ratings yet

- Composite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloDocument15 pagesComposite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloSharan KharthikNo ratings yet

- Listening Exercise 1Document1 pageListening Exercise 1Ma. Luiggie Teresita PerezNo ratings yet

- Legends and Lairs - Elemental Lore PDFDocument66 pagesLegends and Lairs - Elemental Lore PDFAlexis LoboNo ratings yet

- N4 Electrotechnics August 2021 MemorandumDocument8 pagesN4 Electrotechnics August 2021 MemorandumPetro Susan BarnardNo ratings yet

- GP Rating GSK Exit ExamDocument108 pagesGP Rating GSK Exit ExamMicle VM100% (4)

- Indian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewDocument8 pagesIndian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewPRINCIPAL BHILWARANo ratings yet

- Job Order Costing: Patrick Louie E. Reyes, CTT, Micb, Rca, CpaDocument45 pagesJob Order Costing: Patrick Louie E. Reyes, CTT, Micb, Rca, CpaClaudette Clemente100% (1)

- Efaverenz p1Document4 pagesEfaverenz p1Pragat KumarNo ratings yet

- Hipotension 6Document16 pagesHipotension 6arturo castilloNo ratings yet

- Physics Derived Units and Unit Prefixes Derived UnitDocument15 pagesPhysics Derived Units and Unit Prefixes Derived UnitJohnRenzoMolinarNo ratings yet

- Shouldice Hospital Ltd.Document5 pagesShouldice Hospital Ltd.Martín Gómez CortésNo ratings yet

- Ofper 1 Application For Seagoing AppointmentDocument4 pagesOfper 1 Application For Seagoing AppointmentNarayana ReddyNo ratings yet

- Evil Days of Luckless JohnDocument5 pagesEvil Days of Luckless JohnadikressNo ratings yet

- C4 ISRchapterDocument16 pagesC4 ISRchapterSerkan KalaycıNo ratings yet

- Guia de Usuario GPS Spectra SP80 PDFDocument118 pagesGuia de Usuario GPS Spectra SP80 PDFAlbrichs BennettNo ratings yet

- Mobile ApplicationDocument2 pagesMobile Applicationdarebusi1No ratings yet

- Grading System The Inconvenient Use of The Computing Grades in PortalDocument5 pagesGrading System The Inconvenient Use of The Computing Grades in PortalJm WhoooNo ratings yet

- Returnable Goods Register: STR/4/005 Issue 1 Page1Of1Document1 pageReturnable Goods Register: STR/4/005 Issue 1 Page1Of1Zohaib QasimNo ratings yet

- Inborn Errors of Metabolism in Infancy: A Guide To DiagnosisDocument11 pagesInborn Errors of Metabolism in Infancy: A Guide To DiagnosisEdu Diaperlover São PauloNo ratings yet

- Gapped SentencesDocument8 pagesGapped SentencesKianujillaNo ratings yet

- Prac Res Q2 Module 1Document14 pagesPrac Res Q2 Module 1oea aoueoNo ratings yet

- Typical T Intersection On Rural Local Road With Left Turn LanesDocument1 pageTypical T Intersection On Rural Local Road With Left Turn Lanesahmed.almakawyNo ratings yet

- Basic Features of The Microcredit Regulatory Authority Act, 2006Document10 pagesBasic Features of The Microcredit Regulatory Authority Act, 2006Asif Hasan DhimanNo ratings yet

- IELTS Speaking Q&ADocument17 pagesIELTS Speaking Q&ABDApp Star100% (1)

- Longman ESOL Skills For Life - ShoppingDocument4 pagesLongman ESOL Skills For Life - ShoppingAstri Natalia Permatasari83% (6)

- Oxgen Sensor Cat WEBDocument184 pagesOxgen Sensor Cat WEBBuddy Davis100% (2)

- Special Power of Attorney: Benedict Joseph M. CruzDocument1 pageSpecial Power of Attorney: Benedict Joseph M. CruzJson GalvezNo ratings yet

- SNC 2p1 Course Overview 2015Document2 pagesSNC 2p1 Course Overview 2015api-212901753No ratings yet

- Journals OREF Vs ORIF D3rd RadiusDocument9 pagesJournals OREF Vs ORIF D3rd RadiusironNo ratings yet