Professional Documents

Culture Documents

ACCA Example of Duct Sizing

Uploaded by

hfguerracOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACCA Example of Duct Sizing

Uploaded by

hfguerracCopyright:

Available Formats

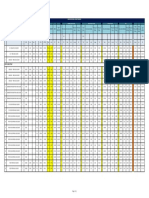

Below is an example of duct sizing

The load calculation indicates a heat gain of 28,000 BTUH, Therefore a 2-1/2 ton A/C unit is needed. The total system CFM is 1000 (for heating only, use the furnace cfm). The cfm of each branch is determined using the example shown for room C. The return trunk must handle 1000 cfm. The first section of the supply trunk must handle 1000 cfm while the second section will have to handle the remaining 517 cfm

Room C 3000 btuh Heat Gain (obtain from room-by-room load calculation) 3000/28,000 X 1000 = 107 CFM C 107 cfm 88 cfm AHU 1000 cfm

125 cfm

135 cfm B

1000 cfm A return

1000 cfm

517 cfm

68 cfm 110 cfm 110 cfm

50 cfm 123 cfm 84 cfm

Measured length of duct (A to B ) = Equivalent lengths of turns and fittings between A and B = Total effective length =

65 feet 190 feet 255 feet

External static pressure of air handler @ 100 cfmwet coil Air filter registers Grille Total Available Static Pressure

.5 w.c -.10 w.c. -.15 w.c. -.03 w.c. -.03 w.c. .19 w.c.

Friction Rate = .19 X 100 255 = .075 w.c. (Size all ducts at this friction rate)

Use the Friction Rate (.075) to size all trunks and branches

Return and first section of supply trunk will be 20 diameter (1000 cfm @ .075 w.c. Second section of supply trunk will be 16 diameter (517 cfm @.075 w.c.) Outlet C will be 8 diameter (107 cfm @ .075 w.c.)

Size the remaining outlets according to their CFM @ .075 w.c.

You might also like

- Duct Design Rev2Document18 pagesDuct Design Rev2AshokNo ratings yet

- High Velocity Duct Design Tips by TraneDocument50 pagesHigh Velocity Duct Design Tips by TraneInventor SolidworksNo ratings yet

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- Duct Pressure Loss CalculationDocument24 pagesDuct Pressure Loss CalculationbernardsilvanoNo ratings yet

- Correct Duct SizingDocument3 pagesCorrect Duct Sizingnim_gourav1997100% (1)

- Ventilation Design Sample For Locker Rooms and HACCPDocument10 pagesVentilation Design Sample For Locker Rooms and HACCPerickquinto100% (1)

- Need For Balancing ValvesDocument12 pagesNeed For Balancing ValvesBubai111No ratings yet

- Duct DesignDocument18 pagesDuct DesignKarthy Ganesan100% (1)

- Pan Humidifier CalculaitonDocument1 pagePan Humidifier CalculaitonAshok KrishnamurthyNo ratings yet

- Duct Presentation MaineDocument22 pagesDuct Presentation MaineCharmaine ManliguezNo ratings yet

- AL HVAC Contractor Comprehensive Tutorial 10Document278 pagesAL HVAC Contractor Comprehensive Tutorial 10William Worrell100% (1)

- Air Distribution SystemDocument21 pagesAir Distribution SystemRohit JainNo ratings yet

- Back To Basics - Duct DesignDocument17 pagesBack To Basics - Duct DesignAntonio LebrunNo ratings yet

- Duct Static Pressure Calculation PDFDocument6 pagesDuct Static Pressure Calculation PDFVenkata Subramanyam KotaNo ratings yet

- Duct DesignDocument49 pagesDuct DesignabianshbaralNo ratings yet

- % Outdoor Air CalculationDocument6 pages% Outdoor Air Calculationamirin_kingNo ratings yet

- Heat Load Calculation FormatDocument6 pagesHeat Load Calculation Formatmeesam1No ratings yet

- Part 1 - Air in MotionDocument5 pagesPart 1 - Air in Motionrahuldubey1987100% (1)

- Static Regain Method NEWDocument6 pagesStatic Regain Method NEWMarzookNo ratings yet

- Plenum Box Sizing For Air Handling Unit (AHU) : Q AxvDocument2 pagesPlenum Box Sizing For Air Handling Unit (AHU) : Q Axvganesh gundNo ratings yet

- Fan Fundamentals - Greenheck (May2005)Document24 pagesFan Fundamentals - Greenheck (May2005)jagdishgharoteNo ratings yet

- Fan Fundamentals PDFDocument57 pagesFan Fundamentals PDFPablo Guzman RetamalNo ratings yet

- Ashrae 15-34-Rev 3 MitsubishiDocument7 pagesAshrae 15-34-Rev 3 MitsubishiJosho SandovalNo ratings yet

- Ductulator - Air Duct CalculatorDocument1 pageDuctulator - Air Duct CalculatorCarlos R. SantiagoNo ratings yet

- Stair PressDocument5 pagesStair Press45saulNo ratings yet

- Fresh Air Louver Selection - 11-10-2015Document1 pageFresh Air Louver Selection - 11-10-2015organicspolybondNo ratings yet

- Design of Cond TrapDocument7 pagesDesign of Cond TrapgtdprasadNo ratings yet

- HPAC A Fresh Look at Fans-FinalDocument10 pagesHPAC A Fresh Look at Fans-FinalsajuhereNo ratings yet

- Air Distribution-Part 2 CarrierDocument99 pagesAir Distribution-Part 2 Carriercamaleon86100% (1)

- Second Floor Load CalculationsDocument1 pageSecond Floor Load CalculationsSudhir KulkarniNo ratings yet

- Fcu PipingDocument20 pagesFcu PipingRamadan RashadNo ratings yet

- One Btu Equals 1.055 KJ.: Joule (J)Document3 pagesOne Btu Equals 1.055 KJ.: Joule (J)suboo0678No ratings yet

- Duct CalculationsDocument38 pagesDuct CalculationsDilnesa EjiguNo ratings yet

- HPAC Article On Specifying VAV BoxesDocument4 pagesHPAC Article On Specifying VAV Boxesjoejex123No ratings yet

- Prima Usaha ACMV Duct Sizing Table 2017 LockedDocument1 pagePrima Usaha ACMV Duct Sizing Table 2017 LockedShaikh Tauseef100% (2)

- AIA DHHS Ventilation Requirements For Areas Affecting Patient Care in HospitalsDocument4 pagesAIA DHHS Ventilation Requirements For Areas Affecting Patient Care in HospitalsMahipal Singh RaoNo ratings yet

- Project Name: Doc No: Air System Name: Rev: Equipment Type: Date: Space Used For: Sheet No: Floor: Reference: ClientDocument10 pagesProject Name: Doc No: Air System Name: Rev: Equipment Type: Date: Space Used For: Sheet No: Floor: Reference: ClientMukti WibowoNo ratings yet

- Air Master Linear Bar Grille With Air Flow DataDocument0 pagesAir Master Linear Bar Grille With Air Flow Datamykel_dpNo ratings yet

- ASHRAE Commercial Duct CalculationsDocument4 pagesASHRAE Commercial Duct CalculationsNirmal KvNo ratings yet

- Calculo de CFM Pump Room Ventilation Calculation PDFDocument1 pageCalculo de CFM Pump Room Ventilation Calculation PDFsusansue50% (2)

- 346N No06 HVAC Cooling LoadDocument33 pages346N No06 HVAC Cooling LoadmartinqNo ratings yet

- Heat Load CalculationsDocument35 pagesHeat Load CalculationsAbiodun Ilori100% (1)

- Duct Design: ME 425 - Air Distribution & ASHRAE Outlet SelectionDocument9 pagesDuct Design: ME 425 - Air Distribution & ASHRAE Outlet SelectionAbul ShaikhNo ratings yet

- Cop V/S Eer V/S SeerDocument7 pagesCop V/S Eer V/S SeerRaj Deep TiwariNo ratings yet

- 2012 VAV Boxes Energy Efficiency, Air Leakage and ASHRAE 90.1Document29 pages2012 VAV Boxes Energy Efficiency, Air Leakage and ASHRAE 90.1din_thorpe3248No ratings yet

- Air Distribution Sys DesignDocument6 pagesAir Distribution Sys DesignpauloNo ratings yet

- Basics of Duct DesignDocument2 pagesBasics of Duct DesignApurv Goyal100% (1)

- Ides-Edu: Lecture 7: Sizing Natural Ventilation SystemsDocument17 pagesIdes-Edu: Lecture 7: Sizing Natural Ventilation Systemsabhijeet7362No ratings yet

- Air Conditioning Design - Psychrometrics & Coil Load CalculationDocument13 pagesAir Conditioning Design - Psychrometrics & Coil Load Calculationvsajv83% (6)

- Hap Free CoolingDocument2 pagesHap Free CoolingHnin PwintNo ratings yet

- Design Analysis VRVDocument47 pagesDesign Analysis VRVAnonymous YVUsY9JG0% (1)

- Ngineering ATA: Temperature & Altitude Effects On FansDocument3 pagesNgineering ATA: Temperature & Altitude Effects On FansMohamed TahounNo ratings yet

- People/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMDocument8 pagesPeople/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMPola OsamaNo ratings yet

- HVAC Controls Answers CHP 1-5Document11 pagesHVAC Controls Answers CHP 1-5Cheuk To ChanNo ratings yet

- Air Distribution and BalanceDocument11 pagesAir Distribution and BalanceradusettNo ratings yet

- 7.5 Appendix 7.5.1 The Number of Tubes in CondenserDocument5 pages7.5 Appendix 7.5.1 The Number of Tubes in CondenserAhmad Najie ZulkifliNo ratings yet

- Kitchen Ventilation ExampleDocument4 pagesKitchen Ventilation ExamplePretty NatyNo ratings yet

- Power Plant CalculationDocument4 pagesPower Plant CalculationSreenbabu100% (1)

- HVACDocument27 pagesHVACajuhaseenNo ratings yet

- Microcontroilador ArduinoDocument21 pagesMicrocontroilador ArduinohfguerracNo ratings yet

- Growing A Green Corporation White PaperDocument22 pagesGrowing A Green Corporation White PaperRaja DhanapalNo ratings yet

- Duct Sizing and HVAC CalculationDocument21 pagesDuct Sizing and HVAC Calculationsardarmkhan80% (5)

- WPB1091201 BDDocument16 pagesWPB1091201 BDhfguerracNo ratings yet

- Duct DesignDocument18 pagesDuct Designhfguerrac95% (21)

- Modulo ArduinoDocument9 pagesModulo ArduinohfguerracNo ratings yet

- Rme Calc Duct Sizing-1Document8 pagesRme Calc Duct Sizing-1hfguerracNo ratings yet

- Air Conditioning Duct Design-Lecture 38Document20 pagesAir Conditioning Duct Design-Lecture 38Mrityunjay TiwariNo ratings yet

- Generator Set VentilationDocument2 pagesGenerator Set VentilationhfguerracNo ratings yet

- Kinetics Silencer SpecificationDocument3 pagesKinetics Silencer SpecificationhfguerracNo ratings yet

- Calculate Size of Exhaust Pipe-2Document33 pagesCalculate Size of Exhaust Pipe-2Mạnh Ngô Đức75% (4)

- Generator Set VentilationDocument2 pagesGenerator Set VentilationhfguerracNo ratings yet

- Calibracion EimDocument1 pageCalibracion EimhfguerracNo ratings yet

- Energy Efficient Data Center Achieves 2N ReliabilityDocument4 pagesEnergy Efficient Data Center Achieves 2N ReliabilityhfguerracNo ratings yet

- FMS Eo Eef CDocument2 pagesFMS Eo Eef ChfguerracNo ratings yet

- EIMDocument3 pagesEIMjuanlukaNo ratings yet

- Fallas StartDocument1 pageFallas StarthfguerracNo ratings yet

- Donalsson PDFDocument193 pagesDonalsson PDFhfguerracNo ratings yet

- MetallgesellschaftDocument7 pagesMetallgesellschaftBobby HartantoNo ratings yet

- Donalsson PDFDocument193 pagesDonalsson PDFhfguerracNo ratings yet