Professional Documents

Culture Documents

Painting Repair Procedure

Uploaded by

Aneesh JoseCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Painting Repair Procedure

Uploaded by

Aneesh JoseCopyright:

Available Formats

Page : 1 of 25

KLM Technology Group

Project Engineering Standard

Rev: 01 July 2013

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

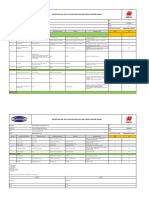

PAINTING REPAIR PROCEDURE (PROJECT STANDARDS AND SPECIFICATIONS)

TABLE OF CONTENT Scope Purpose Reference Definition Procedure

1. General Requirement 2. Typical Paint Defects 3. Coating System (Touch up / Repair)

2 2 2 2 3

3 5 11

Special Requirements Records

24 24

Page 2 of 25

KLM Technology Group

Project Engineering Standard

PAINTING REPAIR PROCEDURE

Rev: 01

(PROJECT STANDARDS AND SPECIFICATIONS)

July 2013

SCOPE This procedure covers the minimum requirements on the surface preparation and painting / coating for the touch-up and repair of damaged external or internal surfaces of existing structures and facilities including structural steel works, process piping, pressure vessels, galvanized surfaces and equipment. PURPOSE This procedure outlines the general requirements for the repair of painted/coated surfaces. REFERENCES SSPC-SP 1 SSPC-SP 2 SSPC-SP 3 SSPC-SP 10 SSPC-SP 11 Solvent Cleaning Hand Tool Cleaning Power Tool Cleaning Near-White Blast Cleaning Power Tool Cleaning to Bare Metal

Page 3 of 25

KLM Technology Group

Project Engineering Standard

PAINTING REPAIR PROCEDURE

Rev: 01

(PROJECT STANDARDS AND SPECIFICATIONS)

July 2013

DEFINITIONS Contractor: A firm that performs paint removal, surface preparation, and coatings application in the industrial market. Painting System: A term intended to include, with equal emphasis, not only the well accepted components of the system such as surface preparation and paint materials, but also the application, inspection, and safety function. Coating System: A term which refers to the applied and cured multi layer film or the components of a system based on non-paint type coating. Work: A term which refers to all works associated with the selection of the painting and coating systems, surface preparation, paint application, and inspection. Repair SSPC Dft Wit - Minor repair of coated / painted surfaces. - Steel Structures Painting Council - Dry Film Thickness - Wet Film Thickness

PROCEDURES 1. General Requirements i. Every possible precaution shall he taken to ensure that the damaged surface(s) shall be thoroughly clean, dry, free from condensation, moisture, dust, oil grease, rust, dirt and other contaminants before the application of the touch-up/repair processes. ii. Blast cleaning and painting shall not be conducted when the surfaces are less than 3 C above dew point or when the relative humidity of the air is greater than 85%.

Page 4 of 25

KLM Technology Group

Project Engineering Standard

PAINTING REPAIR PROCEDURE

Rev: 01

(PROJECT STANDARDS AND SPECIFICATIONS)

July 2013

iii. Any paint found to be incorrectly applied shall be removed and repainted to the appropriate painting/coating requirement. iv. Surface preparation, whenever possible, shall be carried out by dry blast-cleaning. Where dry blast cleaning is not feasible due to limited access, risk of damage to equipment, light gauge steel, proximity to electrical or instrumentation components, hand or power tool cleaning shall be applied. This shall be followed by solvent cleaning prior to painting. v. Where the damaged surface being repaired lies adjacent to a previously coated surface, the cleaning shall extend to the surrounding coating by a minimum of 25 mm on all sides and the edges shall be "chamfered" to ensure continuity of the patch coating. vi. Appropriate protection, shields or screens shall be used to cover the remainder of the previously coated surface to prevent any possibility of damage to or contamination of the coating before starting any repair work. vii. Any paint coating found inadvertently applied to areas where it is not required e.g. machined or polished surfaces, surface of stainless steel or non-ferrous alloys, name plates, manufacturers identification tags, instruments and instrument glasses, sight glasses, control valve stem, high friction grip bolt assemblies, etc. shall be hand wiped clean with thinner or cleaner while the coating is still wet or rubbed down with fine sand paper if it is dry and restored to their original surface condition. viii. The use of brushes or rollers for touch-up/repair on localized damaged surfaces where proper coating by spray application is not feasible may be used upon COMPANY approval. When using brushes, ensure that a smooth coat, as uniform in thickness as possible, is obtained with no deep or detrimental brush marks. Paint shall be worked into all crevices and corners. Runs and sags shall be brushed out immediately during paint application.

You might also like

- SurfaceProcedure Preparation-085 R3Document17 pagesSurfaceProcedure Preparation-085 R3Vinu Raveendran100% (1)

- Daily Painting Report System P 01ndDocument49 pagesDaily Painting Report System P 01ndArung IdNo ratings yet

- Blasting and Painting ProcedureDocument6 pagesBlasting and Painting Procedureanon_994898767No ratings yet

- WIS QCWT GE 15 Rev.1 - Painting InspectionDocument6 pagesWIS QCWT GE 15 Rev.1 - Painting Inspectionfajar aljogjaNo ratings yet

- AKP Storage TanksDocument51 pagesAKP Storage Tankscris_2010No ratings yet

- Inar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaDocument14 pagesInar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaSreedhar Patnaik.MNo ratings yet

- ISO 9001, ISO 14001 & OHSAS 18001 Certified Product Data SheetDocument3 pagesISO 9001, ISO 14001 & OHSAS 18001 Certified Product Data SheetHendri Dwi cahyonoNo ratings yet

- Contractor IOT Infrastructure & Energy Services LTDDocument38 pagesContractor IOT Infrastructure & Energy Services LTDNaveen KurupNo ratings yet

- 32 Samss 005 PDFDocument33 pages32 Samss 005 PDFRajan SteeveNo ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDocument31 pages8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Pttep Painitng of Offshore FacilitiesDocument66 pagesPttep Painitng of Offshore FacilitiesSufianNo ratings yet

- Technical Proposal Descaling Removal Pulai - A (2013 ASD)Document22 pagesTechnical Proposal Descaling Removal Pulai - A (2013 ASD)hash117No ratings yet

- Tank Field Inspection and Test ProcedureDocument29 pagesTank Field Inspection and Test ProcedureFadlul Akbar Herfianto100% (2)

- Date Sheet For PaintingDocument5 pagesDate Sheet For PaintingAws MohamedNo ratings yet

- Itp Internal CoatingDocument4 pagesItp Internal CoatingkamlNo ratings yet

- SATIP-N-001-02 Rev. 4Document2 pagesSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- Kansai Paint System Guide: Environmental CorrosivelyDocument16 pagesKansai Paint System Guide: Environmental Corrosivelyscribdfreeasus100% (1)

- IRM2700 Curing and DryoutDocument8 pagesIRM2700 Curing and Dryoutmika cabelloNo ratings yet

- Daily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanDocument4 pagesDaily Consumed Productive Hours: Job No: MRT-FRM-304-109 Responsible Engineer: Saif Ullah KhanSUKhanNo ratings yet

- Dewpoint: Coating & Painting InspectionDocument6 pagesDewpoint: Coating & Painting InspectionMeet Patel100% (1)

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pages8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- INSPECTION AND TEST PLAN FOR PIPE RACK AND PIPING PAINTING WORKSDocument2 pagesINSPECTION AND TEST PLAN FOR PIPE RACK AND PIPING PAINTING WORKSRanjan KumarNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- Inspection and Test Plan: Offshore Pipeline RecertificationDocument3 pagesInspection and Test Plan: Offshore Pipeline RecertificationArisNo ratings yet

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- AV650 Petrochemical Fireproofing Application MethodDocument4 pagesAV650 Petrochemical Fireproofing Application MethodNizarHamrouniNo ratings yet

- Painting Procedure TemplateDocument14 pagesPainting Procedure TemplateNnamdi Celestine NnamdiNo ratings yet

- Blasting & Painting ProcedureDocument10 pagesBlasting & Painting ProcedurepraksahNo ratings yet

- Erection Tank Settlement Check Schedule 103 110 165Document8 pagesErection Tank Settlement Check Schedule 103 110 165hrdsby100% (1)

- Monthly Blasting and Painting Inspection ReportDocument1 pageMonthly Blasting and Painting Inspection ReportTayyab MayoNo ratings yet

- Procédure MTDocument11 pagesProcédure MTAslaouiNo ratings yet

- CAT Group Painting Works QA ProcedureDocument7 pagesCAT Group Painting Works QA ProcedurekbldamNo ratings yet

- Tank Inspection NotesDocument5 pagesTank Inspection Notesaneeshjose013No ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiNo ratings yet

- Tender No. 3300005682: Earth Work, Excavation and BackfillingDocument16 pagesTender No. 3300005682: Earth Work, Excavation and BackfillingNanda KumarNo ratings yet

- 09 Job Procedure For Fire ProofingDocument4 pages09 Job Procedure For Fire ProofingAlvin Smith100% (2)

- Construction QC PlanDocument13 pagesConstruction QC PlanAbdallah YounisNo ratings yet

- Ts Remarks: of Raw Materials Item Manufacture System / Requiremen Thicknes S (Min. MM) Resin % Glass % Testing FrequencyDocument1 pageTs Remarks: of Raw Materials Item Manufacture System / Requiremen Thicknes S (Min. MM) Resin % Glass % Testing FrequencySaud PathiranaNo ratings yet

- 001 Itp For Painting Rev 0Document7 pages001 Itp For Painting Rev 0Alif Rahmat FebriantoNo ratings yet

- Surface Preparation Standards JotunDocument2 pagesSurface Preparation Standards JotunbacabacabacaNo ratings yet

- Painting ProcedureDocument4 pagesPainting ProcedureRidoNo ratings yet

- GTS-PP-120: 3 LayerDocument2 pagesGTS-PP-120: 3 Layershoaib1985100% (1)

- Aban Constructions Pvt. LTD: Procedure For PaintingDocument4 pagesAban Constructions Pvt. LTD: Procedure For PaintingAkhilesh KumarNo ratings yet

- Daily Paint ReportDocument2 pagesDaily Paint Reportcarey stewart100% (3)

- Resume For Painting InspectorDocument3 pagesResume For Painting InspectorMITHUNNo ratings yet

- Painting Procedure For Field Erected Tank FINAL (13850)Document22 pagesPainting Procedure For Field Erected Tank FINAL (13850)Parthiban NCNo ratings yet

- Cathodic Protection Reading InspectionDocument1 pageCathodic Protection Reading InspectionFarook MohideenNo ratings yet

- INSPECTION REPORT TITLEDocument7 pagesINSPECTION REPORT TITLEABEC Trombay siteNo ratings yet

- Project Standards and Specifications Painting Repair Procedure Rev01webDocument4 pagesProject Standards and Specifications Painting Repair Procedure Rev01webMajid Dawood Khan0% (1)

- GRP General Procedure (EWS)Document16 pagesGRP General Procedure (EWS)Maged Ali Ragheb100% (1)

- Ripen Offshore Calmbuoy Cleaning and Painting Works ProcedureDocument6 pagesRipen Offshore Calmbuoy Cleaning and Painting Works ProcedureAdamu Jebo100% (1)

- Recommended Application Procedures: CoatingsDocument1 pageRecommended Application Procedures: CoatingsVenkata RaoNo ratings yet

- Method Statement For Surface Preparation Prtective CoatingDocument11 pagesMethod Statement For Surface Preparation Prtective CoatingJaved MANo ratings yet

- Method Statement For Surface Preparation Prtective CoatingDocument10 pagesMethod Statement For Surface Preparation Prtective CoatingJaved MANo ratings yet

- Coating Procedure Hydac PL2653 Siemens D Ineos 1Document6 pagesCoating Procedure Hydac PL2653 Siemens D Ineos 1rjgoonerNo ratings yet

- Enviroline 125LV Application GuidelineDocument17 pagesEnviroline 125LV Application GuidelineAhmed IbrahimNo ratings yet

- Work Method ProceduresDocument37 pagesWork Method ProceduresAnonymous K0fqIO100% (2)

- Internal Painting of Fuel TanksDocument9 pagesInternal Painting of Fuel Tankstzimtiger50% (2)

- Sec 685Document10 pagesSec 685junior vegaNo ratings yet

- Datasheet For Carbon Steel A333 Grade 6Document10 pagesDatasheet For Carbon Steel A333 Grade 6Aneesh JoseNo ratings yet

- Class 1 2 - Issuance FlowchartDocument1 pageClass 1 2 - Issuance FlowchartAneesh JoseNo ratings yet

- 9 Cswip 3.1 Question Answers SPECIMEN WRITTEN EXAMINATION QUESTIONS Question Answers Solved Past Papers Cswip 3.1Document32 pages9 Cswip 3.1 Question Answers SPECIMEN WRITTEN EXAMINATION QUESTIONS Question Answers Solved Past Papers Cswip 3.1Mohammed Amjad AliNo ratings yet

- SS316 Stainless Steel Banding Product Data SheetDocument1 pageSS316 Stainless Steel Banding Product Data SheetAneesh JoseNo ratings yet

- 3Document1 page3Aneesh JoseNo ratings yet

- Tillc-Doc006-Pds-Ss316 Wire PDFDocument1 pageTillc-Doc006-Pds-Ss316 Wire PDFAneesh JoseNo ratings yet

- Aluminium Coil / Sheet / Corrugated: Aluminium Alloy - AA 1100, 1050, 1060 - AA 3003 - AA 5005, 5052, 5754Document1 pageAluminium Coil / Sheet / Corrugated: Aluminium Alloy - AA 1100, 1050, 1060 - AA 3003 - AA 5005, 5052, 5754Aneesh JoseNo ratings yet

- Tillc-Doc003-Pds-Ss316 Toggle Latch PDFDocument1 pageTillc-Doc003-Pds-Ss316 Toggle Latch PDFAneesh JoseNo ratings yet

- Stainless Steel Wire - Ss316/316L: Product Data SheetDocument1 pageStainless Steel Wire - Ss316/316L: Product Data SheetAneesh JoseNo ratings yet

- BANDINGDocument1 pageBANDINGAneesh JoseNo ratings yet

- Tillc-Doc004-Pds-Ss316 Screw PDFDocument1 pageTillc-Doc004-Pds-Ss316 Screw PDFAneesh JoseNo ratings yet

- SwitchDocument2 pagesSwitchAneesh JoseNo ratings yet

- Rounded Indication ChartDocument8 pagesRounded Indication ChartAneesh JoseNo ratings yet

- ABB Proposal Is Found Acceptable, Code-1. This Approval Does Not Relieve EPC Contractor From Any Responsibility As Stated in SOWDocument2 pagesABB Proposal Is Found Acceptable, Code-1. This Approval Does Not Relieve EPC Contractor From Any Responsibility As Stated in SOWAneesh JoseNo ratings yet

- Pneumatic Test CertificateDocument1 pagePneumatic Test CertificateAneesh JoseNo ratings yet

- Defect 955 PL-01Document6 pagesDefect 955 PL-01Aneesh JoseNo ratings yet

- ABB-RL-3 918: Added Battery Limit Acoustic Insulation HCDocument1 pageABB-RL-3 918: Added Battery Limit Acoustic Insulation HCAneesh JoseNo ratings yet

- Steel Moment Frame Guidelines Chapter 2 DefinitionsDocument14 pagesSteel Moment Frame Guidelines Chapter 2 DefinitionsAneesh JoseNo ratings yet

- Labels - '1 To 39Document39 pagesLabels - '1 To 39Aneesh JoseNo ratings yet

- Bro Pocket GuideDocument72 pagesBro Pocket Guide윤병택No ratings yet

- PurgingDocument10 pagesPurgingSai PrasathNo ratings yet

- Flame ArresterDocument2 pagesFlame ArresterAneesh JoseNo ratings yet

- Controlvalvesandactuators 090617042347 Phpapp01Document34 pagesControlvalvesandactuators 090617042347 Phpapp01Vijaya LakshmiNo ratings yet

- Controlvalvesandactuators 090617042347 Phpapp01Document34 pagesControlvalvesandactuators 090617042347 Phpapp01Vijaya LakshmiNo ratings yet

- NDT-Status 24 June PDFDocument1 pageNDT-Status 24 June PDFAneesh JoseNo ratings yet

- FddeDocument4 pagesFddeAneesh JoseNo ratings yet

- Painting Defects-Mud CrackingDocument4 pagesPainting Defects-Mud CrackingAneesh JoseNo ratings yet

- EpoxyDocument21 pagesEpoxyAneesh JoseNo ratings yet

- Interpreting What Your Voltmeter Is Telling You: Reading What Reading IndicatesDocument3 pagesInterpreting What Your Voltmeter Is Telling You: Reading What Reading IndicatesAneesh JoseNo ratings yet

- Co SDocument62 pagesCo SAneesh JoseNo ratings yet