Professional Documents

Culture Documents

27 AprvdGma

Uploaded by

cereferOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

27 AprvdGma

Uploaded by

cereferCopyright:

Available Formats

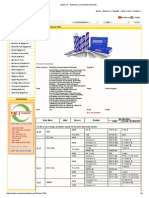

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

ARGENTINA

Air Liquide Argentina S.A. Nertalic 70 Check test pending ABS CO-2 3SA All dcep 0.9 - 1.2 mm Buenos Aires

Electrodos S.A. Conarco S6 OK Autrod 12.51 ABS ABS CO-2 CO-2 3SA 3SA All, V-down All, V-down dcep dcep 0.9 - 1.2 mm 0.9 - 1.2 mm Buenos Aires Buenos Aires

AUSTRALIA

Comweld Group Pty., Ltd. MetalCor XP MetalCor XP SuperCor 5 SuperCor 5 SuperCor 5 Verti-Cor 3XP Verti-Cor Ultra Verticor Ultra 3 ABS ABS ABS ABS ABS ABS ABS ABS Argoshield 52 Argoshield Universal Argoshield 52 Argoshield Universal CO-2 75% Ar, 25% CO-2 CO-2 CO-2 3SA, 3YSA H5 (FC) 3SA, 3YSA H5 (FC) 3SA, 3YSA H5 (FC) 3SA, 3YSA H5 (FC) 3SA, 3YSA H5 (FC) 3SA, 3YSA H5 2SA, 2YSA H10 3SA, 3YSA H5 (FC) F F All, V-down All, V-down All, V-down All All, V-down All dcep dcep dcep dcep dcep dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 0.9 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Melbourne Melbourne Melbourne Melbourne Melbourne Melbourne Melbourne Melbourne

Lincoln Electric Company Superarc LA-100 ABS 75% Ar, 25%, CO-2 4YQ550SA F dcep 1.2 mm Sydney

AUSTRIA

Bhler Schweisstechnik Austria GmbH Bhler 2.5 Ni-IG Bhler CN 22/9 N-FD ABS M21 / EN 439 5YQ460 SA F, V dcep 0.8 - 1.6 mm Munich

AWS M21 / EN439 E2209T0-4 dcep 1.2 mm Munich A5.22-95 For duplex stainless (UNS S31803), welding same to C/Mn steels, & one-side welding with ceramic backing. Test temp. -30C. Strict control of dilution is mandatory to prevent martensitic phases in welds near to carbon steel fusion boundary. Bhler CN 22/9 N-IG AWS Ar ER2209 F, V, O dcen 1.6 - 4.0 mm Essen A5.9-93 TIG rods recommended by mfr for welding austneitic-ferritic steel (Duplex), UNS S31803 (& sim.) & for welding these alloys to Grade AH36 (C-Mn Steel). Mfr's Guaranteed min., Grade UNS S31803 to AH36: T.S. 500 N/mm2; ISO-V at -20 C, 47 J. Bhler CN 22/9 PW-FD AWS C1 / EN 439 E2209T1-4 dcep 1.2 mm Munich A5.22-95 For duplex stainless (UNS S31803), welding same to C/Mn steels, & one-side welding with ceramic backing. Test temp. -30C. Strict control of dilution is mandatory to prevent martensitic phases in welds near to carbon steel fusion boundary.

14/Feb/2005 Approved Welding Consumables

III - 1

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

AUSTRIA

Bhler Schweisstechnik Austria GmbH Bhler CN 22/9 PW-FD AWS M21 / EN439 E2209T1-4 dcep 1.2 mm Munich A5.22-95 For duplex stainless (UNS S31803), welding same to C/Mn steels, & one-side welding with ceramic backing. Test temp. -30C. Strict control of dilution is mandatory to prevent martensitic phases in welds near to carbon steel fusion boundary. Bhler CN23/12 Mo-FD AWS M21 / EN439 E308MoLT0-4 dcep 1.2 mm A5.22-95 For austenitic stainless steels, welding same to C/Mn steels, & for one side welding with ceramic backing. Test temp.: -60C. Bhler CN23/12 PW-FD AWS A5.22-95 Munich

Ar + 18-25% E309LT1-4 dcep 1.2 mm Munich CO-2; M21 per EN 439 For duplex stainless (UNS 31803), welding same to C/Mn steels, & one-side welding with ceramic backing. Test temp. -60C. Strict control of dilution is mandatory to prevent martensitic phases in welds near to carbon fusion boundary. Bhler CN23/12 PW-FD AWS CO-2; C1 per EN E309LT1-1 dcep 1.2 mm Munich A5.22-95 439 For duplex stainless (UNS 31803), welding same to C/Mn steels, & one-side welding with ceramic backing. Test temp. -60C. Strict control of dilution is mandatory to prevent martensitic phases in welds near to carbon fusion boundary. Bhler EMK6 Bhler EMK6 Bhler EMK8 Bhler EMK8 Bhler EMK8 Bhler HL 51-FD Bohler HL-51-FD Bhler NiCrMo 2.5-IG Bhler TI 52-FD Bhler TI 52-FD ABS ABS ABS ABS ABS ABS ABS ABS ABS C1 / EN 439 M21 / EN 439 C1 / EN 439 M21 / EN 439 M22 / EN 439 80% Ar, 20% CO-2 80% Ar, 20% CO-2 M21 / EN 439 CO-2 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 4SA, 4YSA H5 4SA, 4YSA, H5 5YQ690 SA 3SA, 3YSA H10 F, V, V-down F, V, V-down F, V, V-down F, V, V-down F, V, V-down dcep dcep dcep dcep dcep 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.4 - 1.6 mm 0.8 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Munich Munich Munich Munich Munich Venice Venice Munich Essen Essen

F, V, H, V-down dcep F ,V, H, V-down dcep F, V All, V-down dcep dcep dcep

ABS, AWS All, V-down 75 - 85% Ar, 3SA, 3YSA*, A5.20 CO-2 E71T-1M * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. Bhler X 70-IG ABS M21 / EN439 4YQ690 SA F, V, H

dcep

1.0 - 1.2 mm

Munich

x See also Bhler Thyssen Schweisstechnik Deutschland GmbH

BRAZIL

Belgo Bekaert Arames S.A. BMEC-4 ABS CO-2 3YSA All dcep 0.6 - 1.6 mm So Paulo

14/Feb/2005 Approved Welding Consumables

III - 2

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

BRAZIL

Boehler Thyssen Tcnica de Soldagem Ltda. BTS A 387 BTS A 68 LC BTS A 68 MoLC BTS A 682 LC BTS ARS 5 BTS EML-5 CN 22/9 N-IG AWS A5.7-84R AWS A5.9-93 AWS A5.9-93 AWS A5.9-93 ABS AWS A5.18-01 AWS A5.9-93 CO-2 Ar ERCuNi ER308L ER316L ER309L 2Y400 ER70S-3 ER2209 All F dcep dcen 1.2 - 3.25 mm 2.5 - 3.25 mm 2.4 - 3.25 mm 2.5 - 3.25 mm 1.2 mm 2.4 - 3.25 mm 2.4 - 3.25 mm So Paulo So Paulo So Paulo So Paulo So Paulo So Paulo So Paulo

Esab S.A. Industria e Comercio OK Autrod 12.51 OK Tubrod 71 Ultra OK Tubrod 71 Ultra OK Tubrod 75 OK Tubrod 75 ABS ABS ABS ABS ABS CO-2 75% Ar, 25% CO-2 CO-2 75% Ar, 25% CO-2 CO-2 3YSA 3SA, 3YSA H10 3SA, 3YSA H10 4YSA, H10 4YSA, H10 All All, V-down All, V-down F, H, V F, H, V dcep dcep dcep dcep dcep 0.6 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm So Paulo So Paulo So Paulo So Paulo So Paulo

Gerdau S/A Arames para Solda Gerdau MIG S6 / CO-2 MIG-ER70S-3 TIG ER70S-3 ABS AWS A5.18-01 AWS A5.18-01 CO-2 CO-2 Ar 3YSA ER70S-3 ER70S-3 All, V-down F F dcep dcep dcen 0.6 - 1.6 mm 0.8 - 1.6 mm 1.6 - 4.76 mm So Paulo So Paulo So Paulo

Kestra Universal Soldas Indstria, Comrcio, Importao e Exportao Ltda. KST G 4517 N AWS A5.9-93 ER2553 2.4 - 3.2 mm So Paulo

CANADA

Air Liquide Canada Inc. LA 75G / LA S-6 LA High Tensile / LA S3 LA T-9 LA T-9 LA T-91 ABS ABS ABS ABS ABS CO-2 CO-2 75% Ar, 25% CO-2 CO-2 75% Ar, 25% CO-2 3YSA 3SA 2SA, 2YSA H10 2SA, 2YSA H10 3SA, 3YSA H10 All All F, HF F, HF All dcep dcep dcep dcep dcep 1.6 mm 1.6 mm .045 - 3/32" .045 - 3/32" .045 - 1/16" Montreal Montreal Cleveland Cleveland Cleveland

14/Feb/2005 Approved Welding Consumables

III - 3

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

CANADA

Air Liquide Canada Inc. LA T-91 ABS **NOTE: BS8 is 75% Ar, 25% CO-2 LA T-91 ABS BS8** 3YSA All dcep 1.6 mm Montreal

CO-2 BS8**

3SA, 3YSA H10 5YSA H10

All All

dcep dcep

.045 - 1/16" 1.6 mm

Cleveland Montreal

LA T-91 C60Ni-1 ABS **NOTE: BS8 is 75% Ar, 25% CO-2

Hobart Brothers of Canada Fabco 96 Fabco 96 Fabco XL 71 ABS ABS ABS 75% Ar, 25% CO-2 98% Ar, 08% CO-2 3Y400SA H5 3Y400SA H5 F F dcep dcep dcep 1.6 mm 1.6 mm 1.6 mm Montreal Montreal Montreal

75% Ar, 25% 3Y400SA* All CO-2 * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. Fabco XL 71 ABS CO-2 3Y400SA* All * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel.

dcep

1.6 mm

Montreal

Indalco Alloys IA 5183 IA 5356 IACS W26 IACS W26 Ar (I-1) Ar (I-1) WC WB All All dcep dcep 0.9 - 1.6 mm 0.9 - 1.6 mm Montreal Montreal

Lincoln Electric Co. of Canada Ltd. L-56 L-56 Outershield 71 Elite Outershield 71 Elite ABS ABS ABS ABS 75% Ar, 25% CO-2 CO-2 75% Ar, 25% CO-2 CO-2 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA H10 3SA, 3YSA H10 All All All All dcep dcep dcep dcep 1.1 - 1.6 mm 1.1 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Montreal Montreal Montreal Montreal

Praxair Prostar 70 Supreme Prostar 71 Supreme AWS A5.20-95 ABS CO-2 E70T-1 H, F dcep dcep .045" - 3/32" .035" - 1/16" Toledo Toledo

75% Ar, 25% 3SA, 3YSA* All CO-2 * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. Prostar 71 Supreme ABS CO-2 3SA, 3YSA* All * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel.

dcep

.035" - 1/16"

Toledo

14/Feb/2005 Approved Welding Consumables

III - 4

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

CHILE

Industria y Comercio Indura S.A. Indura 70S-3 Indura 70S-6 ABS ABS CO-2 CO-2 3SA, 3YSA 3SA, 3YSA All, V-down All dcep dcep 0.8 - 1.6 mm 0.6 - 1.6 mm Valparaiso Valparaiso

M & H Comercial e Industrial Ltd. M & H 70S-6 ABS CO-2 3SA, 3YSA All dcep 0.8 - 1.2 mm Valparaiso

CHINA, PEOPLES REPUBLIC OF

Advanced Technology & Materials Co., Ltd. AT-YJ502 (Q) AT-YJ502 (Q) ABS ABS CO-2 CO-2 3YSA H10 3YSA H10 F, H, V All, V-down dcep dcep 1.6 mm 1.2 - 1.4 mm Guangzhou Guangzhou

Atlantic China Welding Consumables (China Welding Electrode Plant) CHT711 CHT711 ABS ABS CO-2 CO-2 3YSA H10 3YSA H10 V-down All dc dc 1.2 mm 1.2 - 1.6 mm Guangzhou Guangzhou

Beijing Ganglian Welding Materials Co. Ltd. GL-YJ502 (Q) GL-YJ502 (Q) GL-YJ502 (Q) ABS ABS ABS CO-2 CO-2 CO-2 3YSA H10 3YSA H10 3YSA H10 F, H All, V-down F, H, V dcep dcep dcep 1.6 mm 1.2 mm 1.4 mm Guangzhou Guangzhou Guangzhou

Beijing Golden Sun Flux-Cored Wire Co., Ltd. TY-YJ502(Q) TY-YJ502(Q) TY-YJ502(Q) ABS ABS ABS CO-2 CO-2 CO-2 3YSA H10 3YSA H10 3YSA H10 F, H, V F, H All, V-down dcep dcep dcep 1.4 mm 1.6 mm 1.2 mm Guangzhou Guangzhou Guangzhou

Changzhou Huatong Welding Wire Co., Ltd. HTW-50 ABS CO-2 3YSA* All * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. dcep 0.8 - 1.6 mm Shanghai

Hebei Yichen Industrial Group Co., Ltd. YC-YJ502(Q) YC-YJ502(Q) YC-YJ502(Q) ABS ABS ABS CO-2 CO-2 CO-2 3YSA 3YSA 3YSA F, H F, H, V All, V-down dcep dcep dcep 1.6 mm 1.4 mm 1.2 mm Guangzhou Guangzhou Guangzhou

14/Feb/2005 Approved Welding Consumables

III - 5

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

CHINA, PEOPLES REPUBLIC OF

Jinzhou Jin Tai Welding & Metal Co. Ltd. JM-54 JM-56 JM-56Z JM-56Z JM-58 JM-58Z JM-58Z JM-68 ABS ABS ABS ABS ABS ABS ABS ABS CO-2 CO-2 CO-2 CO-2 CO-2 CO-2 CO-2 CO-2 3YSA 3YSA 3YSA 3YSA 3YSA 3YSA 3YSA 3YQ500SA All, V-down All, V-down All, V-down F F, H, V, V-down F dcep dcep dcep dcep dcep dcep 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.2 mm 1.6 mm 1.2 - 1.6 mm 1.6 mm 1.2 mm 0.8 - 1.6 mm Guangzhou Guangzhou Guangzhou Guangzhou Guangzhou Guangzhou Guangzhou Guangzhou

F, H, V, V-down dcep All dcep

Kiswel Dalian Ltd. K-71TLF KX-200 ABS ABS CO-2 CO-2 (FC) 3SA, 3YSA H10 All, V-down dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm Guangzhou Guangzhou

2SA H10, 2YSA H10 F

Lincoln Electric (Shanghai) Trading and Warehousing Co., Ltd. Lincoln LW-71 Lincoln LW-81Ni1 ABS ABS CO-2 CO-2 3SA, 3YSA H10 4Y400SA H10 All All, V-down dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm Shanghai Shanghai

Ningbo Longxing Electric Welding Machine Co., Ltd. HXQ506 ABS CO-2 3SA, 3YSA All dcep 0.8 - 1.6 mm Shanghai

Shanghai Atlantic Welding Consumables Co., Ltd. CHW-50C6SM ABS CO-2 3SA, 3YSA All dcep 0.8 - 1.6 mm Shanghai

Shanghai Baogang Metallurgy Construction Corp. BH-503 BH-503 ABS ABS CO-2 CO-2 3YSA 3YSA All F dc dc 0.8 - 1.2 mm 1.6 mm Shanghai Shanghai

Shanghai Lincoln Electric Co., Ltd. KFX-712C KFX-71T ABS ABS CO-2 CO-2 3SA, 3YSA H10 3SA, 3YSA H10 All, V-down All, V-down dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm Shanghai Shanghai

Shanghai Welding Equipment & Consumables, Shanghai Goodweld Corp. SH.ER50-6 ABS CO-2 3YSA F dcep 1.6 mm Shanghai

14/Feb/2005 Approved Welding Consumables

III - 6

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

CHINA, PEOPLES REPUBLIC OF

Shanghai Welding Equipment & Consumables, Shanghai Goodweld Corp. SH.ER50-6 ABS CO-2 3YSA All dcep 0.8 - 1.2 mm Shanghai

Shijiazhuang Rada Welding Materials Co. Ltd. RD-YJ502(Q) RD-YJ502(Q) RD-YJ502(Q) ABS ABS ABS CO-2 CO-2 CO-2 3YSA H10 3YSA H10 3YSA H10 F, H, V-Up All, V-Down F, H dcep dcep dcep 1.4 mm 1.2 mm 1.6 mm Guangzhou Guangzhou Guangzhou

Supertech (Kunshan) Co., Ltd. SF-70MX SF-71 SM-70 SM-70 Supercored 71 Supercored 71H ABS ABS ABS ABS ABS ABS CO-2 CO-2 CO-2 CO-2 CO-2 CO-2 2YSA H10 2YSA H10 3YSA 3YSA 3YSA H10 3YSA H10 F, HF All, V-down All, V-down F All, V-down All, V-down dcep dcep dcep dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 0.8 - 1.2 mm 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai

Taizhou Universe Welding Material Co., Ltd. TH-S206 TH-S206 ABS ABS CO-2 CO-2 3YSA 3YSA F All dcep dcep 1.6 mm 0.8 - 1.2 mm Guangzhou Guangzhou

Tianjin Bridge Welding Material Group Co. Ltd. THY-51B THY-55 ABS ABS CO-2 CO-2 3YSA 3YSA H10 All F dc dc 1.2 - 1.4 mm 1.2 - 1.6 mm Guangzhou Guangzhou

Tianjin Golden Bridge Welding Materials Co., Ltd. JQ, MG50-6 JQ, YJ501-1 ABS ABS CO-2 CO-2 3YSA H10 3YSA H10 All All, V-down dcep dcep 0.8 - 1.6 mm 1.2 - 1.6 mm Guangzhou Guangzhou

Tianjin Sainteagle Welding Co., Ltd. SQJ501 SQJ501 SQJ501Ni SQJ501Ni ABS ABS ABS ABS CO-2 CO-2 CO-2 CO-2 3YSA H10 3YSA H10 3YSA H10 3YSA H10 F, H, V, V-down All dcep dcep 1.4 mm 1.2 mm 1.4 mm 1.2 mm Guangzhou Guangzhou Guangzhou Guangzhou

F, H, V, V-down dcep All dcep

14/Feb/2005 Approved Welding Consumables

III - 7

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

CHINA, PEOPLES REPUBLIC OF

Tien Tai Electrode (Kunshan) Co., Ltd. TFW-308L TFW-309L TFW-316L TGS-308L TGS-309L TGS-309MoL TGS-316L TIG-1CM (TIG-80B2) TIG-2CM (TIG-90B3) TIG-50 TM-54 TM-56 TM-70C TWE-711 TWE-711Ni TWE-712 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.9-93 AWS A5.9-93 AWS A5.9-93 AWS A5.9-93 AWS A5.28-96 AWS A5.28-96 ABS ABS ABS ABS ABS ABS ABS CO-2 CO-2 CO-2 Ar Ar Ar Ar Ar Ar Ar CO-2 CO-2 CO-2 CO-2 CO-2 CO-2 E308LT1-1 E309LT1-1 E316LT1-1 ER308L ER309L ER309LMo ER316L ER80S-B2 ER90S-B3 3, 3Y 3YSA 3YSA 3YSA H10 3SA H10, 3YSA 4YSA 3SA H10, 3YSA All All All F, H All, V-down All All, V-down All All All All All dcep dcep dcep dcen dcen dcen dcen dcen dcen dcen dcep dcep dcep dcep dcep dcep 0.9 - 1.6 mm 0.9 - 1.6 mm 0.9 - 1.6 mm 1.2 - 3.2 mm 1.6 - 3.2 mm 1.2 - 3.2 mm 1.2 - 3.2 mm 2.4 mm 2.4 mm 1.2 - 3.2 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai Shanghai

Wuhan Marine Machinery Plant (Wuhan Marine Welding Consumables Factory WH50-6 WH50-6 YCJ501-1 YCJ502-1 ABS ABS ABS ABS CO-2 CO-2 CO-2 CO-2 3YSA H10 3YSA H10 3YSA H10 3YSA H10 F All All F dcep dcep dcep dcep 1.4 - 1.6 mm 0.8 - 1.2 mm 1.2 - 1.6 mm 1.2 mm Guangzhou Guangzhou Guangzhou Guangzhou

Zibo Feile Welding Products Co., Ltd. FL-YJ502 FL-YJ502 ABS ABS CO-2 CO-2 3YSA 3YSA H10 All, V-down All, V-down dcep dcep 1.4 - 1.6 mm 1.2 mm Guangzhou Guangzhou

Zigong Atlantic Welding Wires Co., Ltd. CHW-50C6SM ABS CO-2 3SA, 3YSA All dcep 0.8 - 1.6 mm Guangzhou

14/Feb/2005 Approved Welding Consumables

III - 8

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

COLOMBIA

Electromanufacturas S.A. WA-86 ABS CO-2 2SA All, V-down dcep 0.76 - 1.14 mm Cartagena

CROATIA

Elektroda Zagreb EZ-CO-2 EZ-Fil-1 ABS ABS CO-2 CO-2 3YSA 3SA, 3YSA H5 All All, V-down dcep dcep 0.8 - 1.6 mm 1.2 - 1.6 mm Rijeka Venice

CZECH REPUBLIC

Esab Vamberk s.r.o. Filarc PZ 6102 ABS 80%Ar, 20% CO2 3SA, 3YSA^ All, V-down dcep ^ One side welding with ceramic backing material, subject to satisfactory procedure tests at user's plant. Filarc PZ 6104 ABS 80%Ar, 20% CO2 3SA, 3YSA** ** Manufacturer's guaranteed minimum CVN 54 J at -40C. Filarc PZ 6111 Filarc PZ 6111 Filarc PZ 6111HS Filarc PZ 6111HS ABS ABS ABS ABS 80%Ar, 20% CO2 3SA, 3YSA CO-2 3SA, 3YSA All dcep 1.2 - 1.6 mm Pilsen

1.2 - 1.6 mm

Pilsen

F, V F, V F F

dcep dcep dcep dcep

1.2 - 1.6 mm 1.2 - 1.6 mm 1.6 mm 1.6 mm 1.2 - 1.6 mm

Pilsen Pilsen Pilsen Pilsen Pilsen

80%Ar, 20% CO2 3SA, 3YSA H5 CO-2 3SA, 3YSA H5

Filarc PZ 6113 ABS 80%Ar, 20% CO2 3SA, 3YSA^ All dcep ^ One side welding with ceramic backing material, subject to satisfactory procedure tests at user's plant. Filarc PZ 6113 ABS CO-2 3SA, 3YSA^ All dcep ^ One side welding with ceramic backing material, subject to satisfactory procedure tests at user's plant. Filarc PZ 6113S ABS CO-2 **Manufacturer's guaranteed minimum CVN 47 J @ -60 C Filarc PZ 6114 ABS 3SA H5** All, V-down dcep

1.2 - 1.6 mm

Pilsen

1.2 mm

Pilsen

80%Ar, 20% CO2 4YSA H5

F, H, V

dcep

1.2 mm 1.2 mm

Pilsen Pilsen

Filarc PZ 6114S ABS CO-2 4YSA H5^ All dcep ^ One side welding with ceramic backing material, subject to satisfactory procedure tests at user's plant. ABS CO-2 3SA H5, 3YSA H5^ All, V-down dcep Filarc PZ 6116S ^ One side welding with ceramic backing material, subject to satisfactory procedure tests at user's plant Filarc PZ 6125 ABS 80%Ar, 20% CO2 3SA, 3YSA^ All, V-down dcen ^ One side welding with ceramic backing material, subject to satisfactory procedure tests at user's plant.

1.2 mm

Pilsen

1.0 - 1.6 mm

Pilsen

Filarc PZ 6130HS ABS 80%Ar, 20% CO2 3SA, 3YSA^ All dcen 1.4 - 1.6 mm Pilsen ^ Manufacturer's guaranteed minimum CVN 35 J at -40C. One side welding with ceramic backing material subject to satisfactory procedure tests at user's plant.

14/Feb/2005 Approved Welding Consumables

III - 9

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

CZECH REPUBLIC

Esab Vamberk s.r.o. Filarc PZ 6130HS ABS CO-2 3SA, 3YSA^ F, V dcen 1.4 - 1.6 mm Pilsen ^ Manufacturer's guaranteed minimum CVN 35 J at -40C. One side welding with ceramic backing material subject to satisfactory procedure tests at user's plant. Filarc PZ 6138 ABS 80%Ar, 20% CO2 3SA H5, 3YSA H5^ All, V-down dcep 1.2 - 1.4 mm Pilsen ^ Manufacturer's guaranteed minimum CVN 30 J at -60C. One side welding with ceramic backing material, subject to satisfactory procedure tests at user's plant. Filarc PZ 6138SR ABS 80%Ar, 20% CO2 4YSA H5^ F, H, V dcep 1.2 mm Pilsen ^ Tested in both conditions "as welded" and "stress relieved". Mfr. recommends wire for thick plate where stress-relieving is required. One side welding with ceramic backing strip subject to satisfactory procedure testing at user's plant. OK E71-T 82% Ar, 18% CO-2 **Manufacturer's guaranteed minimum CVN 47 J @ -60 C OK E71-T ABS CO-2 ABS 3SA, 3YSA** All dcep 1.2 mm Pilsen

3SA, 3YSA

All

dcep dcep

1.2 mm 1.2 mm

Pilsen Pilsen

OK Tubrod 14.13 ABS 80%Ar, 20% CO2 3SA, 3YSA* All * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. OK Tubrod 15.13 OK Tubrod 15.13 OK Tubrod 15.13C OKTubrod 15.13S ABS ABS ABS ABS 82% Ar, 18% C0-2 CO-2 CO-2 CO-2 3SA, 3YSA 3SA, 3YSA 4YSA H5 3SA H5 All All F, H, V All, V-down

dcep dcep dcep dcep

1.2 mm 1.2 mm 1.2 mm 1.2 mm

Pilsen Pilsen Pilsen Pilsen

EGYPT

Alex Wire Co. AW-SG2 AW-SG3 ABS ABS CO-2 CO-2 3YSA 3YSA F, H, V F, H, V dcep dcep 1.2 - 1.6 mm 1.2 mm Alexandria Alexandria

Oerlikon Egypt for Electrodes and Welding Equipment Carbofil 90 E ABS CO-2 3SA F, H, V dcep 1.2, 1.6 mm Cairo

FRANCE

Mig Weld S.A. ML 5183, AlMg4.5Mn AWS A5.10-99, IACS W26 AWS A5.10-99, IACS W26 AWS A5.10-99, IACS W26 Argon ER5183 All dcep 0.8 - 1.6 mm Mulhouse

ML 5183, AlMg4.5Mn

Argon

ER5556

All

dcep

0.8 - 1.6 mm

Mulhouse

ML 5356, AlMg5

Argon

ER5356

All

dcep

0.8 - 1.6 mm

Mulhouse

14/Feb/2005 Approved Welding Consumables

III - 10

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

FRANCE

Oerlikon Soudure France Citoflux 100 C / C1 Citoflux 100 C / M21 Citoflux 128 ABS ABS ABS CO-2 M21 3YSA H5 3YSA H10 F, V, H F, V, H dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm Bucharest Bucharest

85% Ar, 15% 4Y400SA* All dcep 1.2 - 1.6 mm Mulhouse CO-2 * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. Manufacturer's guaranteed properties: CVN 47 J at -46C.

Sauvageau Commercy Soudure FF 16 / Atal FF16Ni / Atal SG 21 ABS ABS 85% Ar, 15% CO-2 85% Ar, 15% CO-2 (M21) 3YSA 4Y400 SA F, V, H F, V, H dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm Mulhouse Mulhouse

AWS All dcep 0.8 - 1.6 mm Mulhouse ** ER5356** A5.10-99 **Manufacturer's minimum guaranteed values: T.S.: 240 N/mm2 - Y.S.: 110 N/mm2 - EL (5D): 16%. Shielding gas per manufacturer's recommendation or user's procedure qualification SG 21 A AWS All dcep 0.8 - 1.6 mm Mulhouse ** ER5183** A5.10-99 **Manufacturer's minimum guaranteed values: T.S.: 275 N/mm2 - Y.S.: 125 N/mm2 - EL (5D): 17%. Shielding gas per manufacturer's recommendation or user's procedure qualification SG6 / Atal X71 / Atal ABS ABS 85% Ar, 15% CO-2 85% Ar, 15% CO-2 3SA 3YSA All F, V dcep dcep 1.0 - 1.6 mm 1.2 - 1.6 mm Mulhouse Mulhouse

Soudure Autogene Francaise Cristal F 100 / C1 Cristal F 100 / M21 ABS ABS CO-2 85% Ar, 15% CO-2 3YSA 3YSA F, V, H F, V, H dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Mulhouse Mulhouse Mulhouse

Lexal T 22 9 3 N / C1 ABS CO-2 E2209T1-1** All **Manufacturer's guaranteed properties: 690 MPa min. tensile strength, 20% min. elongation 85% Ar, 15% E2209T1-4** All CO-2 **Manufacturer's guaranteed properties: 690 MPa min. tensile strength, 20% min. elongation Lexal T 22 9 3 N / M21 Nertalic 70A / M21 Nertalic 70S / C1 Nertalic 70S / M21 SAFDual 100 / C1 SAFDual 100 / M21 SAFDual 100 C / C1 SAFDual 100 C / M21 ABS ABS ABS ABS ABS ABS ABS 85% Ar, 15% CO-2 CO-2 85% Ar, 15% CO-2 CO-2 85% Ar, 15% CO-2 CO-2 85% Ar, 15% CO-2 3SA 3SA 3SA 3YSA 3YSA 3YSA 3YSA All All, V-Down All F, V, H F, V, H F, V, H F, V, H ABS

dcep

1.2 - 1.6 mm

Mulhouse

dcep dcep dcep dcep dcep dcep dcep

1.0 - 1.6 mm 1.0 - 1.6 mm 1.0 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm

Mulhouse Mulhouse Mulhouse Mulhouse Mulhouse Mulhouse Mulhouse

14/Feb/2005 Approved Welding Consumables

III - 11

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

FRANCE

Soudure Autogene Francaise SAFDual 100 Plus / M21 SAFDual 100Ni / C1 SAFDual 100Ni / M21 SAFDual 102C SAFDual 105 / C1 SAFDual 105A / M21 SAFDual 128 / M21 ABS ABS ABS ABS ABS ABS ABS 85% Ar, 15% CO-2 CO-2 85% Ar, 15% CO-2 CO-2 CO-2 80% Ar, 15% CO-2 4Y400SA H5 4Y400SA 4Y400SA 4Y400SA 3Y400 3YSA, 3Y400SA 4Y400SA All F, V, H F, V, H F, H, V F F, H, V All dcep dcep dcep dcep dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 mm 1.2 - 1.6 mm Mulhouse Mulhouse Mulhouse Mulhouse Mulhouse Mulhouse Mulhouse

85% Ar, 15% CO-2 Manufacturer's guaranteed properties: CVN 47 J at -46C SAFDual 162 / M21 ABS

85% Ar, 15% ** All dcep 1.2 - 1.6 mm Mulhouse CO-2 **Manufacturer's guaranteed properties: 700 MPa min. tensile strength, 620 MPa min. yield strength, 18% min. elongation, CVN 47 J at -40C. Recommended by manufacturer for welding high yield strength steels. SAFDual 200 / M21 SAFDual 270 / M21 ABS ABS 85% Ar, 15% CO-2 3YSA F, V dcep 1.2 - 1.6 mm Mulhouse

85% Ar, 15% ** F, V, H dcep 1.2 - 1.6 mm Mulhouse CO-2 **Manufacturer's guaranteed properties: 840 MPa min TS, 740 MPA min YS, 17% min. elongation., CVN 47 J at -40C. Recommended by manufacturer for welding high yield strength steels. SAFDual 31 / M21 ABS 85% Ar, 15% CO-2 3YSA F, V, H All dcep dcen 1.2 - 1.6 mm 1.2 - 1.6 mm Mulhouse Mulhouse

SAFDual 400 / C1 ABS CO-2 3YSA** **Manufacturer's guaranteed properties: CVN 47 J at -40C. 85% Ar, 15% 3YSA** CO-2 **Manufacturer's guaranteed properties: CVN 47 J at -40C. SAFDual 400 / M21 ABS

All

dcen

1.2 - 1.6 mm

Mulhouse

SD 654 - Blueshield ABS BS8 ** F, H dcep 1.2 - 1.6 mm 654-309L / BS8 **Manufacturer's guaranteed properties: 520 MPa min TS, 385 MPa min YS, 30% min. elongation., CVN 27 J at -60C SD 654 - Blueshield ABS CO-2 ** F, H dcep 1.2 - 1.6 mm 654-309L / CO-2 **Manufacturer's guaranteed properties: 520 MPa min TS, 385 MPa min YS, 30% min. elongation., CVN 27 J at -60C SD 654P - Blueshield ABS BS8 ** F,V, OH dcep 1.2 - 1.6 mm 654P-309L / BS8 **Manufacturer's guaranteed properties: 520 MPa min TS, 385 MPa min YS, 30% min. elongation., CVN 27 J at -60C SD 654P - Blueshield ABS CO-2 ** F, V, OH dcep 1.2 - 1.6 mm 654P-309L / CO-2 **Manufacturer's guaranteed properties: 520 MPa min TS, 385 MPa min YS, 30% min. elongation., CVN 27 J at -60C

Mulhouse

Mulhouse

Mulhouse

Mulhouse

14/Feb/2005 Approved Welding Consumables

III - 12

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

GERMANY

Bhler Thyssen Schweisstechnik Deutschland GmbH Bohler EMK6-D Bohler EMK6-D Bohler EMK8-D Bohler EMK8-D Thermanit 22/09 ABS ABS ABS ABS 82% Ar, 18% CO-2 CO-2 82% Ar, 18% CO-2 CO-2 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA All, V-down All, V-down All All dcep dcep dcep dcep 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm Essen Essen Essen Essen

AWS Ar ER2209 F, V, O dcen 1.6 - 4.0 mm Essen A5.9-93 TIG rods recommended by mfr for welding austneitic-ferritic steel (duplex), UNS S31803 (& sim.) & for welding these alloys to Grade AH36 (C-Mn Steel). Mfr's Guaranteed min., Grade UNS S31803 to AH36: T.S. 500 N/mm2; ISO-V at -20 C, 47 J. Thermanit 22/09-PW AWS C1 / EN 439 E2209T1-1 dcep 1.2 mm Essen A5.22-95 For duplex stainless (UNS S31803), welding same to C/Mn steels & one-side welding with ceramic backing. Test temp. -30C. Strict control of dilution is mandatory to prevent martensitic phases in welds near to carbon steel fusion boundary. Thermanit 22/09-PW AWS M21 / EN439 E2209T1-4 dcep 1.2 mm Essen A5.22-95 For duplex stainless (UNS S31803), welding same to C/Mn steels & one-side welding with ceramic backing. Test temp. -30C. Strict control of dilution is mandatory to prevent martensitic phases in welds near to carbon steel fusion boundary. Thermanit TG 22/09 AWS M21 / EN439 E2209T0-4 dcep 1.2 mm Essen A5.22-95 For duplex stainless (UNS S31803), welding same to C/Mn steels & one-side welding with ceramic backing. Test temp. -30C. Strict control of dilution is mandatory to prevent martensitic phases in welds near to carbon steel fusion boundary. Thermanit TG 309MoL AWS M21 / EN439 E309MoLT0-4 dcep 1.2 mm A5.22-95 For austenitic stainless steels, welding same to C/Mn steels, & for one-side wedling with ceramic backing. Test temp.: -60C Thyssen TG 55M Union BA 70 Union BA 70 Union K52 Union K52 Union K52 Union K52S Union K52S Union K52S Union K56 Union K56 Union MV 70 ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS 80%Ar-20%CO2 3SA, 3YSA, H5 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 83% Ar, 13% CO-2, 4% O-2 CO-2 80% Ar, 20% CO-2 83% Ar, 13% CO-2, 4% O-2 CO-2 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 4SA, 4YSA H5 4SA, 4YSA H5 3SA, 3YSA 3SA, 3YSA 3SA, 2YSA 3SA, 2YSA 3SA, 2YSA 3SA, 2YSA 3SA, 3YSA 3SA, 2YSA 4SA, 4YSA H5 All, V-Down F F All All All, V-down All All All, V-down All F, V F. V, H dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.6 - 1.6 mm 1.2 - 1.6 mm Essen

Venice Venice Venice Essen Essen Essen Essen Essen Essen Essen Essen Venice

14/Feb/2005 Approved Welding Consumables

III - 13

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

GERMANY

Bhler Thyssen Schweisstechnik Deutschland GmbH Union MV 70 Union Ni 2.5 ABS CO-2 4SA, 4YSA H5 F. V, H dcep 1.2 - 1.6 mm Venice

80% Ar, 20% ** All dcep 0.8 - 1.2mm Essen CO-2 **Low alloy electrode; specified nickel content of wire 2.20-2.45%; specified minimum mechanical properties: T.S. 486 N/mm2, Y.P. 276 N/mm2, El. 19%, CVN 27 J at -60C. Union NiMoCr Corgon 20 ** All **Approved specficially for welding higher strength steel Naxtra 70. CVN 30 J at -60 C. Union Rob 3 (Thyssen Rob ABS 3) Union RV 71 Union SG 2-H ABS ABS CO-2 80% Ar, 20% CO-2 5-25% CO-2 balance Ar (M21/DIN EN 439) 82% Ar, 18% CO-2 CO-2 80% Ar, 20% CO-2 3SA, 2YSA 3SA, 3YSA H5 3SA, 3YSA F, V All, V-down All dcep 0.8 - 1.2mm Essen

dcep dcep dcep

0.6 - 1.6 mm 1.2 - 1.6 mm 0.8 - 1.6 mm

Essen Venice Essen

Union SG 2-H Union SG 2-H Union TG 55M (Thyssen SG 2-H)

ABS ABS ABS

3SA, 3YSA 3SA, 3YSA 3SA, 3YSA H5

All, V-down All, V-down All, V-down

dcep dcep dcep

0.8 - 1.6 mm 0.8 - 1.6 mm 1.2 - 1.6 mm

Essen Essen Venice

x See also Bhler Schweisstechnik Austria GmbH. The manufacturer is qualified in accordance with ABS Quality Assurance Approval

Deutsche Nickel AG IGS Nickel IGS Silverin AWS A5.14-97 AWS A5.14-97 ERNi-1 ERNiCu-7 0.8 - 4.0 mm 0.8 - 4.0 mm Essen Essen

Drahtwerk Elisental DE-58 AWS ** ER5356 A5.10-99 **Shielding gas per manufacturer's recommendation or user's procedure qualification DE-63 AWS ** ER5183 A5.10-99 **Shielding gas per manufacturer's recommendation or user's procedure qualification DE-64 DIN 1732 Ar SG-AlMg4.5 MnZr dcep 1.2 - 1.6 mm Essen

1.2 - 1.6 mm

Essen

1.2 - 1.6 mm

Essen

Drahtzug Stein Wire & Welding GmbH Megafil 710M Megafil 710M Megafil 713R ABS ABS ABS 82% Ar, 18% CO-2 82% Ar, 18% CO-2 82% Ar, 18% CO-2 3Y400SA H5 3Y400SA H5 4YSA, 4Y400 SA All, V-down All, V-down F, H, V dcen dcep dcep 1.0 - 1.2 mm 1.0 - 1.2 mm 1.2 - 1.6 mm Essen Essen Essen

14/Feb/2005 Approved Welding Consumables

III - 14

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

GERMANY

Drahtzug Stein Wire & Welding GmbH Megafil 713R ABS CO-2 3YSA, 3Y400SA^ F, H, V dcep ^ One side welding with ceramic backing material subject to satisfactory procedure test at user's plant Megafil 713R Megafil 731B ABS ABS CO-2 82% Ar, 18% CO-2 4YSA H5, 4Y400 SA Fillet H5 4YSA, 4Y400 SA H dcep dcep 1.2 - 1.6 mm Essen

2.4 mm 1.2 - 1.6 mm 1.2 - 1.6 mm

Essen Essen Essen

Megafil 731B ABS CO-2 4YSA, 4Y400 SA^ H dcep ^ One side welding with ceramic backing material subject to satisfactory procedure test at user's plant Megafil 821 R 82% Ar, 18% 3Y400 SA** All, V-down CO-2 **Manufacturer's guaranteed minimum properties: 47 J at -60C and YS 460 N/mm2 at RT Megafil 821R SDA 2 SDA 2 SDA 3 SDA 3 ABS ABS ABS ABS ABS CO-2 82% Ar, 18% CO-2 CO-2 82% Ar, 18% CO-2 CO-2 3YQ460 SA 3YSA 3YSA 3YSA 3YSA All All All All All ABS dcep

1.2 - 1.6 mm

Essen

dcep dcep dcep dcep dcep

1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm

Essen Essen Essen Essen Essen

Oerlikon Schweisstechnik GmbH Carbofil 1 Carbofil 1 Carbofil 1a Carbofil 1a Cristal F116 ABS ABS ABS ABS ABS 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 CO-2 3YSA 3SA 3YSA 2YSA 3SA, 3YSA H5 3SA, 3Y400SA H5 F, V F, V All F, V All, V-down All, V-down dcep dcep dcep dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 0.8 - 1.6 mm 1.0 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Essen Essen Essen Essen Venice Venice

Cristal F119 ABS One side welding with ceramic backing Fluxinox 308-L

80% Ar, 20% ** F, V dcep 1.2 mm Essen CO-2 **For welding corrosion resisting Cr-Ni steels. Mfr. guaranteed chem & min mech. prop: C max .04; Mn 1.2-2; Si max 1.0; Cr 18-21, Ni 9.0-11.0, P max .030; S max .025, Y.P.min 350 N/mm2; T.S. 550-620 N/mm2, EL: 35%; CVN 35 J @ -20C. Fluxinox 316-L 82% Ar, 18% ** F, V dcep 1.2 mm Essen CO-2 **For welding corrosion resisting Cr-Ni steels. Mfr. guar. chem & min mech prop: C max .04; Mn 1.2-2.0; Si max 1; Cr 17.0-20.0; Ni 10.0-13.0; Mo 2.5-3; P max .03; S max .025; Y.P. min 380 N/mm2; T.S. 560-620 N/mm2; EL 30%, CVN 35 J @ -20 C Fluxofil 12 ABS One side welding with ceramic backing. Fluxofil 12 S ABS One side welding with ceramic backing. CO-2 3SA H5, 3YSA H5 All, V-down dcep 1.2 - 1.6 mm Venice

CO-2

3SA H5, 3YSA H5

All, V-down

dcep

1.2 - 1.6 mm

Venice

14/Feb/2005 Approved Welding Consumables

III - 15

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

GERMANY

Oerlikon Schweisstechnik GmbH Fluxofil 13 Fluxofil 14 Fluxofil 14 HD ABS ABS ABS CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 3YSA H5 3SA H5, 3YSA H5 3SA H5, 3Y400SA H5 All, V-down All, V-down All, V-down dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Venice Venice Venice

One side welding with ceramic backing Fluxofil 14 HD ABS CO-2 3SA H5, 3Y400SA H5 All, V-down dcep 1.2 - 1.6 mm Venice

One side welding with ceramic backing Fluxofil 14 HDS ABS 80% Ar, 20% CO-2 3SA H5, 3Y400SA H5 All, V-down dcep 1.2 - 1.6 mm Venice

One side welding with ceramic backing Fluxofil 14 HDS ABS CO-2 3SA H5, 3Y400SA H5 All, V-down dcep 1.2 - 1.6 mm Venice

One side welding with ceramic backing Fluxofil 14 S Fluxofil 19 HD Fluxofil 19 HDS Fluxofil 20 Fluxofil 20 Fluxofil 20 HD Fluxofil 20 HD Fluxofil 21 HD Fluxofil 30 Fluxofil 31 ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS 80% Ar, 20% CO-2 CO-2 CO-2 80% Ar, 20% CO-2 (FC) CO-2 80% Ar, 20% CO-2 CO-2 CO-2 CO-2 80% Ar, 20% CO-2 3SA H5, 3YSA H5 3SA H5, 3Y400SA H5 3SA H5, 3Y400SA H5 4YSA H5 4YSA H5 4YSA H5 4YSA H5 4YSA H5 3SA H5, 3YSA H5 3SA H5, 3YSA H5 All, V-down All, V-down All, V-down All All All All All F F dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6mm 1.2 - 1.6 mm Venice Venice Venice Venice

1.2, 1.4, 1.6 mm Venice 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.0 - 3.2 mm 1.2 - 3.2 mm Venice Venice Venice Venice Venice

One side welding with ceramic backing. Fluxofil 31 ABS One side welding with ceramic backing. Fluxofil 31 S ABS CO-2 3SA H5, 3YSA H5 F dcep 1.2 - 3.2 mm Venice

80% Ar, 20% CO-2

3SA H5, 3YSA, H5

dcep

1.2 - 3.2 mm

Venice

One side welding with ceramic backing. Fluxofil 31 S ABS One side welding with ceramic backing. CO-2 3SA H5, 3YSA H5 F dcep 1.2 - 3.2 mm Venice

Fluxofil 42 ABS CO-2 3YQ690SA** F dcep 1.2 - 2.4 mm **Approved for welding higher strength steel NAXTRA 70. Manufacturer's guaranteed min.: YS: 690 N/mm2 TS: 780 N/mm2

Venice

14/Feb/2005 Approved Welding Consumables

III - 16

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

GERMANY

Oerlikon Schweisstechnik GmbH Fluxofil M10 Fluxofil M10 PG ABS ABS 80% Ar, 20% CO-2 80% Ar, 20% CO-2 4SA H5, 4YSA H5 4SA H5, 4YSA H5 All, V-down All, V-down dcep dcep 1.0 - 1.6 mm 1.0 - 1.6 mm Venice Venice

ThyssenKrupp-VDM GmbH Cunifer S7030 Nickel S9604 Nicorros S6530 Nicrofer S5716 Nicrofer S5923 Nicrofer S6020 Nicrofer S7020 AWS A5.7-84R AWS A5.14-97 AWS A5.14-97 AWS A5.14-97 AWS A5.14-97 AWS A5.14-97 AWS A5.14-97 ERCuNi ERNi-1 ERNiCu-7 ERNiCrMo-4 ERNiCrMo-13 ERNiCrMo-3 ERNiCr-3 0.8 - 4.0 mm 0.8 - 4.0 mm 0.8 - 4.0 mm 1.0 - 3.2 mm 0.8 - 3.0 mm 1.0 - 3.2 mm 0.8 - 4.0 mm Essen Essen Essen Essen Essen Essen Essen

UTP-Schweissmaterial GmbH & Co. UTP A 068 HH UTP A 6222 Mo UTP A 80 M UTP A 80 Ni AWS A5.14-97 AWS A5.14-97 AWS A5.14-97 AWS A5.14-97 ERNiCr-3 ERNiCrMo-3 ERNiCu-7 ERNi-1 0.8 - 4.0 mm 1.0 - 3.2 mm 0.8 - 4.0 mm 0.8 - 4.0 mm Essen Essen Essen Essen

Westfalische Drahtindustrie GmbH Hoesch Weko 2 Hoesch Weko 2 Hoesch Weko 2 Hoesch Weko 2 Hoesch Weko 4 Hoesch Weko 4 Hoesch Weko 4 Hoesch Weko 4 VDG 15/60 VDG 15/60 ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS 82% Ar, 18% CO-2 3SA, 3YSA All, V-down All, V-down All, V-down All, V-down All All All, V-down All All, V-down All, V-down dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm Essen Essen Essen Essen Essen Essen Essen Essen Essen Essen

88% Ar, 12% O-2 3SA, 3SYA 90% Ar, 5% O-2, 3SA, 3YSA 5% CO-2 CO-2 82% Ar, 18% CO-2 3SA, 3YSA 3SA, 3YSA

88% Ar, 12% O-2 3SA, 2YSA 90% Ar, 5% O-2, 3SA, 3YSA 5% CO-2 CO-2 82% Ar, 18% CO-2 3SA, 3YSA 3SA, 3YSA

88% Ar, 12% O-2 3SA, 3YSA

14/Feb/2005 Approved Welding Consumables

III - 17

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

GERMANY

Westfalische Drahtindustrie GmbH VDG 15/60 VDG 15/60 VDG 16/60 VDG 16/60 VDG 16/60 VDG 16/60 ABS ABS ABS ABS ABS ABS 90% Ar, 5% O-2, 3SA, 3YSA 5% CO-2 CO-2 82% Ar, 18% CO-2 3SA, 3YSA 3SA, 3YSA All, V-down All, V-down All All All, V-down All dcep dcep dcep dcep dcep dcep 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm Essen Essen Essen Essen Essen Essen

88% Ar, 12% O-2 3SA, 2YSA 90% Ar, 5% O-2, 3SA, 3YSA 5% CO-2 CO-2 3SA, 3YSA

INDIA

Ador Welding Ltd. (Ahmednagar) AutoMig FC-12 ABS CO-2 3YSA H5 All dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm Mumbai Mumbai

AutoMig FC-31 ABS CO-2 3YSA* F, H * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. AutoMig-1 ABS CO-2 2YSA H, V

dcep

0.8 - 1.6 mm

Mumbai

Ador Welding Ltd. (Bhandup) AutoMig-1 AutoMig-1 ABS ABS CO-2 CO-2 3YSA 3YSA All All dcep dcep 0.8 - 1.6 mm 0.8 - 2.0 mm Mumbai Madras

Esab India Ltd. (Chennai) Esab MW1 ABS CO-2 2SA All ac / dc 0.8 - 1.6 mm Chennai

Mailam India Ltd. MGA 12 MGA 31 ABS ABS CO-2 CO-2 3YSA H5 3YSA H5 All All dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm Chennai Chennai

ITALY

BTF S.R.L. Fileur PMC Fileur PR5 Fileur PRS ABS ABS ABS 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 4YSA H5 3SA, 3YSA H5 3SA, 3YSA H5 F, H, V, V-Down All, V-down All, V-down dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Venice Venice Venice

14/Feb/2005 Approved Welding Consumables

III - 18

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

ITALY

CIFE s.r.l. CF 14/16 S3 CF 14/16 S6 CF 14/16 S6 CF 14/16 S6 - Ultramig AWS A5.18-01 ABS ABS AWS A5.18-01 CO-2 75% Ar, 25% CO-2 CO-2 CO-2 ER70S-3 3YSA 3YSA ER70S-6 F F F F dcep dcep dcep dcep 0.8 - 1.2 mm 0.8 - 1.2 mm 0.8 - 1.2 mm 0.8 - 1.2 mm Viareggio Viareggio Viareggio Viareggio

CIFE s.r.l. (World Wire) CF 14/16 S6 CF 14/16 S6 ABS ABS 75% Ar, 25% CO-2 CO-2 3YSA 3YSA F F dcep dcep 0.8 - 1.2 mm 0.8 - 1.2 mm Viareggio Viareggio

ETC Elettrotermochimica SpA Cristal F116 ABS 80% Ar, 20% CO-2 3SA, 3Y400SA H5 All, V-down dcep 1.2 - 1.6 mm Venice

One side welding with ceramic backing Cristal F119 ABS One side welding with ceramic backing ETC 6103 ETC 6105 ETC 6111 ETC 6111 ETC 6112 ETC 6114 ETC 6114E ABS ABS ABS ABS ABS ABS ABS CO-2 3SA, 3Y400SA H5 All, V-down dcep 1.2 - 1.6 mm Venice

80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 CO-2 CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2

4YSA H5 4YSA H5 3YSA H5 3YSA H5 3SA, 3YSA H5 3SA, 3YSA H5 3SA, 3Y400SA H5

All, V-down All, V-down All All F, V, V-down All, V-down All, V-down

dcep dcep dcep dcep dcep dcep dcep

1.0 - 1.6 mm 1.0 - 1.6 mm 1.0 - 1.6 mm 1.0 - 1.6 mm 1.0 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm

Venice Venice Venice Venice Venice Venice Venice

One side welding with ceramic backing ETC 6114E ABS One side welding with ceramic backing ETC 6119 ABS One side welding with ceramic backing ETC 6123 ETC 6130 ABS ABS CO-2 3SA, 3Y400SA H5 All, V-down dcep 1.2 - 1.6 mm Venice

CO-2

3SA, 3Y400SA H5

All, V-down

dcep

1.2 - 1.6 mm

Venice

CO-2 80% Ar, 20% CO2

4YSA H5 3SA, 3YSA H5

All F

dcep dcep

1.2 - 1.6 mm 1.0 - 3.2 mm

Venice Venice

One side welding with ceramic backing ETC 6130 ABS One side welding with ceramic backing CO-2 3SA, 3YSA H5 F dcep 1.0 - 3.2 mm Venice

14/Feb/2005 Approved Welding Consumables

III - 19

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

ITALY

ETC Elettrotermochimica SpA ETC 6131 ABS 80% Ar, 20% CO-2 4YSA H5 F, V, V-down dc 1.2 - 1.6 mm Venice

ETC 6132 ABS CO-2 3YQ690SA** F dcep 1.2 - 1.6 mm Venice **Approved specifically for welding higher strength steel Naxtra 70. Manufacturer's guaranteed min.: YS 690 N/mm2; TS 780N/mm2 ETC 6133 ABS CO-2 3YQ690SA** F dcep 1.2 - 1.6 mm Venice **Approved specifically for welding higher strength steel Naxtra 70. Manufacturer's guaranteed min.: YS 690 N/mm2; TS 780N/mm2

Fidat S.R.L. AlMg4.5Mn AWS All ** ER5183 A5.10-99 **Shielding gas per manufacturer's recommendation or user's procedure qualification AWS All ** ER5356 A5.10-99 **Shielding gas per manufacturer's recommendation or user's procedure qualification AWS All ** ER4043 A5.10-99 **Shielding gas per manufacturer's recommendation or user's procedure qualification AlSi5 AlMg5 dcep 0.8 - 1.6 mm Genoa

dcep

0.8 - 1.6 mm

Genoa

dcep

0.8 - 1.6 mm

Genoa

FRO SRL Alufil 5 Mg IACS UR ** ER5356 All dcep 0.8 - 1.6 mm Milan W26 **Manufacturer's minimum guaranteed values: T.S.: 240 N/mm2 - Y.S.: 110 N/mm2 - EL (5D): 16%. Shielding gas per manufacturer's recommendation or user's procedure qualification Filcord C Filcord C Filcord D Fluxofil M10 Fluxofil M10 PG Fluxofil 11 HD ABS ABS ABS ABS ABS ABS 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% C0-2 3YSA 3YSA 4YSA 4YSA H5 4YSA H5 3SA, 3Y400SA H5 All, V-down All, V-down All, V-down All, V-down All, V-down All, V-down dcep dcep dcep dcep dc / dcep dcep 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 1.0 - 1.6 mm 1.0 - 1.6 mm 1.2 - 1.6 mm Milan Milan Milan Venice Venice Venice

One side welding with ceramic backing Fluxofil 11 HD ABS One side welding with ceramic backing Fluxofil 12 ABS One side welding with ceramic backing Fluxofil 13 Fluxofil 131 Fluxofil 14 ABS ABS ABS CO-2 3SA, 3Y400SA H5 All, V-down dcep 1.2 - 1.6 mm Venice

CO-2

3SA, 3YSA H5

All, V-down

dcep

1.2, 1.4, 1.6 mm Venice

CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2

3YSA H5 4YSA H5 3SA, 3YSA H5

All, V-down F, V, V-down All, V-down

dcep dc dcep

1.2 mm 1.2 - 1.6 mm 1.2 - 1.6 mm

Venice Venice Venice

14/Feb/2005 Approved Welding Consumables

III - 20

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

ITALY

FRO SRL Fluxofil 14 HD ABS 80% Ar, 20% CO-2 3SA, 3Y400SA H5 All, V-down dcep 1.2 - 1.6 mm Venice

One side welding with ceramic backing Fluxofil 14 HD ABS One side welding with ceramic backing Fluxofil 19 HD ABS One side welding with ceramic backing Fluxofil 20 Fluxofil 20 Fluxofil 20 HD Fluxofil 21 HD Fluxofil 21 HD Fluxofil 30 Fluxofil 31 ABS ABS ABS ABS ABS ABS ABS CO-2 3SA, 3Y400SA H5 All, V-down dcep 1.2 - 1.6 mm Venice

CO-2

3SA, 3Y400SA H5

All, V-down

dcep

1.2 - 1.6 mm

Venice

80% Ar, 20% CO-2 CO-2 80% Ar, 20 % CO-2 CO2 CO-2 CO-2 80% Ar, 20% CO-2

4YSA H5 4YSA H5 4YSA H5 4YSA H5 4YSA H5 3SA H5, 3YSA H5 3SA, 3YSA H5

All All All ALL All F F

dcep dcep dcep dcep dcep dcep dcep

1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 1.2 - 1.6 mm 1.0 - 3.2 mm 1.2 - 3.2 mm

Venice Venice Venice Venice Venice Venice Venice

One side welding with ceramic backing Fluxofil 31 ABS One side welding with ceramic backing CO-2 3SA, 3YSA H5 F dcep 1.2 - 3.2 mm Venice

Fluxofil 42 ABS CO-2 3YQ690SA** F dcep 1.2 - 1.6 mm Venice **Approved specifically for welding higher strength steel Naxtra 70. Manufacturer's guaranteed min.: YS 690 N/mm2; TS 780N/mm2 Fluxofilcord 116 Fluxofilcord 16 Fluxofilcord 16 Fluxofilcord 16 F Fluxofilcord 31 ABS ABS ABS ABS ABS CO-2 80% Ar, 20% CO-2 CO-2 CO-2 80% Ar, 20% CO2 3SA, 3YSA H5 3YSA H5 3YSA H5 4YSA H5 3SA, 3YSA H5 F, V, V-down All All All F dcep dcep dcep dcep dcep 1.0 - 1.6 mm 1 - 1.6 mm 1 - 1.6 mm 1.2 - 1.6 mm 1.0 - 3.2 mm Venice Venice Venice Venice Venice

One side welding with ceramic backing Fluxofilcord 31 ABS One side welding with ceramic backing Steelcore R 1400 ABS CO-2 3SA, 3YSA H5 F dcep 1.0 - 3.2 mm Venice

80% Ar, 20% CO-2

3SA, 3Y400SA H5

All, V-down

dcep

1.2 - 1.6 mm

Venice

One side welding with ceramic backing Steelcore R 1400 ABS One side welding with ceramic backing Steelcore R 1900 ABS CO-2 3SA, 3Y400SA H5 All, V-down dcep 1.2 - 1.6 mm Venice

CO-2

3SA, 3Y400SA H5

All, V-down

dcep

1.2 - 1.6 mm

Venice

14/Feb/2005 Approved Welding Consumables

III - 21

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

ITALY

INE-Industria Nazionale Elettrodi S.p.A. INEfil INEfil INEfil N.R. INEfil N.R. INEtub B71 T5 INEtub M71 TG INEtub R71 T1 INEtub R71 T1 CO2 ABS ABS ABS ABS ABS ABS ABS ABS 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 CO-2 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA H5, 3YSA H5 3SA, 3YSA 3SA H5, 3YSA H5 3SA H5, 3YSA H5 All All All All F, V, H F, V, H F, V, H F, V, H dc dc dc dc dcep dcep dcep dcep 8.0 - 1.6 mm 8.0 - 1.6 mm 8.0 - 1.6 mm 8.0 - 1.6 mm 1.0 - 1.6 mm 0.9 - 1.6 mm 1.0 - 1.6 mm 0.9 - 1.6 mm Venice Venice Venice Venice Venice Venice Venice Venice

ISAF S.p.A. IS 10 IS 10 IS 10 S ABS ABS ABS 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 3YSA 3YSA 4YSA All, V-down All, V-down All, V-down dcep dcep dcep 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.2 mm Milan Milan Milan

La Fili s.r.l. LA/S6N ABS CO-2 3SA F dcep 0.8 - 1.2 mm Milan

Metalli Trafilati-Laminati s.r.l. MTL 5183 AWS All dc 1.2 - 1.6 mm Milan ** ER5183 A5.10-99 **Manufacturer's minimum guaranteed values: T.S.: 275 N/mm2 - Y.S.: 125 N/mm2 - EL (5D): 17%. Shielding gas per manufacturer's recommendation or user's procedure qualification MTL 5356 AWS ** ER5356 F, V dc 1.2 - 1.6 mm Milan A5.10-99 **Manufacturer's minimum guaranteed values: T.S.: 240 N/mm2 - Y.S.: 110 N/mm2 - EL (5D): 16%. Shielding gas per manufacturer's recommendation or user's procedure qualification

Novofil S.R.L. Novofil 70 ABS 80% Ar, 20% CO-2 3SA, 3YSA All dcep 0.8 - 1.2 Naples

Safra, SpA AL.MG 4.5 Mn AWS All dcep 0.8 - 1.6 mm Milan ** ER5183 A5.10-99 **Manufacturer's minimum guaranteed values: T.S.: 275 N/mm2 - Y.S.: 125 N/mm2 - EL (5D): 17%. Shielding gas per manufacturer's recommendation or user's procedure qualification

14/Feb/2005 Approved Welding Consumables

III - 22

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

ITALY

Safra, SpA AL.MG 5 AWS All dcep 0.8 - 1.6 mm Milan ** ER5356 A5.10-99 **Manufacturer's minimum guaranteed values: T.S.: 240 N/mm2 - Y.S.: 110 N/mm2 - EL (5D): 16%. Shielding gas per manufacturer's recommendation or user's procedure qualification

SIAT S.p.A. Sezione Pittarc Pittarc G 6 Pittarc G 6 Pittarc G 9 Pittarc G 9 ABS ABS ABS ABS Atal CO-2 Atal CO-2 3SA, 3YSA 3SA, 3YSA 3YSA 3YSA All All All dcep dcep dcep 0.8 - 1.6 mm 1.0 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm Venice Venice Venice Venice

F, H, V, V-down dcep

Sidergas S.r.l. Sidergas S6 ABS CO-2 3YSA All dcep 0.6 - 1.6 mm Venice

Trafilerie di Cittadella Filuer S.p.a. Fileur AB Fileur AB Fileur AMC 01 Fileur AMC 01 Fileur ARS Fileur ARS 10 Fileur ARS 10 Fileur ARS 5 Fileur G2 Fileur G2 Fileur G3 Fileur G3 Fileur GPM Fileur PR5 ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 CO-2 CO-2 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 CO-2 4YSA H5 4YSA H5 4YSA H5 4YSA H5 3SA, 3YSA H5 4YSA H5 4YSA H5 3SA, 3YSA H5 3SA, 3YSA 3SA, 3YSA 3YSA 3YSA 3SA, 3YSA H5 3SA, 3YSA H5 F F F, V, H F, V, H All, V-Down F, H, V, V-Down dcep dcep dcep dcep dcep dcep 1.2 - 2.0 mm 1.2 - 2.0 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 1.0 - 1.6 mm 1.2 - 1.6 mm Venice Venice Venice Venice Venice Venice Venice Venice Venice Venice Venice Venice Venice Venice

F, H, V, V-down dcep All, V-Down All, V-Down All, V-Down All All All All, V-down dcep dcep dcep dcep dcep dcep dcep

14/Feb/2005 Approved Welding Consumables

III - 23

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

JAPAN

JFE Steel Corporation FG-50P ABS CO-2 (FC) 2YSA* F, HF * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. FG-50S FG-50S FS-50S KC-45 KC-50 KC-50 KC-50T KC-50T KM-50 KM-50 KM-50 KM-50T KM-60 KM-60 ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS AWS A5.28-96 AWS A5.28-96 CO-2 (FC) CO-2 (FC) CO-2 (FC) CO-2 CO-2 CO-2 CO-2 CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 2SA, 2YSA 2SA, 2YSA 2SA, 2YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA ER90S-G ER90S-G All, V-down F F All F, H, V-down F, H F, H All, V-down F, H, V-down F, H All, V-down All All F, V, H dcep 1.2, 1.4 mm Kobe

dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep

1.2 - 1.4 mm 1.6 mm 1.6 mm 0.8 - 1.6 mm 1.2 - 1.4 mm 1.6 mm 1.6 mm 0.9 - 1.4 mm 1.4 mm 1.6 mm 0.9 - 1.2 mm 0.8 - 1.4 mm 1.2 mm 1.6 mm

Kobe Kobe Kobe Kobe Kobe Kobe Kobe Kobe Kobe Kobe Kobe Kobe Kobe Kobe

Kobe Steel Ltd., Fujisawa Branch DW-308 CO-2 ** F, V, H dcep 1.2 - 1.6 mm **Manufacturer's guaranteed minimum properties and chemical composition equivalent to AWS A5.22 E308T0-1. Yokohama

DW-308L CO-2 (FC) ** F, V dcep 1.2 - 1.6 mm Yokohama **Manufacturer's guaranteed minimum properties:T.S. 53 kg/mm2, El. 35%, CVN 3 kg-m at -196C. Chem: max. C 0.04, Mn 1.0-2.5, max. Si 1.0, max. P 0.04, max. S 0.03, Ni. 9.0-11.0, Cr 18.0-21.0%. DW-308LP CO-2 (FC) ** All **Manufacturer's guaranteed physical properties: Equivalent to AWS A5.22 E308LT1-1 dcep 1.2 mm Yokohama

DW-309L CO-2 (FC) ** F, V dcep 1.2 - 1.6 mm Yokohama **Manufacturer's guaranteed minimum properties:T.S. 53 kg/mm2, El. 30%, Chem: C 0.04, Mn 1.0-2.5, max. Si 1.0, max. P 0.04, max. S 0.03, Ni. 12.0-14.0, Cr 22.0-25.0%. DW-309MoL CO-2 (FC) ** F, V dcep 1.2 - 1.6 mm Yokohama **Manufacturer's guaranteed minimum T.S. 53 kg/sq mm, El. 20%, Chem.: C 0.04, Mn 1.0-2.5, max. Si 1.0, max. P 0.04, max. S 0.03, Ni 12.0-14.0, Cr 22.0-25.0, Mo 2.0-3.0% DW-316L CO-2 (FC) ** F, V dcep 1.2 - 1.6 mm Yokohama **Manufacturer's guaranteed minimum T.S. 50 kg/sq mm, El. 30%, Chem.: C 0.04, Mn 1.0-2.5, max. Si 1.0, max. P 0.04, max. S 0.03, Ni 11.0-14.0, Cr 17.0-20.0, Mo 2.0-3.0%

14/Feb/2005 Approved Welding Consumables

III - 24

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

JAPAN

Kobe Steel Ltd., Fujisawa Branch DW-316LT CO-2 (FC) ** All **Manufacturer's guaranteed physical properties: (min. T.S. 485 N/mm2, EL. 30%) dcep 1.2 mm Yokohama

DWS-1LG ABS CO-2 (FC) 3A, 3YA** V dcep 1.6 mm Yokohama **Mfr's guaranteed min. CVN 2.8 kg-m at -60C. Suitable for EGW of 20 mm plates with root opening 5 mm & 40 included angle and 30 mm plates at 5mm/30. DWS-43G ABS CO-2 (FC) 3A, 3YA** V **Suitable for electrogas welding when Nb content in steel does not exceed 0.03%. dcep 1.6 mm Yokohama

DWS-50GTF / ABS CO-2 (FC) 4Y400 V dcep / 1.6 mm Yokohama DWS-50GTR / KL-4** dcen **Mfr's guaranteed min. properties: Y.S. 400 N/mm2, T.S. 510-690 N/mm2, EL. 22%, Chem.: C 0.06, Mn 1.60, Si 0.20, P 0.013, S 0.008, Ni 1.3, Cr, Mo 0.15%. DWS-50GTR** dcep / 1.6 mm Yokohama dcen **Use with Kobe DWS-50GTF wire & KL-4 flux. Mfr's guar. min. properties: YS 400 N/mm2, TS 510-690 N/mm2, EL. 22%, Chem.: C 0.06, Mn 1.60, Si 0.20, P 0.013, S 0.008, Ni 1.3, Cr, Mo 0.15%. Frontiarc-711 ABS CO-2 (FC) 3SA, 3YSA All, V-down dcep ac / dcep .045 - 1/16" 2.4 - 3.2 mm Yokohama Yokohama ABS CO-2 (FC) 4Y400 V

HS-42G ABS CO-2 (FC) 3A, 3YA** V **Suitable for electrogas welding when Nb content in steel does not exceed 0.03%. TGS-308 AWS Ar ER308** All A5.9-93 **Manufacturer's guaranteed min. properties T.S. 80,000 psi, El. 35%, CVN 20 ft-lbs at 0F. TGS-308L

dcen

1.2 - 2.4 mm

Yokohama

AWS Ar ER308L** dcen 1.2 - 3.2 mm Yokohama A5.9-93 **Approved for all position welding. Manufacturer's guaranteed min. properties: Y.S. 21 kgf/mm2, T.S. 52 kgf/mm2, El. 35%,CVN 3.0 kgf-m at -196C. TGS-316L AWS A5.9-93 Ar ER316L dcen 1.2 - 3.2 mm Yokohama

Kobe Steel Ltd., Fukuchiyama Plant JC-45 JM-50T KOBE A5183-BY KOBE A5183-WY MG-50 MG-50 MG-50 MG-50D MG-50D ABS ABS CO-2 80% Ar, 20% CO-2 3SA, 3YSA 3SA, 3YSA All All, V-down All All 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA F, H F, H, V-down F, H All, V-down F dcep dcep ac dcep dcep dcep dcep dcep dcep 0.8 - 1.6 mm 0.8 - 1.4 mm 1.6 - 5.0 mm 1.2 - 4.8 mm 1.2 - 1.6 mm 1.2 - 1.4 mm 1.6 mm 1.2 - 1.4 mm 1.6 mm Kobe Kobe Kobe Kobe Kobe Kobe Kobe Kobe Kobe

JIS Ar Z3232-2000 JIS Ar or Ar-He mix Z3232-2000 ABS ABS ABS ABS ABS 85% Ar, 15% CO-2 CO-2 CO-2 CO-2 CO-2

14/Feb/2005 Approved Welding Consumables

III - 25

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

JAPAN

Kobe Steel Ltd., Fukuchiyama Plant MG-50D / Metal Grits ABS CO-2 2YA^ F ^ Suitable for one-side welding and subject to satisfactory procedure tests at user's plant. MG-50T MG-50T MG-50T ABS ABS ABS 85% Ar, 15% CO-2 CO-2 CO-2 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA All All, V-down F, H dcep 1.6 mm Kobe

dcep dcep dcep

0.9 - 1.2 mm 0.9 - 1.4 mm 1.6 mm 1.2 - 1.6 mm

Kobe Kobe Kobe Kobe

MG-50T / Metal Powder ABS 80% Ar + 20% 3YSA^ F dcep RR-2 CO-2 ^ Suitable for semiautomatic one-side welding subject to satisfactory procedure tests at user's plant. MGS-1CM

AWS All dcep 0.8 - 1.6 mm 80% Ar + 20% ER80S-G A5.28-96 CO2 **Manufacturer's guaranteed propertes: min. propertes: T.S. 550 MPa, Y.S. 470 MPa, EL. 19%, PWHT: 620 15 C X 1 hr. MGS-50LT 80% Ar, 20% CO-2 **Mfr's guaranteed min. CVN 3.5 KGf-m (34J) at -60 C. MGS-80 ABS 3YSA F, H, V dcep 1.2 mm

Kobe

Kobe

AWS All dcep 1.2 - 1.6 mm Kobe 80% Ar, 20% ER110S-G** A5.28-96 CO-2 **Mfr's guaranteed properties: Y.S. 100 ksi (690 MPa), T.S. 114 ksi (785 MPa), El. 14%, CVN 26 ft-lbs (35 J) at -40 C, and wire composition: C 0.12 max., Mn 1.1-16, Si 0.3-0.6, S 0.03 max., P 0.03 max., Ni 2.4-3.0, Mo 0.3-07, Cr 0.1-0.4. MIX-50 MIX-50 MIX-50S MIX-50S MIX-50S SE-50T ABS ABS ABS ABS ABS ABS 80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 CO-2 3SA, 3YSA 3SA, 3YSA 3SA, 3SYA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA All F, H F, H, V-down All, V-down F, H All, V-down dcep dcep dcep dcep dcep dcep 0.9 - 1.2 mm 1.4 - 1.6 mm 1.4 mm 0.9 - 1.2 mm 1.6 mm 0.9 - 1.2 mm Kobe Kobe Kobe Kobe Kobe Kobe

TGS-1CM Ar ** All dcen 0.8 - 3.2 mm Kobe **TIG welding of 1.25 Cr/0.50 Mo steels: Properties under stress-relieved conditions: min. T.S. 53 kgf/mm2 (520 N/mm2) , Y.P. 32 kgf/mm2 (315 N/mm2), El. 22%. TGS-1N ABS Ar **Mfr's guaranteed CVN properties: min. 47 Joule at -60C 4Y** All dcen 1.6 - 2.4 mm Kobe

Ar ** All dcen 0.8 - 3.2 mm Kobe TGS-2CM **TIG Welding of 2.25 Cr/1.0 Mo steel: Properties under stress-relieved conditions: min. T.S. 53KGf/mm2 (520N/mm2) Y.P. 32 KGf/mm2 (315 N/mm2), EL. 18% TGS-50 **GTA welding only ABS Ar 3**, 3Y** All dcen 1.6 - 3.2 mm Kobe

Kobe Steel Ltd., Ibaraki Plant DW-100 ABS CO-2 (FC) 2SA, 2Y400SA H10 All, V-down dcep 1.0- 1.6 mm Kobe

14/Feb/2005 Approved Welding Consumables

III - 26

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

JAPAN

Kobe Steel Ltd., Ibaraki Plant DW-100E ABS CO-2 (FC) 3SA, 3Y400SA H10 All, V-down dcep dcep 1.2 - 1.6 mm 1.2- 1.4 mm Kobe Kobe

DW-100N ABS CO-2 (FC) 2SA, 2YSA* All, V-down * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. DW-100V DW-200 DW-50 DW-55E ABS ABS ABS ABS CO-2 (FC) CO-2 (FC) CO-2 (FC) CO-2 (FC) 2SA, 2YSA 3SA, 3YSA 3SA, 3YSA H5 3SA, 3Y400SA H5 All, V-down F All, V-down All, V-down

dcep dcep dcep dcep dcep

1.2 - 1.4 mm 1.2 - 1.4 mm 1.1 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.4 mm

Kobe Kobe Kobe Kobe Kobe

DW-55L ABS CO-2 (FC) 3SA, 4Y400SA H5** All, V-down **Mfr's guaranteed min. properties: CVN 54 J at -20 C and 34 J at -60 C DW-55LSR ABS 80% Ar + 20% CO-2(FC) 5YQ420SA H5 All, V-down

dcep

1.2 mm 1.2 - 1.6 mm

Kobe Kobe

DW-60 ABS CO-2 (FC) ** All, V-down dcep **Mfr's guaranteed minimum properties: T.S. 590-740 N/mm2, Y.P. 490 N/mm2, El. 20%, CVN 47 J at -30 C. DWA-50 DWA-55E DWA-55ESR DWA-55L ABS ABS ABS ABS 80% Ar, 20% CO-2 (FC) 80% Ar, 20% CO-2 (FC) 80% Ar, 20% CO-2 (FC) 3SA, 3YSA H5 4Y400SA H5 4Y400SA H5 3SA, 3YSA** All, V-down All, V-down All, V-down All dcep dcep dcep dcep

1.2 - 1.6 mm 1.2 - 1.6 mm 1.1 mm (.045") 1.0 - 1.6 mm

Kobe Kobe Kobe Kobe

80% Ar, 20% CO2 (FC) **Mfr's guaranteed Min. properties: 34J at -60 C DWA-55LSR DWA-81Ni1 ABS ABS CO-2 (FC) 80% Ar, 20% CO-2 (FC)

5YQ420SA H5, 4Y400SA H5 5YQ420SA H5, 4Y400SA H5**

All, V-down F, H, V, HF

dcep dcep

1.2 - 1.4 mm 1.2 mm

Kobe Kobe

**Mfr's guaranteed Min. CVN 47J at -60 C DW-Z1 DW-Z100 Frontiarc-711 Frontiarc-711 MX-100 MX-100E MX-100T MX-200 ABS ABS ABS ABS ABS ABS ABS ABS CO-2 (FC) CO-2 (FC) 75% Ar, 25% CO-2 (FC) CO-2 (FC) CO-2 (FC) CO-2 (FC) CO-2 (FC) CO-2 (FC) 2SA, 2YSA H10 2SA, 2YSA 3SA, 3YSA 3SA, 3YSA 2SA, 2YSA 3SA, 3YSA 3SA, 3YSA H5 2SA, 2Y400SA H5 All, V-down All, V-down All, V-down All, V-down F F, H All F F, HF dcep dcep dcep dcep dcep dcep dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm .045 - 1/16" .045 - 1/16" 1.2 - 2.0 mm 1.2 - 2.0 mm 1.2 - 1.4 mm 1.2 - 1.6 mm 1.4 - 1.6 mm Kobe Kobe Kobe Kobe Kobe Kobe Kobe Kobe Kobe

MX-200H ABS CO-2 (FC) 3SA, 3YSA** **Suitable for use with semi-automatic single or automatic tandem welding.

14/Feb/2005 Approved Welding Consumables

III - 27

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

JAPAN

Kobe Steel Ltd., Ibaraki Plant MX-200HS (X2) MX-200S MX-55LF ABS ABS ABS CO-2 (FC) CO-2 (FC) CO-2 (FC) 3A H5, 3YA H5 2Y400 SA H5 3SA, 3YSA** H fillet F, HF Fillet only (F&H) dcep dcep dcep 1.6 mm 1.2 - 1.6 mm 1.2 - 1.4 mm Kobe Kobe Kobe

**Mfr's guaranteed minimum CVN 47 J at -60 C. MX-55LF (X2)** ABS CO-2 (FC) **Mfr's guaranteed min.: CVN 47 J at -60 C MX-Z200 MX-Z200K **Fillet welding only MX-Z200K MX-Z210 ABS ABS CO-2 (FC) CO-2 (FC) 3YA HF dcep 1.6 mm Kobe

2SA, 2YSA 2SA, 2YSA

F, HF V**

dcep dcep

1.2 - 1.6 mm 1.4 mm

Kobe Kobe

ABS ABS

CO-2 (FC) CO-2 (FC)

2SA, 2YSA 2SA, 2YSA H5

F F, H-Fillet

dcep dcep

1.4 mm 1.2 - 1.4 mm

Kobe Kobe

Matsushita Welding Systems Co., Ltd. YM-1F ABS CO-2 2SA, 2YSA* All, V-down * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. YM-50 YM-50T1 ABS ABS CO-2 CO-2 3SA, 3YSA 3SA, 3YSA F All dcep 1.2 - 1.6 mm Kobe

dcep dcep

1.2 - 2.0 mm 0.9 - 1.2 mm

Kobe Kobe

Nikko Yozai Manufacturing Co., Ltd. NF-50 NF-50T NX-50 NX-50T ABS ABS ABS ABS CO-2 CO-2 CO-2 CO-2 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA F, V All, V-down F, V All, V-down dcep dcep dcep dcep 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm 0.8 - 1.6 mm Kobe Kobe Kobe Kobe

Nippon Seisen Co., Ltd., Hirakata Plant NAS Y308 AWS Ar ER308 A5.9-93 Manufacturer's guaranteed minimum properties: T.S. 550 MPa, EL. 35%. NAS Y308L NAS Y308L NAS Y309 NAS Y309 AWS A5.9-93 AWS A5.9-93 AWS A5.9-93 AWS A5.9-93 Ar Ar + 2% O-2 Ar Ar + 2% O-2 ER308L ER308L ER309 ER309 All dcen 1.0 - 5.0 mm Kobe

All All All All

dcen dcep dcen dcep

1.0 - 5.0 mm (rod) 0.6 - 4.8 mm (wire) 1.0 - 5.0 mm (rod) 0.6 - 4.8 mm (wire)

Kobe Kobe Kobe Kobe

14/Feb/2005 Approved Welding Consumables

III - 28

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

JAPAN

Nippon Seisen Co., Ltd., Hirakata Plant NAS Y309Mo AWS A5.9-93 Ar ER309Mo All dcen 1.0 - 5.0 mm Kobe

Nippon Steel & Sumikin Welding Co., Ltd. #AS-1 #AS-1 ABS ABS CO-2 (FC) CO-2 (FC) 2SA, 2YSA 2SA, 2YSA 3SA, 3YSA** F, H, V, V-down All, V-down All, V-down dcep dcep dcep 1.6 mm 1.2 - 1.4 mm 1.2 mm Yokohama Yokohama Yokohama

#AS-2NL ABS CO-2 (FC) **Manufacturer's guaranteed min. CVN 4.8 kgf-m at -60 C. #AS-308L #AS-309L #AS-309MoL #AS-316L #AS-347 #AS-3E #AS-3E #PL-22 #SCO #SCO #SCR #SCR #SCT #SCT #SR-3 #SR-3 Nittetsu SF-1 Nittetsu SF-1 Nittetsu SF-1A Nittetsu SF-1A Nittetsu SF-1-EX AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS ABS CO-2 (FC) CO-2 (FC) CO-2 (FC) CO-2 (FC) CO-2 (FC) CO-2 (FC) CO-2 (FC) CO-2 (FC) CO-2 CO-2 80% Ar, 20% CO-2 80%Ar, 20% CO-2 CO-2 CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 CO-2 (FC) CO-2 (FC)

E308LT0-1 E309LT0-1 E309LMoT0-1 E316LT0-1 E347T0-1 3SA, 3YSA, 3Y400SA* 3SA, 3YSA, 3Y400SA* 2SA, 2YSA* 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 2SA, 2YSA* 2Y400SA* F, H, V, V-down dcep All, V-down F V F All, V-down F V F F F, V All, V-down All, V-down All All All, V-down dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep dcep

0.9 - 1.6 mm 0.9 - 1.6 mm 0.9 - 1.6 mm 0.9 - 1.6 mm 0.9 - 1.6 mm 1.6 mm 1.2 - 1.4 mm 1.2 - 1.6 mm 0.9 - 1.2 mm 0.9 - 1.6 mm 1.2 mm 1.6 mm 0.9 - 1.2 mm 0.9 - 2.0 mm 1.6 mm 0.9 - 1.2 mm 1.0 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.4 mm 1.2 mm 1.2 - 1.6 mm

Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Nagasaki Nagasaki Nagasaki Yokohama Nagasaki

70-80% Ar, CO-2 2SA, 2YSA* 80% Ar, 20% CO-2 (FC) CO-2 2SA, 2YSA* 2SA, 2YSA*

14/Feb/2005 Approved Welding Consumables

III - 29

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

JAPAN

Nippon Steel & Sumikin Welding Co., Ltd. Nittetsu SF-1F Nittetsu SF-3 ABS ABS CO-2 (FC) CO-2 (FC) 2SA, 2YSA* 3SA, 3YSA, 3Y400SA F All, V-down F, V dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 0.9 - 1.2 mm Yokohama Yokohama Nagasaki

Nittetsu SF-308L CO-2 Mfr's** **Mfr's guarantee: T.S. 510 N/mm2, Y.P. 245 N/mm2, El. 35%, CVN 34 J at -20C Nittetsu SF-308L CO-2 Mfr's** **Mfr's guarantee: T.S. 510 N/mm2, Y.P. 245 N/mm2, El. 35%, CVN 34 J at -20C

dcep

1.6 mm

Nagasaki

Nittetsu SF-309L CO-2 Mfr's** F **Mfr's guarantee: T.S. 510 N/mm2, Y.P. 245 N/mm2, El. 30%, CVN 34 J at -20 C. Nittetsu SF-309L CO-2 Mfr's** F, V **Mfr's guarantee: T.S. 510 N/mm2, Y.P. 245 N/mm2, El. 30%, CVN 34 J at -20C.

dcep

1.6 mm

Nagasaki

dcep

0.9 - 1.2 mm

Nagasaki

Nittetsu SF-309MoL ABS CO-2 Mfr's** F, HF, V dcep **Manufacturer's guaranteed min. properties: TS 510 N/mm2, YP 205 N/mm2, El 20%, CVN 27 J at -20C. Nittetsu SF-309MoL ABS CO-2 Mfr's** F, HF dcep **Manufacturer's guaranteed min. properties: TS 510 N/mm2, YP 205 N/mm2, El 20%, CVN 27 J at -20C. Nittetsu SF-316L ABS CO-2 Mfr's** F, HF dcep **Manufacturer's guaranteed min. properties: TS 510 N/mm2, YP 205 N/mm2, El 35%, CVN 27 J at -20C. Nittetsu SF-316L ABS CO-2 Mfr's** F, HF, V dcep **Manufacturer's guaranteed min. properties: TS 510 N/mm2, YP 205 N/mm2, El 35%, CVN 27 J at -20C. Nittetsu SF-329J3LP AWS CO-2 A5.22-95 **Manufacturer's guaranteed minimum CVN 27J at -20 C Nittetsu SF-36E ABS CO-2 (FC) **Manufacturer's guaranteed min. CVN 34 J at -60 C. ABS CO-2 (FC) Nittetsu SF-36F **Manufacturer's guaranteed min. CVN 34 J at -60 C. Nittetsu SF-3A Nittetsu SF-3Y Nittetsu SF-3Y Nittetsu SF-3Y Nittetsu SM-1 Nittetsu SM-1F Nittetsu SM-1F Nittetsu SM-1F-EX Nittetsu SM-1H ABS ABS ABS ABS ABS ABS ABS ABS ABS 80% Ar, 20% CO-2 (FC) 80%Ar, 20% CO-2 CO-2 CO-2 CO-2 (FC) CO-2 CO-2 (FC) CO-2 CO-2 (FC) E2209T1-1** All dcep

0.9 - 1.2 mm

Nagasaki

1.6 mm

Nagasaki

1.6 mm

Nagasaki

0.9 - 1.2 mm

Nagasaki

1.2 mm

Nagasaki

3SA, 3YSA**

All

dcep

1.2 - 1.4 mm

Yokohama

3SA, 3YSA**

dcep

1.2 - 1.4 mm

Yokohama

3A, 3YA 3Y400SA 3Y400SA 3Y400SA H10 2SA, 2YSA 2SA, 2YSA* 2SA, 2YSA* 2SA, 2YSA* 2SA, 2YSA*

All All All All F, H F, H F F H

dcep dcep dcep dcep dcep dcep dcep dcep dcep

1.2 mm 1.2 - 1.6 mm 1.2 - 1.4 mm 1.2 - 1.4 mm 1.4 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.4 mm

Yokohama Yokohama Yokohama Yokohama Yokohama Nagasaki Yokohama Nagasaki Yokohama

14/Feb/2005 Approved Welding Consumables

III - 30

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

JAPAN

Nippon Steel & Sumikin Welding Co., Ltd. Nittetsu SM-1S Nittetsu YM-25 Nittetsu YM-26 Nittetsu YM-28 Nittetsu YM-28 Nittetsu YM-28E Nittetsu YM-28S Nittetsu YM-28S Nittetsu YM-36E ABS ABS ABS ABS ABS ABS ABS ABS ABS CO-2 (FC) 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 80% Ar, 20% CO-2 2SA, 2YSA* 3A, 3YA 3SA, 3YSA 3A, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA** F F F, V All All All F, V, H V-down, Fillet F dcep dcep dcep dcep dcep dcep dcep dcep dcep 1.4 mm 1.2 mm 0.9 - 1.6 mm 1.2 mm 0.9 - 1.6 mm 1.0 - 1.6 mm 1.2 - 1.6 mm 1.2 mm 1.6 mm Yokohama Nagasaki Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama

80% Ar, 20% CO-2 **Manufacturer's guaranteed CVN 3.5 kgf-m at -60 C. Nittetsu YM-36E 80% Ar, 20% CO-2 **Manufacturer's guaranteed CVN 3.5 kgf-m at -60 C. Nittetsu YM-55A Nittetsu YM-55H Nittetsu YM-55H / Nittetsu YK-CM ABS ABS ABS 80% Ar, 20% CO-2 CO-2 CO-2 ABS

3SA, 3YSA**

All

dcep

1.2 mm

Yokohama

3SA, 3YSA 3SA, 3YSA 3SA, 3YSA

All F, V, H F

dcep dcep dcep

1.2 - 1.6 mm 1.2 - 1.6 mm 1.6 mm

Nagasaki Yokohama Yokohama

Nittetsu YM-55H/ Nittetsu ABS CO-2 3Y400A** V-up dcep / EG-3T / Nittetsu SB-60VT dcen **Suitable for tandem wire electrogas welding, thickness 60 mm. Root opening 8 mm with 20 included angle. Nittetsu YM-55H/ Nittetsu ABS CO-2 SF-1 / Nittetsu YK-CM / Nittetsu SB-41 ^Suitable for use with multi-arc tandem one-side welding Nittetsu YM-55RSA Nittetsu YM-60A ABS 80% Ar, 20% CO-2 2Y^ F dcep

1.6 mm, 1.6 mm Yokohama

1.6 mm, 1.6 mm Yokohama

2SA, 2YSA

F, V, H

dcep

1.2 mm

Yokohama Yokohama

80% Ar, 20% ** F dcep 0.8 - 1.6 mm CO-2 **Manufacturer's guaranteed min. properties: Y.P. 50 kgf/mm2, T.S. 60 kgf/mm2, El. 20% and CVN 4.8 kgf-m at -40 C. Nittetsu YM-80A 80% Ar, 20% ** F dcep 1.0 - 1.6 mm CO-2 **Manufacturer's guaranteed min. properties: Y.P. 70 kgf/mm2, T.S. 80-95 kgf/mm2, El. 16%, CVN 4.1 kgf-m at -60 C. Nittetsu YM-80C AWS CO-2 ER110S-G** F dcep 0.9 - 1.6 mm A5.28-96 **Manufacturer's guaranteed min. properties: Y.S. 98,000 psi, T.S. 110,000 psi, min El. 15%, CVN 20 ft-lb at 0F. x * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel.

Yokohama

Yokohama

14/Feb/2005 Approved Welding Consumables

III - 31

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

JAPAN

Nippon Welding Rod Co., Ltd. (Hamakita) WEL AutoTIG 347H WEL FCW 2RM2-K AWS A5.9-93 * Ar ER347 F dcen 1.0 - 1.6 mm Yokohama

80% Ar, 20% ** F dcep 0.9 - 1.6 mm Yokohama CO2 **Mfr. guar. dep. metal chem.: C .04 max., Si .2-.8, P .03 max., S .015 max., Ni 4.5-5.3, Cr 12-13, Mo .2-.6, Fe bal; Mech. prop. in PHT condition: UTS 98.4 kgf/mm2, YS 91.8 kgf/mm2, EL 12%, RA 45%, CVN avg. 2.8 kgf-m (singl 2 kgf-m) @0 C WEL FCW 308LT WEL FCW 309LT WEL FCW 309MoLT WEL FCW 316LT WEL MIG 309 WEL MIG 316L AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.9-93 CO-2 CO-2 CO-2 CO-2 98% Ar, 2% 0-2 E308LT1-1 E309LT1-1 E309LMoT1-1 E316LT1-1 ER309 F, H, V F, H, V F, H, V F, H, V F dcep dcep dcep dcep dcep 0.9 - 1.6 mm 0.9 - 1.6 mm 0.9 - 1.6 mm 0.9 - 1.6 mm 1.2 mm 1.2 - 1.6 mm Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama

AWS 98% Ar, 2% 0-2 ER316L** F dcep A5.9-93 **Manufacturer's guaranteed all-weld metal min mechanical properties: T.S. 490 N/mm2, Elongation 30% WEL MIG 82 WEL TIG 308L WEL TIG 316L AWS A5.14-97 AWS A5.9-93 Ar Ar ERNiCr-3 ER308L F All All dcen dcen dcen

1.0 - 1.6 mm 1.6 - 3.2 mm 1.2 - 4.0 mm

Yokohama Yokohama Yokohama

AWS Ar ER316L** A5.9-93 **Manufacturer's guaranteed min. properties: T.S. 490 N/mm2, Elongation 30%.

Sumitomo Electric Toyama Co., Ltd. A5183-BY A5183-WY A5556-BY A5556-WY JIS Ar Z3232-2000 JIS Ar or Ar-He mix Z3232-2000 JIS Ar Z3232-2000 JIS Ar or Ar-He mix Z3232-2000 A5183-BY A5183-WY A5556-BY A5556-WY All All All All ac dcep ac dcep 1.6 - 6.0 mm 0.6 - 6.4 mm 1.6 - 6.0 mm 0.6 - 6.4 mm Kobe Kobe Kobe Kobe

Taseto Co., Ltd. GFW 308L GFW 309 GFW 309L GFW 309MoL GFW 316L GFW 317L AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 CO-2 CO-2 CO-2 CO-2 CO-2 CO-2 E308LT0-1 E309T0-1 E309LT0-1 E309LMoT0-1 E316LT0-1 E317LT0-1 F, V F, H F, H F, H F, H F, H dcep dcep dcep dcep dcep dcep 1.2 - 2.0 mm 1.2 - 2.0 mm 1.2 - 2.0 mm 1.2 - 2.0 mm 1.2 - 2.0 mm 1.2 - 2.0 mm Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama

14/Feb/2005 Approved Welding Consumables

III - 32

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

JAPAN

Taseto Co., Ltd. MG 308L MG 309 MG 316L TG 308L TG 309 TG 316L TG910 AWS A5.9-93 AWS A5 9-93 AWS A5.9-93 AWS A5.9-93 AWS A5.9-93 AWS A5.9-93 98% Ar + 2% O2 ER308L 98% Ar + 2% O2 ER309 98% Ar + 2% O2 ER316L Ar Ar Ar ER308L ER309 ER316L All All All All All All dcep dcep dcep dcen dcen dcen dcen 0.8 - 3.2 mm 0.8 - 3.2 mm 0.8 - 3.2 mm 0.8 - 3.2 mm 0.8 - 3.2 mm 0.8 - 3.2 mm 0.8 - 3.2 mm Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama Yokohama

JIS Ar YCuNi-1** All Z3341-1999 **TIG Welding Rod, Manufacturer's guaranteed minimum properties: TS: 28 kgf/mm2, El. 25%

Tokuden Co. Ltd. CPW-1 CO-2 (FC) ** F dcep 1.2 - 1.6 mm Kobe **Mfr's guaranteed all weld metal properties (as welded): T.S. 635-785 N/mm2, Y.S. 490 N/mm2, EL. 16% min, CVN 29 J at 0 C & C 0.15% max, Si 1.0% max, Mn 0.5-1.5%, P 0.04% max, S 0.03% max, Cr 0.5-1.5% MT-308LF MT-309LF MT-309MoLF MT-316LF MT-317LF AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 CO-2 CO-2 CO-2 CO-2 CO-2 E308LT0-1 E309LT0-1 E309LMoT0-1 E316LT0-1 E317LT0-1 F F F F F dcep dcep dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Kobe Kobe Kobe Kobe Kobe

KOREA

Chosun Steel Wire Company (Pohang Plant) MC-50 MC-50T TGC-50 TGC-50S ABS ABS ABS ABS CO-2 CO-2 Ar Ar 3SA, 3YSA 3SA, 3YSA 3SA, 3YSA 3YSA All All, V-down All All dcep dcep dcen dcen 1.2 - 1.6 mm 0.9 - 1.2 mm 1.6 - 3.2 mm 1.2 - 3.2 mm Ulsan Ulsan Ulsan Ulsan

Chosun Steel Wire Company (Ulsan Plant) CSF-308L CSF-309L CSF-316L AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 CO-2 CO-2 CO-2 E308LT0-1 E309LT0-1 E316LT0-1 F F F dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Ulsan Ulsan Ulsan

14/Feb/2005 Approved Welding Consumables

III - 33

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

KOREA

Chosun Steel Wire Company (Ulsan Plant) CSF-71T CSF-71T CSF-71U CSF-81K2 CSM-70T MGC-308L MGC-309L TGC-309 TGC-309L ABS ABS ABS ABS ABS AWS A5.9-93 AWS A5.9-93 AWS A5.9-93 AWS A5.9-93 75% Ar, 25% CO-2 CO-2 CO-2 CO-2 CO-2 98% Ar, 2% O-2 98% Ar, 2% O-2 Ar Ar 2YSA 2SA H15, 2YSA 3YSA H10 4YSA 2SA H15, 2YSA ER308L ER309L ER309 ER309L All, V-down All, V-down All, V-down All, V-down F All, V-down All, V-down All All dcep dcep dcep dcep dcep dcep dcep dcen dcen 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 0.9 - 1.6 mm 0.9 - 1.6 mm 1.2 - 3.2 mm 1.2 - 3.2 mm Ulsan Ulsan Ulsan Ulsan Ulsan Ulsan Ulsan Ulsan Ulsan

Esab SeAH Corp. Coreweld 111 Ultra ABS CO-2 3SA, 3YSA* F * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. Coreweld 111 Ultra ABS CO-2 3A, 3YA* F (Tandem) * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. Coreweld 111RB ABS CO-2 2SA, 2YSA H10 3A, 3YA** All, V-down F dcep 1.2 - 1.6 mm Busan

dcep

1.2 - 2.0 mm

Busan

dcep dcep

1.2 - 1.6 mm 1.2 - 2.4 mm

Busan Busan

Coreweld 111RB ABS CO-2 **Suitable for use with automatic tandem welding only Coreweld 70 AWS A5.18-01 75% Ar, 25% CO-2

E70C-6M 4Y400SA H10**

All F

dcep dcep

0.9 - 1.6 mm 1.2 - 1.6 mm

Busan Busan

Coreweld 80-K2 ABS CO-2 **Manufacturer's guaranteed CVN 47 J at -60 C Coreweld Ultra Coreweld Ultra Dual Shield 111RB ABS ABS ABS 75% Ar, 25% CO-2 CO-2

3SA, 3YSA 3SA, 3YSA H10

All, V-down All, V-down

dcep dcep dcep

1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm

Busan Busan Busan

75% Ar, 25% 2SA, 2YSA* F, H, V-down CO-2 * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. Dual Shield 111RB ABS CO-2 2SA, 2YSA* F, H * Non-low-hydrogen FCAW wire; requires special approval for use on higher strength steel. Dual Shield 70 Ultra Plus Dual Shield 7100 Dual Shield 7100 Ultra ABS ABS ABS 90% Ar, 10% CO-2 CO-2 75% Ar, 25% CO-2 3SA, 3YSA H10 2SA, 2YSA H10 3SA, 3YSA H10 All All, V-down All, V-down

dcep

1.2 - 1.6 mm

Busan

dcep dcep dcep

1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm

Busan Busan Busan

14/Feb/2005 Approved Welding Consumables

III - 34

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

KOREA

Esab SeAH Corp. Dual Shield 7100 Ultra Dual Shield 7100S Dual Shield 7100SR ABS ABS ABS CO-2 CO-2 CO-2 3SA, 3YSA H10 2SA, 2YSA H10 3YSA H10 3SA, 3YSA H10** All, V-down All, V-down All, V-down All, V-down dcep dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.4 mm 1.2 - 1.6 mm 1.2 - 1.6 mm Busan Busan Busan Busan

Dual Shield 8100W ABS CO-2 **Manufacturer's guaranteed CVN 47 J at -30 C Dual Shield 9100

AWS All CO-2 E91T1-G** A5.29-98 **Manufacturer's guaranteed properties: Y.P. min. 540 N/mm2, T.S. 620-760 N/mm2, El. min. 17% Dual Shield II 101TC

dcep

1.2 - 1.6 mm

Busan

AWS All dcep 1.2 - 1.6 mm CO-2 E91T1-K2 A5.29-98 **Manufacturer's guaranteed properties: Y.P. min. 540 N/mm2, T.S. 620-760 N/mm2, El. min. 17%, CVN 27 J at -18 C Dual Shield II 70 Dual Shield II 70 Ultra Dual Shield II 71 Ultra Dual Shield II 71HI ABS ABS ABS ABS 75% Ar, 25% CO-2 75% Ar, 25% CO-2 CO-2 CO-2 3SA, 3YSA H5 3SA, 3YSA H5 3SA, 3YSA 4YSA H10 4Y400SA H10** All All All, V-down All, V-down All, V-down dcep dcep dcep dcep dcep 0.9 - 1.6 mm 0.9 - 1.6 mm 0.9 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm

Busan

Busan Busan Busan Busan Busan

Dual Shield II 81-K2 ABS CO-2 **Manufacturer's guaranteed CVN 47J at -60 C Dual Shield II 81-K2LH 75% Ar, 25% CO-2 **Manufacturer's guaranteed CVN 47J at -60 C Dual Shield II 81K2-LH ABS CO-2 **Manufacturer's guaranteed CVN 47J at -60 C Dual Shield II-110 Dual Shield R-70 Dual Shield T-115 Dual Shield T-5 ESAB 71 L-Tec FC-707 NCU - T70R OK 15.14A OK 15.14A Shield Bright 308L AWS A5.29-98 ABS AWS A5.29-98 ABS ABS ABS AWS A5.14 97 ABS ABS AWS A5.22-95 75% Ar, 25% CO-2 CO-2 CO-2 75% Ar, 25% CO-2 CO-2 75% Ar, 25% CO-2 75% Ar, 25% CO-2 CO-2 CO-2 ABS

4YSA H5**

All, V-down

dcep

1.2 - 1.6 mm

Busan

4YSA H5**

All, V-down

dcep

1.2 - 1.6 mm

Busan

E110T1-K3 3SA, 3YSA H10 E110T5-K4 3SA, 3YSA H10 2SA, 2YSA 2SA, 2YSA H10 ERNiCu - 7 3SA, 3YSA H10 3SA, 3YSA H10 E308LT1-1

All F All All, V-down All, V-down All, V-down

dcep dcep dcep dc dcep dcep

1.2 - 1.6 mm 1.2 - 2.4 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.6 - 4.0mm

Busan Busan Busan Busan Busan Busan Busan Busan Busan Busan

All, V-down All, V-down All

dcep dcep dcep

1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm

14/Feb/2005 Approved Welding Consumables

III - 35

ABS

Gas Metal Arc Welding and Flux Cored Arc Welding

Trade Name Spec Shielding Gas Grade Position Current Polarity Sizes Port Office

KOREA

Esab SeAH Corp. Shield Bright 308L X-Tra Shield Bright 309L Shield Bright 309L X-Tra Shield Bright 316L X-Tra Shield-Bright 316L SMP 71T SMP T316 SMP T316 L TC-T100 TC-T800 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 AWS A5.22-95 ABS AWS A5.9 93 AWS A5.9 93 AWS A5.7-84R AWS A5.7-84R CO-2 CO-2 CO-2 CO-2 CO-2 CO-2 E308LT0-1 E309LT1-1 E309LT0-1 E316LT0-1 E316LT1-1 2SA, 2YSA H10 ER316 ER316L ERCu ERCuNi F, H All F, H F, H All All, V-down dcep dcep dcep dcep dcep dcep 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.2 - 1.6 mm 1.6 - 4.0 mm 1.6 - 4.0 mm 1.6 - 4.0mm 1.6 - 4.0mm Busan Busan Busan Busan Busan Busan Busan Busan Busan Busan