Professional Documents

Culture Documents

Engineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee Members

Uploaded by

brecht1980Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee Members

Uploaded by

brecht1980Copyright:

Available Formats

Engineering Procedure

SAEP-310 13 J anuary 2008

Piping and Pipeline Repair

Piping Standards Committee Members

Nasri, Nadhir Ibrahim, Chairman

Dib, Tony Georges, Vice Chairman

Balhareth, Nasser Mohammad

Bannai, Nabeel Saad

Fadley, Gary Lowell

Holland, Brad John

Khashab, Jaafar M.

Lewis, Trevor

Mahmoud, Khalid Ahmed

Phan, Howard Cong

Rao, Sanyasi

Rasheed, Mahmood A.

Sharif, Talal Mahmoud

Shiha, Saad Mohammed

Swar, Ahmad H. (ABQ PLANTS)

Saudi Aramco DeskTop Standards

Table of Contents

1 Scope............................................................. 2

2 Applicable Documents................................... 2

3 Definition........................................................ 5

4 General Requirements................................... 5

5 Excavation and Burial (Buried Pipe).............. 6

6 Pipe Defect Removal and Replacement........ 7

7 Repair Methods and Requirements............... 8

8 Repair Applications...................................... 12

9 Welding on Pipelines and

Process Piping for Repairs................... 13

10 Pressure Testing.......................................... 15

11 Coatings....................................................... 16

12 Cathodic Protection...................................... 16

Appendix A Typical Metallic Repair Sleeve..... 17

Previous Issue: 29 November 2006 Next Planned Update: 29 November 2011

Revised paragraphs are indicated in the right margin Page 1 of 39

Primary contact: Nasri, Nadhir Ibrahim on 966-3-8734525

CopyrightSaudi Aramco 2008. All rights reserved.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 2 of 39

1 Scope

1.1 This SAEP describes the procedures to be followed for the repair of in-plant

piping and onshore/offshore pipelines, as covered by ASME B31.4, ASME B31.8

and API RP 570.

1.2 The repair method for offshore piping and pipeline selection shall be based on

the most economical and the most practical.

1.3 The methods and procedures set forth herein are minimum requirements and are

not a release from the responsibility for prudent action that circumstances make

advisable.

2 Applicable Documents

2.1 Saudi Aramco References

Saudi Aramco Engineering Procedures

SAEP-306 Assessment of the Remaining Strength of

Corroded Pipes

SAEP-311 Installation of Hot Tapped and Stopple

Connections

SAEP-321 Performance Qualification Testing and

Certification of Saudi Aramco Welders

SAEP-345 Composite Non-Metallic Repair Systems for

Pipelines and Pipework

SAEP-1143 Radiographic Examination

Saudi Aramco Engineering Standards

SAES-A-004 General Requirements for Pressure Testing

SAES-H-002 Internal and External Coating for Steel Pipeline

and Piping

SAES-H-203 Hand-Applied Tape Wrapping of Buried Pipe

SAES-L-150 Pressure Testing of Piping and Pipelines

SAES-L-350 Construction of Plant Piping

SAES-L-410 Design of Pipelines

SAES-L-450 Construction Requirements for Cross Country

Pipelines

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 3 of 39

SAES-W-011 Welding Requirements for On-Plot Piping

SAES-W-012 Welding Requirements for Pipelines

SAES-X-400 Cathodic Protection of Buried Pipelines

Saudi Aramco General Instructions

GI-0002.100 Work Permit System

GI-0002.102 Pressure Testing Safely

GI-0002.711 Fire and Safety Watch

GI-0006.012 Isolation, Lockout and Use of Hold Tags

GI-0006.021 Safety Requirements for Abrasive Blast Cleaning

GI-0150.001 Asbestos Regulations

GI-1780.001 Atmosphere-Supplying Respirators

Saudi Aramco Standard Drawings

AB-036029 Non-Pressure Containing Repair Sleeves with

Welded Buttstraps

AC-036261 Pipeline Corrosion Barrier Patch

AB-036262 Pressure Containing Repair Sleeves with Full

Penetration Butt Welded Seams

AC-036263 Weld Metal Build-Up for the Repair of Pipeline

Surface Defects

AE-036265 Pipeline Repair Patch for Minimum Wall

Thickness Violations

AC-036279 Corrugated Weld Repair Sleeve Pipe Size 6"

Through 48"

AA-036352 Details of Installation, Galvanic Anodes for Road

& Camel Pipelines Crossing, Pipeline Repair

Locations

AB-036381 Cathodic Protection Thermit Welding of Cables to

Buried Pipelines

AB-036478 Magnesium Anode Installation at Pipeline Repair

Locations, Layout, Sections and Details

AB-036526 Weld over Sleeve for Repair of Leaking Sleeves on

30" & 31" O.D. Pipe

AC-036655 Tie Rod Arrangement for Weld+Ends Coupling

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 4 of 39

AC-036660 Road Crossing for P/L Sht. 1, 2, 3, 4

AB-036880 Sleeved Crossing for Restrained Pipelines

AE-036833 Detail of Pipe Repair Plug

AB-036899 Shoring Trenches

Saudi Aramco Manuals

Saudi Aramco Construction Safety Manual

Saudi Aramco Crane Safety Handbook

2.2 Industry Codes and Standards

American Society of Mechanical Engineers

ASME B31.3 Process Piping

ASME B31.4 Liquid Transportation Systems for Hydrocarbons,

Liquid Petroleum Gas, Anhydrous Ammonia

and Alcohols

ASME B31.8 Gas Transmission and Distribution Piping

Systems

ASME B31G Manual for Determining the Remaining Strength

of Corroded Pipelines

American Petroleum Institute

API STD 1104 Standard for Welding Pipelines and Related

Facilities

API RP 570 Piping Inspection Code: Inspection, Repair and

Re-rating of In Service Piping System

API RP 579 Fitness-for-Service

National Association of Corrosion Engineers

NACE RP0177 Mitigation of Alternating Current and Lightning

Effects on Metallic Structures and Corrosion

Control Systems (Item 53039)

American Gas Association

Gas Purging Principles and Practices

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 5 of 39

3 Definition

Pyrphoric Material: Self igniting material (iron sulfide). In the absence of oxygen,

sulfur compounds or hydrogen sulfide in hydrocarbon stream react with steel to form

iron sulfide.

4 General Requirements

4.1 Any repair methods that are not addressed in this procedure shall be reviewed

and approved by the Chairman of the Piping Standards Committee.

4.2 Prior to commencing repair activities, defect assessment for metal loss shall be

conducted in accordance with SAEP-306 for pipelines, and in accordance to

API RP 570 in-plant piping design to ASME B31.3.

4.3 Engineering calculations should be performed to determine the permissible pipe

movement and the required support system during any repair.

4.4 Prior commencing any repair work, a written procedure shall be developed. The

procedure shall be approved by all parties involved in the repair activities.

4.4.1 The procedure shall comply with GI-0002.100, "Work Permit System",

GI-1780.001,"Atmosphere-Supplying Respirators", GI-0002.102,

"Pressure Testing Safely", GI-0006.012, "Isolation, Lockout, and Use of

Hold Tags", GI-0002.711 "Fire and Safety Watch".

4.4.2 The procedure shall include detailed requirements for safe working

conditions. Repair shall be performed under qualified supervision by

trained personnel aware of and familiar with hazards to personnel, public

and environment. Appendix B, protection against electric shock from

induced voltage and underground cable may be used as minimum

requirements.

4.4.3 The procedure shall detail the safety measures associated with all

mechanized repair equipment.

4.4.4 The procedure shall include all required data such as pipe diameter, wall

thickness, grade, etc.

4.4.5 All repairs shall be tracked in accordance with Management of Change

Procedure of the operating organization.

4.5 In case of small leak (weeping), the pipe pressure shall be lowered to 80% of the

current operating pressure if the pipe is operating at more than 40% SMYS.

Once the pressure level has been controlled, the pipe defect shall be examined,

and repaired.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 6 of 39

4.6 Pressure reduction, when the pipeline defects are not acceptable per SAEP-306

or API RP 579 for pipelines and in-plant piping respectively, shall be considered

if the pipe is operating at more than 40% SMYS.

Commentary Note:

Pressure reduction provides a minimum level of assurance that the defect or

anomaly will not fail during the course of its examinations and repair.

5 Excavation and Burial (Buried Pipe)

5.1 Prior to the start of excavation, the Operation Department shall identify all

underground piping and cables crossing in the vicinity of the excavation, and

notify the appropriate authorities to assist in the supervision of the excavation.

5.2 The buried pipe shall be located by electronic locating devices, manual probing,

or test excavations. The pipe locations shall be marked with brightly colored

flags. If crawler dozers are used, mark and flag all lines within 60 m (200 ft) of

the repair site.

Commentary Note:

Crawler dozers are used to remove sand dune in case of transportation pipelines.

5.3 The buried pipe depth shall be identified and marked. Manual excavation is

mandatory when the pipelines depth of cover reach 1220 mm (4 ft) or the

excavation is 914 mm (3 ft) adjacent to the buried pipe.

5.4 The underground sections of pipe requiring repairs shall be uncovered, while

under pressure, in sections up to 15.24 m (50 ft) long and separated by buried

sections of equal length. There is no limitation on the total length of pipeline

that may be uncovered in alternating 15.24 m (50 ft) sections. Approval of the

Chairman of the Piping Standards Committee is required when exposing more

than 15.24 m (50 ft) of the buried pipe section.

5.5 The working clearance around the buried pipe shall be adequate for work being

performed.

5.6 For excavations over 1219 mm (4 ft) deep, the sides of the pits and trenches

should be sloped back to the natural repose of the soil to avoid a cave-in. Sides

which cannot be sloped to natural repose shall be shored according to Standard

Drawing AB-036899.

5.7 Backfilling shall be according to SAES-L-450 for pipelines and SAES-L-350 for

in-plant.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 7 of 39

6 Pipe Defect Removal and Replacement

6.1 Pipeline sections with cracks, rupture or with defects that cannot be repaired

shall be removed or replaced.

The repair of cracks, other than their complete removal, shall be reviewed and

approved Consulting Services Department.

6.2 The minimum length of any replacement section shall not be less than two times

of the pipe diameter but not shorter than 305 mm (12"). The new section shall

not be installed closer than 152.5 mm (6") to an existing weld.

Commentary Note:

Minimum length of the new section is required to ensure the proper fit-up and

high integrity welds. Full radiographic examination is required in some cases.

6.3 Prior commencing any replacement, pipe isolation and displacing or purging of

hydrocarbon procedure shall be developed according to paragraph 4.4. The

procedure shall ensure safe, non-combustible atmosphere in the pipe and in the

vicinity of the work area.

6.3.1 The pipe shall be isolated by blind flanges, blanks or two isolation

valves. When using isolation valves, verification before and during the

work is required to ensure that the valves do not leak. Bleed connection

shall be installed between the two isolation valves to ensure no pressure

build up.

6.3.2 Testing of the atmosphere in the pipe and in the vicinity of the work area

shall be conducted before the work is started and at intervals as the work

progresses.

6.4 Pipe cut should be made with mechanical cutters. Torch cut can be performed

on pipe only if the pipe is free from combustible material.

An engineering evaluation shall be conducted before performing pipe cut

according to paragraph 4.3.

6.5 Hydrocarbon spillage is not permitted in hot work area. In case of cross country

pipelines, oil saturated sand shall be removed or completely covered with clean

sand.

Pyrophoric material shall be kept wet to prevent auto-ignition. Sludge in

pipelines suspected of containing iron sulfide shall be drained to an isolated area

at least 32 meters away from any other flammable substance.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 8 of 39

6.6 The open hydrocarbon shall be isolated, when possible, by a plug prior

conducting any hot work. Vents/drains shall be installed upstream the plug to

prevent pressure build up and drain standing liquid. For the type of plugs see

Appendix C.

6.6.1 When installing a plug is not practical in an open hydrocarbon pipe, the

isolated section shall not include any combustible atmosphere.

6.6.2 The vent/drains shall be sized to permit draining/venting the line section

in one hour with atmospheric pressure. Table A-2 of appendix A can be

used as a guideline to size the drain line.

6.7 The new replacement section shall meet the requirements of SAES-L-410 and

SAES-L-450 for pipeline and SAES-L-310 and SAES-L-350 for in-plant piping.

6.8 The welding procedure shall be according to paragraph 9.

6.9 The use of repair couplings such as Weld+Ends is permitted only for cross

country pipeline. They should be used only where it is not practical to perform

the girth welds. The rating of the repair couplings shall meet the design

condition of the pipeline.

6.9.1 The tie rod arrangement of Weld+Ends couplings, when required, shall

be installed as per Standard Drawing AC-036655.

6.9.2 The Weld+Ends couplings shall be installed in accordance with

Appendix-D of this procedure.

6.9.3 For FBE or cement line pipe, specially designed and fabricated couplings

shall be used.

7 Repair Methods and Requirements

7.1 Grinding is permitted to repair stress concentrating effect such as a gouge,

scratch, arch burns, or grooves. The grinding contour shall be smooth.

7.1.1 The limit of the metal removal shall be according to SAEP-306 for metal

loss criteria. The maximum metal loss shall not exceed 40% of the

nominal wall thickness.

7.1.2 The removal of the defect shall be verified by conducting NDE such as

dye penetrant or magnetic particle inspection.

7.1.3 Surface cracks can be removed by grinding following the approval of the

Consulting Services Department. The crack shall be mapped to

determine the extent of the defect.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 9 of 39

7.2 Weld metal build up may be used only for pipeline defects with metal loss. The

metal loss can be caused by external corrosion or gouges, groove and excessive

grinding.

7.2.1 The pipeline metal loss defect assessment shall be according to

paragraph 4.3. Welding on pressurized pipeline shall be according to

paragraph 9.6.

7.2.2 The maximum length or width of any individual repair area shall not

exceed 102 mm (4"). The repair area shall be separated by at least

102 mm (4") from any other repair area.

7.2.3 Weld metal build up shall be according to Standard Drawing AC-036263.

7.3 Patches and half sleeve repair techniques are allowed only on pipe with

specified minimum yield strength (SMYS) of 275,800 kPa (40,000 psi) or less.

Commentary Note:

Research and test have shown that the longitudinal fillet weld to pipe is a

potential weak point.

7.3.1 The patches shall be according to standard drawing AC-036261.

7.3.2 This method shall not be used for internal corrosion defects.

7.4 Pipeline Repair Sleeves

7.4.1 Type A repair sleeve (Pressure Containing Sleeve, Figure 1, Appendix

A) may be used for leaks or for pipe with internal corrosion defects.

7.4.1.1 The design strength (SMYS) of the repair sleeve shall be the

same or greater than the pipe.

7.4.1.2 For leaking pipe, a steel or wooden plug shall be installed prior

installing the repair sleeve. The repair sleeve shall not be

welded until the leak is completely stopped and no combustible

fumes are presents in the annulus.

7.4.1.3 The minimum length of type A sleeve shall not be less than

102 mm (4"). The sleeve shall extend a minimum of 50.8 mm

(2") on either side of the defect.

7.4.1.4 Multiple sleeves may be used for extended defects. When the

length of the sleeve or sleeves exceeds 4 pipe diameters, formal

analysis is required according to paragraph 4.3 to avoid any

sagging of the pipe.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 10 of 39

7.4.1.5 The repair sleeve shall be cut to provide close fit-up

dimensions and installation of the sleeve shall be according to

Standard Drawing AB-036262.

7.4.1.6 The welding of the sleeves shall be according to paragraph 9.

7.4.2 Type B repair sleeve (Butt Strap Non Pressure Containing Sleeve Figure

2, Appendix A) shall be used as corrosion barriers or to provide added

reinforcement to the pipe metal loss due to external corrosion or excessive

grinding. It also can be used for dents violating the applicable code.

Commentary Note:

Type B repair sleeve shall not be used to contain internal pressure

because the lap-type joint in the buttstrap is not as flexible as the butt-

welded seam to absorb the required strains induced while containing the

internal pipeline pressure.

7.4.2.1 Type B repair sleeve shall be in according to Standard Drawing

AB-036029.

7.4.2.2 Hardenable fillers such as epoxy or polyester shall be used to

fill the gaps between the sleeve and the pipe in all defect

locations.

7.4.2.3 The circumferential welds to the carrier pipe are not

mandatory. However, the annulus shall be sealed from dirt and

debris. The sealant compound shall be approved by the

Chairman of the Piping Standards Committee.

7.4.3 Type C repair sleeve (Corrugated Weld Repair Sleeves, Figure 3,

Appendix A) may be used for repair of leaking girth welds.

7.4.3.1 The repair sleeve shall be vented through the vent to a safe

location. Refer to paragraphs 7.4.1.2 and 7.4.1.3.

7.4.3.2 The repair sleeve shall be according to Standard Drawing

AC-036279.

7.4.4 Type F repair sleeve (Weld over Sleeves, Figure 4, Appendix A) may be

used for Type C repair sleeves suffering leaks. It is specially designed

according to Standard Drawing AB-036526.

Type A repair sleeve, when experience cracking at the toes of the fillet

welds, may be repaired by installing sleeve-on-sleeve. The configuration

shall be approved by the Engineering Division of the Operating

Organization.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 11 of 39

7.4.5 Epoxy filled repair sleeve may be used instead of Type B repair sleeve.

Epoxy fill repair sleeves do not require welding to the carrier pipe.

Installer shall be certified by the repair sleeve manufactures.

Commentary Note:

The repair comprises two oversized steel half-shells that are joined to

encircle the damaged area, leaving an annular gap. The annulus is

sealed at each end of the sleeve using a simply applied fast-setting

material, and then filled at very low pressure with a stiff epoxy-based

compound.

7.4.6 Bolt on Clamps such as PLIDCO Split Sleeves or PLIDCO

SMITH+CLAMP may be used on blowouts or punctures which cannot

be readily sealed by plugs or patches.

7.4.6.1 Bolt on Clamps should not be used instead of Type A repair

sleeve unless it is economically justified.

7.4.6.2 Bolt on Clamps shall not be used for pipe with general

corrosion of 70% wall loss and more.

7.4.6.3 Bolt on Clamps packing material shall be compatible with the

service fluid.

7.4.6.4 Permanent Bolt on Clamps may be welded. The maximum

interpass temperature shall not exceed the maximum design

temperature for packing material.

7.4.6.5 Bolt on Clamps, if approved by CSD, are acceptable for use up

to their rated pressure and temperature.

7.4.6.6 All coatings rust and scale shall be removed from the pipe

surface where the Bolt on Clamps circumferential seals will

contact the pipe.

7.4.6.7 The Bolt on Clamps seals shall not be installed in surface

irregularities greater than 1/32".

7.4.7 Bolt on Clamp with injection sealant may be used as a temporary repair

for leaking flanges or pipe to avoid plant shutdown.

7.4.7.1 Formal analysis shall be conducted to evaluate the additional

clamp weight on the piping system.

7.4.7.2 The injection sealant shall be compatible with the service fluid

and shall not affect the downstream components.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 12 of 39

7.4.7.3 The design and the rating of the clamp shall be reviewed and

approved by the Engineering Division of the operating

organization.

7.4.7.4 The Clamp shall be monitored periodically for leaks.

7.4.8 Saudi Aramco approved Non-metallic repair sleeves may be used for

external metal loss and mechanical defects such as dents.

7.4.8.1 Non-metallic repair sleeve installation procedure shall be

review and approved by the Chairman of the Piping Standards

Committee. Workers shall be certified by the non-metallic

repair sleeve manufacturer.

7.4.8.2 Non-metallic repair sleeve shall be used on a temporary basis

for internal metal loss with inactive corrosion or known

corrosion rate provided that it meets all the requirements of the

SAEP-345.

7.5 Bolted patch clamp (bolted clamp with elastomeric material) are permitted only

in low pressure utility piping.

7.6 Epoxy patch such as Belzona repair batch is permitted only to restore the

original external profile. It shall not be used as repair by itself.

7.7 Pipe defects may be removed by hot-taping. For hot tap procedure refer to

SAEP-311.

8 Repair Applications

8.1 All in-plant piping repairs are temporary until replacement can be carried out in

the next available shutdown window.

8.1.1 The selection of repair method for in-plant piping shall take into

consideration not only the design condition, but other perceivable

conditions such as upset condition and emergency.

8.1.2 Repair methods consist of non-metallic material such as elastomeric

seals are not permitted in piping system intended to retain their integrity

under external fire loading.

8.2 Plant piping and pipelines repair methods should be according to Table A-1,

Appendix A. Selection of the repair method should be evaluated on the

economics and the practicality of the repair methods.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 13 of 39

8.3 Pipe defects that are not addressed in Table A-1 should be reviewed by the

engineering division to select proper corrective action.

8.4 Pipe with an unacceptable Hydrogen Induced Cracking (HIC) defect should be

replaced. If the replacement of hydrogen damaged pipe is not feasible, then the

requirements of this section shall be followed.

8.4.1 Expose the full joint of pipe as well as a portion of the adjacent joint on

each side and determine the extent of the defect indications. Continue

exposing as much pipe as necessary until the extent of the area with

defect indications is determined.

8.4.2 Determine the size and depth of the defects with ultrasonic testing.

Ultrasonic indications may mean any of several things, including on-

going cracking, corrosion damage, the presence of pre-existing and

rather harmless laminations, or simply elongated inclusions in the steel.

When ultrasonic or radiographic inspection reveals crack-like defects,

further examination is required to determine the nature of the defects.

8.4.3 The HIC decision tree, (Appendix E), assesses the severity of the

hydrogen damage and provides recommendation for corrective action.

Assessment may require removal by Hot-Tapping of coupons for

metallurgical analysis. Hydrotesting, monitoring, increased inhibition,

sleeving or replacement of cracked areas may be required. No corrective

action shall be taken without the concurrence of the Coordinator,

Materials Engineering and Corrosion Control Division, Consulting

Services Department.

9 Welding on Pipelines and Process Piping for Repairs

9.1 Welders and welding procedures shall be qualified according to SAES-W-011,

Welding Requirements for On-Plot Piping and SAES-W-012, Welding

Requirements for Pipelines.

9.2 All welding of patches, sleeves, and weld build-up shall be in accordance with

applicable Saudi Aramco Welding Procedure Specification.

9.3 Welding longitudinally to the axis of the pipeline is not permitted except as

approved by this procedure.

9.4 For carbon steels with minimum specified yield stresses greater than 60 ksi, the

Consulting Services Department shall be contacted for welding procedure

approval.

9.5 Pipeline retaining residual magnetism above 20 Oe (Oersteds) shall be

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

demagnetized before conducting any welding.

Commentary Note:

Pipelines often retain residual magnetism following a cleaning run by a Magnetic

Cleaning scraper, or an inspection by MagneScan or other magnetic Flux leakage

tool.

9.6 Welding on pressurized pipeline.

9.6.1 The pressure in the pipe during welding shall not exceed that calculated

by the following formula:

Pmax =

2S(t 0.10)F

OD

(1)

Where:

Pmax = Maximum operating pressure of the pipeline during welding,

psig

S = Specified minimum yield strength of the pipe, psi

t = Minimum measured wall thickness of the pipe at the weld

area, inches.

F = 0.72 (Design factor of the pipeline).

OD = Outside diameter of the pipe, inches.

Commentary Notes:

1. The minus 0.10 inch wall thickness takes into account the molten and

heat affected portion of the base metal which does not contribute to

pressure containment.

2. For in-plant piping designed to ASME B31.3, replace S and F in the

formula with the allowable stress in Table A-1 of ASME B31.3.

To ensure the wall thickness is thoroughly measured, a continuous UT

scan shall be conducted around the circumference of the pipe weld areas.

9.6.2 To further minimize the possibility of "burn through", no welding shall

be allowed in areas with a wall thickness below 5 mm or below the

pressure design thickness of the pipe. Welding can be carried out on

pipe containing hydrocarbon, only when there has been no combustible

mixture.

9.6.3 In cases where a pipeline has been cut or ingress of air has otherwise

been allowed, the air must be removed from the pipeline before welding

can be performed. One method of removing the air is by putting the line

Page 14 of 39

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 15 of 39

in service with an adequate flow rate to ensure that the air is displaced

from the pipeline. Once this has been achieved, welding can proceed

with or without flow.

9.7 Non-Destructive Examination

9.7.1 All welds made for the installation of pipe sleeving or patching for

pressure containment (Type A and PLIDCO Split Sleeve), and for weld

metal build-up, shall be inspected by M. T. or P.T.

9.7.2 Welds within 19 mm or 3 times the wall thickness of the pipe from an

existing girth weld shall be inspected by MT or PT.

9.7.3 Additional inspection may be requested as required by the assigned the

responsible Inspection Organization.

9.7.4 Thickness Measurement using ultrasonic thickness shall be taken on all

pipe areas where welding is to be done.

9.7.5 The defect removal shall be verified be the same methods that detected it

originally.

10 Pressure Testing

10.1 When the new pipe replacement section is to be hydrotested prior installation,

the hydrotest shall be according to SAES-A-004 and SAES-L-150.

10.2 When the piping system with replacement section is to be hydrotested, the test

shall be in full compliance with SAES-A-004 and SAES-L-150.

10.3 When the hydrotest is not practical, full compliance of SAES-A-004 shall be

adhered to along with the following requirements:

1) Verification of the pipe mechanical prosperities through the mill

certificate.

2) Visually inspect all mill applied welds of the spiral or longitudinally

welded joint(s) of new pipe prior to installation in the pipeline.

3) Radiograph or ultrasonically check all suspect areas of the manufacturers'

welds found to be defective by visual inspection.

4) Repair all manufacturers weld defects and radiograph repairs to assure

defects are removed.

5) Visually inspect the pipe ends for proper bevel and evidence of no

laminations. Repair as required.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 16 of 39

6) Radiograph all butt welds required to install the new pipeline section and

repair defects as required.

7) Provide an approve NDE In-Lieu-of Pressure Test.

11 Coatings

11.1 Refer to SAES-H-002 and SAES-H-203 for selection and application of internal

and external coating systems and tape wrapping for pipelines.

11.2 Refer to GI-0006.021, "Safety Requirements for Abrasive Blast Cleaning",

when preparing pipe surfaces for coating using abrasive blast cleaning.

12 Cathodic Protection

12.1 When repairs are made due to external corrosion, the proponent cathodic

protection unit within the operating organization shall determine when and

where supplemental "Hot Spot" cathodic protection will be used.

12.2 A minimum of two (2) magnesium anodes shall be used for supplemental

cathodic protection. The anodes shall be installed on alternate sides of the

pipeline. The placement shall be such that one anode is installed at each end of

the repair area.

12.3 Anode requirements and installation details are found in Standard Drawings

AB-036478, "Magnesium Anode Installation at Pipeline Repair Locations;

Layout, Sections and Details", and AA-036352, "Details of Installation of

Galvanic Anodes for Road and Camel Crossing and Pipeline Repair Locations".

12.4 Anode connections to the pipeline shall be Thermit welded as per Standard

Drawing AB-036381, "Cathodic Protection; Thermit Welding of Cables to

Buried Pipe lines".

Revision Summary

29 November 2006 Major revision.

13 J anuary 2008 Editorial revision.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Appendix A Typical Metallic Repair Sleeve

Figure 1 Type A Sleeve, Pressure Containing Full Encirclement Sleeve

Figure 2 Type B Sleeve, Butt Strap Non-Pressure Containing Sleeve

Page 17 of 39

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Figure 3 Type C Sleeve, Corrugated Weld Repair Sleeve

Figure 4 Type F Sleeve, Weld over Sleeve

Page 18 of 39

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 19 of 39

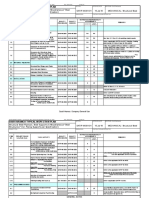

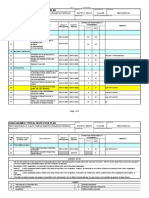

Appendix A-1: Repair Method Selection Table

Table A-1: Saudi Aramco Repair Applications

1

G

r

i

n

d

i

n

g

W

e

l

d

m

e

t

a

l

b

u

i

l

d

W

e

l

d

e

d

P

a

t

c

h

e

s

o

r

h

a

l

f

S

l

e

e

v

e

T

y

p

e

A

S

l

e

e

v

e

T

y

p

e

B

S

l

e

e

v

e

E

p

o

x

y

F

i

l

l

e

d

R

e

p

a

i

r

S

l

e

e

v

e

B

o

l

t

o

n

C

l

a

m

p

s

B

o

l

t

o

n

C

l

a

m

p

w

i

t

h

I

n

j

e

c

t

i

o

n

S

l

t

N

o

n

m

e

t

a

l

l

i

c

s

l

e

e

v

e

s

H

o

t

T

a

p

i

n

g

Plant Piping

2

Yes No Yes Yes No No Yes Yes No Yes

On shore

Pipeline

Yes Yes Yes Yes Yes Yes Yes No Yes Yes

P

i

p

e

A

p

p

l

i

c

a

t

i

o

n

Off Shore

Pipeline

Yes No No No No Yes Yes No Yes No

Small defect

<0.5D

Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

D

e

f

e

c

t

S

i

z

e

Large Defect

>0.5D

No No No Yes Yes Yes Yes No Yes No

Leaks

No No No Yes No No Yes Yes No Yes

External

Corrosion

Yes Yes Yes Yes Yes Yes Yes No Yes Yes

Pitting Lake <

0.85t

No Yes Yes Yes Yes Yes Yes No Yes No

Pitting Lake

>0.85t

No No No Yes No No Yes No No Yes

C

o

r

r

o

s

i

o

n

D

e

f

e

c

t

s

Internal

corrosion

No No No Yes No No Yes No No No

Dents No No No Yes Yes Yes Yes No Yes No

Dents/ Gouge No No No Yes Yes Yes Yes No Yes No

M

e

c

h

a

n

i

c

a

l

D

a

m

a

g

e

Wrinkle Bend No No No Yes Yes Yes Yes No No No

Shallow

Cracks

4

<0.4t

Yes Yes Yes Yes Yes Yes Yes No Yes Yes

C

r

a

c

k

s

3

Deep Cracks

>0.4t

No No No Yes No No Yes No No Yes

Blisters

No No No Yes No No Yes No NO No

O

t

h

e

r

s

Girth Weld

Defects

Yes Yes No Yes No No No No Yes No

1

This table shall not be used without addressing the repair techniques limitations in paragraphs 7 and 8 of the SAEP-310.

2

All plant piping repair are temporary maximum until the next plan shutdown.

3

All crack defects require a qualified corrosion /metallurgy engineer to investigate the cause and review the corrective action or

repair procedure

4

Shallow cracks shall be grinding before applying any repair technique.

Notes:

1. Assigned inspection unit shall review the repair procedure, add any quality requirements, attend all hold points specified by

inspector and approve repair work when completed.

2. For dents and external metal loss, the pipe original external profile shall be restored by applying Hardenable fillers.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 20 of 39

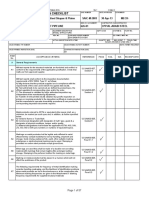

Table A-2: Vents/Drain Sizes

Size

(in)

Approx. Capacity

(barrel/hr)

1 15 - 30

2 65 - 130

3 145 - 300

4 260 - 500

6 600 - 2000

8 1000 - 4000

EXAMPLE: Consider 609.6 m of 6 in flow line. Contents are approximately

2000/1000 x 6 =72 barrels. A 2 in drain should be provided.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 21 of 39

Appendix B Protection against Electric Shock

from Induced Voltage and Underground Cables

This Appendix contains mandatory practices which safeguard personnel against the hazards of

electric shock during the installation, operation, or maintenance of above ground and buried

pipelines routed near overhead, high-voltage power lines. These practices apply to pipelines

routed within 152.4 m of any energized 115-kV and 230-kV power lines, and also to 69-kV

lines if parallel lengths are 1.6 km or greater.

Safety precautions to prevent shock due to induced voltage, as stated in this Appendix, for

pipelines routed in the vicinity of lower voltage power lines, i.e., (4.16-kV and 13.8-kV), are

normally not required.

All work on pipelines shall stop during lightning and thunderstorms.

The following conditions are not exempt from the mandatory practices of this section:

a) Line not cathodically protected.

b) Line section isolated by insulation flanges.

c) Cathodic protection rectifiers and generators shutdown.

B-1 Buried Pipelines

B-1.1 No special precautions need to be taken during local excavations

exposing less than 15.24 m of pipeline except when cutting into an

existing line and/or removing a section of the pipeline, then Paragraph

B-2.4 shall be observed. Paragraph 5.4 limits the length of pressurized

piping, which can be exposed in a single excavation to 15.24 m.

B-1.2 When work on existing buried pipelines requires the exposing of 15.24

m or more of the line, it shall be regarded as an above ground pipeline.

Appropriate precautions, taken in accordance with Section B -2, shall be

implemented.

B-1.3 Prior to the start of excavation, the Operations Department shall identify

all underground cables crossing in the vicinity of the pipeline excavation,

and notify the appropriate authorities, i.e., (Power Distribution

Dispatchers, SEC), to assist in the supervision of the excavation. A

minimum spacing of 914 mm is required between the bottom of the

pipeline and the top of the cable duct bank. Therefore, extreme care

must be taken when excavating below the pipe. Normally, buried cable

markers indicate the location of the cables, but they may have been

inadvertently removed or never installed. When cable markers are not

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 22 of 39

shown, a safe maximum distance of 610 mm from the bottom of the pipe

should not be exceeded.

B-2 Above Ground Pipelines

B-2.1 All work on exposed pipelines shall be carried out from a wire mat that

is electrically bonded to the pipeline at each end of the repair area.

B-2.2 If the ground mat can not be bonded to the pipeline, two (2) carbon steel,

13 mm diameter studs shall be welded at each end of the pipeline repair

area to provide the required grounding connections. The areas where the

studs are to be welded shall be cleaned prior to welding as per SAES-W-

012. If studs are removed, the weld areas shall be ground flush with the

pipe and a Liquid Penetrant or Magnetic Particle Test (PT or MT)

inspection shall be made to insure no harmful defects remain.

B-2.3 Rubber gloves shall be worn for all operations on the line until the mat is

properly positioned and bonded to the line. Similarly, rubber gloves

shall be worn when removing the bonds.

B-2.4 When the repair of a pipeline requires cutting an existing line or

unbolting flanged connections, a flexible bonding cable, no less than No.

2 AWG, shall be attached across the section of line to be separated prior

to cutting or unbolting. Bonding cables may be thermit welded to the

pipe as per Standard Drawing AB-036381. The cable shall remain

attached until after the line is repaired. After the removal of the of the

bonding cable, the attachment areas shall be ground flush with the pipe

surface and a Liquid Penetrant or Magnetic Particle Test (PT or MT)

inspection shall be made to insure no harmful defects remain.

Grounding mats shall not be used as a bonding cable. The cable shall be

installed so that it is fully protected from movement of workers and

equipment. Refer to NACE RP0177 Item No. 53039.

B-2.5 All electric arc welding operations shall be carried out with the welding

machine bonded to the ground mat and pipeline, with the welder working

on the ground mat.

B-2.6 When working on lines supported on steel structures, such as at road

crossings, etc., ground mats are not necessary. However, the lines

should be bonded to the steel structure to ensure a proper ground and the

requirements of Paragraph B-2.4 implemented.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 23 of 39

B-3 Valves on Above Ground and Buried Pipelines

B-3.1 Unless noted otherwise on the Work Permit, no special precautions need

to be taken when operating or maintaining valves located below ground

and form part of a buried pipeline.

B-3.2 Where metal platforms or temporary scaffolds are installed to provide

access to valves on an above ground pipeline, the platforms shall be

electrically bonded to the pipeline on each side of the valve before work

starts. The requirements of Paragraph B-2.4 shall be observed when

making and removing the bonding connection.

B-3.3 The electrical bond shall consist of a No. 2 AWG flexible conductor,

such as a welding cable, connected to the platforms at one end and

terminated at the free end by a 50 amp rated test clip with insulator.

Access to the platform shall be by a 36 inch square rubber mat.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 24 of 39

Appendix C Types of Isolation Plugs

Saudi Aramco stocks three types of plugs: Balloons, Mud Plugs and Mechanical Plugs.

However, there are many other plugs available in the market which could be used if they were

proven to be equivalent or better than the types described in this Appendix. Any plug, other

than a mud plug, shall be removed before the line is closed. Mud plugs normally remain in the

line but may be removed, if circumstances dictate or must be removed if they contain Gypsum

Plaster see C-2.5 below.

C-1 Balloons (Stopper)

The inflatable balloons have polyester cover and gum rubber bladder, bag type.

They are also fitted with inflating valve nipple and hose clamp. Balloons are

available in Saudi Aramco material system for nominal pipe sizes 2 through

60 inch.

C-1.1 The canvas covers of the balloons are at best only moderately fire

resistant. Additional precautions that make their use safer include mud

dams and inert gas purges.

C-1.2 Balloons shall be inflated carefully so as to ensure that the relatively low

allowable pressures are not exceeded. A suitably graduated pressure

gauge shall be utilized during inflation. For sizes 22 inch and larger, the

pressure gauge shall be graduated in inches of water. Table C-1 gives the

maximum inflation pressure of the balloon.

C-1.3 The balloon can withstand only a small differential pressure (up to

10 psig for small diameters and only up to 1 psig for large diameters),

and therefore, the job must be planned to have zero line pressure.

C-2 Mud Plugs

Mud plugs are a mixture of special types of mud with water. After preparation in

the field, the mud is erected to provide the required seal. Table C-2 shows a

comparison between the balloon plug and mud plug.

C-2.1 The mud plug is composed of the following components:

Bentonite (clay), 23 kg sack, Material no. 1000021551

Cottonseed hull, 23 kg sack, Material no. 1000021603

Expanded Vermiculite, 15 kg sack, Material no. 1000248228

Gypsum Plaster, 45 kg sack, Material no. 100188115

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 25 of 39

C-2.2 In building a mud plug, Bentonite should be mixed with only sufficient

water to make a very stiff paste, refer to Table B-3 for guidelines of the

Bentonite and water quantities.

C-2.3 For lines larger than 305 mm diameter, light-weight material such as

expanded Vermiculite can be added to reduce the tendency of the plug to

slump. Mix the Bentonite and Vermiculite dry, in a mortar box. Add

only enough water to make a very stiff paste as per guidelines of Table

C-3. The Vermiculite will shrink when handled, so try to avoid

excessive mixing.

C-2.4 Avoid the use of heavy materials in the mud mixture, such as Baryte

(Baroid). They are not sticky and can only make it more difficult to

build the plug up to the top of the pipe.

C-2.5 If Gypsum plaster is used to increase the strength of the plug, it must be

removed prior to closing the line.

C-2.6 Structural support for starting a mud plug can be provided by a balloon.

Effectiveness of the balloon can be increased by running a rope through

the end ring to hold the balloon while the mud is forced against it. A

balloon should not be used unless provisions are made for removing it

after closing the line.

C-2.7 In very large lines, a dam can be started with full sacks of Bentonite or

Baryte. However, the sacks must be removed after welding is

completed. As an added precaution, it may be advisable to use two plugs

separated by a purged section of line.

C-3 Mechanical Plugs

These are proprietary plugs that can withstand higher pressure than balloons or

mud plugs, therefore, they create a much better seal for use in welding flanges or

valves onto the open ends of operating lines. Saudi Aramco stocks mechanical

plugs (steel/rubber) for nominal pipe sizes 3 through 12 inch of the wing nut

type. Larger sizes may be obtained on a direct requisition form.

C-3.1 Additional safety precautions for mechanical plugs can include: venting,

use of mud plugs for added sealant, inert gas purges, and water seals.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 26 of 39

Table C-1: Maximum Inflation and P/L Pressure for Balloons of Size 2-60"

Maximum Inflation

Nominal Size

Kpa (in) Psig (in) Water

2, 3, 4, 6 03 15 413

8 83 12 330

10 69 10 275

12 55 8 220

14 48 7 193

16 41 6 165

18 38 5.5 151

20 34 5 138

22 28 4 110

Table C-2: Comparison between Balloon and Mud Plug

Balloon Mud Plug

Location from

weld

It has to be far from end of

line. Balloon could rupture

from heat or inadvertent

puncture if close to end of

line. (D)

Closer to end of line (A)

Installation Easier to install

For large lines, mud plugs are

difficult to erect. It needs

careful and skillful erection Mud

shrinks as it dries. Plugs that

are too wet may slump and fail.

For these last two reasons,

cutting and welding work must

be completed as soon as

possible after the plug is

completed. (D)

Sealing pressure Between 1 and 10 psig

Cannot be estimated, 0 psig

must be assumed. (D)

Removal

Balloons require special

hot taps for insertion and

removal except when they

are used to weld flanges

or valves to the open end

of the line.

Mud plugs can be left in the

line after welding. They can be

washed away by the line fluid.

(A)

Note: (A) is advantage (D) is disadvantage

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 27 of 39

Table C-3: Composition of Mud Plugs

Nominal Size Bentonite Vermiculite Water

(in) (sacks) (sacks) (m

3

) (ft.

3

) (U.S.

gal)

6 1 - 0.03 1 7.5

10 2 - 0.06 2 15

12 3 - 0.08 3 2.5

16 3 2 0.08 3 22.5

20 6 4 0.17 6 45

24 9 5 0.25 9 67.5

30 14 8 0.40 14 105

36 22 13 0.62 22 164.5

40 28 17 0.80 28 209.5

42 33 20 0.93 33 247

48 50 30 0.93 50 374

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 28 of 39

Appendix D PLIDCO Weld+Ends Couplings

This Appendix supplements the PLIDCO manufacturer manual which must be the main

reference for a successful installation. This Appendix describes the uses, limitations, and

installation of PLIDCO Weld+Ends couplings for the purpose of making quick, safe unions on

onshore and offshore pipelines, underwater risers, and process piping.

D-1 General

D-1.1 PLIDCO Weld+Ends are specialized couplings, used where it is difficult

to make quick and safe pipe unions by any other means. They may be

used in the repair of onshore or offshore hydrocarbon pipelines, water,

steam, or chemical process lines, and underwater risers. PLIDCO

Weld+Ends can be welded to the pipe ends or they can be left with

clamping and thrust screws tightened, depending on the field situation

and product conditions.

D-1.2 Standard PLIDCO Weld+Ends have single rows of clamping screw

located on the circumference of each end of the coupling.

D-1.3 Special PLIDCO Weld+Ends have double rows of clamping screws

located on the circumference of each end of the coupling. They are

designed specially for excessive end pulling loads, and are restricted

(color coded white) by Saudi Aramco for submarine pipeline repair only.

D-1.4 In general, the Weld+Ends shall be welded directly to the pipe ends after

installation, and by this they are considered anchored and their pressure

rating should be the Welded Maximum Allowable Operating Pressure

D-1.5 If the Weld+Ends cannot be welded, they are considered not anchored

and their pressure rating should be the UnWelded Maximum Allowable

Operating Pressure.

D-1.6 Clamp+Rings are special PLIDCO Weld+Ends and useful in situations

where end pulling loads exceed the coupling's "UnWelded Maximum

Allowable Operating Pressure (MAOP)" Rating and conditions do not

allow for welding on the line, e.g., underwater pipeline repairs.

D-2 Packing (Sealant) Material

To ensure a safe, leak-free seal, it is vitally important that the proper packing

material is chosen. This included pressure rating, temperature limitation and

product compatibility. This is especially important if the coupling will not be

welded and the packing will be the only means to seal the product.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 29 of 39

D-2.1 Saudi Aramco is mainly using Silicon, Viton, or Buna-N as packing.

Silicon is being mostly specified because it is of lower cost than Viton.

D-2.2 Viton shall be used for crude, gas, and hydrocarbon lines if the coupling

will not be welded.

D-2.3 Viton GF or Aflas should be used for products with amine corrosion

inhibitor if the coupling will not be welded.

D-2.4 Silicon or Buna-N should be used for water service.

D-2.5 If the packing is not compatible with the product, it could still be used

subject that coupling shall be completely welded to the line as soon as

possible. There shall be no delay between the start and completion of

welding.

D-2.6 For LPG service and H

2

S service, the coupling shall be completely

welded to the line as soon as possible. There shall be no delay between

the start and completion of welding.

D-2.7 The manufacturer limits the operating temperature range for:

i) Silicone packing at -54 to 232C.

ii) Viton packing at -26 to 121C.

iii) Buna-N packing, at -29 to 107C.

D-3 Shelf Life

D-3.1 Buna-N has a short shelf life of 2 to 5 years whereas Viton and silicone

packing shelf lives of up to twenty (20) years depending on storage

condition. Follow the manufacturer recommendations to prolong shelf

life of the packing.

D-3.2 The bolts shall be covered with heavy grease to protect them from

rusting, and the packing shall be wrapped in plastic wrap to protect them

from deteriorating environmental conditions.

D-4 Maximum Allowable Operating Pressure (MAOP)

The method of installing PLIDCO Weld+Ends determines the MAOP of the

coupling.

D-4.1 UnWelded MAOP Ratings

After completing the installation and prior to welding the coupling to the

pipe, the rating is defined as the "UnWelded MAOP Rating". The rating

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 30 of 39

for sizes 2-60" are listed in Table D-1 for single row of clamping screws

and Table D-2 for double rows of clamping screws.

D-4.2 Packing Material's "Sealant Strength" Pressure Limitations

D-4.2.1 Silicone packing is limited to a "Sealant Strength" of 1000 psig.

D-4.2.2 Viton and Buna-N packing have no pressure limitations for

"Sealant Strength". The MAOP should be equal to the

UnWelded MAOP

D-4.3 Welded MAOP Ratings

After welding, the coupling is conisedred as anchored and it has higher

rating defined as "Welded MAOP Rating". The rating for sizes 2-60" are

listed in Table D-1 for single row of clamping screws and Table D-2 for

double rows of clamping screws.

Prior to welding, if it is determined that the total longitudinal forces

exerted on a coupling will exceed the total gripping strength of it's

clamping screws, the ends of the line shall then be anchored using a tie

rod arrangement as shown in Saudi Aramco Standard Drawing

AC-036655.

D-4.4 Derated MAOP for Thin-Wall Pipes

For PLIDCO Weld+Ends that will be installed on thin-wall pipes, the

MAOP should be derated because the applied torque should be

decreased. Refer to Table D-3 for derated values of MAOP.

D-5 Installation

D-5.1 Preparation of Pipe Ends

D-5.1.1 Select the location of pipe cuts so that the coupling's clamping

screws can grip on a smooth, unpitted surface and the packing

material can form a tight even seal. Remove any coatings or

general corrosion around the entire area to be coupled.

Longitudinal or spiral weld seams shall be ground flush with

the pipe wall and all burrs removed. If the coupling is to be

welded after installation, the pipe wall thickness in the vicinity

of the fillet girth welds shall be checked by ultrasonic testing

(U.T.) to ensure there is a minimum of 5.1 mm (0.20 in.)

around the girth weld area.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 31 of 39

D-5.1.2 Check the diameters at both ends of the pipe to be coupled for

out-of-roundness and repair if necessary using external line-up

clamps or internal jacking. No other special preparation of

pipe ends is required.

D-5.2 Inspection of Weld+Ends

Inspect the coupling for evidence of corrosion, fouling, and damaged

packing. Be sure all the screws are free to turn and that no sand or any

foreign material is in the packing grooves. One practical method of

checking the packing is the thumb nail test. Push your thumb nail into

the exposed packing. If the packing returns to the original shape, it

should be acceptable for use. If the thumb nail imprint stays, the packing

shall be replaced.

D-5.3 Tightening the Clamping Screws

D-5.3.1 Use manufacturer recommended procedure and torque for

tightening the clamping screws.

D-5.3.2 For thin-wall pipe of less than Sch. 40 or inch, the clamping

screws shall be tightened to the recommended torque values as

shown in Table C-3 the torque and pressure derating graphs for

thin wall pipe. These lesser clamp screw torque values shall be

used to prevent damage to the pipe ends.

D-5.3.3 In order to obtain a tight fit with equal and accurate clamp

screw torque values, the following steps shall be followed:

Step 1) Center the Weld+Ends using the clamp screws at the

12, 6, 3, and 9 o'clock positions. These screws are

only hand tightened (snug).

Step 2) Adjust the gap between the pipe and coupling

interface to ensure equal spacing. It is very important

to provide a concentric, equal gap between this

interface to ensure an optimum packing seal when the

thrust screws are tightened.

Step 3) Hand tighten any remaining clamp screws and adjust

the gaps as stated in Steps 1 and 2.

Step 4) Advancing circumferentially, begin torquing the

clamping screws to equal portions of their final

recommended torque value. Check the gaps and

adjust them to ensure uniformity.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Step 5) Repeat Step 4 several times until the final

recommended torque is achieved. A final torque and

gap check of all the clamping screws is

recommended.

D-5.3.4 Tightening the Thrust Screws

Thrust screws activate the seal packing. These screws are

tightened AFTER the clamping screws are torqued. Tighten

the thrust screws using the following steps:

Step 1) Tighten all screws until they are snug.

Step 2) Advance each screw about

8

1

of a turn before

advancing to the next, adjacent screw. Repeat this

process as many times as necessary until the

manufacturer recommended torque is reached.

Step 3) Pressurize the line slowly and steadily without surges

or slugging, which could vibrate and pull the line

ends from the coupling. Do Not exceed the lesser

value of the following:

i) The recommended UnWelded MAOP of the

coupling.

ii) The maximum design pressure of the line.

iii) The maximum calculated pressure as stated in

during welding if the coupling is to be welded to

the pipeline.

Step 4) Tighten the thrust screws as required to stop any

leaks that may have developed to complete the

Weld+Ends installation. If welding is specified, refer

to Section C-6.

D-6 Welding

D-6.1 All welding of PLIDCO Weld+Ends to piping shall conform to an

approved Saudi Aramco Welding Procedure Specification, e.g., WPS

No. PLIDCO-001.

D-6.2 The minimum remaining pipe wall thickness at the area to be welded

shall be at least 5.1 mm.

Page 32 of 39

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 33 of 39

D-6.3 The line shall remain pressurized for at least hour prior to any

welding to ensure no leaks form. Tighten the thrust screws as required

to stop any leaks that may have developed.

D-6.4 All welding shall be made with low-hydrogen electrodes. If the pipe

wall thickness is less than 0.35 inches, all first layer weld passes onto

the pipe shall be made using 2.4 mm diameter electrodes. Subsequent

weld passes may be made with 3.2 or 4 mm diameter electrodes.

D-6.5 Weld surfaces, such as the clamping and thrust screws, and the

coupling body and adjacent pipe surfaces, shall be free of oil, grease,

moisture, rust, scale, paint, metallic coatings, or other foreign matter,

prior to welding. Refer to SAES-W-012.

D-6.6 Prior to fillet welding the coupling to the pipe ends, a maximum fit-up

gap of 3.2 mm between the two surfaces shall not be exceeded. If the

fit-up gap exceeds 3.2 mm, a weld build-up (buttering) shall be made

on the pipe at the deficient area to reduce the gap distance. Remove

one clamp screw from each top end of the coupling to act as a vent

during welding and as a pressure test point after welding.

D-6.7 Only the stringer bead weld technique shall be used for all root passes

and all subsequent passes if the pipe wall thickness is less than inch.

For pipe wall thickness equal to or greater than inch, either the

stringer bead or weave technique may be used. The weave width shall

not exceed three (3) times the diameter of electrode.

D-6.8 The temperature of the metal during welding should be monitored as

per manufacturer recommendation to avoid damaging the seal.

D-6.9 The final girth fillet weld leg size shall be a minimum of 1.5 times the

nominal pipe wall thickness.

D-6.10 The fillet weld profile shall be as smooth as possible and should be

slightly concave. The toe of the fillet weld shall blend smoothly into

the pipe wall. It shall be the responsibility the welding inspector to

accept the final weld size and profile.

D-6.11 The Weld+Ends shall be welded using the following steps:

Step 1) Tack weld all of the end thrust screws. Cut them off flush

with the coupling face using a wheel grinder. Hold a metal

strip between the bolt and pipe to prevent damaging the pipe

wall with the grinder. Some projection of the outer edge of

the bolt is acceptable.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 34 of 39

Step 2) Depending on the position of the coupling, and the proximity

of it's ends, both of the Weld+Ends girth welds should be

made at the same time. Where possible, use two welders at

each end of the coupling to weld on opposite quadrants

simultaneously. All passes on the girth fillet weld shall be in

the following sequence:

1) Weld from 3:00 to 12:00 o'clock position.

2) Weld from 6:00 to 9:00 o'clock position.

3) Weld from 6:00 to 3:00 o'clock position.

4) Weld from 9:00 to 12:00 o'clock position.

Commentary Note:

All of the thrust screw ends shall be welded over.

Step 3) Make a in. fillet weld, (at least two passes), around all of

the clamping screws, except the ones used for venting and

leak testing. After welding, either burn off or cold cut the

remainder of the clamping screws just above the weld.

Step 4) Apply an air test (5 to 10 psi) at each end of the coupling

through the top clamping screw holes. Put soap solution over

all the welds and check for leaks. Any areas found leaking

shall be ground out, re-welded and air tested as previous.

Step 5) Upon completion of the air test, replace the remaining clamp

screws at each end of the coupling. Tighten the clamp screw

as described in section D-5.3. Weld and cut off the screw

ends as described in Step 4.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 35 of 39

Table D-1: Maximum Allowable Operating Pressure (MAOP) Ratings

Standard PLIDCO Weld+Ends with Single Rows of Clamping Screws*

Coupling

Size

Unwelded MAOP Welded MAOP

(inches)

Coupling

Body Spec.

MPa (psig) MPa (psig)

2

A519 Gr. C

1018-1026

6.89 (1000) 13.79 (2000)

3 A106 Gr.B 6.89 (1000) 13.79 (2000)

4 A106 Gr.B 6.89 (1000) 13.79 (2000)

6 A106 Gr.B 4.80 (696) 13.79 (2000)

8 A106 Gr.B 3.53 (513) 13.79 (2000)

10 A106 Gr.B 2.73 (396) 10.34 (1500)

12 A106 Gr.B 2.26 (328) 8.27 (1200)

14 A106 Gr.B 2.14 (311) 8.27 (1200)

16 A106 Gr.B 1.64 (238) 8.27 (1200)

18 A285 Gr.C 1.73 (251) 8.27 (1200)

20 A285 Gr.C 1.40 (203) 8.27 (1200)

22 A285 Gr.C 1.74 (252) 8.27 (1200)

24 A285 Gr.C 1.46 (212) 8.27 (1200)

26 A285 Gr.C 1.24 (180) 6.89 (1000)

28 A285 Gr.C 1.068 (155) 6.89 (1000)

30 A285 Gr.C 0.931 (135 6.89 (1000)

31 A285 Gr.C 0.875 (127) 6.89 (1000)

32 A285 Gr.C 1.096 (159) 6.89 (1000)

34 A285 Gr.C 0.965 (140) 6.89 (1000)

36 A285 Gr.C 0.861 (125) 6.89 (1000)

38 A285 Gr.C 0.869 (126) 6.21 (900)

40 A285 Gr.C 0.786 (114) 5.52 (800)

42 A285 Gr.C 0.710 (103) 5.52 (800)

46 A516 Gr.70 0.696 (101) 4.48 (650)

48 A516 Gr.70 0.634 (92) 4.12 (600)

48 A516 Gr.70 0.634 (92) 6.89 (1000)

56 A516 Gr.70 0.655 (95) 5.52 (800)

56 A516 Gr.70 0.723 (105) 6.89 (1000)

60 A516 Gr.70 0.599 (87) 5.52 (800)

Note 1: Sizes 2 through 42 inch use silicone packing. Sizes 46 thru 60 inch use Viton.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 36 of 39

Table D-2: Maximum Allowable Operating Pressure (MAOP) Ratings

Special PLIDCO Weld+Ends with Double Rows of Clamping Screws*

Coupling

Size

Unwelded

MAOP

Welded

MAOP

(inches)

Coupling

Body Spec.

MPa (psig) MPa (psig)

8 A106 Gr.B 6.19 (898) 13.79 (2000)

8 A106 Gr.B 6.19 (898) 6.89 (1000)

10 A106 Gr.B 4.78 (693) 13.79 (2000)

10 A106 Gr.B 4.78 (693) 6.89 (1000)

12 A516 Gr.70 3.96 (574) 20.68 3000)

12 A106 Gr.B 3.96 (574) 13.79 (2000)

12 A106 Gr.B 3.96 (574) 6.89 (1000)

14 A516 Gr.70 3.75 (544) 20.68 (3000)

14 A106 Gr.B 3.75 (544) 6.89 (1000)

16 A516 Gr.70 2.87 (416) 20.68 (3000)

16 A516 Gr.70 2.87 (416) 13.79 (2000)

18 A516 Gr.70 3.03 (439) 20.68 (3000)

18 A285 Gr.C 3.03 (439) 6.89 (1000)

20 A516 Gr.70 2.45 (355) 20.68 (3000)

20 A516 Gr.70 2.45 (355) 13.79 (2000)

20 A285 Gr.C 2.45 (355) 6.89 (1000)

22 A516 Gr.70 3.04 (441) 20.68 (3000)

22 A516 Gr.70 3.04 (441) 13.79 (2000)

24 A516 Gr.70 2.56 (371) 20.68 (3000)

24 A516 Gr.70 2.56 (371) 13.79 (2000)

24 A285 Gr.C 2.56 (371) 6.89 (1000)

30 A285 Gr.C 1.63 (236) 6.89 (1000)

or

Buna-N

Packing

A515 Gr. 55

or

A516 Gr.55 1.63 (236) 6.89 (1000)

30 A516 Gr.70 1.63 (236) 13.79 (2000)

30 A285 Gr.C 1.63 (236) 6.89 (1000)

31 A285 Gr.C 1.53 (222) 6.89 (1000)

Buna-N

Packing

or

A515 Gr.55

or

A516 Gr.C

32 A285 Gr.C 1.92 (278) 6.89 (1000)

36 A516 Gr.70 1.51 (219) 13.79 (2000)

40 A285 Gr.C 1.38 (200) 6.89 (1000)

42 A285 Gr.C 1.24 (180) 6.89 (1000)

48 A516 Gr.70 1.11 (161) 6.89 (1000)

56 A516 Gr.70 6.89 (1000)

60 A516 Gr.70 6.89 (1000)

Notes:

1. All couplings are color coded white and restricted to submarine pipe repair.

2. All coupling supplied with Viton packing unless otherwise note.

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 37 of 39

Table D-3: Maximum Allowable Operating Pressure (MAOP) Ratings and Clamping Screw

Torque Values for Special PLIDCO Weld+Ends on Thin-Wall Pipes

Diameter Thickness

Clamping

Screw Torque

MAOP Diameter Thickness

Clamping

Screw Torque

MAOP

3" 0.188 75 310 18" 0.25 50 50

3" 0.198 80 497 18" 0.3 70 90.2

3" 0.208 85 685 18" 0.35 90 130.4

3" 0.217 90 872 18" 0.4 110 170.6

3" 0.227 95 1060 18" 0.45 130 210.8

3" 0.237 100 1247 18" 0.5 150 251

4" 0.156 75 310 20" 0.312 125 80

4" 0.172 80 474 20" 0.3496 130 104.6

4" 0.188 85 638 20" 0.3872 135 129.2

4" 0.205 90 803 20" 0.4248 140 153.8

4" 0.221 95 967 20" 0.4624 145 178.4

4" 0.237 100 1131 20" 0.5 150 203

6" 0.156 30 160 22" 0.25 50 50

6" 0.181 44 267 22" 0.3 70 90.4

6" 0.206 58 374 22" 0.35 90 130.8

6" 0.230 72 482 22" 0.4 110 171.2

6" 0.255 86 589 22" 0.45 130 211.6

6" 0.280 100 696 22" 0.5 150 252

8" 0.188 50 155 24" 0.312 125 80

8" 0.215 60 227 24" 0.3496 130 106.4

8" 0.242 70 298 24" 0.3872 135 132.8

8" 0.268 80 370 24" 0.4248 140 159.2

8" 0.295 90 441 24" 0.4624 145 185.6

8" 0.322 100 513 24" 0.5 150 212

10" 0.188 70 145 26" 0.312 125 50

10" 0.223 76 195 26" 0.3496 130 76

10" 0.259 82 245 26" 0.3872 135 102

10" 0.294 88 296 26" 0.4248 140 128

10" 0.330 94 346 26" 0.4624 145 154

10" 0.365 100 396 26" 0.5 150 180

12" 0.250 75 80 30" 0.312 125 40

12" 0.281 80 130 30" 0.3496 130 59

12" 0.312 85 179 30" 0.3872 135 78

12" 0.344 90 229 30" 0.4248 140 97

12" 0.375 95 278 30" 0.4624 145 116

12" 0.406 100 328 30" 0.5 150 135

14" 0.228 60 100 36" 0.312 40 32

14" 0.270 68 142 36" 0.3496 62 50.6

14" 0.312 76 184 36" 0.3872 84 69.2

14" 0.354 84 227 36" 0.4248 106 87.8

14" 0.396 92 269 36" 0.4624 128 106.4

14" 0.438 100 311 36" 0.5 150 125

16" 0.250 40 57 40" 0.312 50 18

16" 0.300 52 93 40" 0.3496 70 37.2

16" 0.350 64 129 40" 0.3872 90 56.4

16" 0.400 76 166 40" 0.4248 110 75.6

16" 0.450 88 202 40" 0.4624 130 94.8

16" 0.500 100 238 40" 0.5 150 114

10" 0.188 70 145 48" 0.375 125 50

10" 0.223 76 195 48" 0.4 130 58.4

10" 0.259 82 245 48" 0.425 135 66.8

10" 0.294 88 296 48" 0.45 140 75.2

10" 0.330 94 346 48" 0.475 145 83.6

10" 0.365 100 396 48" 0.5 150 92

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Appendix E Hydrogen Induced Cracking (HIC) Decision Tree

SWC = Step Wise Cracking.

t = Wall thickness of vessel or pipe.

Depth = defect depth below nearest surface, whether ID or OD.

(a through i) = See Notes.

Notes Hydrogen Induced Cracking (HIC) Decision Tree

a) Once suspected hydrogen induced cracking (HIC) damage is located, it should be surveyed to determine

the size and shape of the damaged area, whether the suspected HIC occurs as small isolated spots or

nearly continuous fields, and the depths at which the suspected HIC is detected. Such surveys are

normally conducted using ultrasonic examination.

Page 38 of 39

Document Responsibility: Piping Standards Committee SAEP-310

Issue Date: 13 J anuary 2008

Next Planned Update: 29 November 2011 Piping and Pipeline Repair

Page 39 of 39

b) Before assuming that the depth of a defect is less than 0.1 t, the area should be ultrasonically examined

from both inside and outside surfaces, when possible, to insure that additional areas of HIC at different

depths are not masked from detection by the near-surface defect.

c) Hydrogen blistering at mid-wall is a common manifestation of HIC. Such mid-wall blistering produces little

strength loss unless accompanied by Step-Wise Cracking (SWC), in which blisters are several different

depths link up at shear steps.

d) Contact the CSD/ME&CCD/Materials Engineering Unit, for appropriate sample locations and for the

metallographic examination to detect SWC.

e) High, sharply crowned blisters may have SWC around the blister periphery which may be difficult to detect

with ultrasonic examination. Sample such areas as in note (d) to check for SWC.

f) Monitoring of items with HIC normally involves regular and frequent ultrasonic examination of the damaged

area to determine whether the HIC is growing or not. If the HIC continues to grow, periodic reassessment

through the decision tree will be necessary. Hydrogen evolution monitoring is used to check the inhibitor

effectiveness in pipelines. In general, items with a history of HIC should also be internally inspected more

frequently than similar equipment free of HIC.

g) The inhibitor injection rates required for arresting HIC are much higher than those normally used for

suppressing general corrosion. Contact the CSD/ME&CCD, for specific application details.

h) It is assumed that arresting further HIC in plant piping, which cannot be coated in place and may be

difficult to inhibit effectively, may be uncertain and thus replacement will eventually be required. The

urgency of replacement will vary widely depending on operational circumstances and the extent of HIC

damage. Consult the CSD/ME&CCD/MEU.

i) If blistering is extensive, of if SWC is observed, the residual strength of the item is best determined by a

hydrostatic test at a nominal stress of 90% of yield. After revalidation hydrotesting, vessels or cross-

country pipelines with HIC may be continued in service provided further HIC growth is arrested with

coatings, inhibitors or both. Intensive monitoring may be required.

You might also like

- 1 SATIP-L-350-01 On-Plot Piping - Rev 01Document4 pages1 SATIP-L-350-01 On-Plot Piping - Rev 01zooplado75% (4)