Professional Documents

Culture Documents

KTM DUKE 125 & 200 2012 Workshop Repair Manual

Uploaded by

ЮрийКудисов94%(54)94% found this document useful (54 votes)

34K views249 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

94%(54)94% found this document useful (54 votes)

34K views249 pagesKTM DUKE 125 & 200 2012 Workshop Repair Manual

Uploaded by

ЮрийКудисовCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 249

REPAIR MANUAL 2012 | ammo

125 Duke EU

125 Duke DE

200 Duke EU

Art. no. 3206127en

INTRODUCTION 1

‘ad this repair manual carefully and thorovarly be

work

1 vehicle will only be able te meet the denands placed on it the saecitied service

1h 's performed regulerly and properly

We reserve to ake changes inthe i

ing this Tan

We shall no prow de @ descr pt or of gereral workstop methods. likew se, safety rules that apply in @ workshop are not specif ed here

Ie is assumed that :he rep work wll be perfored by 2 fully rained mechanic

G sp

erica

reasons, :o adept

ular medel without prcr netce, KTM accepts no lability for delivery

misprints ard ocher erors, The models portrayed partly contain spe

ape of supply

Al specications are con-bind ng, KTM Spert motor

tions, arices,colrs,f

these fo local craitens, 25 well as to sop preduct en ofp

apt ons, deviat ens from illustrations and descriptions, as wel

hat does not belorg tothe

ly reserves the right to med fy or delete tech

12 KTW-Sport moter

All ighss reserved

Rearodul

owner

180 9001112 100 6062)

ding to the in

fen Austra

tothe maximu

Issued by: TOY Wt

KTM-Sportotoreycle AG

30 Matlighofen, Austra

TABLE OF CONTENTS

1 MEANS OF 2EPRESENTATION 6

Li Symbdls used 6

1 6

2 8 7

2.1 Repair Manual 7

22 Safety adi ce 7

23 sk and sym ?

2a 7

3. IMPORTANT NOTES 8

2.1 Guarantee, warrenty s

32 nd euxilary substances, 8

33 fe parts, accessories 5s

24 Fours 8

4 SERIAL NUMBERS: 8

al ss cumberitype 8

42 Key number 9

43 Engine rumber 8

5 MOTORCYCLE 10

Raising the motorcycle with the rear wheel 2

ereyele aff of the rear wheel

cle with the front whee!

Taking the metoreyce aff of tre front wheel

stand)

le with the work stand

le from the work stand

Starting.

Starting the metercycle to make checks

6 FORK, TRIPLE CLAMP

6.1 Clearing the dust boos ofthe fork legs.

6.2 ReTovrg fork less

63 Installing she for

Disassembling the fork legs

Checking the fork les,

Assembling the frk

Removing the loner =r ple elemp

Inscalling the lower a

Check rg the steer

Adjust ng the sca

7 MANOLEBAR, CONTROL

TL Checking the pay in

7.2 Adjusting tre play

7.3 Checking he clute

7A Adjustiog the clutel

8 SHOCK ABSORBER, SWINGARM

82 Ie oad

8 “4

8

8

9

9.1 Removing the exraus: manifold

Inscalling he exaust ~anifold

Remewrg the main silencer

Insualling he main silen

10 Ala FILTER

0.1 Removirg the air iter

10.2 Installing she a filter.

ANK, SEAT, TRIM

Opening the Fle

2 Closing tre filler cap

3. Remov ng the seat

A Meurting the sea

5 Removing the

8

9

Moursing the p

Removing the fuel tark cover

Insvalirg te fuel t2rk

Removing the fuel tank

alg the fuel tark

Removing the fron: spoiler

Ft rg font spies

Chang re the fuel fer

L117. Replecirg the fuel pump

WHEELS

12] Check ng the Ure alr pressure

12.2 Checking the tre congit on

123 Checking the brake discs.

24 Hon whee

12.4.1 Removing the font wheel

12.4.2 Irsalling the frort whee

2.43 Removing *he brake dsc ofthe front brake

12.44 _ Installing the brake d's of the front brake

12.5 Rear whee!

12.5.1 Removing the rear whee!

2.5.2 Iestalling the reat wheel

1253 2 he on rear brake

12.54 Installing the brake dsc of the rear brake

12.5.5 Checking the crain tersion

12.5.6 — Adjusting the chain tension

12.5.7 Check ng the che n, rear sprockel, 2nd

engine sprocket

22.58 leaning th

125.9 Grecking the rar Pub rubber dampers

WIRING HARNFSS, BATTERY.

18.1. Remouing the battery

18.2 _Instalirg the battery

133 Disconnecting the negat ve cable of the

battery

18.4 Reconnecting the regative cable of the

a

18.5. Rechargng the battery

135 Checking the charging voltage

137 1g the fuses of irividual

sumers

BRAKE SYSTEM

14, ching the fror: brake lin gs

14.2 Changrg the front brake linings

14.3 Checking the brake fluid level ofthe font

14.4 Adding frort brake flu

14.5 Changing the front brake fluid

14.5 Checking the rear brake ln nas

4.7 Changirg the reer brake linings

24.8 Checking the tr of foo: brake lever

14.9 Adjusting the free cravel of the foot brake

fluid level

TABLE OF CONTENTS

rear brake fluid 2

ing the rer brake uid 73

15. LIGHTING SYSTEM, INSTRUMENTS 75

8.1 Setting kilometers er miles 78

Ajesting the shift speed RPM L re

Adjesting tne shi speed RPM 2 78

Setsing the time 76

Reselting the service interval display 76

Checkirg the headlight seting. 6

Adjusting the headliar: range "

CChenging the parking light bul, 78,

CChenging the Peadiigh: bulb 9

16 ENGINE 8

16.1 Removing the erg al

16.2 Installing he engine Ba

16.3. Dsessemblirg tre engine a9

163.1 Preparat ons (128 Duke) 88

16.3.2 Drainrg the engine 0! (126 Duke) ao

1633 hain securing au de (128

59

16.3.4 Removing the vale cover (126 Duke) 90

16.3.5 Removing the soark plug 90

263.6 Removing the clutch 0

16.3.7 Setting the engine to ignition top deed n

163.8 a1

16.3.9 Removing the tim ng chain tens one

Duke}

i the carshatt (1

the

ing the pistor (126 Qube

ing the water pump wheel (125,

Removing the rotor (125 Duke)

Removing the starter drive (128 Duke)

he balancer sraf drive wheel

9a

Removing the alterrator cover (126 Duke)... $5

96

ke)

ing the gear posto

ser (125

ing he spacer (125 Duke)

Removing shee

Removing the prim

Removing the oil ump (2

Removing the shift staf (125

Removing the sift drum loca

Duke} 200

Removing the lacking

Rerevin

Duke}

Removing the shift als (126 Dekel

Removing the shift drum (125 Duke}

Removing the sift forks (125 Duke}

Removing the transriss.on shatts (

Duke}

Removing the balarcer shaft (125 Duke)

Removing the crankshaf: (28 Duke)

Preparat ors (200 Duke)

re the engine o! (200 Duke)

ing the chain securing guide (200,

ye cover (200 Duke)... 104

3

he spark plug (200 Quke) 104

ing the vivich cover (200 Duke) ..... 104

16.3.40 Setting tre engine to ignition top deed

ccerzer (200 Duke)

Rerroving he starter motor (200 Duke

Rerrov ng she iming chain tensioner (260

Duke}

163.43 Rerozing the camshaf: (200 Duke}

16.3.44 Removing the cylinder head (200 Duke}

16.345 Removing the pistor (200 Duke}

163.46 Removing the water pump wheel (200,

Duke} 08

163.47 Removng the alleraser cover (200

Duke}

26.348. Reroving the rotor (200 Du

16.349 Reroving the slarer drve (200 Duke}... 120

163.50 Removing the balancer staf: drive wheel

(200 Duke} no

Rerroving the gear position sensor (200

uke}

Re he epacer (200 Duke} 1

Removing the clu:ch

Removing the pr rary gear (

‘ovng the cil purnp (200 Dul

Reroving he left ergire

Duke}

Rerraving the shift rails (200 Duke)

‘oung the shift crum (200 Duke)

Rerroving the shift forks (200 Duke)

Removing the ransriss.en shafts (200

Duke) 116

Removing the bslancer shaft (200 Duke)... 117

Removing the crarkshaft (200 Dukeb...... 117

k on ind dual parts ur?

Work or the left section of the ergre

82 (200

uy

1642

1643 :

164e 19

645

16.4.6 ranging the

16.4.7 hanging the balancer shaft

Dukel

1648 Charging re

Duke}

16.49 Work or theo

Checking :h Duke)... 124

oslinder (125

164.13 Gheckingimeasuring tne pistor

Duke} 125

16.4.14 Crecking the 9 ston‘eyl rder re.

cleararce (-25 Juke). 126

16.4.1 Grecking the oil pump (125 Duked 126

TABLE OF CONTENTS

Mont 2

cooeahcht bear na (204 ° 16.524

16.438 Werk onthe cylinder nead (200 Deke)

16.439. Crecking th jr head (200 Duke)... 144

164.40 Creckinglmeasuring the cylinder (200

Duke} 144

16.4.1 Checking the

Duke} 148

164.42. heckingimeasuring tne pister (200

Duk 145

6.443. Checking the p stonleyl cder mourting

clearance (200 Duke} 146 16.533

16.444 Checking the 01 pump (200 Duke) 146 1653

164.45 Checking the ell pressure regulator value

(200 Dike} 146 16.535

164.46 Checking the clutch (200 Duke) up 6.5.36

16.441 Preassembling the clutch {200 Dy 148 l653r

16.448 Check ng the shift echanism (200

Duke} 149 16.538

164.89 senbling the shit sheft (200 Duke)... 160 165.39

Disassembling the main shaft (200 16.540

Duke} ip541

Dismantling zhe countershatt (200 Duke).

recking the transmiss.on (200 Duke.

Assenbl rg the "ain shaft (200 Duke)

Assembling the counters 10 Duke

16.4.89 Checking she s ming essembly (260

Duke} 6645

Chang ng the ator (200 Duke) 165.46

6.4.57 Checking the electric starter deve (200 16.547

Duke} 16.548

16.4.58 Checking the reewee! (200 Duke) 165.49

lestalling tre sh ft forks (125 uke)

lestalling the sh ft drum (225 Duke)

lestallng tne shit ails (12 Duked

ling the left 92 (125

lestalling the ail iter (128 Duke)

lestalling the lacking lever (125 Duke)

lestalling tre sh ft drum locating (128

Duke}

lestalling the shift shaft (£25 Qube}

lestalling tne oil amp (228 Duke)

lestalling the primary gear (125 Duke),

lestalling the clutch cage (228 Duke)

(128 Duke}

lestalling the gear pos “on sensor (125

Duke}

Iestalling the balancer shaft deve wheel

(128 Duke}

Iestallig the starter dive (125 Duke)

lestallng tne rotor (125 Duke)

lestallng tne alternator cover (128 Duke)

lstalling te water pump cover (125

Duke}

ng the pston (225 Dekel

lestalling the cylinder head (225 Duke)

lestalling the i528 Duked

lestallng tre t rng chain tens cner (125

Duke}

Adjusting the val

Iestalling the st

lestalling the clutch cover (

lestalling the sparkplug (125

Iestalling the valve cover (

Iestalling the

lestallng ire balancer shaft (200 Duke)

lestalling the trarsmission

Duke}

lestalling tne shi forks (209 Duke}

lestallng the shit: drum (200 Duked

lestalling the shif: rails (200 Dul

Iestalling the left engine case (200

Duke}

lesta

ithe ol ficer (200 Duke)

the lacking lever (200 Duke)

ing the shift drum locating (200

lestalling tre sh ft sraft (200 Duke}

lestalling te oil pump (200 Duke

lestalling the primary gear (200 Duke}

lestalling the clu:ch cage (200 Duke)

lestalling tne spacer (200 Duke)

TABLE OF CONTENTS 5

26.5.50 Installing the gear pos ion sensor (200 23 stone 212

che a0 232 Storage 2:2

lrsaling te balancer shat deve wheal 23.2 reoarng lor vse alter storage 212

(200 bu 24 SERVICE SCHEDU: 2

trstal 24.. Servce sted 2

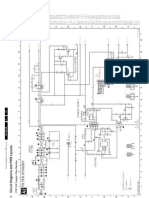

Irstalg the rot (200 Duke 26. WIRING DIAGRAM 2a

Install g the altemator 25.1 Page Lof8 2a

Irstaling he water pump 252 Pate 2018 2

Duke) ; 253 Pape 30f8 2

Urstaling the pista (200 Duke) 25.4 Page 40h 8 2

trstalrg the eylincer read (200 Duke) 285 aye 508 2

ee 2 tre 7 25.6 608 224

rs ap DBP Pate 70 2

258 Pape Bol 8

26 SUBSTANCES

Crecki leararce (200 Duke)... 188

Ausra ce 200 uke) «1882 aupiLnay SUBSTANCES

Irstal the clutch cover (200 Duke) 1gg 28. SPECIAL TOOLS

Italo the sat lg 200 Dae ze Sianoanos

ist (200 Duke °

Ital the chen searing aide 200

bute) 230

Italie i seeen 200 De). 180

Reroung the egne ror the engre

sen sand 000 ule

17 SHIFT MEGHAN

17. Adising te sit er

18 WATER PUP, COOLiNe sVSTEM

Draining he celert

Fingeedg ie cog en is

tere and alan eel» 198

Cesk te cat 5

19 Lueelention sisrew SI

aie o

Chek re ene pessice o

Chang ng the angire ol ard il fer,

clear ng the ol creer

19.5 Addog engine il

20. IGNITION SYSTEM

20.1 Alternator - checking the stator wrcing

21 TESHNICAL nr

21. 125 Duke

212 200 duke

21.3 Engine tolerance, wear | mits

LBL 125 due

2132 200 duke

21.4 Engine tightening torques.

DLS Capec ties

2181 Engrecil

2182 oi

218

216

21? sen,

218 sak

21.10 Shock absorber

2 tighten og tora 207

22.0) ROTEGTIVE TREATMENT

22.1 Cleaning the ratrcyele

222 Checks and mainerance steps for winter

ion 2

1 MEANS OF REPRESENTATION 6

AA Symbols used

The meaning of specific synbols 's described below,

lon (eg ofa work siep or foncsony

an unexpected rt

ion fe.g. of 2 werk step er a furctior)

Pa Ingicates a page relererce (rrore informa cn is provided on the specified page)

Indicates information with mare details cr tps

Incicates the result ofa testing step.

wi Derotes a voltage measurement

w Denotes a curent measurement

The typographical formats used in this deeu'nent are expleinad below

Proprietary name Teerates 3 propre nae

Name® Identifies 2 protected name,

Brand Identifies @ trademark

2 SAFETY ADVICE 7

2A Repair Manual

Read this Repair Manual cavelully and thoroveiy before begin rg work, It contairs useful infermation and tins hat wil help you

reper ard ma ntain your veh cle

This ‘ranval essumres thatthe necess

1y spec al KTM tools and KTM workplace are workshop equ amet ate avalable

A numberof sefety instructions need to be flawed to operate the vehicle safely. Therefore, read this anual carefully. The setety

instruct ors are hgrlighed vthe cext and are refered :9 atthe relevant passages.

= Info

The vehicle has varous formation and watrirg labels 2t prominer: locations. Do not rerneve infermaticnl

they are missing, you of others may rt recogrize dangers and 7ay therefore be injred.

Danger

Identifies a danger that will media

janine labels. It

od iveriably lead to fatal or ser'ous permanent injury i

Warning

Identifies a danger at is kely to lead #0 fatal o serious injury if the appropriate mesures ar not Saker.

ao

Identifies a danger that ay lead to minor injuries if the appropriate nessures are not

Note

Idersiies a danger thet will ead‘ considerable machine and “aterial damage ifthe appropriate measures are nat ‘aken,

Warning

Iersifies a danger at wl lead to environ rental damage i he appropriate meesures are not ‘aken.

‘Special tools are necessary for certain tasks. The tools are not cor‘ained in the vehicle but can be erdered under the number in peren-

theses. & 2: beerng puller (15112017000)

Durirg assembly, con-reusable parts (e.g sell-locking screws and nuts, seals and sel rings, O-ings, pins, lock washers) must be

faciurer instructions for use “ust be falloned.

them for damage and wear, Change damaged or warn pars,

ofthe

‘ter dszssembly, clear she pars tate ob

ler you complete tre repair or service nork

she ooeratng

3 IMPORTANT NOTES 8

BL Guarantee, warranty

The work prescrited inthe service schedule must be cetried out by an authorized KTM workshop orly ard confirmed in the customer's

service record and nm “heKTM dealer.net ctreraise all warrarsy clams will be vows. Ne warrarty claims car be corsidered for camage

result ng fron "manipulations ardor alterations to the veh cle

Additional nfermation on the guarantee or watran'y ard she procedures invclued car be four inthe sere ce record

Warning

Environmental hazard Improper handling of fuel isa darger isthe env ronment

‘= De notallow fuel to get into the ground water, the ground, o the sewage system

Use the operating and aviilary substances (suchas fuel ard lube canis} as specif ed in the manual

Only use spare pars and accessories approved arclor recommended ty KTM, KTM accepts no lablity fr o:her produe's ard ary

result na damage or loss

The current KTM PowerParts for your vehicle can be fourd on the KTM website

Incernatonal KTM Website: htpwww.ktr.com

The figures cantzined in the marual may depict special equipment

In the ircerest of clary, some components may be shown d sessembled ar may nat

‘semi the comporer lo perform the activly in queston, Please fallow the stu

4 — SERIAL NUMBERS 8

irber @ is tayped on the right ofthe steering hes

@ ison she right of the Trae behind the steering hes

The Hey rumber @.

| =—=—0 = Info

| ANI DH You need the key rumber to order

pla

be found ar the KEYCODECARD.

se hey. Keog the KEYCODECARD in =

e075

The engine number @ is stav)ped or the left side

sprocke!

f the engine under the engine

5 MOTORCYCLE 10

‘5.1 Raising the motoreyele withthe rearwheel stand

Note

Danger of damage The parked vehicle

= Always place the veticle on a firn and ev

‘Adapter

Rear wheel stand (6202905

= Stand the motorcycle upright, a

adapters, an It the

2505513011 p. 285)

400) (Fp. 235)

he wreel star

wh the link frk ane the

Note

Danger of damage The parked vehicle may roll anay or fall over

place the veticle on a firm and even surface.

= Secure tre motoreycle aga st 1

— Rerrove the rear wheel stand and lear the veh cle or the side stand @,

e 4

pert of the wheel

Note

Danger of damage The parked vehicle may toll anay or fall over,

= _Always place she vehicle on a firm and even surface

Preparatory work

= Rase the m

Condition

=

le withthe rear wheel stand. (Fp. 20}

ove cap ©.

5

MOTORCYCLE 1"

8 gear ‘0

54

Note

Danger of damage The parke

= Always place the vel

Taking the motorcycle off of the front wheel stand

vehicle may rll anay or fll 0

en sur

cnafirna

= Mount ea

5.5 Raising the motorcycle with the work stand

Note

Danger of damage The parke

vehicle may roll anay or fall oer

Always place the vehicle ana firm and even surface

fhe veh ele

= Mourt spec al tool @ on she right s

Tard Ooe2oSSOOO > p 2ET

5 MOTORCYCLE 12

= Mourt s

cial tool @ on the left side of the veticle

Wark stara (25200500001 (% p. 236)

sition the motoreycle upright, elign the specal tool ard reise the motorcycle

o1ae10

Note

Danger of damage The parked vehicle may roll anay or fall over

- Al

a firm and even surface.

place the vec!

= Secure the motorcycle aga rst falling over

= Remove special tool @

Danger

Danger of poisoning Extaust gases are nic ard irralirg them oray result n unconscieusress ardor death

tres suf

ve exhaust exracton system

= Wren running he engine, aluays rake

ventlatin, and do nat stator run the engire in an enclesed

space witha are

my om

Danger of accidents If the vehicle's operated with a d scharged battery o without a batter, electrer'c components ard sete

equipment may be demened

= Never operate the vehicle with 2 discharged battery or w thout 2 battery

Note

Engine failure Unf lieve

airhas a negative effec

he sence life ofthe engre.

= Never ride the vehicle without an air Fler since dust and wit can get into the engine ard resull in inoreased weer,

Note

Engine failure High ergire spe

n cole eng a negative effect on the service life ofthe engi.

= Always wer up at lw engine s

5

MOTORCYCLE

OQ}

®

0732-10

13

Sion thew

Turn the er ‘wich tothe position ©.

‘Sw tch on the ignition by turning the ignition key

1% Alter you swtch on the ignitan, you

two seconds. The furcton test ofthe combinal on instrument

Shift gear te neutral

1 The green idling speed indicator lame Nig

Press the elec er buiten@.

1d, and move up all the way.

he position ©.

fel pup working oral

ural

mf

Info

De not press the electric s

nation rstrumert is fin

When ster’ eg, OO NOT}

slang procedure, fuel

and the engire

Press te starter for @ maxim of

before ty 8 een

the function est ofthe combi

T you open the tnotle dering the

d by the eng re managerert gysien

nds, Wait fora least § seconds

= ransmiss on is in nevital or

tor seg fine sie stands ld a

lease the clutch, the engine stops,

Danger

Danger of poisoning Extavsi

eahaust

usress ardor death

ye

ventlation, and do nt

run the engive in an enclosed

tater for a maximum of 8 seconds, Wal for @

OQ}

®

eoo7e2.20

Turn the en

he ignition by turnrg the ignition key zo the position ©.

Press the electric starter button ®.

= Info

Do not open the title

6 — FORK, TRIPLE CLAMP 4

6.1 Gleaning the dust hoots ofthe forklegs

A

Push dus: baot @ of both fork les cow wards,

Info

Bo The ous les from the fork

tubes. Over Lime, dirt can penetrate behird the dust boats, If this drt is not

recoved, the oil Sea's ber nd can start to leak

A Waring

Danger af ancidents Reduced brah

brake disc

= Always keep she brake discs free af ol and grees, an

he cleaner niien necessary

= Clean and oll the dust boots and innar fork tube of bath fork le

Taw

= Press the dus: boots back into tre normal os

= Remove excess cil

ToT spray p22)

Preparatory work

= Rase the otoceycle withthe work stand, (@ p. 11)

= Tie the rear of th denn,

= Dismount the fer: fender, (© p. 47)

Main wark

= Reniove seraus @

= Press back the brak Vent

brake d se, Pull she retully

ore side

= Info

fr when the brake cal

er has been renow

De not pull the had b

1s © ered sorew ©.

= Unsoren screw @ abavt sk urns and press your hand or the sera

whee! sp ndle out ofthe ade clamp, Remove screw

-—@ Warning

Danger of accidents. Resuced uraking

ds

sen

by camaged brake

the wheel Gown ic suet 2 way that the brake diss are

the wh Take the front wheel out of

ole binder and heng the wheel speed sersr to are sd,

6 — FORK, TRIPLE CLAMP 18

= Loosen soraws @. Rernove the fork legs from the bottom

iy ne

Danger of accidents Mocificatons tothe suspens en sett ngs can seriously alter the vehicle's ride behavior

= Following modifications ride slowly a Ft :o get the feel of the new ri

Main wark

= Push the fo the tople clamps.

= Align the fork egs in the required pes ior using the fork rings

= Tighter screw @,

eli

Sa nS TING FD

J] - Fully tgnter screns @.

Guideline

Seren, bation ple Garp Te

Position che wheel speed sersor. Mount and t ghter screws ©.

ieline

Fe

ie ann Bee

6

FORK, TRIPLE CLAMP

= Mour

‘a pressure point

The brake

= Fullytighten screw @.

deli

sleigh

16

Spindle

= Lift the front fork, postion tard srt the wreel spindle,

deli

Mont weal sp ale ne 25 Nm

(8.4 tot

= Position the treke cal pers ard check thatthe brake linings a weeily

= Mourt screws @ bu do rot tighten

ted until the brake linings are in contact wth

Tron brave cal

Tote 243

1 Fxation of

ad the rear of

1 motoreycle fre

the front brake ard com

legs siaighten.

= Tiahten screws @

Guideline

Screw, Fak sub rr rT

Te

64

Finishing wark

= Intell Front fender p. 47)

Disassembling the fork legs

operat ors are the s

Jn both fork eps

Condition

he fork lags have been remrved,

a of the lo

ak leg in the

Clampre sand TOLOSH™ p24

POLED

6 — FORK, TRIPLE CLAMP

Empty the

Devaeh the

Info

Unclamp

ark il

wth the fork tut,

outer tube from the iprer tube

ne inner tube, Drain the ol

we the screw cap

6 — FORK, TRIPLE CLAMP 18

ring ®.

Info

The lock ring

rer can be appl

2018

= Remove seal ring @ Remove support ring @.

h

ust fall out af

tube ona

a

n board

Y Sire bushing ®

1 -

i pois:s.20

6.5 Checking the fork legs

Condition

he fork lags have

a

20186.

6 — FORK, TRIPLE CLAMP

19

Charge the fork

Measure the run-aut of the inner tube

Measure the outside diameter of the inver tube in several places

Exernal diameter f iver tube 975, 48.005 wm (1 69193

16981) ry

+ WF the measured value ig less than the specified value

Ru-out of nner ube

©020 nm EOOOTI NT

Cha

ge the fork leg

2cKs50

op

k the euter tude for damane.

It Garrage ' found:

Change the fork leg,

= Gheck the surface of the slicing bushings.

IF the dark layer @ is worn

= Charge the fork

Ifthe measured velue is greater tran the specif ed valve

fork eg

Preparatory work

= Creck the fork lees. (7 p. 18)

Main wark

=" Clamp in the inner ‘ube with the axe clam

Guideline

P

Use soi js

Grease and slide or dust boo

a

Tobrean TST

Info

We always charge tne dust boot, ook

Install the dust boot with the sean

werd

I rg, ard support rig.

wlip ard spring exparder Fac re down

6

FORK, TRIPLE CLAMP

Slide on lock ring @,

de or seal ring @.

20

Lobrean SLD

= Info

Mount w ch the sealing ip f2cirg down and the oper s de facing up.

Slide on suppor: ring ©.

Sand the edges of s ding bushing @ w th 600- drive (SO TPSOBOGOOI I p. 2407

= Renove wasrer ®,

Remove steer ng head bearing ®.

= Re

ce the lower tr

clamp with t

lamp

Main wark

= Ob s, check for damage, ard

- th the steering stem

= Mourt washer @ with the cut-out facing dossnsard

Alternative 1

Arew steering head bearing is used.

= Mount and tighten the nut ®,

Guideline

Mat, searing Pe

Nm (37 Itt)

Case nul wach

G01 750501

OF

Altomnatve 2

The steering head bearing is used again

= fount and tighten the nut ®,

greet ¥ Sm GFA

6 — FORK, TRIPLE CLAMP 2

Caste nul ore

mop aa)

= Positir the upper tr ple clamp wh the handlebar

sher but do not Lighten it ye.

Tie

BON

(38.4 bor

TINn BIE

= Plug r conrectors @ ard @,

= Plug r conrecters ® and ®.

6 — FORK, TRIPLE CLAMP 25

Fold the headligh ask up.

= Mourt and sighen

Guideline

‘Sereu_ hezdlaht mask We

Tne A

Mount expanding rivets ® on tot

Testall te fork

(pl

Using a pleste he

Tighten screw ®,

er tap lightly en the upper triple elem to evo strain

Guideline

‘Screw, top Seerng heed G2Nm

(38.4 bor 1)

Tighten sa

Guideline

Seren, op wiple damp cE Tele AT

Finishing work

=. Check thatthe wiring

Ireedor of moven

= Check ng head bearing lay. (* p. 25)

dt pL

a ine

Danger of accidents Uns ile handlieg from

= Adjust the steering Feed bearing play withcut del.

= Remove the matoreycle from the werk

Info

th play 1 the steering head bearing, the bea

Proparatory work

= Raise the motorcycle with the werk

Main wark

= Move the handlebar to che sira ght hes ot ron

the ciection af trax

abe he steering head bear

t

= Adjust tre play of the steering nese bear ng. (Fp. 26)

Move the hardletar to and fo over the artire

ove easy over the ene Seer

iceable,

6 — FORK, TRIPLE CLAMP 26

click positions are naiceable

= Adjust the play of the steerng nese bear ng. (Fp. 26)

= Check the steering heed bearing and change if necessary

Finishing work

= Rerrove the motoreyele from the work stand. ¢% p. 1

Preparatory work

~ Raise the “otoreycle withthe work stand. (Fp. 11)

Main wark

sen serous @,

= Loosen serew @

= Tighter nut © withthe special tool until there ro play inthe s

ing,

Ke

Ser ng Fed bearing (501:

OOOH p. 240)

= Using plastic hammer, tap lightly er the upper triple clamp to

= Tighter screw @.

Guideline

‘Screw, top Seerng heed CON

8.4 tof ty

= Tighter sew @.

Guideline

Seren, led

m7 cE

Finishing work

= Check the steering heed bearing play. ( p. 251

e the motoreycle from the work stand. ¢® p. 12}

7 HANDLEBAR, CONTROLS 2

‘TA Checking the playinthe twatle cable

= Check the throttle gr p for smeoth operation

— Move the handlebar tothe ss gh-ahead pusition, Move she th

wards and forwards to ascer y the thratle cable

wearin

Troe cable play Sn ommia02 a

e throttle

= Adjust the play in the throttle

le play does not mee: sp

ble. (p27)

Danger

200392.10 Danger of poisoning Exhau

in urcenseiousness andor des*h

= When runring the engine, alvays make sure there is sufficient verve

ton, anc do nt startorrun tre engine in an enclosed space w thout an

effect ve extaus: extract on svster,

— Siar he engine and let ¢run idle, Move the handlebar to ard fro over the entire

steering ra

The idle speed must

More the handlebar to the straighter

Push beck le

sen tek nut @

= Agius the play she thot cable ty tring adjusting scren ©.

videtine

rote cable ley asa O12 027

= Tiahten lock @.

= Side on sleeve

the clutch lever for smooth operation,

= Move the hardlebar tothe sa ght-ahe:

ascertain the clutch

Clutch lever play Td mm 04, O12 in)

+ Wthecluteh lever

= Adjust the clutch cal

position. Lightly pull the cluteh lever

ions

Note

Clutch damage If there is no pley on the cl the clutch will beg ta sip

= When operating the motoreyele, always check the clutch Fever play

= Move the Pardlebar fo and fo over ing range

The eloch lever pl

‘Ua nol charge

+ [the clutch lever play changes

= Check the rout ng of the clut

7 HANDLEBAR, CONTROLS 28

e

Pust tack s

nut @.

Adjust the play in the cluch level @ by turning adjusting sciew ©.

8 SHOCK ABSORBER, SWINGARM 29

8.1 Adjusting the spring preload of the shock absorber

Warning.

By sangerotaccitents ovat on he susgonson se res can serusy ae side bebavion

= Following modifications ride slowly at frst :o get the feel of the new ride bet

Info

The spring preload defines the in Jal situation of the spring process on the shock atsorber

The best spring preload seting ig ach eved when its set for tre neigh of the r der and that of ary bageage and a passenger,

thus ersuring 21 Geal compromise between aneuverabil'y ard stabil y

— Ture adjusting rng @ to adjust the spring preload.

Guideline

‘Spring preload

Slander

Fall payload Bclicks

Hi

conch (TTO6SH p. 2417

= Info

The spring preload can be set to 20 different postions

Preparatory work

= Raise the rotor

Main nat

= Re

le with the work stand. (© p. 11)

Info

Proveet the link fork 2

Ersure thatthe chain and brake | re re na

tachments from

= Renove fiting @

— Lift the link fork ar sake out the shock absorber @ toward the rear

Main wark

= Lifs the link fork snd position sheck abseroer @

= Mourt fiting © but do rot tighter ye

Guideline

Fiting, bottom shock absorber TOE

sw

(33.2 bot ft)

8 SHOCK ABSORBER, SWINGARM 30

= Lift the link fork

= Mount and tighten screw .

Guideline

‘Screw top shock absorber WoL 25 ONT

(35.5 tet

= Tighter Pting ®.

Guideline

iting, bolton shock a WOK 25 Wm

(33.2 tot ft)

Finishing work

= Rerrove the motoreyele from the work stand. (& pL

Condition

The shock absorber has been removed

= Clamp the stack aasorber in the vise usrg soft jaws for pretect en.

= Note the position of tre spring preload

= Looser adjusting ring @

Hook wrench (11065106 p. 241)

= Clamp the stack absorber inte the special too

‘Spring cornpressor (TLAOBOS) I p 242)

= Info

Use the ring of she special tool with the smallest poss ble inside @ameter. IL

mustbe pressed d rectly arto the spring,

= Sonpresthe re

= Rereve spring eta rer®,

= Release te spring Reravet

= Remove the spire

85 Instalingthe spring

= Mout the spring

shack absorber from the spec al tool

A The ight col of the spring atthe bottom.

Clap the shock absorber into the special tool

‘Spring compressor (ILAOSOS) (ep 2A2)

= Info

Use the ring of she special tool with the sna

must be pressed d actly ara the sper

9.

7 The open eres oppeste the

Release she spring. Remave the skack absorker fom the spee’al tel.

= Clamp the stack aasarber in the vise using soft jaws for protect on,

lest possible inside Gamer, It

Mount sori

8 SHOCK ABSORBER, SWINGARM 3

Alternative 1

‘= Tersion tre spring ‘othe prescribed pesitior by turing the adjusting rg

ieline

Spring preload

Sianda

Full

Hook wrench (TT

Altemative 2

i ne

Danger of a

cushy alte

we 2

9 EXHAUST 32

my ne

Danger of buns The ice is driven

hot components

or forward slighly

‘ove the cable binder, expose the corrector @ of the lambda probe, and

= Reove lambada sensor ®,

= Remove te culs ©.

33

ve tre exhaust man fold toward th frort

sition the exhaust manifold

nt nuts @ but da ot tighten hem ye

Guideline

Tit, exvaust Nange (128 Duke} 1 ZN

(262 bor

it, exhaust any 18

Onna

1 ZN

(6.2 or

5

‘Mount and tighten lamb

Guideline

Tair Wigs Lubre:

Plug in connector @.

Secure the cable with the cable pincers,

9 EXHAUST a4

Nut, reciator We ERIERAEG)

Proparatory work

wen

= Remove the front spe le

Mai

= Ri

= Remove

© Info

Bde not mse

coward the bottom,

9

EXHAUST

35

Main ark

=. Position the main slencer

= Mount end vighten screw @.

Guideline

‘Serou, Tain STeneer

ua

2am AT eT

= Mount and tighten screw @ with the

‘Séerew main slencer

= Mount and tight

Guideline

ew © with the washers

‘Serou an Sener

rg

SLR

Finishing wark

= Fithe front spoler (p46)

= Irstal the exhaust manifold. OF p. 3

10 AIR FILTER 36

1O.4__-Removingthe aifite

Note

Engine failure Unf lied intake air has @ negative effec: 0

ehicle without an air flr since dust and wit can get into the engine ard resull in inoreased weer

he service life af the engi.

Proparatory work

riferrove the passenger seat. p. 38)

= Remove the se

Main wark

=. Renove st

= Pull the air ft

tothe sde

= Revove ar titer @.

=. Clean the air filter box

Main mark

Pesivon ar flier @,

Mount air fter bax tid

Info

Moke sure

he air iter box Id seated comectly,

= Moor

Guideline

air flte bow

i tighten screws

EN a Tata

Finishing work

= Mourt tne seat (© p, 38)

= Mourt the passenger seat. p. 38)

11. FUEL TANK, SEAT, TRIM 3

Danger

Fire hazard Fuel s ghly flanirable

es or burning cigarettes, and always snitch off tre orgie frst, Be careful that no

miparenis, Clear up spilt fuel mrmeciatey

scage ifthe ark severed, Si

fuel s spilt, especially

= Fuel nthe fuel tank

Warning

Danger of poisoning Fuel spo'sorevs and 2 health hazard

— Avoid contact between fuel and skin, ees and clothing. 90 not inhale

ately wth water and contact a doctor, Wash affected skin areas mired

tacts doctor mmediztely, Change cletrirg that fas come inta carta

to regulations and heep it out of tre reach of

ds when warm and c he notes or refueling

Warning

Environmental hazard. I proper handling of fuel is

und water, the ground, of the sew

ger te the environment

em

= De not allow fuel to get ito the a

= Lift she cover @ of the Tiller cap and inser the ign ian key in the

Note

Danger of damage Ignition key breskeze

sh dow on the filler cap

= To the pressure off of the igrtion key

tion keys must be replaced

= Turn the ignition bey 90° clockwise

= Open the Filer cap,

= Remove the grtion bey,

Warning

Fire hazard. Fuel s highly lanmadle, po soraus ard harmful te your

health

= When closing the filer

clothing that came in

came contact

fuel using soap and water

the filler cap.

= Push down the Filer cap until the lock engages.

Preparatory work

= Remove the passenger seat. (7p. 28)

Main wark

= Reniove seraus @,

= Raise the rear of the seat, pull towards the rear, and renow it uowards

11. FUEL TANK, SEAT, TRIM 38

11.4 Mounting the seat

Main wark

=. Flech seat recesses ® 2

= Mourt ard tighten screws

2s @ and loner at the

ue Nas

Finishing wark

= Mourt the passenger seat. 1% p, 38)

11.5 Removing the passenger seat

11.6 Mounting the passenger seat

16 @ on the subframe, ard lower it

rte place

Warning

Danger of accidents. The p from the anchoring

if tis not mounted conectly

= Alter ne check that i is locked correctly ay

pulling u

- heck th ns

11.7 Removing the fuel tank cover

Danger

Fre hazard Fue

= Never tes, and always snitch off the engine fist. Be careful the

fuel s spil up spilt fuel mediately.

= Fuel nth warm ard can escape ifthe tark overt he nates or refueling

11. FUEL TANK, SEAT, TRIM 39

Warning

Danger of poisoning Fuel s po'sorevs and 2 health haard

= Avoid contact between fuel and skin, eyes and clothing, Do rot inhale fuel vapors. If fuel ges into youre

ately with water and contact @ docter. Wash affected shin areas med ‘ely wth scap ard water, If felis swallow

Cra tact with fuel. Stoe fue in 2 suitable car ster a

es, rinse immed

facta docior mediately. Crange clotirg that has cone

to regulations and heep it out of tre reach of

Warning

Environmental hazard. Iproper handling of felis @darger to the eneonmert

= De not allow fuel to get to the ground water, the ground, oF the sewage sytem,

Preparatory work

= Remove the passenger seat. (% p, 28)

Remove the seat. (€ p. 37)

Create the tool (special screw)

Four ordinary serevs are needed

= Curl sere © to length @,

Tena ® a0 nm 1167

= Cute slot nto the top end of she screw,

ind dually and replace therm with a spe

01d distorting the fue lark.

and tighten spec

e.

ier another special screw @.

11

FUEL TANK, SEAT, TRIM

40

= Remove screw ®.

Mount and tighter anather special screw @,

= Open the filler cap. p 37)

= Renove filer cap ©,

Fy — Remove screws © with the washers

— Renove seraus ©,

= Remove screws @,

= Remove cap @ fram the compensating tank

— Renove seraus ©,

11. FUEL TANK, SEAT, TRIM a

Lift the fuel zank cover.

= Detach the side c

oF beth sides

= Push back pose clamp ®

= Pulloff she ven: hose

= Remove the fuel tank cover

= Close the fuel tank with 2 su table plug

Danger

Fie hazard Fuel s ghly llavwrable

fe ergire first, Be careful that no

Up spilt fuel me

escape ifthe tank s overt

2 he nates or refueling

Warning

Danger of poisoning Fuel + po sorces and @ health hacer

— Avoid contact between fuel and skin, ees and clothing. 90 not inhale

ately wth mater and contact a doctor, Wash al

lect doctor mmediazely, Crange clo

to regulstions and keep it out of tre

swallowed, com

riser according

Warning

Environmental hazard. Ieproper handling of fuel is

= De net allow fuel tc get ito the ground

Main wark

=. Remove the slug

11. FUEL TANK, SEAT, TRIM 2

Position the fuel tank cover

Attach the side cover on both sides

= Mourt ane sighten screws @,

Guideline

Reva nr Sores, Chassis We sna eT

— Mourt filer cap ©

ce then with serene @.

a serons © inciv dually and 1

Info

HL stways replace the serews rd vidually, or the fuel tank wil

di il the screws,

be possible 9

0 Thm BTL

11. FUEL TANK, SEAT, TRIM “3

= Mount plug@

= Mourt ane sighten screws @ with the washer.

Guideline

‘Screw foal tk We TINn eID

= Mourt ane sighten screws:

Guideline

‘Sereu, fal anki Me in (8.7 AD

= Mourt and sighien screws.

Guideline

‘Screw, ont seat Dine NG SAT

Finishing wark

= Mourt tne seat, (* p, 38)

= Mourt the passenger sest. IF p. 38)

Danger

Fire hazard Fuel 9 ghly flavwrable

= Never refuel the vetile n

fees spilt, csp

=r flmes or bucring cigarettes, and elways sm

ally on hot veh cle compocents, Clean up spill fuel rmmeiately

ff tre engine first. Be

= Fual rhe fuel tank expards wher ifthe ark soverfled, See she nates or refueling.

Warning

Danger of poisoning Fuel po soreus and

5, rinse immedi:

aly wth sosp ard water I uel is swallow

with fuel, Slow feel in 2

Warning

Environmental hazard proper handling of fuel is a darger to the env ronmart

= De not alow Fuel to get ito the ground water, the ground, or the sewepe system,

Preparatory work

— "Remove the passenger seat. (* p, 28)

= Remove she seat. (Fp. 37)

= Remeve the fuel tank co

(9. 38)

11. FUEL TANK, SEAT, TRIM 4

Main nark

= Renove screws @,

= Toke off the holder ©.

= Detach eo

Dezzeh the fuel line with 2 suitable tool

= Push ba

Pol off the

and rerove the fuel tark

11. FUEL TANK, SEAT, TRIM 45

Danger

Fire hazard Fuel s ghly flanirable

- hi g

fuel s pil cle comparents, Clean up spilt fuel rrmecively.

= Fuel inthe fuel tank expargs wher warm and can escape ifthe tark ‘ overfilled, See

Warning

TA vance cf poisoning. Fuels posorausan Sh hazard

= Avoid contact between fuel ang skin, eyes and eleshing. 90

ately wth water and contact a doctor, Wash alfecied skin areas

tacts doctor mmedizcely, Change cletrirg th has come inta cart

to regulations and keep it out of the resch of ch laren.

Warning

Environmental hazard. [proper hand!

= De not alow fuel to get ito th

environment

of fuel isa darger to

und water, the ground, or the som,

Main wark

= Connee the fue

= Pesiton hose clarp @,

Remove tool ©,

Plug in con

ition the fuel tank

on the haluer @,

11. FUEL TANK, SEAT, TRIM 46

Mourt ane sighten serens @,

w tighten sorens @,

Guideline

EFL conch ui wa Tm BAT

Finishing work

= Irstal he fuel tank cover. (% p. 41)

= Mourt tne seat. (© p, 38)

onger seat. (Fp, 38)

11. FUEL TANK, SEAT, TRIM a

= Mount

We tighten screws

Guideline

Reran rg se

ei, NESS i DONT TAIT

= Higher screw @,

Guideline

Reman rg screws, chasse ne DONA aI A

Remove sorews @, Remove the front fender

Positios the font ferder. Maur

Guideline

tighten sex

‘Screw front fender Me TIN (G1 FR)

Danger

Fre hazard Fue

mes or burning cigarettes, and always svitch ol

snporens. Clear up spilt fuel mrmeciately

‘ds wher warm ard can escape ifthe tark ‘overfill, S

fe ergire first, Be careul that no

= Fuel in the fuel tank

he notes or refueling

Warning

Danger of poisoning Fuel s po'sarous and = healt

— Avoid contact between fuel and skin, eyes and clothing, Do rot inhale fuel v2

ately wth mater and contact 2 doctor. Wash affected shin areas mired

tact doctor mmediztely, Crange cloth that has cone into carta

lo regulations and keep il out of the reach of cil

acer

pors, I fuel gets into your eyes, rinse immedi

wth scap ard water. If fel 1s swall

with fue, Sto fe! i

Condition

The fuel ‘ank s completely full.

Ersure thal the battery vllage does

he gnsior sch

The diagnostics tools connected

drop below

11. FUEL TANK, SEAT, TRIM

Sout

Derzeh the fi

Push back Fos

re with 2 suiteble tol

1p @ er pull eff the fuel ire

Mourt spec al tool @,

48

Pressure testing 0

som

Tp 228)

Mourt spee al teal © with nozzle ea

Testing fox

Guideline

Minima

TOMe5 US eh

Sw teh the ignition

rol unit"Motranik Bosc

Press "Continue

Select "Actuator test

"Please entr the passwort"

Press "Continue"

Solect Fuel pump relay function test

Press "Contin!

Te che KT dagr

wth "Continue"

Guideline

the information page and

he actuator test

Mex doalion ot acum test [3mm

vel pressure wah the filler ca

ro

hen the fuel pump ac

© bar 36

>If the specification is nat rezched:

nthe fille cap. (7 p. 37)

= Check the tank air vert system,

(Check the fuel pressure withthe filler cap open,

Foal press

When the fuel pump is active

Ifthe spes fication snot reached

= Check tat the fuel lie el

= Change the fuel fe: (p43)

= Replace the fuel pun. (© p.

jop he "Function test of fue! pump contr" 2

ton,

Dsmantle the special to

test by pressing

uit" but

11. FUEL TANK, SEAT, TRIM 49

= Gonneet the fuel Hine and ps

= Remove the to

Danger

Fire hazard Fuel 9 ghly flavwrable

1 oper

= Never refuel the

mes or burr 5, and always sv fe ergire first, Be careful that no

i ‘ot ven cle conparents, Clean up spilt uel mmediately

= Fuel she fuel tank expar if the tark s overfiled. See the nates or refueling,

Warning

Danger of poisoning Fuel spo sorvs and 2 health hazard

— Avoid contact between fuel and skin, ees and clothing. Do rot inhale fuel

ately with water and contact a doctor. Wash alfecie skin areas mired ately w ths

lect doctor mmediately, Ci has come into cartac: with fuel, Stow (vel i

lo reguletions and kes

Warning

Environmental hazard. Improper handing of fuel is a darger to the env ronmrt

= Be net allow fuel to get ito the ground water, tre ground, or the sewage system.

Preparatory work

= Remove the passenger seat. (* p, 28)

= Remove she seat. (7 p. 37)

= Remove the fuel tank cover. (% p, 38)

= Dismount the fuel tank. p. 43)

= Drain the

Main mark

= Toke fuel fier @ out of the holder

uel from the fuel

k into a suitable co

3018871

Remove hese clamp @ ard pull eff the fuel hose

11. FUEL TANK, SEAT, TRIM 50

sition the fue flter

Connection @ faces tothe lef

= Positian the fuel roses and mount nos

= Position hose clans ©.

co fuel filter @ ir che holder

o1aa

Finishing work

= Irstall te fuel tark.(% p. 49)

= Irstal he fuel tank cover. (& p. 42)

= Move! the seat. p, 38)

Mourt the passenger sest. p. 38)

Danger

Fire hazard Fuel sh ehly flee

= Never refuel

fuel s spilt, esp

= Ful he fuel tank exp

igarettes, and zluay

miporents. Clear up spilt fuel or

is wher warm ard can escape ifthe ‘ark s verflled, See the notes or refueling

off tre engine fist, Be careful thet no

my ee

Danger of poisoning Fuel s po-sorcus and = health hazard

= Avoid contact between fuel a

ately wth mater and contact 2 doctor. Wi

lect doctor medi

lo regulations and keep it out of

hing. Do rot inhale fuel vapors. If fuel ges into your eyes, rinse immed

shin areas miredataly wth scap ard water. If fuel 1s svalicu

nie into cartact with fuel, Store

Warning

Environmental hazard Improper handling of fuel is @ danger te the

= De not allow fuel to get ito the aroun

Preparatory work

= Remove the passenger seat. (* p, 38)

= Remove the seat. (® p. 37)

Remove the fuel tank cover. (& p, 38)

= Dismount the fuel tank. (% p.4

= Dain the fuel from the fuel rk into a suitable container.

Main ark

= Rens 5@,

= Remeve the fuel pum with

301939.

11

FUEL TANK, SEAT, TRIM

0180,

pump with the

ns @ ered tighten them di

51

Slat

Ter

Finishing work

= Irstall te fuel tark.(% p. 49)

= Testa he fuel tank cov

seat. ( p38)

= Move! th

= Mourt tre p

(p42)

LU p38)

12 WHEELS 52

4124 Cheeking the tie airpressue

= Info

Low tre a pressure leads to abnorral wear ard overheating of he tre

Correct Ure ar pressure ersures optimal rid rg cerfor: ard trax rum tre service life

eRe,

Front

ear

Gas

Bos

Tre ar pressure with passennerul pay

Front ps

Rear (SZ esi

= lie tre air o ions

= Correct t

Mount the dus: cap,

Warning.

Danger of accidents Uncontrollable vehicle Farag in the event ofa flat tie

= Ie the interest of safety, replace damaged er worn tires immediately

Warning

Danger of crashing Por vehicle handling dve te different sire tread patterns on front and rear wheels

loss of cor‘ol over the vehicle

= The froot ard rear wheels must be fitted with tres with sim lar ‘read

lems to p

Warning

Danger af accidents Uncon‘olletle handling characrarstic dus to nan approved andlor non-racem™ended *resiwheals

= oniy

Ihe eorrespor ding speed index should be used

Info

Do the type

Worn tires

ye @ major impact. on the riding behavior of

pecially ar wet surfaces

we motorcycle

= Check the front ard rea ties for cu

+ Ifthe tres exhibit cuts, run-in obj

= Change the tres

= Chack the depth ofthe tread

rur-in objects ard ether damage

or other damage:

Info

Note local nat onal regulations cancer ng

sonia Minimo we2d deh 22 em @ OORT)

1d depth 6 less than the eminrrum permissible depth

re te bres

Info

The tre's date of the manufacture is usually part of the tre markings and is

ingicares by the last four dgits of the DOT marking, The fist two digs refer

tothe week of manvizccure and last two digits reer to the year of manufas

KTM recommends thatthe

atthe lates after 5 years,

3 are chenged regardless of the actual weer,

12 WHEELS 33

+ Mathes more tha

years old

= Change the tres

i ine

Danger of accidents Resi.ced braking eff ciancy due to worn orake vise)

= Charge the worn brake disols) wthout delay.

= Check the thickness ofthe fron: ard reer brake discs al s

lo see if confers to messurement @.

I places or the disk

= Info

Wear reduces the th ckness oft

@ of the brake disc

ake dis in ar

Brake dies weer It

Ze nm O12

Bem (0.192

95 ig lass than the sei ed value

= Change the brake discs,

hack the font and rear brake discs fa

» I the brake dso shows signs of dara

the brake

crackirg, and deformation,

cracking, or deformation

= Changs cs

12.4.1 Removing the front whee!

Preparatory work

= Raise the metoroycle wit the rear wreel stand. (Fp. 10)

= Raise the ‘otereycle with the font wheel stand. p. 10)

Main wark

= Loosen screw @ and serens ®.

© 2bout si turns and press your hand or the serew to push the

= Unseren sox

‘wheel spirale out of the axle clap, Remove screw @,

Warning

Danger of accidents Reduced braking ef ed by damaged brake

discs

= Always lay the wheel dow in such 2 way thatthe brake dses are not

ores. damaged.

the wheel spre. Take the font wheel eut of

= Hold the fort wheel, withar

the fork

Info

BE be not pull the hand

wher the front wheel is eeneved

12.4.2 _ Installing the front whi

i rine

Danger of accidents Reduced traking efficiency due weil ora

= Al

beep the brake d ses fee of ol and grease, end clean ther wh brake cleaner wh

12 WHEELS

Main nark

Check

wheel be

el bearing is dam

Change the

n and prea

4

ing for damage ard weet

zed oF worn

lean the

Lift the fran

The brake linings are in contact wih

port

sland pL

herd on the fork several tres to align

iS Wm

Ie)

Finishing work

ake the

12.4.2 Removing the brake disc ofthe front brake

Proparatory work

bead sand, (Fp. 1

= Paso tre he rear wreel stand. (Fp

Rae th fand. (% p. 10)

Main wark

= Remove screns @.

= Rerrove the broke dise

12.4.4 _ Installing the brake disc of the front brake

Main wark

facing outward

ie 7aNm Tectia

(22.4 tbs tt)

Finishing work

= Irstal she front nbel. (© p. 83)

= Take the motorcycle off of tre rear weal stand. (% p. 10

12 WHEELS

85

12.5 Rear wheel

12.5.1 Removing the rear wheel

Preparatory work

— "Raise the motorcycle with the rear wreel stand. (Fp

Main nark

= Remove nul @end the washer. Renove chain adjuster @,

= Holding the rear wheel, w hd

wh

= Push she ear wheel forward 2s far 8s pass

spracke

Warning

Danger of accidents Reduced trahing elect caused by carmaged brake

diss

= Always lay the te

damaged.

ses are

istemoved

12.5.2 Installing the rear wheel

ay ine

Danger of accidents Reed. ced brakiny

= Alnays keep

e brake d ses

‘ne

Danger of accidents No braking effect wh

= Aller

vb rubber dampers. (Fp

ing for damage ard wear

el bearing is damaged or warn:

= Change the

support ang swingarm

= Irstall the rubber darrper ard rear sp

he rear whee! in the swings

= Position the rear wheel ov she contact surfaces in

= Push the rear wh

sprocket

12 WHEELS

= Pl the rear wheel back and mourt whee

Info

BH sount the lef

= Moun: not @ a

= Push the ear wh

tiah:er nut @,

Guideline

86

Tr order fer the rear wheel be cowecily

right chain adjusters rrust be in the save positon relat ve

rnarks ®,

Tut, rear wheel spindle Was ON

(443 ory

Finishing work

= Teke the meter stand. (7 p

12.5.3 Removing the brake dise ofthe rear brake

Proparatory work

= Rase ihe rotorey

= Remove the rer

Main wark

= Renove

wheel

and. p

ser20s @,

— Remove the brake disc.

1805

12.5.4 Installing the brake dise of the rear brake

Main nark

n the contact surface of the brake disc

= Position the brake dis with the label facing cubward

= Mourt and tighten screws

ideline

rake tise | MB 2a Nm

awn

Toctiie™ 243

301805.

bead sand, ( pI

12 WHEELS 3

42.5.5 Checking the chain tension

my ee

Danger of accidents Dager caused by incor

=H the char

ings in rar

rupture othe eou

sprocket or the rer sprocket and bl

hain slidirg guard, press the chain upward toward the link

in tension

Info

Hh The upper chain © rust be tau

Chavo wear is not 0 yOu should renezt this measurement at

different chan posit

Chan sensi ba Fm, O28

Tithe chain tension ns

= Adjust thea

12.5.6 Adjusting the chain tension

a vine

Danger of accidents. Darger cau

= lithe a

ings traci

rupture or

y powertrain (chain, engine spr

‘par from premature wea i ar

and, i Foose, i

or darrage the engin, hain tension an

Preparatory work

= Check the chair tersion. (Fp

12 WHEELS

58

Main nark

u

Tu adjusting soreas © o7

and right

maths @. Tre reer

ster © are the sae posi an in lato

ys even, $0 you should check the seting al diferent

Tighter nuts @.

ure tha chain adjusters @ are fitted corectly on anjusting sorens @,

Nut, rear wheel spindle

Wie

ON

(443 ory

12.5.7 Checking the chain, rear sprocket, and engine sprocket

= Chack she rear sprocket and eng re sprocket for nea.

If the rear sprocket ang eng)

DE: of Se

The engine sproc

replaced tngere

= Shift gear ton

ehi®,

15g ST

in Ls i

o you should renest this measurement at

Taaimum

aban se

elongest [30

ithe distare

an the specified

= Change t

~ 7 Info

CHEK -—--COCD I ed, the ear sprocket and er

123 181920 s

arose New chains wear out faster on old, worn spre

12 WHEELS 59

= Reno © and © end reer

Sh the chain guard aside,

the chain sliin

hat the chain

Ifthe chain siding

BOT Pe Nim OF AD

BOT PT A Nm Bel

Tin Soren, CHAS Sha Ga

12.5.8 Cleaning the chain

i ne

Danger of accidents i ore

= Revo

a ie

Danger of accidents qi ney the orake ¢

san them wh brake

leaner whey

12 WHEELS 60

Warning

Environmental hazard He

ardous subsiarces cause env ronmental damage

= Gil, rease, flees, fuel, clearer, brake flu

ele., should be disposed af 2s stipulates in ap

nits maintenance

lean the chain regulanly

= Rinse off loose drt witha soft ie

~

old grease remains with cha

Char cleaner p

= Aller drying, apply chain spray

Ghar lube forroad ise

12.5.9 Checking the rear hub rubber dampers

Info

Proparatory work

= Raise th wheel stand. (Fp

Main ark

=. Check bearing @.

If the bear ng is damaged or wor

= Change the bearing.

Check the rubber dampers @ ofthe reer hub for da

re dame

hub

IF the rubber dampers of the rear hub

= Change all rubber dampers in the

facing upwards and

and tny to rorate the rear spr

Info

a wheel Emm ©0210

© play @ is larger chan the spec Tied valve

= Change ll rubber dempers i the rear hub,

Finishing wark

= Install she rear whos

ake the meter

13 WIRING HARNESS, BATTERY 6

413.4 -Removingthe battery

Warning

Risk of injury Brtlery acid»

‘2p batteries ovt af the reach ofc

1 su able protecive clothing and goggles.

= fvoid contact with battery acid and battery gases.

9 he baltery anay from sparks or open Tl

he event of skin contact, rinse with large amou'

5 minutes and cortec: a physician

i battery gases cause se

only i well-vertilated areas,

of water, I battery acid gets in the eyes, rinse mith water for at least

Preparatory work

= Remove the passenger seat. (Fp, 38)

= Remove the seat. (* p. 37)

Main ark

the negative erminal cover @

‘the battery

= Pull beck tre pesit'vecerminal cover ©.

= Disconnect the positve cable @ of the battery

= Detach rubber vand ©.

= Pull the battery up and out of the battery ta

Info

Never operate the moter

Ie bth ‘neal companents and

The vehicle is therefore na longer toed

artery o without a battery.

devices can be damaged.

Main ark

Position the battery inthe batter

Info

The battery term nals rust be atthe top

rubber band @.

= Reconract the pes tv

= Position postive term

= Connect the

= Pos

ion the negative terminal cover @,

Finishing work

= Mourt tne seat, (© p, 38)

— Mourt the passenger seat. p, 38)

= Set the clock. p. 78)

13 WIRING HARNESS, BATTERY 8

133. Disconnecting the negative cable ofthe battery

Preparatory work

= Remove the passenger seat. p. 28)

= Remove the seat. (Fp. 37)

Main wark

=" Pull back the negative erminal cover @

— Disconnect the negative cable @ of the battery.

Main wark

=. Connect the

Finishing work

= Maur! tne seat, (© p, 38)

= Mourt the passenger seat. 1% p, 38)

= Set the clock. (© p. 78)

Warning.

Risk of injury. Battery acid and be

p batteries out ofthe reach of

Se protective clothing and ee

= Avoid contact with tattery acid ard batt

9 the battery sway from sparks or open flames. Charge only well ventilated areas

Ie the evert of skin contact, rinse wth large amcunts of water. I battery acd gets in tre eyes, rin

9 minutes and contac: @ physician,

with water for atleast

Warning

Environmental hazard The betlery conta elev’

= Be not d scard batteries w ch tre household trash, D sp xe battery in an er

Give tre battery to your KTM dealer arto a recycling center that accep's used batleies

thal are hanmful te the environmen

compatible ma

Info

TW Even when there is ne load on the loses power stead ly

fhe serw.ce life of the battery

eile

chargire with a high ch

IF the charging current ct

rough the safety valves, This

reduces the battery capac ty.

Ifthe betery is depleted fram staring the vehicle repeatedly, che battery must be charged mmediately

IF the betiery is le in @ discharged state for an extended period, = will become over-dscharged and he

battery.

The battery is maintenance-free, which means thatthe a eed te be ehee

13 WIRING HARNESS, BATTERY 63

Proparatory work

= Sw:ch off all poner corsumers and

= Remove the passenger seat. (Fp. 38)

= Remove she seat. p. 37)

switch off the eng ve.

- the battery to avoid damage ta the rot

electron

Main ark

= Correct the ba to the betvery, Sw ch on the battery cherger

Bae charger (6BAZS07 40001

You can also use the batary cher

bettery, and

tery

rest potertiel and start peteriel of he

ce, you cennct cvercharge the bat

Info

Neve ron

ge the dtxy with a ax rum of 10% of

battery rousing 8

— Swich off the charger after charging, Dscannect the battery

Guideline

The charge ourert, charge

an

3 mons

Finishing wark

= Mourt tne seat, (Fp. 38)

= Mlourt tre passenger seet. % p. 38)

= Sel the clock (© p76)

Condition

The batlery must be fully furetianal and complete

Proparatory work

= Remove the

= Rene

Main wark

= Sart the metorcyele to make checks. (* p. 12

Vv

(Charging wita

charged.

ssenger seat. (F p38)

sure the voltage between :he specified poinss

sing 90 nL Plus (4)~ Measuring po nt Ground (=)

rer 135. 150¥

+ IF the disolayed value is less thar the specified value

= ch le from the elternator to the voltage

le from che voltage reguleter to the wiring Pseness

the stator winding of he alternator. p. 201)

rer than the specified valve

13 WIRING HARNESS, BATTERY 64

1347 Changing the fuses of individual power consumers

© Info

The fuse bor withthe main fuse ard the fuses ofthe ind vidual po

Proparatory work

= "Sw ch off ll power consumers and sw e

- the passenger seat. p. 38)

Main wark

=" Open fuse box cover @.

= Remove the

Guideline

Fuse 1-308

Fuse 2- 16 A combinat on instrument

Foes 10m Ua mane

Fusea~ 15 A grition col alarm system (OPTIONAL)

Fuge 5-15 A radiator fan

Fuse6- 15 A horn, brake lghi, in seal, high bear, Tow beam,

Tight, taillight, Vcense plete lamp

Info

Ti detective fuse

dicated by 2 burresd-ou: fuse wire ®,

Warning

Fire hazard

Used.

electrical syster can be cverlaaded ifshe wrorg fuses are

ly fses with the prescribes

amperage. Mever by-pass or repair

rating ory.

a

a)

BOI p. 206)

ial

he spare fuse in the fuse box so the

@ pou

= Close the fuse

Finishing work

= Mourt the

is function rg propery

nger seat. p. 38),

14 BRAKE SYSTEM 65

“144 Cheeking the font brake nips

Warning.

Danger of accidents Re

ficiency caused by worn brake I rings

= Change wore breke Inings immediately,

Note

Danger of accidents Res.ced braking efficiency caused by de

ged brake dises

= the beake lings are ret c ir time, she steel brake lining carers grind on the brake disc. The braking effect i greatly

brake gises are destroyed, Check the brake lin ras regulary

Check the brake linings for minimum thickness @.

TMinimor tekress @ 1am @ 008

+ Ifthe minimum thickness 6 less than specified

= Charge the frort brake lings.

= hack the brake linings for damage and crack ng

+ If shere ss wear or lear rg:

= Change the frort brake lings. (* p. 65)

Warning.

Skin tation Brake fl. & can cause skin iitation on cartec

= Avoid contact with skin and ayes, and keep out ef the reach of eh laren,

le

= brake tid

Warning

Danger of accidents Reduced traking efficiency due to old brake Mui

ve clothing and goggles

es nto contact withthe eyes, Mus!

eyes thoroughly with water and corsul: 2p

= Charge the brake fluid of the font andr

Warning

Danger of accidents Red.ced braking effciency due tail or grea

ake according o the sevice schedule,

2.0n he brake dis

= Always Keep the brake d ses fre of el and gr

Warning

Danger ofaesons esc ak gal cen se ose af a poe se igs

ase, and clean ther w :h brake cleaner when recessary

~ Bt ngs vel fm access supe

tion ena

cense, The

Warning

Environmental hazard Hazardous sub

se environmental damage

= Oil, grease, filters, Iuel clearer, take fluo, ete, should be disposed of as stinlated ir apo cable regulations

Info

DH) Avo contact between brake fluid and painted parts. Brak

Use only cleen brake tut rsainer

14 BRAKE SYSTEM 66

+ mounted on the handlebar ‘0 a hor zortel positon

Remove breke liniras @,

Clean the brake caliper

i position and ake sure that ro brake fluid

‘ange the brake lines pas.

14 BRAKE SYSTEM 6

= Position springs ®,

7 The artow on the spring ports ©

= Mount bolts ®,

reccior ef trevel

Info

vate the

springs are se

hy

brake lever until here isa frm pressure por

= Gorrecs the brake fluid lave ta level @,

Guideline

eae Samm (02m

Bake fd bors OO SLI

— Position the cover with the membrane. Mount ard tighten the sores

= Info

lean up overflowed lid immediately with water,

my ee

Danger of accidents Fe [ure of che brake system

- is below the MIN nark, this indicates @ or worn-out brake liring

de nat cortinue ridrg.

my ve

Danger of accidents Res ciency due to ad brake fuid

= Charge the brake fluid of the frent and reer brake according to tre service schedule

= Move the brake fluid reservar mounted on the

= Check she brake fu d level in viewer @,

IF the brake fluid is below the MINMmarking

= Add frort brake flud p67)

ay ee

Danger of accidents Fs lure of she brake system

= Hi the brake uid level

Check the brake site

below the MIN met, this indicates @

ince ridieg

nthe brake sy

or worn-out brake lining

ay vine

Skin tation Brake fl. & can cause skin initation onc

= Avoid contact with skin and iaren,

= Wear su able protective clothing and gos

= Hf brake fluid eves thorougtly with water and aby

my ee

Danger of accidents Reduced braking eficiency due te old brake fluid

= Charge the brake tid of the front and

bake according to tre seevice schedule,

14 BRAKE SYSTEM 68

Warning

Environmental hazard He

ardous subsiarces cause env ronmental damage

= Gil, rease, flees, fuel, clearer, brake flu

ele., should be disposed af 2s stipulates in ap

Info

parts. Brake fluid att

sled con‘ainer

= Move the brake fluid reservar mounted or

= Renove screus @,

= Remove cover @ with rem

= Add brake flu d to level @.

Sanam

Baetea Dora sors TM pe

= Pesition the cover» eribvane Mount ard tighten the

Info

BH ciean up or spilt brake fluid immediately with wa

14.5 Changing the front brake fluid

i ere

Skin imitation rake fluc can cause skin iriation

= Avoid contact with skin and ayes, and keep out ofthe reach of children

= Wear su able protective lething and g¢

= Hf brake fluid cores nto contact wit the

flush the eves thoroughly with water and corsul: a physic‘ar

Warning

Environmental hazard Hazardous substarces vtonmental damage

= Oil, grease, fltersMuel, clearers, brake flu ete., should bs

4 af a8 stipulated rapa) cable regulations

Info

Avo contact between brake Muid ard pa

Use orlyclezn br

parts. Brake fluid attacks pa

Move the breke fluid reservar maunted on the handlebar vo a har zartal posi

= Cover she painted per

= Remove screws @.

ver @ with membrare

- id brake fluid cut of the bree fluid reserecr using a syringe and fl wh

fresh broke ‘uid

a BOGTOO Tp 2a)

Baked OT a DOT SL

Mount the corres Dleeder cover © ftor the special tool set

Blee

= Connees the bleed ng

201825.

14 BRAKE SYSTEM

68

=. Open shutoff

Info

BD Folicu the operating structions ofthe bleeding dey ce.

= Ersure that the filling pressure is set cn pressure gauge @, Correct the filling res:

sure on the pressure regulator @ if rec

Guideline

Filling pressure 225 bar 29. 36 ps)

ap @ ofthe bleeder

rll

ofthe brake caliper. Connect the hose of

Blending device 1

STATO p. PBA

= Open tl

screw @ by approximately ore half tur

= Info

Drain until fresh brake flu

without bubbles,

erges from the hose of the bleeder bot

= Tighten the

= Close shutof val

= Open the ble

der scren

Info

Ths prevents cverfiling ofthe brake fluid reservo

Remove the hove cf

the bal

Guideline

Lew &

Brake fd DOT 41001

= Positan

cover th

the seren

Info

BH Giean up ovettiowed or spit brake fluid immediately with we

= Oreck

Warning.

Danger of accidents Re

A

= ob

Note

Danger of accidents

iuced braking efficiency caused by den

caused by worn brake lings

rrr brake linings im-reditaly.

2ged brake dises

brake lining carers grind on the brake

. The braking

=. hack the brake linings for rinimur thickness @.

Minin me Elam @ 008 Ta)

+ Ifthe minimum thickness ‘ less than specified

= Charge the rear brake linirgs. (% p. 70)

= Check the brake linings for damage and ers

© WFehere s weer or tearing:

= Change the wear brake

gs. p. 70)

14

BRAKE SYSTEM 70

A

Warning.

Skin tation Brake fk & ca

= Avoid contact with skin and ay

= Wear su sable pro’

zach of chiluren,

= Hf brake fluid cores nto contact withthe eves

Warning

flush the eves thoroughly with water and corsul: a physic‘ar

Danger of accidents Reduced braking eficiency due te old brake fluid

= Charge the brake fluid of the frent and reer brake according to tre service schedule

Warning

1 grease ont

Danger of accidents Reduced braking af ion he

Always keep the brake d's free cf ol and grease, and clean them wh brake cleaner when

Warning

Danger of accidents Pos

1 braking eff cien

= Breke linings avaiable frem accessowy suppl cl tested ard approved for use en KTM vehick

tion and friction factr of the brake linings and therefore the brake power car ffer cons derably fromthe o

brake linings, I brake linings nee that they corny wh

nal /cense, The veh cle no longer correspands te the corciton at delivery, and sh lid

Warning

Environmental hazard Hazardous substarces cause ene onsnental

ase, Flters fel, ce

ers, brake flue, ete. s

culd be disposed af 2s stipulates in apa!

Info

Avo contact between brake luid ard pa

id fom 2 se

= Push the trake caliper toward the brake @'sc wth your hand to push back the brake

pistor; ensure that brake Tluid does ro: curs out ofthe brake uid reservar, remov

ing tif toes

breke lings @

brake cal

14 BRAKE SYSTEM ”

= Position brake lin ngs @,

= Moun: bolts,

ing clips ©,

= Operate she foo: bra

the brake o se and

= Adjust the o

ua

Mount the soren

Info

BH Giesn up ovettiowed or spit brake fluid immediately with w

mee

Danger of accidents Broke eystem ‘eilre

= Hite

oveth

is no free tr

2. dius

= Dsvonnect saring @,

he feat brake lever back and forth between the erd stop and she contact‘

the feat brake cylinder psten ar tice revel @.

Guideline

Free ravel at foot brake [ever Za ommie 02a

4

= Adjust the tee i

= Recanrac spring @,

14 BRAKE SYSTEM n

Warning.

By sangerotaccitentsexche ster ii

=H there is no fee travel oth

‘overheating. Adjust the free a

pressure builds up on the ear orake creult, The rear brake can

fon: brake lever accercing “0 spec ficaiors,

= Desvonnect saring @,

= Release nut @ ard use screw © to aejust the specif ed fh

Guideline

Free wravel at Toot by

ele 3 smn

Info

B the rani

f adjustment isl ited,

= Hold sere @ end tighten nut ©,

= fectach spring @

my Ye

Danger of accidents Fe [ure of che brake system

— Ifthe brake fluid level fells below the MIN mark, this indicates @ leakage che brake system or worn-out brake I rings

Check the brake system and cp not cartinue ridirg,

Warning

WS cancer ot accidents Res.ced broking efficiency de too brake ui

brake according tc tre sevice schedule

= Oharge the brake tld of the ent andr

— Stand she vehicle varie

= Check the brake flu level inthe brake tuid reserva