Professional Documents

Culture Documents

Flange Leakage

Uploaded by

Anjani PrabhakarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flange Leakage

Uploaded by

Anjani PrabhakarCopyright:

Available Formats

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page2 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

TABLE OF CONTENTS

1 SCOPE ........................................................................................................................ 3

2 CODES / STANDARDS............................................................................................... 3

3 WORK PROCEDURE FOR CAESAR ......................................................................... 3

4 WORK PROCEDURE FOR AUTOPIPE. ................................................................... 18

5 REFERENCE DOCUMENTS .................................................................................... 48

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page3 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

1 SCOPE

This document states the guidelines to perform flange leakage calculation on CAESAR II

and Auto Pipe V8i.

2 CODES / STANDARDS

ANSI B16.5 Pipe flanges and flanged fittings.

ASME B16.47 Large diameter steel flanges.

ASME Sec. VIII Div.1&2 Rules for construction of pressure vessels.

ASME B 16.20 Metallic gaskets for pipe flanges.

ASME Sec. II, Part D Properties of materials.

ASME B31.3 Process piping.

3 WORK PROCEDURE FOR CAESAR

The procedure for calculation shall be explained through a sample calculation.

Flange size : 10

Flange Rating : 900#

Gasket type : RTJ-octagonal, B16.20 Cl.900 (as per PMS)

Material : Soft iron (as per PMS)

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page4 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

The input in CAESAR shall be as per following steps:

3.1 Select Analysis > flanges, to open the New job name specification dialog box shown

below:

File name shall be entered in Enter the name for the new job file field. (File name shall

be FlangeN where N is the flange node no. The flange with maximum load shall be

selected).

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page5 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

In Enter the data directory field select the directory from the database dropdown and

press ok. This will trigger dialogs for flange leakage calculation.

3.2 Flange

Refer table as per class from ANSI B16.5, Table 18 to get dimensional data

a. Select flange type : As per PMS

b. Enter flange class : As per PMS

c. Flange grade : Col. 1 of table -1A from B16.5 for the

corresponding flange material.

d. Flange outside diameter [A] : Col.2 (O)

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page6 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

e. Flange inside diameter [B] : Col.12 (B) i.e. matching ID of pipe welded

as per note given in ASME B16.5 table 18.

f. Flange thickness [t

f

] : Col.3 (t

f

).

g. Flange face OD or Lapjt cnt OD : Refer table 5 (Dont use this Value for lap joint)

h. Flange face ID or Lapjt cnt ID : Col.12 (B).

i. Small end hub thickness [g0] : (Col.5 col.12) /2 = (A

h

-B) /2.

j. Large end hub thickness [g1] : (Col.4 col.12) /2 = (X-B) /2.

k. Hub length [h] : Col.8 (for weld neck) col.3 =Y- t

f.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page7 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

3.3 Bolts & Gaskets

Refer table as per class from ANSI B16.5, Table 17 for Bolt information.

a. Bolt circle diameter : Col.3. (w)

b. No. of bolts : Col.5.

c. Bolt diameter : Col.6.

d. Bolt initial tightening stress : Omitted (Default value shall be taken as

45000/d^ Psi), where d = Bolt diameter in inch.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page8 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

Refer table 3, ASME B 16.20 / PMS for gasket dimensions.

e. Gasket outer dia. : According to Class/Rating/Ring No.(as per

ASME B 16.20, Table 3/4) i.e. (P+A).

f. Gasket inner dia. : According to Class/Rating/Ring No.(as per

ASME B16.20, table 3/4) i.e. (P - A).

g. Uncompressed gasket thickness : According to Class/Rating/Ring No.(as per

ASME B16.20, table 3/4) i.e. H.

h. Effective gasket modulus : Elastic Modulus at ambient temperature.

(Refer Sec II part D, Table TM-1).

i. Leak pressure ratio [m] : Refer table 2-5.1 of mandatory appendix 2 from

ASME section VIII, Division I.

u. Gasket seating stress [y] : Refer table 2-5.1 of mandatory appendix 2 from

ASME section VIII, Division I.

v Nubbin width (or ring joint width) : Width of ring for RTJ gasket.

X Facing sketch : Refer table 2-5.1 &2-5.2 of mandatory appendix 2

from ASME Section VIII, Division I. use Coade

equivalent no.

y Facing column : Refer table 2-5.1 &2-5.2 of mandatory appendix 2

from ASME Section VIII, Division I. use Coade

equivalent no.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page9 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

3.4 Material Data:

a) Flange material : Select from data base dropdown.

shall be as per PMS.

b) Bolt material : Select from database dropdown.

shall be as per PMS.

c) Design temperature : As per line list.

d) Flange allowable @ design temperature : Considered by CAESAR automatically

as per ASME Sec VIII Div 1.

e) Flange allowable @ ambient temperature : Considered by CAESAR automatically

as per ASME Sec VIII Div 1.

f) Flange modulus of elasticity @ design : Refer table C-6 of B31.3 for flange

material and temperature.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page10 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

g) Flange modulus of elasticity @ ambient : Refer table C-6 of B31.3 for flange

material and temperature.

h) Bolt allowable @ design temperature : Considered by CAESAR automatically as per

bolt material. (Alternatively refer table A2 of

B31.3 for corresponding bolt material and

temperature).

i) Bolt allowable @ ambient temperature : Considered by CAESAR automatically as per

bolt material. (Alternatively refer table A2 of

B31.3 for corresponding bolt material and

temperature).

j) Flange allowable stress multiplier : 1 (Refer para 2-8 of Section VIII Division 1)

k) Bolt allowable stress multiplier ( VIII DIV 2) : 2 (Refer article 4-141of Section VIII Division1)

3.5 Loads

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page11 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

a) Design pressure [P] : As per line list.

b) Axial force [optional] : As per CAESAR output file.

c) Bending moment [optional] : As per CAESAR output file.

d) Disable leakage calculations : Check to disable the leakage calculation.

e) Disable stress calculations : Check to disable the stress calculations.

f) Disable ANSI B16.5 check : Check to turn off the report for the ANSI B16.5

equivalent pressure check.

3.6 Run the leakage calculation.

3.7 Check the result.

3.8 Necessary changes shall be applied to input file if flange check fails.

3.9 After applying changes repeat above steps.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page12 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

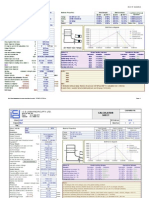

3.10 Caesar output report:

Pass report sample:

FLANGE LEAKAGE/STRESS CALCULATIONS

Flange Inside Diameter [B] (User to verify) ......(mm ) 247.630

Flange Thickness [t]..............................(mm.) 69.900

Flange Rating (Optional) .............................. 900.000

Bolt Circle Diameter .............................(mm ) 469.900

Number of Bolts ....................................... 16.000

Bolt Diameter ....................................(mm ) 34.925

Bolt Initial Tightening Stress ............(lb./sq.in.)

Uncompressed Gasket Thickness ....................(mm ) 16.000

Grade of Attached B16_5 ANSI Flange.................... 1.100

Leak Pressure Ratio [m] ............................... 5.500

Effective Gasket Modulus ..................(Kg/sq.cm. ) 2062620.000

Externally Applied Moment ..... (optional) ....(Kg.m. ) 5000.000

Externally Applied Force ...... (optional) .......(Kg ) 2000.000

Pressure [P]...............................(Kg/sq.cm. ) 22.800

Disable Stress Calculations (Y/N) ..................... N

Flange Type (1-8, see ?-Help or Alt-P to plot) ........ 1.000

Flange Outside Diameter [A].......................(mm ) 545.000

Design Temperature ................................ C 150.000

Small End Hub Thickness [g0]......................(mm ) 12.700

Large End Hub Thickness [g1]......................(mm ) 60.185

Hub Length [h]....................................(mm ) 114.100

Flange Allowable @Design Temperature ......(lb./sq.in.) 20000.000

Flange Allowable @Ambient Temperature .....(lb./sq.in.) 20000.000

Flange Modulus of Elasticity @Design ......(Kg/sq.cm. ) 28288000.000

Flange Modulus of Elasticity @Ambient .....(Kg/sq.cm. ) 29500000.000

Bolt Allowable @Design Temperature ......(lb./sq.in.) 25000.000

Bolt Allowable @Ambient Temperature .....(lb./sq.in.) 25000.000

Gasket Seating Stress [y] .................(lb./sq.in.) 18000.000

Flange Allowable Stress Multiplier .................... 1.500

Bolt Allowable Stress Multiplier (VIII Div 2 4-141) ... 2.000

Disable Leakage Calculations (Y/N) .................... N

Disable ANSI B16.5 Checks (Y/N) ....................... N

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page13 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

Flange Face OD or Lapjt Cnt OD....................(mm ) 362.000

Flange Face ID or Lapjt Cnt ID....................(mm ) 248.000

Gasket Outer Diameter ............................(mm ) 334.980

Gasket Inner Diameter ............................(mm ) 312.720

Nubbin Width .....................................(mm ) 11.130

Facing Sketch ......................................... 9.000

Facing Column ......................................... 1.000

Flange Type: (Integral Weld Neck)

Effective gasket width parameters:

Effective gasket seating width, b......(mm ) 1.3913

Diameter of gasket load reaction, G....(mm ) 323.8500

SAFETY FACTOR SUMMARY for the different Flange Models

analyzed. (SAFETY FACTOR = Allowed/Actual)

SAFETY

FACTOR

Flexibility/Gasket Compression Model (Leakage).. 6.13

ANSI B16.5/Equivalent Pressure (Stress)......... 1.42

ASME Model Operating (Stress)................... 2.00

ASME Model Seating (Stress)..................... 1.21

FLANGE FLEXIBILITY MODEL ---------------------------------

BOLTED FLANGE CHARACTERISTICS:

Initial Tightening Stress in the Bolt (Not the seating

stress): 38376 lb./sq.in.

Approximate Torque required to induce the above initial

stress: 141 Kg.m.

GASKET COMPRESSION: COMPRESSION

(mm )

After Initial Boltup (Ci)........... 0.1128271595

Loss-of due to Pressure (Cp)........ 0.0042581009

Loss-of due to Applied Moment (Cm).. 0.0133846644

Loss-of due to Applied Force (Cf)... 0.0004510691

Loss-of due to all loads (CL)....... 0.0180938356

Initial minus all Losses (Ci-CL).... 0.0947333276

For Leak-Proof Joint (Creq)......... 0.0019454866

Excess available (Ci-Creq) ......... 0.1108816788

LEAKAGE SAFETY FACTOR: (If less than one then joint

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page14 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

leakage is predicted.) (Allowed/Actual)

Pressure Only (Ci-Creq)/Cp ............. 26.04

Force Only (Ci-Creq)/Cf ................ 245.82

Moment Only (Ci-Creq)/Cm ............... 8.28

Pressure+Force+Moment (Ci-Creq)/CL ..... 6.13

EQUIVALENT PRESSURE MODEL ----------------------------

Equivalent Pressure (Kg/sq.cm. ) ............ 96.88

ANSI B16.5 Flange Allowable Pressure Rating . 137.80

STRESS SAFETY FACTOR: (If less than one then joint

failure is predicted.) (Allowed/Actual)

ANSI B16.5/Equivalent Pressure ................. 1.42

ASME SECT VIII DIV 1 STRESS MODEL ------------------------

ACCORDING TO A93 APPENDIX S, THE FOLLOWING RIGIDITY

FACTORS SHOULD BE LESS THAN 1.0

ASME Rigidity Factor "J", Operating Case ....... 0.0074

ASME Rigidity Factor "J", Seating Case ......... 0.1012

CALCULATED STRESSES (lb./sq.in.)

OPERATING ALLOW SEATING ALLOW

--------- ----- ------- -----

Longitudinal Hub .. 8452 30000 12036 30000

Radial Flange ..... 11581 30000 16492 20000

Tangential Flange . 5481 30000 7806 20000

Maximum Average ... 10016 20000 14264 20000

Bolting ........... 9988 50000 2137 25000

"*" Indicates Failure for an item.

STRESS SAFETY FACTOR: (If less than one then joint

failure is predicted.) (Allowed/Actual)

OPERATING SEATING

--------- -------

Longitudinal Hub .... 3.55 2.49

Radial Flange ....... 2.59 1.21

Tangential Flange ... 5.47 2.56

Maximum Average ..... 2.00 1.40

Bolting ............. 5.01 11.70

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page15 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

Failure report sample:

FLANGE LEAKAGE/STRESS CALCULATIONS

Flange Inside Diameter [B] (User to verify) ......(mm ) 247.630

Flange Thickness [t]..............................(mm.) 69.900

Flange Rating (Optional) .............................. 900.000

Bolt Circle Diameter .............................(mm ) 469.900

Number of Bolts ....................................... 16.000

Bolt Diameter ....................................(mm ) 34.925

Bolt Initial Tightening Stress ............(lb./sq.in.)

Uncompressed Gasket Thickness ....................(mm ) 16.000

Grade of Attached B16_5 ANSI Flange.................... 1.100

Leak Pressure Ratio [m] ............................... 5.500

Effective Gasket Modulus ..................(Kg/sq.cm. ) 2062620.000

Externally Applied Moment ..... (optional) ....(Kg.m. ) 15000.000

Externally Applied Force ...... (optional) .......(Kg ) 8000.000

Pressure [P]...............................(Kg/sq.cm. ) 22.800

Disable Stress Calculations (Y/N) ..................... N

Flange Type (1-8, see ?-Help or Alt-P to plot) ........ 1.000

Flange Outside Diameter [A].......................(mm ) 545.000

Design Temperature ................................ C 150.000

Small End Hub Thickness [g0]......................(mm ) 12.700

Large End Hub Thickness [g1]......................(mm ) 60.185

Hub Length [h]....................................(mm ) 114.100

Flange Allowable @Design Temperature ......(lb./sq.in.) 20000.000

Flange Allowable @Ambient Temperature .....(lb./sq.in.) 20000.000

Flange Modulus of Elasticity @Design ......(Kg/sq.cm. ) 28288000.000

Flange Modulus of Elasticity @Ambient .....(Kg/sq.cm. ) 29500000.000

Bolt Allowable @Design Temperature ......(lb./sq.in.) 25000.000

Bolt Allowable @Ambient Temperature .....(lb./sq.in.) 25000.000

Gasket Seating Stress [y] .................(lb./sq.in.) 18000.000

Flange Allowable Stress Multiplier .................... 1.500

Bolt Allowable Stress Multiplier (VIII Div 2 4-141) ... 2.000

Disable Leakage Calculations (Y/N) .................... N

Disable ANSI B16.5 Checks (Y/N) ....................... N

Flange Face OD or Lapjt Cnt OD....................(mm ) 362.000

Flange Face ID or Lapjt Cnt ID....................(mm ) 248.000

Gasket Outer Diameter ............................(mm ) 334.980

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page16 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

Gasket Inner Diameter ............................(mm ) 312.720

Nubbin Width .....................................(mm ) 11.130

Facing Sketch ......................................... 9.000

Facing Column ......................................... 1.000

Flange Type: (Integral Weld Neck)

Effective gasket width parameters:

Effective gasket seating width, b......(mm ) 1.3913

Diameter of gasket load reaction, G....(mm ) 323.8500

SAFETY FACTOR SUMMARY for the different Flange Models

analyzed. (SAFETY FACTOR = Allowed/Actual)

SAFETY

FACTOR

Flexibility/Gasket Compression Model (Leakage).. 2.40

ANSI B16.5/Equivalent Pressure (Stress)......... 0.56

ASME Model Operating (Stress)................... 0.79

ASME Model Seating (Stress)..................... 0.85

FLANGE FLEXIBILITY MODEL ---------------------------------

BOLTED FLANGE CHARACTERISTICS:

Initial Tightening Stress in the Bolt (Not the seating

stress): 38376 lb./sq.in.

Approximate Torque required to induce the above initial

stress: 141 Kg.m.

GASKET COMPRESSION: COMPRESSION

(mm )

After Initial Boltup (Ci)........... 0.1128271595

Loss-of due to Pressure (Cp)........ 0.0042581009

Loss-of due to Applied Moment (Cm).. 0.0401539914

Loss-of due to Applied Force (Cf)... 0.0018042764

Loss-of due to all loads (CL)....... 0.0462163687

Initial minus all Losses (Ci-CL).... 0.0666107908

For Leak-Proof Joint (Creq)......... 0.0019454866

Excess available (Ci-Creq) ......... 0.1108816788

LEAKAGE SAFETY FACTOR: (If less than one then joint

leakage is predicted.) (Allowed/Actual)

Pressure Only (Ci-Creq)/Cp ............. 26.04

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page17 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

Force Only (Ci-Creq)/Cf ................ 61.45

Moment Only (Ci-Creq)/Cm ............... 2.76

Pressure+Force+Moment (Ci-Creq)/CL ..... 2.40

EQUIVALENT PRESSURE MODEL ----------------------------

Equivalent Pressure (Kg/sq.cm. ) ............ 247.47

ANSI B16.5 Flange Allowable Pressure Rating . 137.80

STRESS SAFETY FACTOR: (If less than one then joint

failure is predicted.) (Allowed/Actual)

ANSI B16.5/Equivalent Pressure ................. 0.56

ASME SECT VIII DIV 1 STRESS MODEL ------------------------

ACCORDING TO A93 APPENDIX S, THE FOLLOWING RIGIDITY

FACTORS SHOULD BE LESS THAN 1.0

ASME Rigidity Factor "J", Operating Case ....... 0.0187

ASME Rigidity Factor "J", Seating Case ......... 0.1442

CALCULATED STRESSES (lb./sq.in.)

OPERATING ALLOW SEATING ALLOW

--------- ----- ------- -----

Longitudinal Hub .. 21345 30000 17149 30000

Radial Flange ..... 29248 30000 23498 20000 *

Tangential Flange . 13844 30000 11122 20000

Maximum Average ... 25297 20000 20324 20000 *

Bolting ........... 24850 50000 2137 25000

"*" Indicates Failure for an item.

STRESS SAFETY FACTOR: (If less than one then joint

failure is predicted.) (Allowed/Actual)

OPERATING SEATING

--------- -------

Longitudinal Hub .... 1.41 1.75

Radial Flange ....... 1.03 0.85

Tangential Flange ... 2.17 1.80

Maximum Average ..... 0.79 0.98

Bolting ............. 2.01 11.70

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page18 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

4 WORK PROCEDURE FOR AUTOPIPE.

Flange leakage calculation shall be performed after the piping system is modeled in AutoPIPE.

following steps shall be followed:

The procedure for calculation shall be explained through a sample calculation.

Flange size : 450 mm

Flange rating : 900 #

Gasket type : RTJ-octagonal, B16.20 Cl.900 (as per PMS)

Material : Soft iron (as per PMS)

5.1 Select Tools > Flange Analysis from the main menu / Flange analysis icon

from toolbar to open flange analysis dialog box.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page19 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

5.2 Flange analysis dialog box will appear as shown below.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page20 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

5.3 Analysis

Analysis tab shall be selected from Flange Analysis dialog box. Analysis tab can be used to

define the general analysis options, e.g. the flange attachment, material library, analysis method

etc. Following available fields on the analysis tab shall be defined.

1. Point name : This field is read-only.

2. No. : This field is read-only.

3. Flange type : This field is read-only.

4. Flange rating : This field is read-only.

5. Nom. pipe size : This field is read-only.

6. Tag no. : This field is read-only.

7. Attachment : Select from drop down list, shall be as per PMS.

8. Analysis method : Select from drop down list, shall be

ASME Section VIII Div. 1.

9. Gasket seating bolt load : Select from drop down list, shall be Code required.

10. Consider bolt spacing correction : Shall be enabled to consider the bolt spacing

correction factor in the analysis. [This option does not

apply to the ANSI check analysis method]

11. Analyze : Shall be enabled to include the flange in the analysis.

12. Max. ratio : This field is read-only.

13. Notes : This field is read-only.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page21 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

4.4 Load

The Load tab shall be used to define the loads applied to each flange, including any external

loads (optional). Following available fields on the load tab shall be defined.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page22 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

1. Point name : This field is read-only.

2. No. : This field is read-only.

3. Flange rating : This field is read-only.

4. Nom. Pipe size : This field is read-only.

5. Load combination : Shall be selected from the drop down list to determine the

applied external loads, i.e. axial force & bending moment.

6. Operating case : Operating case shall be selected from the drop down

list to draw the operating pressure and temperature

cases.

7. Operating pressure : Operating press. shall be entered. [ Editable when the

operating case field is set to User. Otherwise, this

field is read-only.

8. Apply B31.3 uninsulated temp. : Shall be selected to use reduced temp., as defined in

section 301.3.2 of B31.3, when determining the

allowable stresses.

9. Operating temperature : Operating temp. shall be entered [ Editable when the

Operating case field is set to user. Otherwise, this

field is read-only].

10. Ambient temperature : This field is read-only.

11. External pressure : This field is optional. An external pressure is not

required to execute the flange analysis.

12. Applied force combination : Force combination shall be selected from the drop

down list to draw the axial force .

13. Axial force : Axial force shall be entered to calculate moment

due to external loads.[ Editable when the Load

combination field is set to user. Otherwise,

this field is read - only]

14. Applied moment combination : Applied moment combination Shall be selected from the

drop down list to draw the bending moment .

15. Bending moment : Bending moment shall be entered. [ Editable when

the Load combination field is set to user.

otherwise, this field is read-only]

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page23 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

4.5 Flange

The Flange tab shall be used to define the entire flange dimension, material properties and

additional attributes i.e. attachment, reverse, ring type. Following available fields on the flange

tab shall be defined.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page24 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

1. Point name : This field is read-only.

2. No. : This field is read- only.

3. Flange type : This field is read- only.

4. Flange rating : This field is read- only.

5. Attachment : Flange attachment type shall be selected from the drop

down list.

6. Joint efficiency factor : Joint efficiency factor shall be entered only for blind flanges.

7. Lap contact OD : Outside diameter of the stub flange shall be

entered. This field is only available for lap joint flanges.

8. Ring type : Ring type shall be selected from the drop down list.

this option is only available for lap joint and slip-on,

with loose attachment, flanges.

9. Reverse : This field shall be checked to consider the flange as a

reversed flange.(not used normally.)

10. Flange material library : Material library shall be selected from the drop down

list.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page25 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

11. Flange material : Select from the drop down list, shall be as per PMS.

12. Select material : Select the flange material using the ASME material

properties dialog, shall be as per PMS.

13. Flange/ Bolt dimensions : Select the dimension library.

14. Nom. Pipe size : This field is read-only.

15. Rigidity factor : Flange rigidity factor shall be entered. This field does

not apply to blind flanges.

KI = Rigidity factor for integral or optional

flange types = 0.3

K

L

= Rigidity factor for loose type flanges = 0.2

16. Outside diameter [A] : Considered by AutoPIPE automatically as per

selected flange /bolt dimensions library

(B16.5/B16.47).

17. Inside diameter [B] : Considered by AutoPIPE automatically as per

selected flange /bolt dimensions library

(B16.5/B16.47).

18. Thickness [T

f

] : Considered by AutoPIPE automatically as per

selected flange /bolt dimensions library

(B16.5/B16.47).

19. Hub length [Y- T

f

] : Considered by AutoPIPE automatically as per

Selected flange /bolt dimensions library

(B16.5/B16.47).

20. Large end hub thickness [g

1

] : Considered by AutoPIPE automatically as per

selected flange /bolt dimensions library

(B16.5/B16.47).

21. Small end hub thickness [g

0

] : Considered by Auto PIPE automatically as per

Selected flange /bolt dimensions library

(B16.5/B16.47).

22. Allow. Stress at opera. temp. [s

f

] : Considered by Auto PIPE automatically as per

material selected. (Table A-1 of ASME B31.3).

23. Allow. Stress at Amb. temp. [s

f

] : Considered by Auto PIPE automatically as per

material selected. (Table A-1 of ASME B31.3).

24. Density : Considered by AutoPIPE automatically as per

material selected.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page26 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

25. Elastic mod. at oper. temp. : Considered by AutoPIPE automatically as per

material selected. (Table C-6 of B31.3).

26. Elastic mod. at Amb. temp. : Considered by AutoPIPE automatically as per

material selected. (Table C-6 of B31.3).

4.6 Pipe

The Pipe tab shall be used to define the pipe material and allowable stresses, as well as

reference piping dimensions when designing the flange. Following available fields on the pipe

tab shall be defined.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page27 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

1. Field title : This field is read only.

2. Point name : This field is read only.

3. No. : This field is read only.

4. Flange rating : This field is read only.

5. Pipe ID : This field is read only.

6. Pipe ID material : This field is read only.

7. Nom. Pipe size : This field is read only.

8. Pipe outside diameter : This field is read only.

9. Pipe inside diameter : This field is read only.

10. Pipe material library : Select Pipe material library to be used for pipe

allowable stresses from the drop down list.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page28 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

11. Pipe material : Pipe material shall be selected from the drop down list.

(Note: This drop down list of materials is filtered based

on the material library selected on the Analysis tab.)

12. Select material : Pipe material shall be selected using the ASME material

properties dialog box.

13. Allow. Stress at oper. temp [S

n

] : Read only, unless NS is selected as the pipe material.

14. Allow. Stress at Amb. temp [S

n

] : Read only, unless NS is selected as the pipe material.

4.7 BOLTS

The bolts tab can be used to define the bolt material and allowable stresses, as well as the bolt

dimensions. Following available fields on the bolts tab shall be defined.

1. Point name : This field is read- only.

2. No. : This field is read- only.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page29 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

3. Flange rating : This field is read-only.

4. Nom. pipe size : This field is read-only.

5. Bolt material : Bolt material shall be selected from the drop down list,

shall be as per PMS.

[Note: This drop down list of materials is filtered based

on the material library selected on the Analysis tab.]

6. Select material : Bolt material shall be selected using the ASME material

properties dialog, shall be as per PMS.

7. Thread type : Bolt thread type shall be selected.

8. Bolt circle diameter [C] : Considered by AutoPIPE automatically as per

B16.5/ B16.47.

9. Number of bolts : Considered by AutoPIPE automatically as per

B16.5/B16.47.

10. Nominal diameter : Considered by Auto PIPE automatically as per

B16.5/ B16.47.

11. Effective diameter : Considered by Auto PIPE automatically as per

B16.5/ B16.47.

12. Bolt hole diameter : Considered by Auto PIPE automatically as per

B16.5/ B16.47.

13. Allow. Stress at oper. temp [s

b

] : Considered by Auto PIPE automatically as per

material selected. (Table A-2 of ASME B31.3).

14. Allow. Stress at amb. temp [s

a

] : Considered by Auto PIPE automatically as per

material selected.(Table A-2 of ASME B31.3).

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page30 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

4.8 GASKET

The Gasket tab can be used to define the gasket material and allowable stresses, as well as

the gasket dimensions. Following available fields on the gasket tab shall be defined.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page31 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

1. Field title : This field is read-only.

2. Point name : This field is read-only.

3. No. : This field is read-only.

4. Flange rating : This field is read-only.

5. Nom. Pipe size : This field is read-only.

6. Width [N] : Considered by Auto PIPE automatically as per

B16.20.

7. Inside diameter : Considered by Auto PIPE automatically as per

B16.20.

8. Gasket material : Gasket material shall be selected from the drop down

list, shall be as per PMS.

9. Configuration : Select the gasket configuration from the drop down list,

shall be as per section VIII Division 1 Appendix 2.

Table 2-5.2.

10. Gasket thickness : Considered by Auto PIPE automatically as per B16.20.

[Note: This field is only editable when the configuration

selected requires a gasket thickness to be defined.]

11. Nubbin width : Considered by Auto PIPE automatically as per B16.20

and Section VIII- Division 1 Appendix 2.

[Note: This field is only editable when the configuration

requires a nubbin width to be defined.]

12. Strength factor [m] : Considered by Auto PIPE automatically as per

Section VIII Division 1 Appendix 2, table 2-5.1.

13. Seating stress [y] : Considered by Auto PIPE automatically as per

Section VIII Division 1 Appendix 2, table 2-5.1.

14. Effective gasket seating width [b] : Considered by Auto PIPE automatically as per

Section VIII- Division 1 Appendix 2 & B16.20.

[Note: This field is editable.]

15. Full face gasket : Shall be selected to consider the gasket Full Faced.

[Note: This option is only available for the weld neck

flange type.]

16. Load react. Diameter [G] : Considered by Auto PIPE automatically.

[Note: This field is only editable when user is

selected as the gasket material.]

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page32 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

4.9 ANSI CHECK

ANSI Check fields get disabled when ASME Section VIII Division 1 is selected as the flange

Analysis method on the Analysis tab.

Notes:

1. ANSI check method shall be performed only when ANSI Check is selected as the flange

analysis method on the Analysis tab.

2. The ANSI flange check can only be executed for flanges set to NS rating when the User

pressure Temp. Data option is checked, i.e. when user P

max

data is used in the ANSI Check

analysis.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page33 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

4.10 Analyze tab shall be selected for performing flange analysis.

4.11 Show report tab shall be selected for generating analysis output report.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page34 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

4.12 Auto PIPE output report:

Pass report Sample:

--------------------------------------------------------------------------------------

--------------------------

01-0010 1

05/10/2013 AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ BENTLEY

10:18 AM AutoPIPE Plus

9.5.0.21

--------------------------------------------------------------------------------------

--------------------------

* ******* ** ******* *******

*** ** ** ** ** ** ** **

** ** ****** ** ** ** ** ** **

** ** ** ** ** ***** ******* ** ******* *****

********* ** ** ** ** ** ** ** ** **

** ** ** ** ** ** ** ** ** ** **

** ** ***** ** ***** ** ** ** *******

Pipe Stress Analysis and Design Program

Version: 09.05.00.21

Edition: Plus

Developed and Maintained by

BENTLEY SYSTEMS, INCORPORATED

1600 Riviera Ave., Suite 300

Walnut Creek, CA 94596

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page35 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

-------------------------------------------------------------------------------------

---------------------------

01-0010 1

05/10/2013 AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ BENTLEY

10:18 AM AutoPIPE Plus

9.5.0.21

-------------------------------------------------------------------------------------

---------------------------

************************************************************

** **

** AUTOPIPE FLANGE ANALYSIS **

** **

************************************************************

SYSTEM NAME : 01-0010 1

PROJECT ID : AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ

PREPARED BY : ______________________________

AP

CHECKED BY : ______________________________

SK

1ST APPROVER : ______________________________

DKD

2ND APPROVER : ______________________________

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page36 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

--------------------------------------------------------------------------------------

--------------------------

01-0010 1

05/10/2013 AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ BENTLEY

10:18 AM AutoPIPE Plus

9.5.0.21

--------------------------------------------------------------------------------------

--------------------------

************************************************************

** **

** POINT A00 FLANGE # 1 **

** WELD-NECK **

** NPS 450.000 mm RATING 900 **

** **

************************************************************

VESSEL DESIGN CODE : ASME Section VIII 2010, Division 1

DIMENSION LIBRARY : FlangeDimLib.mdb

DIMENSION CODE : B16-5

MATERIAL LIBRARY : asme2010.mdb

FLANGE ATTACHMENT : INTEGRAL

FLANGE CONFIGURATION : WHOLE

I N P U T S

1.1 FLANGE:

------

Material : SA-105

Outside diameter, A : 787.400 mm Bore diameter, B : 431.800 mm

Thickness, tf : 101.600 mm Rigidity Factor, K : 0.300

Small End Hub Thk, g0: 12.7000 mm Large End Hub Thk, g1: 66.6750 mm

Hub Length, h : 127.000 mm Bolt Circle Dia., C : 685.800 mm

Allowable at Oper, Sf: 137.895 MPa Allowable at Amb, Sf : 137.895 MPa

Modulus. at Oper, E : 194845.8 MPa Modulus. at Amb, E : 199948.8 MPa

1.2 PIPE:

----

Material : A691-G2.25CR

Standard pipe library file : B313-06

Nominal diameter : 450.000 mm

Pipe schedule : XS

Pipe Inner Diameter : 431.800 mm Pipe Outer Diameter : 457.200 mm

Allowable at Oper, Sn: 125.898 MPa Allowable at Amb, Sn : 137.895 MPa

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page37 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

1.3 GASKET:

------

Gasket Type : Ring joint iron or soft steel

Gasket Config. : Sketch (6) - Column 1 of Table 2-5.2

Inside Diameter : 514.350 mm Seating Width, N : 19.050 mm

Width of Nubbin, w : 19.050 mm Gasket Thickness : 0.000 mm

Strength Factor, m : 5.500 Seating Stress, y : 124.106 MPa

Load Reaction Dia., G: 533.400 mm Eff. Press. Width, b: 2.381 mm

1.4 BOLTS:

-----

Material : SA-193-B16-1

No. of Bolts : 20 Min. Bolt Spacing : 101.6000 mm

Bolt Diameter : 47.6250 mm Eff. Bolt Diameter : 44.1884 mm

Hub Radial Dist. : 60.3250 mm Outer Edge Dist. : 47.6250 mm

Bolt Hole Diameter : 50.8000 mm

Allowable at Oper, Sb: 137.895 MPa Allowable at Amb, Sa : 137.895 MPa

1.5 PRESSURE & TEMPERATURE LOADS:

----------------------------

Internal pressure : 3.300 N/mm2 At temperature : 120.000 deg C

External pressure : 0.000 N/mm2 At temperature : -17.778 deg C

Ambient temp. : 21.100 deg C

D E S I G N

2.0 SUMMARY:

-------

Design code : ASME Section VIII Div. I 2010

Flange Thickness : 101.6000 mm

Flange Volume : 0.42E+08 mm**3 **Flange Weight : 191.994 kg

Flange Diameter : 787.400 mm Flange Bore : 431.800 mm

Polar Mom Inertia : 0.42E+08 mm4 Bend Mom Inertia : 0.35E+08

mm4

Bolt Circle Diameter : 685.800 mm Gasket Load Diameter : 533.400 mm

Gasket Strength Factor : 5.5000 Gasket Seating Stress : 124.106

MPa

**NOTE: This weight is not used in the static/dynamic analysis.

For lap flanges this weight is for the stub flange only.

This weight does not include any bolt or nut weight.

To set the weight use the Modify > Flange menu option.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page38 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

--------------------------------------------------------------------------------------

--------------------------

01-0010 1

05/10/2013 AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ BENTLEY

10:18 AM AutoPIPE Plus

9.5.0.21

--------------------------------------------------------------------------------------

R E S U L T S

3.1 ALLOWABLE STRESSES:

------------------

1. OPERATING CONDITIONS:

INT. PRESS ALLOWABLE INT. PRESS

MPa MPa RATIO

---------- --------- ----------

Longitudinal Hub Stress, SH = 32.090 206.843 0.155

Radial Flange Stress, SR = 27.159 137.895 0.197

Tangential Flange Stress,ST = 22.972 137.895 0.167

Average Stress, (SH+SR)/2.0 = 29.624 137.895 0.215

Average Stress, (SH+ST)/2.0 = 27.531 137.895 0.200

Bolt Tensile Stress = 28.765 137.895 0.209

**2. GASKET SEATING CONDITIONS:

INT. PRESS ALLOWABLE INT. PRESS

MPa MPa RATIO

---------- --------- ----------

Longitudinal Hub Stress, SH = 67.527 206.843 0.326

Radial Flange Stress, SR = 57.151 137.895 0.414

Tangential Flange Stress,ST = 48.340 137.895 0.351

Average Stress, (SH+SR)/2.0 = 62.339 137.895 0.452

Average Stress, (SH+ST)/2.0 = 57.934 137.895 0.420

Bolt Tensile Stress = 86.697 137.895 0.629

**NOTE: The gasket seating condition stresses are calculated using the full available

bolt load,

where Wg = [(Am + Ab)*Sa]/2.

3.2 RIGIDITY CRITERION:

------------------

1. OPERATING CONDITIONS:

INT. PRESS ALLOWABLE INT. PRESS

RATIO

---------- --------- ----------

Rigidity Index, J = 0.092 1.000 0.092

2. GASKET SEATING CONDITIONS:

INT. PRESS ALLOWABLE INT. PRESS

RATIO

---------- --------- ----------

Rigidity Index, J = 0.188 1.000 0.188

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page39 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

--------------------------------------------------------------------------------------

--------------------------

01-0010 1

05/10/2013 AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ BENTLEY

10:18 AM AutoPIPE Plus

9.5.0.21

--------------------------------------------------------------------------------------

--------------------------

S T R E S S F A C T O R S

4.1 DUE TO FLANGE DIAMETER:

----------------------

K = 1.8235 T = 1.5749

Z = 1.8601 Y = 3.4019

U = 3.7383

e = 0.0071 1/mm

d = 2238410. mm**3

ho = 74.0531 mm

Lambda = 1.563

4.2 DUE TO FLANGE HUB:

-----------------

h/ho = 43.5606

G1/G0 = 5.2500

F = 0.5276

V = 0.0199

f = 1.0000

F O R C E S & M O M E N T S

5.1 DUE TO INTERNAL PRESSURE:

------------------------

Total hydrostatic end force, H = 737411.1 N

Minimum operating bolt load, Wm1 = 882259.7 N

Min. gasket seating bolt load, Wm2 = 495221.2 N

Design gasket seating bolt load, Wg = 2659136. N

Ring type moment factor, Fs = 1.0000

Bolt spacing correction factor, Bsc = 1.0000

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page40 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

Mom. Arm x Force = Moment*Bsc*Fs

mm N N.m

-------- -------- -----------------

Hydrostatic end force moment, MD = hd x Hd

93.662 x 483246.8 = 45262.19

Diff. hydrostatic force moment, MT = ht x Ht

101.600 x 254164.4 = 25823.15

Operating gasket load moment, MG = hg x Hg

76.200 x 144848.6 = 11037.48

Total gasket seating moment, Mg = hg x Wg

76.200 x 2659136. = 202626.6

Ext. Bending & Ax. force moment Moe = 4Me.(xr) + Fa.hD = Moment*Fs

14167.04 + 0.000 = 14167.04

Where, xr = [I/(0.3846*Ip+I)]*[hD/(C-2*hD)]

Total operating moment, MO=MD+MT+MG+Moe = 96289.86 N.m

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page41 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

Failure report Sample:

-------------------------------------------------------------------------------------

---------------------------

01-0010 1

05/10/2013 AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ BENTLEY

10:32 AM AutoPIPE Plus

9.5.0.21

-------------------------------------------------------------------------------------

---------------------------

* ******* ** ******* *******

*** ** ** ** ** ** ** **

** ** ****** ** ** ** ** ** **

** ** ** ** ** ***** ******* ** ******* *****

********* ** ** ** ** ** ** ** ** **

** ** ** ** ** ** ** ** ** ** **

** ** ***** ** ***** ** ** ** *******

Pipe Stress Analysis and Design Program

Version: 09.05.00.21

Edition: Plus

Developed and Maintained by

BENTLEY SYSTEMS, INCORPORATED

1600 Riviera Ave., Suite 300

Walnut Creek, CA 94596

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page42 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

-------------------------------------------------------------------------------------

---------------------------

01-0010 1

05/10/2013 AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ BENTLEY

10:32 AM AutoPIPE Plus

9.5.0.21

-------------------------------------------------------------------------------------

---------------------------

************************************************************

** **

** AUTOPIPE FLANGE ANALYSIS **

** **

************************************************************

SYSTEM NAME : 01-0010 1

PROJECT ID : AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ

PREPARED BY : ______________________________

AP

CHECKED BY : ______________________________

SK

1ST APPROVER : ______________________________

DKD

2ND APPROVER : ______________________________

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page43 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

-------------------------------------------------------------------------------------

---------------------------

01-0010 1

05/10/2013 AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ BENTLEY

10:32 AM AutoPIPE Plus

9.5.0.21

-------------------------------------------------------------------------------------

---------------------------

************************************************************

** **

** POINT A00 FLANGE # 1 **

** WELD-NECK **

** NPS 450.000 mm RATING 900 **

** **

************************************************************

VESSEL DESIGN CODE : ASME Section VIII 2010, Division 1

DIMENSION LIBRARY : FlangeDimLib.mdb

DIMENSION CODE : B16-5

MATERIAL LIBRARY : asme2010.mdb

FLANGE ATTACHMENT : INTEGRAL

FLANGE CONFIGURATION : WHOLE

I N P U T S

1.1 FLANGE:

------

Material : SA-105

Outside diameter, A : 787.400 mm Bore diameter, B : 431.800 mm

Thickness, tf : 101.600 mm Rigidity Factor, K : 0.300

Small End Hub Thk, g0: 12.7000 mm Large End Hub Thk, g1: 66.6750 mm

Hub Length, h : 127.000 mm Bolt Circle Dia., C : 685.800 mm

Allowable at Oper, Sf: 137.895 MPa Allowable at Amb, Sf : 137.895 MPa

Modulus. at Oper, E : 201975.8 MPa Modulus. at Amb, E : 199948.8 MPa

1.2 PIPE:

----

Material : A691-G2.25CR

Standard pipe library file : B313-06

Nominal diameter : 450.000 mm

Pipe schedule : XS

Pipe Inner Diameter : 431.800 mm Pipe Outer Diameter : 457.200 mm

Allowable at Oper, Sn: 137.895 MPa Allowable at Amb, Sn : 137.895 MPa

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page44 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

1.3 GASKET:

------

Gasket Type : Ring joint iron or soft steel

Gasket Config. : Sketch (6) - Column 1 of Table 2-5.2

Inside Diameter : 514.350 mm Seating Width, N : 19.050 mm

Width of Nubbin, w : 19.050 mm Gasket Thickness : 0.000 mm

Strength Factor, m : 5.500 Seating Stress, y : 124.106 MPa

Load Reaction Dia., G: 533.400 mm Eff. Press. Width, b: 2.381 mm

1.4 BOLTS:

-----

Material : SA-193-B16-1

No. of Bolts : 20 Min. Bolt Spacing : 101.6000 mm

Bolt Diameter : 47.6250 mm Eff. Bolt Diameter : 44.1884 mm

Hub Radial Dist. : 60.3250 mm Outer Edge Dist. : 47.6250 mm

Bolt Hole Diameter : 50.8000 mm

Allowable at Oper, Sb: 137.895 MPa Allowable at Amb, Sa : 137.895 MPa

1.5 PRESSURE & TEMPERATURE LOADS:

----------------------------

Internal pressure : 20.000 N/mm2 At temperature : -17.778 deg C

External pressure : 0.000 N/mm2 At temperature : -17.778 deg C

Ambient temp. : 21.100 deg C

D E S I G N

2.0 SUMMARY:

-------

Design code : ASME Section VIII Div. I 2010

Flange Thickness : 101.6000 mm

Flange Volume : 0.42E+08 mm**3 **Flange Weight : 191.994

kg

Flange Diameter : 787.400 mm Flange Bore : 431.800

mm

Polar Mom Inertia : 0.42E+08 mm4 Bend Mom Inertia : 0.35E+08

mm4

Bolt Circle Diameter : 685.800 mm Gasket Load Diameter : 533.400

mm

Gasket Strength Factor : 5.5000 Gasket Seating Stress : 124.106

MPa

**NOTE: This weight is not used in the static/dynamic analysis.

For lap flanges this weight is for the stub flange only.

This weight does not include any bolt or nut weight.

To set the weight use the Modify > Flange menu option.

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page45 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

-------------------------------------------------------------------------------------

---------------------------

01-0010 1

05/10/2013 AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ BENTLEY

10:32 AM AutoPIPE Plus

9.5.0.21

-------------------------------------------------------------------------------------

R E S U L T S

3.1 ALLOWABLE STRESSES:

------------------

1. OPERATING CONDITIONS:

INT. PRESS ALLOWABLE INT. PRESS

MPa MPa RATIO

---------- --------- ----------

Longitudinal Hub Stress, SH = 168.658 206.843 0.815

Radial Flange Stress, SR = 142.742 137.895 1.035*

Tangential Flange Stress,ST = 120.736 137.895 0.876

Average Stress, (SH+SR)/2.0 = 155.700 137.895 1.129*

Average Stress, (SH+ST)/2.0 = 144.697 137.895 1.049*

Bolt Tensile Stress = 174.332 137.895 1.264*

**2. GASKET SEATING CONDITIONS:

INT. PRESS ALLOWABLE INT. PRESS

MPa MPa RATIO

---------- --------- ----------

Longitudinal Hub Stress, SH = 123.112 206.843 0.595

Radial Flange Stress, SR = 104.194 137.895 0.756

Tangential Flange Stress,ST = 88.131 137.895 0.639

Average Stress, (SH+SR)/2.0 = 113.653 137.895 0.824

Average Stress, (SH+ST)/2.0 = 105.622 137.895 0.766

Bolt Tensile Stress = 158.061 137.895 1.146*

**NOTE: The gasket seating condition stresses are calculated using the full

available bolt load,

where Wg = [(Am + Ab)*Sa]/2.

3.2 RIGIDITY CRITERION:

------------------

1. OPERATING CONDITIONS:

INT. PRESS ALLOWABLE INT. PRESS

RATIO

---------- --------- ----------

Rigidity Index, J = 0.465 1.000 0.465

2. GASKET SEATING CONDITIONS:

INT. PRESS ALLOWABLE INT. PRESS

RATIO

---------- --------- ----------

Rigidity Index, J = 0.343 1.000 0.343

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page46 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

-------------------------------------------------------------------------------------

---------------------------

01-0010 1

05/10/2013 AMMONIA PLANT FEEDSTOCK CHANGEOVER PROJ BENTLEY

10:32 AM AutoPIPE Plus

9.5.0.21

-------------------------------------------------------------------------------------

---------------------------

S T R E S S F A C T O R S

4.1 DUE TO FLANGE DIAMETER:

----------------------

K = 1.8235 T = 1.5749

Z = 1.8601 Y = 3.4019

U = 3.7383

e = 0.0071 1/mm

d = 2238410. mm**3

ho = 74.0531 mm

Lambda = 1.563

4.2 DUE TO FLANGE HUB:

-----------------

h/ho = 43.5606

G1/G0 = 5.2500

F = 0.5276

V = 0.0199

f = 1.0000

F O R C E S & M O M E N T S

5.1 DUE TO INTERNAL PRESSURE:

------------------------

Total hydrostatic end force, H = 4469158. N

Minimum operating bolt load, Wm1 = 5347028. N

Min. gasket seating bolt load, Wm2 = 495221.2 N

Design gasket seating bolt load, Wg = 4847986. N

Ring type moment factor, Fs = 1.0000

Bolt spacing correction factor, Bsc = 1.0000

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page47 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

Mom. Arm x Force = Moment*Bsc*Fs

mm N N.m

-------- -------- -----------------

Hydrostatic end force moment, MD = hd x Hd

93.662 x 2928768. = 274316.3

Diff. hydrostatic force moment, MT = ht x Ht

101.600 x 1540390. = 156503.9

Operating gasket load moment, MG = hg x Hg

76.200 x 877870.4 = 66893.86

Total gasket seating moment, Mg = hg x Wg

76.200 x 4847986. = 369417.3

Ext. Bending & Ax. force moment Moe = 4Me.(xr) + Fa.hD = Moment*Fs

7715.130 + 655.639 = 8370.770

Where, xr = [I/(0.3846*Ip+I)]*[hD/(C-2*hD)]

Total operating moment, MO=MD+MT+MG+Moe = 506084.8 N.m

L&T Engineering , Faridabad

Document No

PD-DP-0005

Rev 0A

GUIDELINES FOR FLANGE

LEAKAGE CALCULATION

Page48 of 48

Electronic documents once printed are uncontrolled. Control documents are electronic documents on designated server.

L&T- DEC 2005. Contains confidential and/or proprietary information to L&T and its affiliated companies which shall not be used,

disclosed or reproduced in any format by any non-L&T party without L&Ts prior written permission. All rights reserved.

Format EN-FT-4061, Rev 0

5 REFERENCE DOCUMENTS

ASME B16.5 -2009 for pipe flanges & flanged fittings.

ASME B16.20-2007 for metallic gaskets for pipe flanges.

SEC. VIII Division I Appendix 2 for gasket parameters.

.

You might also like

- Flange Leakage L&TDocument48 pagesFlange Leakage L&Tmidnightcowboy100% (1)

- Flange Leakage Check SheetDocument1 pageFlange Leakage Check SheetEhtisham AndrAbiNo ratings yet

- EN1591 Flange DesignDocument9 pagesEN1591 Flange DesignmadodandembeNo ratings yet

- Nozzle Movement CalculationDocument23 pagesNozzle Movement CalculationPriyanathan Thayalan100% (4)

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Flange Leakage CheckingDocument25 pagesFlange Leakage CheckingAMRUTA PATIL100% (1)

- Stress Sample Calculation On Base EllDocument1 pageStress Sample Calculation On Base EllLionel TorradoNo ratings yet

- Top Pipe MomentDocument2 pagesTop Pipe MomentrsubramaniNo ratings yet

- Virtual Anchor Length - KBRDocument22 pagesVirtual Anchor Length - KBRSammar Adhikari100% (2)

- Piping Stress Analysis Design Basis PDFDocument38 pagesPiping Stress Analysis Design Basis PDFSaima SaimaNo ratings yet

- Ancor Flanges Asme ViiiDocument3 pagesAncor Flanges Asme ViiiAnjani PrabhakarNo ratings yet

- Anchor FlangeDocument2 pagesAnchor Flangeannu300100% (1)

- MJPN-PGAS-3514-PL-CA-001 (Calculation For Pipeline Free Span) Rev. B (REVIEW)Document11 pagesMJPN-PGAS-3514-PL-CA-001 (Calculation For Pipeline Free Span) Rev. B (REVIEW)frusdt100% (3)

- Senior Flexonics Expansion JointsDocument93 pagesSenior Flexonics Expansion JointssunethbabuNo ratings yet

- Flange LeakageDocument29 pagesFlange Leakagevrindk80% (5)

- Allowable Pipe Spans LoadsDocument84 pagesAllowable Pipe Spans LoadsMalcolm Hutton100% (5)

- Hexagon PPM Expansion Joints in Piping Systems PPTDocument88 pagesHexagon PPM Expansion Joints in Piping Systems PPTMina Magdy100% (1)

- Pipe Stress Analysis Design BasisDocument25 pagesPipe Stress Analysis Design Basischandru683100% (3)

- Pipe Support Basic - Seminar III, G.palaniDocument67 pagesPipe Support Basic - Seminar III, G.palaniAnonymous Xy309m9Sm9100% (2)

- Pipeline Wall Thickness Calculation PresentationDocument31 pagesPipeline Wall Thickness Calculation PresentationGodwin0% (1)

- Pipe Wall THK Calc For External PressureDocument2 pagesPipe Wall THK Calc For External PressurektejankarNo ratings yet

- Pipe Stress Analysis Information For FRPDocument10 pagesPipe Stress Analysis Information For FRPchemy5No ratings yet

- Kellogg Equivalent Pressure Method For Piping FlangesDocument4 pagesKellogg Equivalent Pressure Method For Piping FlangesLucky Jaswal0% (1)

- Calculator ASME B31 4Document11 pagesCalculator ASME B31 4Denstar Ricardo Silalahi50% (2)

- Special Pipe SupportsDocument293 pagesSpecial Pipe SupportsVijay_Damam100% (2)

- Stress Analysis of GRP GRE FRP Piping System Using Caesar IIDocument5 pagesStress Analysis of GRP GRE FRP Piping System Using Caesar IIiaftNo ratings yet

- Flange Leakage WebinarDocument89 pagesFlange Leakage WebinarAdekimi Emmanuel100% (3)

- ASME B16.5 2013 FlangeRating 1.0Document4 pagesASME B16.5 2013 FlangeRating 1.0sanjaysyNo ratings yet