Professional Documents

Culture Documents

House Plans Cold Denver PDF

Uploaded by

eppg820 ratings0% found this document useful (0 votes)

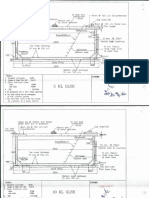

84 views12 pagesThis document contains plans and details for a single family home being built by Habitat for Humanity of MetroDenver. The plans include a foundation plan, first floor framing plan, second floor framing plan, framing elevations, and construction details. The single story home will have 672 square feet on the first floor and 752 square feet on the second floor, for a total of 1,424 square feet. Construction will follow best practices for building science and energy efficiency.

Original Description:

Original Title

House_Plans_Cold_Denver.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains plans and details for a single family home being built by Habitat for Humanity of MetroDenver. The plans include a foundation plan, first floor framing plan, second floor framing plan, framing elevations, and construction details. The single story home will have 672 square feet on the first floor and 752 square feet on the second floor, for a total of 1,424 square feet. Construction will follow best practices for building science and energy efficiency.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

84 views12 pagesHouse Plans Cold Denver PDF

Uploaded by

eppg82This document contains plans and details for a single family home being built by Habitat for Humanity of MetroDenver. The plans include a foundation plan, first floor framing plan, second floor framing plan, framing elevations, and construction details. The single story home will have 672 square feet on the first floor and 752 square feet on the second floor, for a total of 1,424 square feet. Construction will follow best practices for building science and energy efficiency.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Habitat for Humanity of Metr oDenver

Single Family Housing

13thAvenue andNelsonStr eet

Lakewood, Color ado

Building Science Corporation

Architecture and Building Science

22 JANUARY 2001

AND BETSY PETTIT ARCHITECTS

BUILDING SCIENCE CORPORATION

W. 13th AVENUE

N

E

L

S

O

N

S

T

R

E

E

T

RAILROAD TRACKS

LOT A

LOT B LOT C

LOT D

LOT E

LOT F

FOUNDATION PLAN 1

SCALE 1/4"= 1'-0"

34'-0"

20'-0"

8'-0"

28'-0"

24'-0" 10'-0"

-4"STONE PAD (NO FINES)

-6 M IL POLYETHYLENE

-6"W IRE M ESH

-2"CONCRETE SLAB

TOP OF CONCRETE CAISSON

TOP OF CONCRETE W ALL

TOP OF CONCRETE SLAB

ELEVATION -(2'-10")

ELEVATION -(3'-0")

ELEVATION 0'-0"

SOIL GAS

VENT

(GARAGE)

HIGH POINT

ELEVATION -(6")

LOW POINT

ELEVATION -(8 1/2")

M

IN

IM

U

M

S

LO

P

E 1/8" / 1'-0"

1/AA

A-8

RETURN DUCT DOW N SUPPLY DUCT UP

FURN

EXTERNAL FILTER ASSEM BLY

"SOFT"CANVAS CONNECTION

EXHAUST VENT

1/AA

A-8

A-1

3/A

1/A

A-9

-2"EXPANDED POLYSTYRENE

-8"X 3'-0"CONTINUOS CONCRETE

-1/4""HARDIEBACKER"TILE BACKERBOARD

-DAM PROOFING TO GRADE

RIGID INSULATION

FOUNDATION W ALL

(NON-COM BUSTIBLE W HEN TESTED IN

ACCORDANCE W ITH ASTM E-136

M ECHANICALLY FASTENED TO CONCRETE

BEAM POCKET

E

Q

.

E

Q

.

E

Q

.

12"X 12"CONCRETE PAD

10"O CASSION

3"ADJUSTABLE STEEL COLUM N-TYPICAL

W 12 X 16 STEEL BEAM

UP

S S

UP TO FIRST

FLOOR

GFI

EXHAUST VENT 3

SCALE 1"= 1'-0"

PROTECTIVE HOOD W ITH INSECT

SW ITCH TO BE LABELED AS "VENTILATION FAN"

50 CFM (EXHAUST)IN LINE FAN

TO RUN CONTINUOUSLY

4"PVC PIPE

OPENING AT 12"ABOVE SLAB

FLOW

ON/OFF SW ITCH LOCATED AT FURNACE

SCREEN AND BACK DRAFT DAM PER

3'-0"

PROVIDE 3'-0"M ULCH W ITH

DROUGHT RESISTANT PLANTS

1/4"HARDIBAKER 500 CERAM IC TILE

BACKER BOARD

M ECHANICALLY FASTENED TO CONCRETE

1

2

"

M

IN

IM

U

M

CENTRAL RETURN

AT FIRST FLOOR

FURNACE

M AIN SUPPLY

TRUNK

CANVAS CONNECTION (SOFT CONNECTION)

FILTER ASSEM BLY

RETURN DUCT

FIRST FLOOR

FURNACE DETAIL 2

SCALE 1"= 1'-0"

FIRST FLOOR FRAM ING PLAN 1

SCALE 1/4"= 1'-0"

(2)TAKEOFFS (TOP AND SIDE)

OPEN W EB FLOOR TRUSS 24"OC W /7/8"TONGUE

AND GROOVE SUB FLOOR (GLUED AND SCREW ED)

FLOOR W ALLS ABOVE

DASHED LINES INDICATE FIRST

1/AA

A-8

1/AA

A-8

1/A

A-9

1/AA

A-8

1/A

A-9

A-1

3/A

2 SUPPLYS

TO SECOND

(2)SUPPLY

SECOND

(2)SUPPLY

FIRST

SUPPLY

FIRST

SUPPLY

FIRST

SUPPLY

FIRST

CENTRAL RETURN DOW N

SUPPLY

FIRST

4"DRYER VENT W /PROTECTIVE HOOD

90% FURNACE

FURNACE INTAKE

AND EXHAUST

2'-0"

2'-0"

2'-0"

3'-0"

1'-8 1/2"

HATCH

OPENING

EXHAUST VENT

AS PER 504.4,504.6,511.2 IM C

6"INSULATED FLEX DUCT

TO CENTRAL RETURN

DAM PER

VEN

T H

O

O

D

W

ITH

IN

SEC

T SC

REEN

FURNACE EXHAUST T0 BE 4'-0"BELOW W INDOW OPENING

AND AS FAR RIGHT AS POSSIBLE

ENTRY

PORCH

DINING ROOM

8'-1"CLG HGT

8'-1"CLG HGT

PANTRY

KITCHEN

8'-1"CLG HGT

5 SHELVES

LIVING ROOM

8'-1"CLG HGT

8'-1"CLG HGT

2468

8'-1"CLG HGT

BATH

HALL

8'-1"CLG HGT

2868

UP

REF.

HALL

GARAGE

9'-11"CLG HGT

W /D

2868

2868

2668

2668

3068

HEADER HEADER HEADER

3046 3046

E KT s

W ALL 1

s K T c s c KT TK s E c K T KT c s

8'-1"

7'-1 3/4"

2'-4 1/2"

3'-2 1/8" 3'-2 1/8"

2'-0"

E E KT

W ALL 7

K T

9'-8 7/8"

7'-4 1/2"

HEADER

3'-2 1/8"

8'-4 1/2"

INSTALL 1/2"OSB (OR PLYW OOD)

TYPICAL AS SHOW N

TO THE EXTERIOR OF SHEAR PANEL

POLYSTYRENE RIGID INSULATION (XPS)

PANEL -INSTALL 1/2"EXTRUDED

SHEATHING AS SHEAR RESISTING

c

KT

E

s

s

s

KT

W

A

L

L

2

s

s

s

E/K

KT

T

s

s

s

s

s

8'-1"

7'-1 3/4"

2'-4 1/2"

3'-2 1/8"

2'-10 1/8"

7'-1 3/4"

E

s

s

s

s

s

s

s

E

s

s

W

A

L

L

8

9'-5 7/8"

s

s

s

W

A

L

L

4

W

A

L

L

3

CLOSET

7'-3 5/16" 5'-5 3/16" 6'-7 3/16" 14'-8 5/16"

34'-0"

20'-0"

5'-0" 5'-0"

10'-0"

9'-4"

11'-11"

6'-9"

28'-0"

5'-3" 6'-9" 5'-1 1/2" 3'-7 1/2"

34'-0"

5'-3"

2'-9"

8'-0"

24'-0"

23'-1"

5'-1"

5'-1" 4'-11"

19'-1"

9'-6 1/2"

2'-0"

2'-0"

2'-0"

2'-0"

2'-0"

H E A D E RH E A D E R H E A D E R

2 0 3 2 2 0 3 2

E s

W A L L 5

c KTK T EsKTK Ts scK T KTE s s s s E

W A L L 9

9'-5 7/8"

2 ' - 0 "

2 ' - 2 1 / 8 " 2 ' - 1 0 1 / 8 " 2 ' - 2 1 / 8 "

2 ' - 0 "

8'-1"

7'-0 1/4"

3'-5 1/2"

3046

3032

E

K T

s

W

A

L

L

6

KT

c

s

c

s

E

c

KT

s

KT

c

s

s

s

s

s

2'-10 1/8"

3'-2 1/8"

8'-1"

7'-1 3/4"

3'-8 1/2"

2'-0"

2'-4 1/2"

7'-1 3/4"

SUPPLY SUPPLY

SUPPLY

SUPPLY

SUPPLY

SUPPLY

6'-0"

23'-6 3/4"

3'-2 1/8"X 4'-9 1/4" RO

3046

(2)3'-2 1/8"X 4'-9 1/4" RO

(2)3046

3'-2 1/8" X 4'-9 1/4" RO

3046

3'-2 1/8" X 4'-9 1/4" RO

3046

3'-2 1/8" X 3'-5 1/4" RO

3032

2'-2 1/8"X 3'-5 1/4" RO

2032

2'-2 1/8"X 3'-5 1/4" RO

2032

W H

2'-2" 4'-8" 2'-2"

3'-8"

3'-1"

CENTRAL

RETURN

8'-3"

3'-1"

6'-5 1/2"

13'-4"

10'-7"

W ALL 1

W ALL 7

W ALL 9

W ALL 5

W

A

L

L

8

W ALL 3

W ALL 4

W

A

L

L

2

W

A

L

L

6

3'-2"

3'-1"

9"

3'-4"

2'-8"

2'-4"

5'-7"

3 1/2"

5'-0" 7"

3'-0"

9'-2"

4"

3"

11"

HEADER

HEADER

HEADER

HEADER

11'-7"

9'-8"

3'-3"

3046

HEADER

3'-2 1/8"

c s

1

SCALE 1/4"= 1'-0"

FIRST FLOOR PLAN / FRAM ING ELEVATIONS (672 SQ. FT.)

1/AA

A-8

1/AA

A-8

1/A

A-9

1/AA

A-8

1/A

A-9

GRILLE

TRANSFER

GRILLE

SUB-BASEM ENT CRAW L SPACE

TRANSFER GRILLE (4"X 8"TYP.)

TRANSFER

GRILLE

TRANSFER

3'-6"X 3'-0"

STAIR LANDING

DN

20" x 36"

ACCESS HATCH

3'-1"

ALL STAIRS TO HAVE AT LEAST ONE HANDRAIL 34"-38"ABOVE

THE TREAD W /A M INIM UM CIRCUM FERENCE OF A 1 1/2"CIRCLE

AND A M AXIM UM CIRCUM FERENCE OF A 2"CIRCLE

AND A HORIZONTAL CROSS SECTION OF 1 1/2"-3"

A.O.SM ITH "SEALED SHOT"FPD-50-230

SEALED COM BUSTION W ATER HEATER

AIR INTAKE AND EXHAUST FOR W ATER HEATER

IN SECOND FLOOR FRAM E ABOVE

VENT TO OUTSIDE

ss

LANDING AT EXTERIOR DOOR TO

BE M AXIM UM 8"BELOW FINISHED FLOOR

OPPOSING GRIP 3/4"M INIM UM LESS THE W IDEST

CROSS SECTION OF GRIPPING SURFACE

5/8" TYPE X GW

B

ALL CLOSET SURFACES

FRAM E @ INTERIOR W ALL (plan) 2

CONTINUOUS BEAD OF SEALANT AT FIRST STUD TYPICAL

2x4 INTERIOR STUD W ALL 24"OC

HARDIPLANK LAP SIDING

1/2"EXTRUDED POLYSTYRENE (XPS)

RIGID INSULATION

DRYW ALL CLIP

1/2"GYPSUM W ALLBOARD

2x6 STUD W ALL 24"OC

R-19 UNFACED BATT INSULATION

FRAM E @ 2 STUD CORNER (plan) 3

SCALE 1"= 1'-0"

RIGID INSULATION

FRAM ING ELEVATIONS

(AT SHEAR PANEL)-SEE W ALL

1/2"GYPSUM W ALLBOARD

DRYW ALL CLIP

2x6 STUD W ALL 24"OC

R-19 UNFACED BATT INSULATION

1/2"OSB (OR PLYW OOD)SHEATHING

1/2"EXTRUDED POLYSTYRENE (XPS)

HARDIPLANK LAP SIDING

CORNER DETAIL

SCALE 1"= 1'-0"

4

CONTINUES AROUND CORNER

2 -LAYERS 1/2"RIGID INSULATION

CAVITY INSULATION

DRYW ALL CLIP

GARAGE W ALL

2 X 6

1/2"GYPSUM W ALL BOARD

GARAGE W ALL

2 X 6

2 X 6 W ALL STUD

SCALE 1"= 1'-0"

1/2"OSB SHEATHING

LV

L B

EA

M

(S

IZE B

Y O

TH

ER

S

)

OPEN W EB FLOOR TRUSS 24"OC W /7/8"TONGUE

AND GROOVE SUB FLOOR (GLUED AND SCREW ED)

LVL BEAM (SIZE BY OTHERS)

FLOOR W ALLS ABOVE

DASHED LINES INDICATE SECOND

SUPPLY

SECOND

SUPPLY

SECOND

SUPPLY

SECOND

SUPPLY

SECOND

SUPPLY

SECOND

SUPPLY

SECOND

LVL BEAM (SIZE BY OTHERS)

OPEN W EB FLOOR TRUSS 24"OC W /7/8"TONGUE

AND GROOVE SUB FLOOR (GLUED AND SCREW ED)

2'-0"

2'-0"

2'-0"

2'-0"

2'-0"

2'-0"

1

SCALE 1/4"= 1'-0"

SECOND FLOOR FRAM ING PLAN

1/AA

A-8

1/AA

A-8

1/A

A-9

1/AA

A-8

1/A

A-9

AIR INTAKE AND EXHAUST FOR SEALED

COM BUSTION HOT W ATER HEATER

BEDROOM 2

CLOSET

8'-1"CLG HGT

BEDROOM 3

BEDROOM 1

CLOSET

2668

2668

CLOSET

36" HIGH HALF W

ALL

DN

BATH

CLOSET

HALL

2668

BEDROOM 4

2668

2668

CLOSET

CLOSET

2668

1668

2668

8'-1"CLG HGT

8'-1"CLG HGT

8'-1"CLG HGT

8'-1"CLG HGT

1

SCALE 1/4"= 1'-0"

SECOND FLOOR PLAN / W ALL FRAM ING PLAN (752 SQ. FT.)

SUPPLY SUPPLY

SUPPLY

SUPPLY

SUPPLY

SUPPLY

8'-1"CLG HGT

3'-2 1/8"X 4'-9 1/4" RO

3046

3'-2 1/8"X 4'-9 1/4" RO

3046

3'-2 1/8"X 4'-9 1/4" RO

3046

3'-2 1/8"X 4'-9 1/4" RO

3046

2'-2 1/8"X 3'-5 1/4" RO

2032

3'-2 1/8"X 4'-9 1/4" RO

3046

3'-2 1/8" X 4'-9 1/4" RO

3046

3'-2 1/8" X 4'-9 1/4" RO

3046

3'-2 1/8" X 4'-9 1/4" RO

3046

W ALL 1

W ALL 3

W ALL 5

W

A

L

L

6

W

A

L

L

2

W

A

L

L

4

1

4

'-4

"

11'-5 1/2"

5'-3" 13'-6" 5'-3"

24'-0"

6

'-9

"

1

4

'-6

"

6

'-9

"

5'-0" 5'-0"

10'-0"

2

'-9

"

5

'-3

"

2

0

'-0

"

5'-3" 14'-0 11/16" 9'-8 5/16" 5'-0"

34'-0"

1

0

'-1

"

2

'-1

"5'-7"

5'-7"

2'-1"

4

'-2

"

2'-1"

4

'-2

"

1

9

'-1

"

9'-8 1/2"

2'-1"

6

'-4

"

9

'-1

1

1

/2

"

11'-4"

3

'-1

"

8'-3" 3'-1"

6

'-5

1

/2

"

5

'-0

"

1

'-1

0

"

6

'-8

1

/2

"

2'-4 1/2"

8

'-1

"

7

'-1

3

/4

"

2

'-4

1

/2

"

2'-0"

HEADER HEADER

3046 3046

3'-2 1/8" 3'-2 1/8"

E KT s

W ALL 1

s K T c s c s E c K T s KT c s s

E

s

W

A

L

L

4

s

s

s

E

s

s

s

s

s

8'-1"

8'-1"

7'-1 3/4"

2'-4 1/2"

3046

3046

E

K T

s

W

A

L

L

6

s

K T

s

c

s

E

c

KT

s

KT

c

s

s

c

s

s

H E A D E RH E A D E R

3 0 4 6

3 0 4 6

E K Ts

W A L L 5

sKTc sc s Ec KT sK T css

H E A D E R

3 0 4 6

s s s K T KT c

3 ' - 2 1 / 8 "

2

'-4

1

/2

"

7

'-1

3

/4

"

8

'-1

"

2 ' - 0 "

2 ' - 2 1 / 8 "

3 ' - 2 1 / 8 "

E c KT s K T c s E

3046

8

'-1

"

7

'-1

3

/4

"

2

'-4

1

/2

"

2'-0"

3'-2 1/8"

W ALL 2

8'-1"

7'-1 3/4"

2'-4 1/2"

2

'-0

"

HEADER

3046

3

'-2

1

/8

"

E

c

KT

s

KT

c

s

E

W

A

L

L

3

2

8

'-0

"

3

'-2

1

/8

"

2

'-0

"

3

'-2

1

/8

"

TRANSFER

SEE DETAIL 5

GRILLELOW HIGH

LOW

HIGH

TRANSFER

SEE DETAIL 5

GRILLE

TRANSFER

SEE DETAIL 5

GRILLE

LOW

HIGH

TRANSFER

SEE DETAIL 5

GRILLE

LOW

HIGH

22"x30"

ATTIC ACCESS

INSTALL M IXING CONTROL VALVE TO PROVIDE

M AXIM UM OF 120 DEG.F.W ATER TEM PERATURE

M OISTURE RESISTANT GW B

SURROUND AT TUB AREA

AS PER 410.7 UPC

AND UNDERSIDE OF DOOR

DOORS TO BE UNDERCUT 1/2"BETW EEN TOP OF FINISH FLOOR

LOW

SUB FLOOR

TRANSFER GRILLES PROVIDE PRESSURE RELIEF /PRESSURE

EQUALIZATION BETW EEN CLOSED ROOM S AND COM M ON AREAS

DETAIL AT TRANSFER GRILLE

SCALE 1/2"= 1'-0"

4

NOTE 1:

NOTE 2:

TRANSFER PLENUM

STUD CAVITY AS

6x14 GRILLE

6x14 GRILLE

GW B

HIGH

NOTE 3:

AS SHOW N ABOVE)800-222-5932 FAX 508-295-8105

USE ZENON PRESSURE RELIEF VENT (USED AS ALTERENATE TO FIELD CONSTRUCTED M ODEL

PERM ITTED IN STUD CAVITY

*NO ELECTRICAL W IRING

USED AS TRANSFER PLENUM

FRAM E @ INTERIOR W ALL (plan) 2

CONTINUOUS BEAD OF SEALANT AT FIRST STUD TYPICAL

2x4 INTERIOR STUD W ALL 24"OC

HARDIPLANK LAP SIDING

1/2"EXTRUDED POLYSTYRENE (XPS)

RIGID INSULATION

DRYW ALL CLIP

1/2"GYPSUM W ALLBOARD

2x6 STUD W ALL 24"OC

R-19 UNFACED BATT INSULATION

FRAM E @ 2 STUD CORNER (plan) 3

SCALE 1"= 1'-0"

RIGID INSULATION

FRAM ING ELEVATIONS

(AT SHEAR PANEL)-SEE W ALL

1/2"GYPSUM W ALLBOARD

DRYW ALL CLIP

2x6 STUD W ALL 24"OC

R-19 UNFACED BATT INSULATION

1/2"OSB (OR PLYW OOD)SHEATHING

1/2"EXTRUDED POLYSTYRENE (XPS)

HARDIPLANK LAP SIDING

SCALE 1"= 1'-0"

1/2"OSB SHEATHING

5

:1

2

CONTINUOUS RIDGE VENT

5

:1

2

5

:1

2

1'-0"OVERHANG AT RAKE

1'-6"OVERHANG AT EVE

CONTINUOS VINYL SOFFIT

2'-0" 20'-0" 1'-6"

2'-0" 28'-0"

NOTE:TRUSS W EB

CONFIGURATION M AY VARY

W ITH M ANUFACTURER

NOTE:TRUSS W EB

CONFIGURATION M AY VARY

W ITH M ANUFACTURER

ROOF TRUSS TYPE "B"

ROOF TRUSS TYPE "A"

ORGANIC ASPHALT SHINGLE

SUCH AS "IKO"OR EQUAL

25 YEAR

-TRUSS SIZES TO BE VERIFIED BY TRUSS M ANUFACTURER

TRUSS DESIGN /INSTALLATION SPECIFICATIONS

-TRUSS SPACING 2'-0"OC

-SHOP DRAW INGS BEARING A REGISTERED ENGINEER'S CERTIFICATION

SHALL BE SUBM ITTED TO THE ARCHITECT FOR APPROVAL.

SHOP DRAW INGS SHALL INCLUDE:SPECIES,SIZE,GRADE OF LUM BER,

AND CONNECTOR PLATE SIZE AND ORIENTATION FOR EACH TRUSS TYPE.

-ALL LUM BER USED IN THE FABRICATION OF THE TRUSSES SHALL BE

STRESS GRADED AND SHALL BE OF THE SPECIES,SIZE,AND GRADE

SPECIFIED IN THE TRUSS DESIGN.

-ALL CONNECTOR PLATES SHALL BE STAM PED FROM 16,18,OR 20 GAUGE,

GRADE A,GALVANIZED STRUCTURAL STEEL.

-BOTH PLATE W IDTH AND LENGTH M UST EQUAL OR EXCEED THAT SPECIFIED

IN THE TRUSS DESIGN.

-TRUSSES SHALL BE FABRICATED IN ACCORDANCE W ITH THE TRUSS DESIGN

FROM ACCURATELY CUT W OOD M EM BERS CLAM PED IN RIGID FIXTURES DURING

ASSEM BLY TO ENSURE TIGHT FITTING JOINTS AND UNIFORM ITY IN COM PLETED

TRUSS UNITS.

-CONNECTOR PLATES ARE TO BE PRESSED INTO THE W OOD M EM BERS ON BOTH

SIDES OF THE TRUSS AT EACH JOINT SO THAT FULL PENETRATION OF THE TEETH

IS OBTAINED W ITHOUT CRUSHING THE OUTER SURFACE OF THE W OOD.

-EXERCISE CARE AT ALL TIM ES TO AVOID DAM AGE TO TRUSSES DUE TO

CARELESS HANDLING DURING STORAGE,DELIVERY,UNLOADING,AND INSTALLATION.

-TRUSSES SHALL BE INSTALLED PLUM B,ADEQUATELY BRACED,IN PROPER

ORIENTATION,AND AT THE SPACING SPECIFIED IN THE TRUSS DESIGN.

-CUTTING OF TRUSS M EM BERS OR FIELD ALTERATIONS OF ANY TRUSS OR PART

OF TRUSS IN NOT PERM ITTED.

2'-0"

SCALE 1/4"= 1'-0"

ROOF FRAM ING PLAN 1

3

SCALE 1/4"= 1'-0"

ROOF PLAN

SCALE 1/4"= 1'-0"

ROOF TRUSS SCHEDULE 2

12

5

12

10"

TYP

5

10"

TYP

2'-0" 2'-0"

TRUSS TYPE "B"

TRUSS TYPE "A"

W OOD ROOF TRUSSES 24"OC

1/AA

A-8

1/AA

A-8

2'-0" 2'-0" 2'-0"

PROVIDE SOLID BLOCKING BETW EEN

ROOF TRUSSES -TYPICAL

2 X 8 -16"OC

1/A

A-9

5 :12

ALL TRUSSE TO BE LATERAALY SUPPORTED

AT POINTS OF BEARING BY SOLID BLOCKING

TYPICAL

W INDOW SCHEDULE 1

SCALE 1/4"= 1'-0"

C C

C C

1 X 2 SUB-FASCIA TYPICAL

1 X 8 FASCIA TYPICAL

SCALE 1/4"= 1'-0"

LEFT SIDE ELEVATION 4 FRONT ELEVATION

SCALE 1/4"= 1'-0"

2

REAR ELEVATION

SCALE 1/4"= 1'-0"

3 RIGHT SIDE ELEVATION

SCALE 1/4"= 1'-0"

5

C

A

C

B

C C

C

C

C

1 X 4 W INDOW TRIM TYPICAL

C

C

TILT W ASH DOUBLE HUNG

3046

C

3'-1 5/8"X 4'-9 1/4" UD

3'-1 5/8"X 3'-5 1/4" UD

TILT W ASH DOUBLE HUNG

B

3032

2'-1 5/8"X 3'-5 1/4" UD

TILT W ASH DOUBLE HUNG

A

2032

HARDW ARE (W HITE)TO PROPERLY OPERATE

GRILLES,INSECT SCREENS,AND ALL REQUIRED

-ALL W INDOW S TO BE COM PLETE W ITH W HITE

-ALL W INDOW S TO BE W HITE IN COLOR

(STYLES AND SIZES AS NOTED ABOVE)

AND LOCK THE UNIT

-ALL W INDOW S TO BE "ANDERSEN"

4

'-9

1

/4

"

3'-2 1/8"

3

'-5

1

/4

"

3'-2 1/8"

2'-2 1/8"

3

'-5

1

/4

"

R

O

RO

R

O

RO

R

O

RO

W ITH M INIM UM HEIGHT OF 24"AND M INIM UM W IDTH OF 20"

W INDOW W ITH A M INIM UM NET CLEAR OPENING OF 5.7 SQ FT

-EVERY SLLEPING ROOM TO HAVE AT LEAST ONE OPERABLE

AND SILL LOCATED LESS THAN 44"ABOVE FINISHED FLOOR

(M EETS EGRESS REQUIREM ENTS)

1 X 4 W INDOW TRIM TYPICAL

1X6 CORNER TRIM TYPICAL

5 1/4""HARDIPLANK (4"EXPOSURE)

9 1/4""HARDIPLANK (8"EXPOSURE)

A A

KITCHEN

BEDROOM 1

ATTIC

BEDROOM 4

GARAGE

7 5/8"

10"

TYP.

TYP.

-7/8"OSB TONGUE AND GROOVE SUB FLOOR

GLUED AND SCREW ED TO TRUSS CHORD

-FINISH FLOOR

-OPEN W EB FLOOR TRUSS (SEE FRAM ING PLAN)

GLUED AND SCREW ED TO TRUSS CHORD

-7/8"OSB TONGUE AND GROOVE SUB FLOOR

-FINISH FLOOR

-1/2"GYPSUM W ALLBOARD

-W OODEN TRUSS

-1/2"GYPSUM W ALLBOARD

-R-38 UNFACED BATT INSULATION

TOP OF TOP PLATE (SECOND FLOOR)

ELEVATION 19'-1 1/4"

SECOND FLOOR (TOP OF SUB FLOOR)

ELEVATION 11'-0 1/4"

TOP OF PLATE (FIRST FLOOR)

ELEVATION 9'-7 3/8"

7 5/8"

10"

TYP.

TYP.

-OPEN W EB FLOOR TRUSS (SEE FRAM ING PLAN)

GLUED AND SCREW ED TO TRUSS CHORD

-7/8"OSB TONGUE AND GROOVE SUB FLOOR

-FINISH FLOOR

-2 -LAYERS 1/2"EXTRUDED POLYSTYRENE (XPS)

RIGID INSULATION -STAGGERED JOINTS

-5/8""TYPE X"GYPSUM W ALLBOARD

SECTION AA

SCALE 1/2"= 1'-0"

1

-2X6 24"OC STUD W ALL

RIGID INSULATION STAGGER JOINTS -TAPED JOINTS

-(2)lLAYERS 1/2"EXTRUDED POLYSTYRENE (XPS)

-HARDIPLANK LAP SIDING (SEE ELEVATIONS FOR EXPOSURE)

-1/2"GYPSUM W ALLBOARD (INTERIOR FINISH)

-R-19 UNFACED BATT INSULATION

-1/2"OSB SHEATHING AT CORNERS -SEE W ALL FRAM ING ELEVATIONS

CONDITIONED CRAW L SPACE

-OPEN W EB FLOOR TRUSS (SEE FRAM ING PLAN)

FIRST FLOOR (TOP OF SUB FLOOR)

ELEVATION 1'-6 3/8"

TOP OF CONCRETE W ALL

ELEVATION 0'-0"

TOP OF CONCRETE SLAB

ELEVATION -(2'-10")

GARAGE SLAB LOW POINT

ELEVATION -(8 1/2")

TOP OF CAISSON

ELEVATION -(3'-0")

8" M

IN

8" M

IN

*M INIM UM HEADROOM ABOVE NOSING OF ANY

RISER TO BE AT LEAST 6'-8"

*TREADS AND RISERS CANNOT VARY FROM

ONE ANOTHER BY M ORE THAN 3/8"

HATCH BEYOND

36"HIGH HALF W ALL

W ITH W OOD CAP

36"HIGH HALF W ALL

W ITH W OOD CAP

-2X6 24"OC STUD W ALL

RIGID INSULATION STAGGER JOINTS -TAPED JOINTS

-(2)lLAYERS 1/2"EXTRUDED POLYSTYRENE (XPS)

-HARDIPLANK LAP SIDING (SEE ELEVATIONS FOR EXPOSURE)

-1/2"GYPSUM W ALLBOARD (INTERIOR FINISH)

-R-19 UNFACED BATT INSULATION

-1/2"OSB SHEATHING AT CORNERS -SEE W ALL FRAM ING ELEVATIONS

TO UNDERSIDE OF FLOOR SHEATHING

SUPPLY DUCT HELD TIGHT

TRUNK

-2"CONCRETE SLAB (BROOM FINISH)

W /6"X 6"W IRE M ESH

-4"STONE PAD (NO FINES)

SUPPLY

TRUNK

RETURN

FOR LOCATION

FLOOR PLAN A-3

ASSEM BLY -SEE FIRST

TYPICAL TRANSFER GRILLE

ON BOOT -TYPICAL

M INIM UM 8"EXTENSION

W ALL SECTION

SCALE 3/4"= 1'-0"

1

M ANUFACTURED W OODEN ROOF TRUSS

SEE ROOF FRAM ING PLAN

R-38 BLOW N CELLULOSE INSULATION

1/2"GW B

R-19 UNFACED BATT INSULATION

1/2"GW B

CONTINUOUS BEADS OF SEALANT

CONTINUOUS BEAD OF ADHESIVE -TYPICAL ALL TRUSSES

7/8"OSB TONGUE AND GROOVE FLOOR SHEATHING

M ANUFACTURED W OODEN FLOOR TRUSS -SEE FRAM ING PLAN

2x6xCONTINUOUS TREATED M UD SILL

1/2"x10"ANCHOR BOLT 6'-0"OC

AND W ITHIN 12"OF ANY CORNER (BOTH DIRECTIONS)

CONTINUOUS SILL GASKET

2"EXPANDED POLYSTYRENE RIGID INSULATION

6 M IL VAPOR RETARDER TO EXTEND 6"

UP FACE OF RIGID INSULATION

ALL JOINTS TO LAP M IN.12"AND CONTINUOUSLY TAPED

FOUNDATION DESIGN BY OTHERS

4"STONE PAD (NO FINES)

25 YEAR ORGANIC ASPHALT SHINGLE

SUCH AS "IKO"

15# BUILDING PAPER LAPPED 4"

1/2"PLYW OOD OR OSB SHEATHING

36"xCONTINUOUS ROOF M EM BRANE

SEE ROOF PLAN

M ETAL DRIP EDGE

1x2 SUB-FASCIA

1x8 FASCIA

2"CONTINUOS SOFFIT VENT

SEE ROOF PLAN

(2)2x12 HEADER FLUSH W ITH EXTERIOR

FACE OF FRAM ING W ITH INSULATION INFILL

CONTINUOUS BEADS OF SEALANT

CONTINUOUS BEADS OF SEALANT

M INIM AL EXPANDING FOAM SEALANT

ENTIRE PERIM ETER OF W INDOW

"ANDERSEN"NARROLINE DOUBLE HUNG W INDOW

SIZE AS NOTED ON FLOOR PLANS

TYPICAL ALL W INDOW S

CONTINUOUS BEADS OF SEALANT

M INIM AL EXPANDING FOAM SEALANT

ENTIRE PERIM ETER OF W INDOW

TYPICAL ALL W INDOW S

(2)LAYERS 1/2"EXTRUDED POLYSTYRENE RIGID INSULATION

STAGGER JOINTS -ALL JOINTS TAPED (HORIZONTAL AND VERTICAL)

2x6 24"OC STUD FRAM E

R-19 UNFACED BATT INSULATION

1/2"GW B

1/4"HARDIBAKER 500 CERAM IC TILE

1/2"GW B

(2)2x12 HEADER FLUSH W ITH EXTERIOR

FACE OF FRAM ING W ITH INSULATION INFILL

CONTINUOUS BEADS OF SEALANT

CONTINUOUS BEADS OF SEALANT

M INIM AL EXPANDING FOAM SEALANT

ENTIRE PERIM ETER OF W INDOW

TYPICAL ALL W INDOW S

"ANDERSEN"NARROLINE DOUBLE HUNG W INDOW

SIZE AS NOTED ON FLOOR PLANS

M INIM AL EXPANDING FOAM SEALANT

ENTIRE PERIM ETER OF W INDOW

TYPICAL ALL W INDOW S

2"CONCRETE SLAB

7/8"OSB TONGUE AND GROOVE FLOOR SHEATHING

M ANUFACTURED W OODEN FLOOR TRUSS -SEE FRAM ING PLAN

CONTINUOUS BEADS OF SEALANT

TOP AND BOTTOM CHORDS OF TRUSS

1/2"OSB BAND

1/2"OSB BAND

INSULATION BAFFLE -PROVIDE 2"AIRSPACE

SEE ROOF FRAM ING PLAN

EXTEND RIGID INSULATING SHEATHING

BEYOND CONCRETE PORCH BELOW

ADHESIVE M EM BRANE PROTECTION

OVER RIGID INSULATING SHEATHING

PORCH FOUNDATION DESIGN BY OTHERS

ALL LEDGER BOARDS TO BE PLACED

ON TOP OF INSULATING SHEATHING

BACKER BOARD

(2)# 5 TYP.

(2)# 4 TYP.

(2)# 4 TYP.

(2)# 5 TYP.

1/2"OSB SHEATHING AT CORNERS-SEE W ALL FRAM ING ELEVATIONS

M ECHANICALLY FASTENED TO CONCRETE

(2)LAYERS 1/2"EXTRUDED POLYSTYRENE RIGID INSULATION

STAGGER JOINTS -ALL JOINTS TAPED (HORIZONTAL AND VERTICAL)

2x6 24"OC STUD FRAM E

1/2"OSB SHEATHING AT CORNERS-SEE W ALL FRAM ING ELEVATIONS

"SIM PSON AB44"POST ANCHOR

1/4"HARDIBAKER 500 CERAM IC TILE BACKER BOARD

2"CONCRETE SLAB

2"EXPANDED POLYSTYRENE RIGID INSULATION

6 M ILL VAPOR RETARDER -TAPED TO POLYSTYRENE

4"STONE PAD

SECTION DETAILS AT W INDOW FLASHING 2

SCALE 3/4"= 1'-0"

W RINKLES IN APPLIED M EM BRANES

SHEATHING -EXERCISE CARE SO AS TO REDUCE ANY UNNEEDED

A -ENSURE ALL SURFACES TO RECEIVE M EM BRANE FLASHING

B -ENSURE M EM BRANE IS W ELL SEATED AGAINST EXTERIOR

C -INSTALL ADHESIVE M EM BRANE OVER W INDOW JAM B FLANGE AND EXTERIOR FACE OF W ALL

A -INSTALL ADHESIVE M EM BRANE STRIP OVER W INDOW FLANGE

D -INSTALL ADHESIVE M EM BRANE OVER HEAD FLASHING,JAM B M EM BRANE,

B -ENSURE HEAD FLASHING IS AT LEAST AS W IDE AS W INDOW UNIT

2 B

1 B

1 A

ARE CLEAN AND DRY

GENERAL NOTES

5.

4.A -INSTALL HEAD FLASHING

B -INSTALL W INDOW (ACCORDING TO M ANUFACTURER'SPECIFICATIONS)

A -ENSURE A CONTINUOUS BEAD OF SEALANT IS APPLIED TO

BACK SIDE OF NAILING FLANGE OF W INDOW

B -LAP SILL M EM BRANE OVER CORNER PATCH M EM BRANE

A -INSTALL ADHESIVE M EM BRANE STRIP AT W INDOW SILL

C -ENSURE M EM BRANE EXTENDS M INIM UM OF 6"BEYOND SILL

C -ENSURE M EM BRANE EXTENDS TO FULL CAPACITY

A -INSTALL M EM BRANE CORNER PATCHES

4

5 D

2 A

3.

ON EXTERIOR FACE OF W ALL

ON EXTERIOR FACE OF W ALL

2.

1.

ON EXTERIOR FACE OF W ALL

B -FOLD ENDS AT JAM BS

STEP 5

5

3

AND EXTERIOR FACE OF W ALL IN ORDER:

AND EXTERIOR FACE OF W ALL

B -INSTALL ADHESIVE M EM BRANE OVER BOTTOM W INDOW FLANGE AND EXTERIOR FACE OF W ALL

5 A/B

5 C

5

5

CORNER DETAIL

STEP 1

1

STEP 2

2

STEP 3

3

CORNER DETAIL CORNER DETAIL CORNER DETAIL

ENTRY

DINING ROOM

PANTRY

KITCHEN

LIVING ROOM

HALL

REF

HALL

GARAGE

W /D

BEDROOM 2

BEDROOM 3

BEDROOM 1

BATH

HALL

BEDROOM 4

W H

G

FI

G

FI

G

FI

G

FI

S

S

S

S

S

S

S

S

S3 S

S3S3

S3S

S3

UP TO SECOND

FLOOR

S3

S3

S3

S3

D

S

S3

S3

F/L

BATH

S

S

W

S

W

S

W

P

W P(GFI)

W

P

W P(GFI)

W

P

P

S

S

S

S

F/L

S

S

S

S

S

S S

S

S

S

S

S

W 2

S

G

FI

S3

S

S

S3

S3

DOW N TO

FIRST FLOOR

C

P

P

DB

C

C

P

P

C

P

C

S

PORCH

2

SCALE 1/4"= 1'-0"

FIRST FLOOR ELECTRICAL PLAN 1

SCALE 1/4"= 1'-0"

SECOND FLOOR ELECTRICAL PLAN

S

TELEPHONE JACK

NOTES

1.ALL OUTLETS AND LIGHTS IN EXTERIOR W ALLS AND THE SECOND

2.ALL SW ITCHED OUTLETS TO BE BOTTOM OF DUPLEX OUTLET

FLOOR CEILING TO HAVE AIRTIGHT ELECTRICAL BOXES

110 VAC DUPLEX (BOTTOM SW ITCHED)

110 VAC DUPLEX

110 VAC GROUND FAULT INTERCEPT

LIGHT SW ITCH

3 W AY LIGHT SW ITCH

P

GFI

W P

S3

S

D DROPPED FIXTURE

R RECESSED LIGHT FIXTURE

F DUAL FLOOD LIGHT W /M OTION SENSOR

W 1

F/L "PANASONIC"W HISPERLITE 70FV-07VQL

W ALL M OUNTED LIGHT FIXTURE (EXTERIOR)

DOOR BELL

CABLE TV JACK

DB

C

SURFACE M OUNTED LIGHT FIXTURE

ELECTRICAL LEGEND

S

W 2 W ALL M OUNTED LIGHT FIXTURE (INTERIOR)

3.RECEPTACLE OUTLETS TO BE M INIM UM OF 12'-0"OC ALONG

W ALLS OF ALL HABITABLE ROOM S

4.ALL KITCHEN COUNTERS W IDER THAN 12"TO HAVE PROTECTED OUTLETS

A M INIM UM OF 24"OC

S

5.A M INIM UM OF (2)20 AM P SM ALL APPLIANCE BRANCH CIRCUITS

IN KITCHEN,PANTRY,DINING ROOM ,OR SIM ILAR AREA (M AX 3 OUTLETS PER CIRCUIT)

6.A M AXIM UM (8)OUTLETS PER 15 AM P BRANCH CIRCUIT AND 10 OUTLETS PER

20 AM P BRANCH CIRCUIT

7.ALL LIGHT FIXTURES IN CLOSETS TO COM PLY W ITH ARTICLE 410-8,NEC

S

S

S

S

UP TO LIGHT

IN ATTIC

ATTIC

S

S

8.OUTLET IS REQUIRED W ITHIN 6"OF DOOR OPENING ON END OF W ALL

AS PER ARTICLE 210-529 NEC

9.AN "UFER"GROUND IS REQUIRED AS A PART OF THE GROUNDING ELECTRODE SYSTEM .

THIS GROUND CONSISTS OF A M INIM UM 20'LENGTH OF ELECTRICALLY CONDUCTIVE # 4

REINFORCING BAR ENCASED BY AT LEAST 2"OF CONCRETE AND LOCATED NEAR THE

BOTTOM OF A CONCRETE FOUNDATION OR FOOTING THAT IS IN DIRECT CONTACT W ITH

THE EARTH.

You might also like

- Herriman 3Document16 pagesHerriman 3api-193598237No ratings yet

- Existing House Side View With Porch Porch Area: RCC, Inc 1365 Broad ST Johnstown, Pa 15906Document4 pagesExisting House Side View With Porch Porch Area: RCC, Inc 1365 Broad ST Johnstown, Pa 15906Ldriver104No ratings yet

- Sample Plan: Chic CottageDocument8 pagesSample Plan: Chic CottageB R Paul FortinNo ratings yet

- Reiland House Plans Version 2Document5 pagesReiland House Plans Version 2Amanda Smith Sieger100% (2)

- General Standard Drawings: Drawing No. DescriptionDocument11 pagesGeneral Standard Drawings: Drawing No. DescriptionRantharu AttanayakeNo ratings yet

- KolbhomeDocument6 pagesKolbhomeapi-316714069No ratings yet

- Williston 4 PlexDocument14 pagesWilliston 4 Plexsharilyn6156No ratings yet

- Home PlansDocument5 pagesHome PlansRoberto Herrera100% (1)

- Alfond Inn - Set For Portfolio - Part 6Document27 pagesAlfond Inn - Set For Portfolio - Part 6api-224231722No ratings yet

- A Com Ecu PateDocument5 pagesA Com Ecu Pateheels1310No ratings yet

- Final Contruction Document Set Kelsey-RoybalDocument19 pagesFinal Contruction Document Set Kelsey-Roybalapi-289643276No ratings yet

- 11165113Document117 pages11165113Anonymous xFV7bg7QNo ratings yet

- Straightening Vane Assembly Isometric View of Vane: Vane and Spool Piece DimensionsDocument1 pageStraightening Vane Assembly Isometric View of Vane: Vane and Spool Piece Dimensionsaamirtec301No ratings yet

- Material Takeoff ExampleDocument5 pagesMaterial Takeoff ExampleXOZININo ratings yet

- Typical Deck EdgeDocument1 pageTypical Deck EdgeShane AndersonNo ratings yet

- Estado Mecanico Tyc-04Document13 pagesEstado Mecanico Tyc-04Byron marinNo ratings yet

- Restaurant ExistingDocument1 pageRestaurant Existingradhika_reddy321No ratings yet

- Proiect Tehnic CasaDocument8 pagesProiect Tehnic CasaCebotari IvanNo ratings yet

- Foundation/floor Framing Plan and DetailsDocument1 pageFoundation/floor Framing Plan and DetailsBob MadlenerNo ratings yet

- s5-3-1 - Typical Composite and Steel Deck DetailsDocument1 pages5-3-1 - Typical Composite and Steel Deck Detailscewaleed2590No ratings yet

- Equipment List Inquire 1Document1 pageEquipment List Inquire 1Agung Eko PurnomoNo ratings yet

- RSteps and StairsDocument32 pagesRSteps and Stairspawanshrestha1No ratings yet

- Espct - Tba Ensamble Total Monobore 3k Acording With Kom 3-1-8 3k Forging Anda Part NumberDocument1 pageEspct - Tba Ensamble Total Monobore 3k Acording With Kom 3-1-8 3k Forging Anda Part NumberJeaneth HerreraNo ratings yet

- General Notes Jobsite Map Drawing Index: Salem HomeDocument12 pagesGeneral Notes Jobsite Map Drawing Index: Salem HomeChad BNo ratings yet

- BrutusDocument4 pagesBrutusgoloskokovicNo ratings yet

- OurCoolHouse DownloadDocument4 pagesOurCoolHouse DownloadMaurice HernandezNo ratings yet

- DetailingDocument1 pageDetailingGodino ChristianNo ratings yet

- Market Forge 01 25 2010Document208 pagesMarket Forge 01 25 2010Kevin SwotekNo ratings yet

- Bob Hamilton Residential Project PlansDocument13 pagesBob Hamilton Residential Project PlansFelipe PlateroNo ratings yet

- Steel Shop Drawings-Charles StreetDocument13 pagesSteel Shop Drawings-Charles StreetRobert SiqecaNo ratings yet

- Saudi AramcoDocument1 pageSaudi AramcoAbhilash P PaulNo ratings yet

- National Fasteners CatalogDocument70 pagesNational Fasteners CatalogErnesto GuevaraNo ratings yet

- Personal EstimatorDocument636 pagesPersonal EstimatorIgnacio ManzaneraNo ratings yet

- Estandares ElectricosDocument6 pagesEstandares Electricosedcas CastilloNo ratings yet

- Case Supply Thesis Final 1Document13 pagesCase Supply Thesis Final 1api-263164414No ratings yet

- 2 3 1 AaffordablehousedesignDocument4 pages2 3 1 Aaffordablehousedesignapi-273173196No ratings yet

- Grate Frame Detail PDFDocument1 pageGrate Frame Detail PDFKreen132No ratings yet

- CarDocument5 pagesCarHarish GundaNo ratings yet

- CArchitectural SamplesDocument970 pagesCArchitectural SamplesyvanmmuNo ratings yet

- Jessica Clayton PortfolioDocument6 pagesJessica Clayton Portfolioapi-177060611No ratings yet

- Royal Enfield Price ListDocument126 pagesRoyal Enfield Price Listmaniamson50% (20)

- Table 1.1 - Drilling Tools and Equipment Rental Charge (Drill Pipe and Accessories)Document2 pagesTable 1.1 - Drilling Tools and Equipment Rental Charge (Drill Pipe and Accessories)Khairilsyam Abdul RashidNo ratings yet

- Exhibit Hall and Black Box PlansDocument132 pagesExhibit Hall and Black Box Plansdongta123No ratings yet

- Cca BrochureDocument2 pagesCca BrochureFazil DuramanNo ratings yet

- Fishing Tools PDFDocument45 pagesFishing Tools PDFRichard EVNo ratings yet

- Well Completion DataDocument9 pagesWell Completion DataNazir Jihan WeimerNo ratings yet

- Model ICB 100-800 HP Boilers: Table A4-9. Model ICB Steam Boiler Dimensions, 4-Pass and 3-PassDocument4 pagesModel ICB 100-800 HP Boilers: Table A4-9. Model ICB Steam Boiler Dimensions, 4-Pass and 3-PasssebaversaNo ratings yet

- 230 E 63Rd Associates, LLC 230 East 63Rd Street NEW YORK, NY 10021Document10 pages230 E 63Rd Associates, LLC 230 East 63Rd Street NEW YORK, NY 10021dave1443No ratings yet

- Tripac Technical Data - Bolt - Wrench Sizes ChartDocument19 pagesTripac Technical Data - Bolt - Wrench Sizes Chartcmms88100% (2)

- High Performance Butterfly Valve Series 400: FeaturesDocument4 pagesHigh Performance Butterfly Valve Series 400: FeaturesFebry DahyaniNo ratings yet

- Electrical Tools ListDocument20 pagesElectrical Tools Listவனச்செல்வன் நாடார்No ratings yet

- Commercial Building Tekla Sample2Document10 pagesCommercial Building Tekla Sample2sanjibkrjanaNo ratings yet

- Lvo 2010Document10 pagesLvo 2010Kevin SwotekNo ratings yet

- Mlos-Hv: Please Add The Following Instructions To Those SuppliedDocument2 pagesMlos-Hv: Please Add The Following Instructions To Those SuppliedbellscbNo ratings yet

- Drill Collar and Tool SpecificationsDocument78 pagesDrill Collar and Tool SpecificationschonubobbyNo ratings yet

- Retaining Walls 2Document1 pageRetaining Walls 2Mohd HarizamNo ratings yet

- Colt Model F Black Powder Revolver PDFDocument5 pagesColt Model F Black Powder Revolver PDFeppg82100% (2)

- Enfield P53 Rifle-Musket Cal. .577 DetailsDocument2 pagesEnfield P53 Rifle-Musket Cal. .577 Detailseppg82No ratings yet

- Kentucky Flintlock Rifle PDFDocument1 pageKentucky Flintlock Rifle PDFeppg82No ratings yet

- Ramrod Guns PDFDocument7 pagesRamrod Guns PDFeppg82No ratings yet

- General Rules of Muzzle Loaders PDFDocument7 pagesGeneral Rules of Muzzle Loaders PDFeppg82No ratings yet

- Replicas (A 1964 Report) PDFDocument7 pagesReplicas (A 1964 Report) PDFeppg82No ratings yet

- French St-Etienne Model 1774 Flintlock Musket PhotosDocument7 pagesFrench St-Etienne Model 1774 Flintlock Musket Photoseppg82No ratings yet

- Guns of Lewis & Clark PDFDocument8 pagesGuns of Lewis & Clark PDFeppg82No ratings yet

- Kentucky-Pennsylvania Long Rifle PDFDocument2 pagesKentucky-Pennsylvania Long Rifle PDFeppg8250% (2)

- Restoration PDFDocument5 pagesRestoration PDFeppg82No ratings yet

- The Flintlock PDFDocument7 pagesThe Flintlock PDFeppg82No ratings yet

- TC Black Powder PDFDocument92 pagesTC Black Powder PDFeppg82No ratings yet

- Traditions Black Powder Rifle PDFDocument12 pagesTraditions Black Powder Rifle PDFeppg82No ratings yet

- Historic Black Powder Disassembly PDFDocument4 pagesHistoric Black Powder Disassembly PDFeppg82No ratings yet

- Building Shotgun Flasks PDFDocument3 pagesBuilding Shotgun Flasks PDFeppg82No ratings yet

- Guns of Lewis & Clark PDFDocument8 pagesGuns of Lewis & Clark PDFeppg82No ratings yet

- Blackpowder Though The Centuries PDFDocument7 pagesBlackpowder Though The Centuries PDFeppg82No ratings yet

- Blackpowder Pistols PDFDocument7 pagesBlackpowder Pistols PDFeppg82No ratings yet

- Civil Engineering Design of G Plus Two FloorsDocument49 pagesCivil Engineering Design of G Plus Two FloorsMubeen Akhtar100% (1)

- Structural Beam ComputationsDocument12 pagesStructural Beam ComputationsJustine LedesmaNo ratings yet

- Retaining Walls Predesign and Design CalculationDocument9 pagesRetaining Walls Predesign and Design Calculationnkurunzizaapollinaire202No ratings yet

- Canam Joist CatalogDocument166 pagesCanam Joist Catalogcivil89No ratings yet

- Cold Formed Steel PoultryDocument17 pagesCold Formed Steel PoultryWaleedAL-suheelyDNo ratings yet

- Doubly Reinforced BeamDocument8 pagesDoubly Reinforced BeamKARTHIK SGNo ratings yet

- English Heritage TimberDocument20 pagesEnglish Heritage Timbernaconnolly25% (4)

- Howe or Pratt Truss?Document51 pagesHowe or Pratt Truss?MICAH BELOCURANo ratings yet

- Footing Assignment FinalDocument2 pagesFooting Assignment FinaltrungNo ratings yet

- Advance Construction and Project Management-1Document2 pagesAdvance Construction and Project Management-1Karan ThakkarNo ratings yet

- HLBB Auction Fair Listing 28th Nov'17 (Johor)Document3 pagesHLBB Auction Fair Listing 28th Nov'17 (Johor)Jumrang MendengNo ratings yet

- Lecture 1-INTRODUCTION TO HIGH RISE BUILDINGS PDFDocument63 pagesLecture 1-INTRODUCTION TO HIGH RISE BUILDINGS PDFHarold Jackson Mtyana100% (1)

- Boxspan Residential Span TablesDocument36 pagesBoxspan Residential Span TablesÁngel Raúl DipierroNo ratings yet

- Bar Bending Schedule ExampleDocument28 pagesBar Bending Schedule ExampleHussain AbidNo ratings yet

- Lapping and splicing details for reinforced concrete columnsDocument1 pageLapping and splicing details for reinforced concrete columnsVinod Masani100% (1)

- Project Location Map and PlansDocument6 pagesProject Location Map and PlansStephanie Maiko T. BasadaNo ratings yet

- Structural Engineering Design of Reinforced Concrete Framed BuildingsDocument53 pagesStructural Engineering Design of Reinforced Concrete Framed BuildingsValentin Cirlescu100% (1)

- Folded Plates 1Document18 pagesFolded Plates 1Shez ZyNo ratings yet

- Celsius® CHS, Section Properties - Dimensions and PropertiesDocument7 pagesCelsius® CHS, Section Properties - Dimensions and PropertiesNinad KhandagaleNo ratings yet

- Mathcad - 06-Loads On Tile RoofDocument2 pagesMathcad - 06-Loads On Tile RoofMakaraSoyNo ratings yet

- TOP CHORD MEMBER and WEB MEMBER COMPUTATIONDocument3 pagesTOP CHORD MEMBER and WEB MEMBER COMPUTATIONDarius Frane MarasiganNo ratings yet

- Structural Framing Systems: The Trussed Tube Bundled Tube SystemDocument1 pageStructural Framing Systems: The Trussed Tube Bundled Tube SystemTanuja SidduNo ratings yet

- Problem TopicDocument4 pagesProblem TopicKhai MohdNo ratings yet

- LLK Agro System Project SummaryDocument28 pagesLLK Agro System Project SummaryChamika JayasingheNo ratings yet

- Architectural Plan of Row HouseDocument1 pageArchitectural Plan of Row HouseDJNo ratings yet

- Construction Vernacular TermsDocument25 pagesConstruction Vernacular TermsKristineNo ratings yet

- Tji 4000Document20 pagesTji 4000Timothy CruseNo ratings yet

- Building Design OptionsDocument91 pagesBuilding Design OptionsmaheshbandhamNo ratings yet

- CFSEI Shear Wall Design GuideDocument45 pagesCFSEI Shear Wall Design GuideDaniel AielloNo ratings yet

- Water Tanks StructuralDesignsDocument55 pagesWater Tanks StructuralDesignsuma venkata ramanaNo ratings yet