Professional Documents

Culture Documents

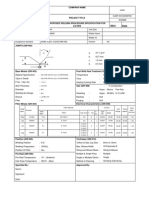

Welding Procedure Specification For 24'' Pipe

Uploaded by

enels77Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification For 24'' Pipe

Uploaded by

enels77Copyright:

Available Formats

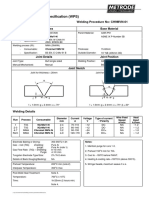

WELDING PROCEDURE SPECIFICATION

(WPS)

Company logo

PROJECT NAME

PJT Contract Number

WPS No. :

Date :

Supporting PQR No. :

Procedure for :

24" X 12.7MM

Welding Process

SMAW / MANUAL

Applicable Code :

ASME B31.3

JOINT

Joint Design :

See Below

Bevel Angle :

30o 5o

Backing

N/A

Root Gap :

2mm0.4mm

N/A

Root Face :

1.6mm 0.8mm

Backing Material :

BASE METAL

Material Specification Type & Grade :

Material Items (Name)

API 5L X60

Pipe to Pipe or Pipe to fittings (CE shall not increase with more than 0.03)

Pipe Diameter Qualified

24"

Pipe Diameter Range

12'' - 36''

Pipe Thickness Qualified:

12.7mm

Pipe Thickness Range :

9.5mm - 19.05mm

FILLER METALS

Weld Run

ROOT

Size

1/8" (3.2mm)

Electrode Brand

Lincoln Fleet Weld

AWS Specification

A 5.1

HOT PASS

1/8" (3.2mm)

Lincoln Jet Weld

A 5.1

FILLING

CAPPING

5/32" (4.0MM)

5/32" (4.0MM)

Lincoln Jet Weld LH70

Lincoln Jet Weld LH70

A 5.5

A 5.5

AWS Classification

E6010 5P+

E7018 H4R

E7018 H4R

E7018 H4R

ELECTRODE STORAGE

Electrode Drying Condition:

E6010

As per manufacturer's recommendation for handling and storage. Redrying not recommended

E7018

As per manufacturer's recommendation.

Pre-drying temperature: 80oC to 105oC for 2hrs.

Re-drying temperature: 340oC to 400oC for 3-4hrs

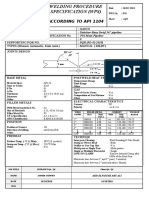

POSITION & DIRECTION OF WELDING

Welding Position

Direction of Welding

Minimum Number of Runs

Number of Welders

Type of Clamp

Removal of Clamp

String or Weave Bead

Max Time, Completion of Root & Commencement of hot pass

Max Time Between Passes

6G

All passes vertical up

12

2

External

After minimum of 50% completion of Root Pass

String/Weave

Less than 5 minutes

Less than 5 minutes

Shall be completed greater than 1/2 wall thickness of pipe, otherwise cutout

Number of runs completed before cooling to ambient temperature

PRE-HEAT

PREHEAT

Preheat Temperature

Inter Pass Temperature

Type of Heater

Inter Pass Cleaning

YES

PWHT

N/A

Mini 40oC

Max 200oC

Rosebud Burner

Grinding and Brushing

Digital Thermometer or Temp Stick shall be used for recording Pre-Heat and inter pass

temperature. Welding shall be protected from rain and wind

Temperature Control

ELECTRICAL CHARACTERISTIC & TECHNIQUE

Weld Run

ROOT

HOT PASS

FILLING

CAPPING

Process/Direction

SMAW/V-UP

SMAW/V-UP

SMAW/V-UP

SMAW/V-UP

Amperage

80-120

100-140

110-150

110-150

Voltage

20-29

24-30

22-27

24-30

Polarity

DC+

DC+

DC+

DC+

Travel Speed (MM/MIN)

66 - 103

96 - 134

117 - 156

121 - 136

Heat Input (KJ/MM)

1.09 - 2.80

1.34 - 2.93

1.30 - 2.99

1.26 - 2.92

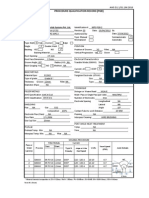

NON DESTRUCTIVE EXAMINATION

VISUAL

BEVEL

NOTE

100% Visual Inspection

100% MPI

After completion of the weld, MPI & 100% MPI and Radiography 12hrs after welding

APPROVAL

NAME:

NAME:

NAME:

SIGNATURE:

SIGNATURE:-

SIGNATURE:

DATE:

DATE:-

DATE:

You might also like

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Welding Procedure Specification Pipe - 6GDocument3 pagesWelding Procedure Specification Pipe - 6Gdndudc96% (26)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- P91 Profile WpsDocument6 pagesP91 Profile WpsZead Ali Adal100% (2)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- WPS GmawDocument2 pagesWPS Gmawasikur100% (6)

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Fit Up ReportDocument5 pagesFit Up ReportAkash Singh Tomar100% (1)

- Fit Up Report Format-1Document1 pageFit Up Report Format-1BalkishanDyavanapellyNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Welder Continuity LogDocument3 pagesWelder Continuity Log942519100% (1)

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- Plates ASTM-A240 Gr 304LDocument6 pagesPlates ASTM-A240 Gr 304Labhishek198327No ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- FM-D-01 Steel Structure ErectionDocument1 pageFM-D-01 Steel Structure ErectionG Vamsi ChandNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Welder Id SampleDocument1 pageWelder Id Sampledevendrasingh202157% (7)

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- Back Gouging ProcedureDocument8 pagesBack Gouging Proceduremahi1437100% (1)

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification Sampleezdi2083% (23)

- PQR SAW ProcessDocument1 pagePQR SAW Processdevendrasingh202133% (3)

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 pagesWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- WPS TITLEDocument2 pagesWPS TITLERichard Periyanayagam86% (14)

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSDocument2 pagesSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSsuria qaqcNo ratings yet

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- ASME P Material NumbersDocument1 pageASME P Material Numbersmahi1437100% (1)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- ASME Section IX Welding Qualification RequirementsDocument5 pagesASME Section IX Welding Qualification Requirementskirubha_karan2000No ratings yet

- ASME BPVC.IX performance thickness limitsDocument1 pageASME BPVC.IX performance thickness limitskumar100% (2)

- PQR Template (Asme)Document2 pagesPQR Template (Asme)jok1974No ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- WELDING PROCEDURE SPECIFICATION DETAILSDocument2 pagesWELDING PROCEDURE SPECIFICATION DETAILStuatk60% (5)

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- Joint Detail (Qw-402)Document2 pagesJoint Detail (Qw-402)Nitesh Patel100% (3)

- Sample WPS SMAW Stainless SteelDocument7 pagesSample WPS SMAW Stainless Steeldaemsal100% (4)

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- WPS SiloDocument1 pageWPS SiloNidhinkorothNo ratings yet

- WPS FormatDocument1 pageWPS FormatAbdullah AnsariNo ratings yet

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Document2 pagesWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNo ratings yet

- WPS - 008Document11 pagesWPS - 008MAT-LIONNo ratings yet

- Noreast Autoweld System Corporate PresentationDocument78 pagesNoreast Autoweld System Corporate Presentationravi00098No ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingcarlmac6183% (6)

- Approved Welding Procedures-Rebar Indirect Butt Joint With Splice AngleDocument8 pagesApproved Welding Procedures-Rebar Indirect Butt Joint With Splice Anglecipele12No ratings yet

- Welding Procedure Specification (WPS)Document0 pagesWelding Procedure Specification (WPS)Oscar Iván Duque DíazNo ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingaamirtec301100% (2)

- WPS - 015Document11 pagesWPS - 015MAT-LIONNo ratings yet

- Pressure Gauge Specification SheetDocument1 pagePressure Gauge Specification Sheetsairam2234No ratings yet

- Wps For Ss Welding in Pump Room: Phase-3A Development at Indira Gandhi International AirportDocument5 pagesWps For Ss Welding in Pump Room: Phase-3A Development at Indira Gandhi International Airportamit rajputNo ratings yet

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- WPS Asme IxDocument4 pagesWPS Asme Ixjcarlosherrerac7100% (1)

- WPS - D1.1 - Prequalified Procedures QSSLDocument26 pagesWPS - D1.1 - Prequalified Procedures QSSLfazeel mohammedNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Monthly Time SheetDocument1 pageMonthly Time Sheetenels77No ratings yet

- Character Reference Check ListDocument1 pageCharacter Reference Check Listenels77No ratings yet

- Rev-N-Upper FloorDocument1 pageRev-N-Upper Floorenels77No ratings yet

- Bearing One Another's BurdensDocument2 pagesBearing One Another's Burdensenels77No ratings yet

- Senior InspectorLocationsDocument2 pagesSenior InspectorLocationsenels77No ratings yet

- Upper FloorDocument1 pageUpper Floorenels77No ratings yet

- Senior InspectorLocationsDocument2 pagesSenior InspectorLocationsenels77No ratings yet

- Senior InspectorLocationsDocument2 pagesSenior InspectorLocationsenels77No ratings yet

- Pipe GradeDocument1 pagePipe Gradeenels77No ratings yet

- Mechanical Fatigue Is Caused by What Material Does Not Have An Endurance Limit?Document1 pageMechanical Fatigue Is Caused by What Material Does Not Have An Endurance Limit?enels77No ratings yet

- 13CR MARTENSITIC STAINLESS STEEL PQR WPS REVIEWDocument1 page13CR MARTENSITIC STAINLESS STEEL PQR WPS REVIEWenels77No ratings yet

- Itp TemplateDocument8 pagesItp Templateenels77100% (1)

- Asme ViiiDocument1 pageAsme Viiienels77No ratings yet

- Golden WeldDocument4 pagesGolden Weldenels77No ratings yet

- Asme ViiiDocument1 pageAsme Viiienels77No ratings yet

- NDTDocument80 pagesNDTsungkang92% (12)

- Sudhy+api+510 2Document310 pagesSudhy+api+510 2sheikmoinNo ratings yet

- Work Method Statement FOR HSS PQTDocument6 pagesWork Method Statement FOR HSS PQTenels77No ratings yet

- H Beam MaterialsDocument1 pageH Beam Materialsenels77No ratings yet

- Faith Ladder To Your Appointed Top.Document3 pagesFaith Ladder To Your Appointed Top.enels77No ratings yet

- Welding Sample QuestionsDocument4 pagesWelding Sample Questionsenels770% (2)

- Radiography QuestionsDocument28 pagesRadiography Questionsenels77No ratings yet

- 40 Inches Pipeline IsometricDocument1 page40 Inches Pipeline Isometricenels77No ratings yet

- Flange RatingsDocument1 pageFlange Ratingsenels77No ratings yet

- Cswip QuestionDocument9 pagesCswip Questionenels77No ratings yet

- Cswip QuestionDocument9 pagesCswip Questionenels77No ratings yet

- Certified Quality Engineer ExpectationsDocument5 pagesCertified Quality Engineer Expectationsenels77No ratings yet