Professional Documents

Culture Documents

WPQR Sample Form

Uploaded by

shwayeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPQR Sample Form

Uploaded by

shwayeCopyright:

Available Formats

:

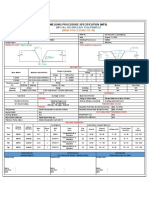

WEL DER PERFORMANCE QUALIFICATION RECORD

Welder Name:

I.D. No.:

Contractor :

Work Order No.

Code No.

PHOTO

Test Descr tion

Using WPS No.:

D

D

Test Coupon

Plate

D Production Weld

D Pipe 0 Renew l

The Above Welder Is Qualified For The Following Ranges

Record Actual Values

Used in Qualification

Welding Variables

Qualification Range

Process (es)

Process Type

Backing (Metal, Weld Metal,

Flux, etc. (QW-402)

Base Material Spec. (QW-403)

P No.- P No.

Thickness - Plate

Groove

Fillet

Thickness - Pipe

Groove

Fillet

Diameter - Pipe

Groove

Fillet

Filler Metal (QW-404)

Spec. No.

Class

F-No.

Diameter

Deposition thickness for each process I filler metal

Process/Filler Metal 1

Process/Filler Metal 2

Position (QW-405)

Weld Progression (QW-410)

Gas Type (QW-408)

Electrical Characteristics

(QW-409)

Root-Current I Polarity

Filler Current I Polarity

RESULTS

VisualExamination of Completed Weld (QW-302.4)

Welding Supervised by:

Appearance of Completed Weld

Date

Guided Bend Test Results QW-462.2 {a) QW-462.3 {a), QW-462.3 (b)

Figure No.and Type

Result

Figure No. and Type

Result

Figure No. and Type

Radiographic Test Results (QW-304 and QW-305)

For Alternative Qualification of Groove Welds by Radiography

Radiographic Results:

Result

You might also like

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Supplier ITP Inspection PlanDocument4 pagesSupplier ITP Inspection PlanHassan SajidNo ratings yet

- CQI-IRCA Certified-PR328 QMS ISO 9001 2015 Lead Auditor-CourseDocument3 pagesCQI-IRCA Certified-PR328 QMS ISO 9001 2015 Lead Auditor-CourseFurkanNo ratings yet

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Hydraulic crash barriers ITPDocument4 pagesHydraulic crash barriers ITPmoytabura96No ratings yet

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocument7 pagesA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNo ratings yet

- 8.5.5 Post Delivery ActivitiesDocument2 pages8.5.5 Post Delivery ActivitiesMaricris Napigkit Serrano100% (1)

- WPS Presentation on Welding Procedures SpecificationsDocument30 pagesWPS Presentation on Welding Procedures SpecificationsHarish RamalingamNo ratings yet

- WIS5 - HandoutDocument319 pagesWIS5 - HandoutReza FakhrizalNo ratings yet

- Itp For Casing, Ducting, StackaaaaaaaaaaaDocument4 pagesItp For Casing, Ducting, Stackaaaaaaaaaaaaymanmalah100% (1)

- Irca 106 Audit LogDocument9 pagesIrca 106 Audit LogrmdarisaNo ratings yet

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- Wps MainlineDocument5 pagesWps MainlineAlfian FebriansyahNo ratings yet

- Optimized Title for Welspun MPQT ReportDocument84 pagesOptimized Title for Welspun MPQT ReportAlam MD SazidNo ratings yet

- IMS Awarness 03-IMSDocument14 pagesIMS Awarness 03-IMSRohit SoniNo ratings yet

- FactoryDocument72 pagesFactorywhitebrosNo ratings yet

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- Control flow diagram for GACC's new welder qualification processDocument1 pageControl flow diagram for GACC's new welder qualification processSiddiqui Abdul KhaliqNo ratings yet

- Satr H 2008Document2 pagesSatr H 2008Moghal AliNo ratings yet

- Audit Checklist TemplateDocument12 pagesAudit Checklist TemplateMurugeswari Rajaselvam100% (1)

- Saudi Aramco Dow Arabia (MFC) Project As Run Data Sheet: Sub-Contractor Welding Inspector DAELIM Welding InspectorDocument1 pageSaudi Aramco Dow Arabia (MFC) Project As Run Data Sheet: Sub-Contractor Welding Inspector DAELIM Welding InspectorSiddiqui Abdul Khaliq100% (1)

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDocument26 pagesNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNo ratings yet

- API Spec Q1 9th Edition - Mandatory Documented Procedures: No. Clause No. DescriptionDocument1 pageAPI Spec Q1 9th Edition - Mandatory Documented Procedures: No. Clause No. Descriptionzae nuddinNo ratings yet

- Closure Weld Mag ProcedureDocument1 pageClosure Weld Mag ProcedurehellionxNo ratings yet

- A106 Pipe Spec SheetDocument7 pagesA106 Pipe Spec SheetyanurarzaqaNo ratings yet

- WFP 2-01 ASME B31 Piping Welding ProcedureDocument8 pagesWFP 2-01 ASME B31 Piping Welding Procedureleodavid87No ratings yet

- Inspection Plan NDTDocument7 pagesInspection Plan NDTEdison WalitNo ratings yet

- ISO9001 OxfordDocument17 pagesISO9001 OxfordManigandan RNo ratings yet

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocument3 pagesSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- DFT Measurement Worksheet: Paint InspectionDocument1 pageDFT Measurement Worksheet: Paint Inspectionjay nathNo ratings yet

- LRQA Training GuideDocument28 pagesLRQA Training GuidePranay KrishnanNo ratings yet

- QT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFDocument3 pagesQT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFGanesh EswaranNo ratings yet

- Ercual A2 (Albronzea2) BWDocument1 pageErcual A2 (Albronzea2) BWJitendra BhosaleNo ratings yet

- 018 M MCD 40001 001 - 0Document138 pages018 M MCD 40001 001 - 0j fNo ratings yet

- CP16 PDFDocument21 pagesCP16 PDFMarcus AntoniusNo ratings yet

- CV - Fabio Madeira en - 082018Document3 pagesCV - Fabio Madeira en - 082018inspetorfabiomadeiraNo ratings yet

- 12 Storage of Parent MaterialsDocument3 pages12 Storage of Parent MaterialselmiraNo ratings yet

- CWRVC-1 2nd Edition 15085Document10 pagesCWRVC-1 2nd Edition 15085Cristi OgaruNo ratings yet

- GTAW Welding ParametersDocument1 pageGTAW Welding ParameterssahadNo ratings yet

- JIMT Visual Inspection ReportDocument1,913 pagesJIMT Visual Inspection Reportgomathyselvi100% (1)

- EXERCISE Nº. 6: Audit Scenarios S: Incident 1Document2 pagesEXERCISE Nº. 6: Audit Scenarios S: Incident 1galadrialNo ratings yet

- 4d48f0f5e09b8 Plant Piping and Pipeline Systems 2010 Maurice For SiskaDocument7 pages4d48f0f5e09b8 Plant Piping and Pipeline Systems 2010 Maurice For Siskau04ajf3No ratings yet

- Bs Tech: Electrodes Issue and Return RegisterDocument1 pageBs Tech: Electrodes Issue and Return RegisterRhannie GarciaNo ratings yet

- IRCA Application FormDocument7 pagesIRCA Application Formpatung patungNo ratings yet

- ISO 9001 2015 Cluases PDFDocument1 pageISO 9001 2015 Cluases PDFA MNo ratings yet

- D-P5-BV-MN-001 Quality ManualDocument27 pagesD-P5-BV-MN-001 Quality ManualThinh Nguyen100% (1)

- CSWIP Re-CertificationDocument9 pagesCSWIP Re-CertificationIyappan BaluNo ratings yet

- MCE Welder Performance Qualification ReportDocument2 pagesMCE Welder Performance Qualification ReporthamidjoyiaNo ratings yet

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveFrom EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveNo ratings yet

- Inspection In Manufacturing A Complete Guide - 2020 EditionFrom EverandInspection In Manufacturing A Complete Guide - 2020 EditionNo ratings yet

- QC Check ListDocument1 pageQC Check ListshwayeNo ratings yet

- Noc Engineer - Iptv and BroadbandDocument2 pagesNoc Engineer - Iptv and BroadbandshwayeNo ratings yet

- GIS RequirementDocument3 pagesGIS RequirementshwayeNo ratings yet

- Welder QualificationDocument1 pageWelder QualificationshwayeNo ratings yet

- Gis 42-103Document1 pageGis 42-103shwayeNo ratings yet

- CharpyDocument1 pageCharpyshwayeNo ratings yet

- Weld Parameters Data SheetDocument1 pageWeld Parameters Data SheetshwayeNo ratings yet

- Difference Between API 650 & API 620Document5 pagesDifference Between API 650 & API 620job saputraNo ratings yet

- International Standard: ISO 18219-2 Iultcs IUC 30-2Document22 pagesInternational Standard: ISO 18219-2 Iultcs IUC 30-2KatrinaNo ratings yet

- S15 Crawler 50 Owners Manual 5-3-12Document80 pagesS15 Crawler 50 Owners Manual 5-3-12BrinkNo ratings yet

- PGW Customer Handbook 2017Document28 pagesPGW Customer Handbook 2017Terry HaynesNo ratings yet

- Ford Wa950Document2 pagesFord Wa950amanNo ratings yet

- Marcus Simpson VS Cal Poly Pomona, Et Al.Document25 pagesMarcus Simpson VS Cal Poly Pomona, Et Al.hko100% (3)

- Vehicles by Country ListDocument6 pagesVehicles by Country Listkevin lassNo ratings yet

- Preliminary Energy Analysis of Parisons Roller Flour MillsDocument17 pagesPreliminary Energy Analysis of Parisons Roller Flour MillsThomasNo ratings yet

- Nissan Hidden Fuses PartDocument2 pagesNissan Hidden Fuses PartOon Koo100% (3)

- Goal Orientation TheoryDocument10 pagesGoal Orientation TheorympsbhadauriaNo ratings yet

- Homework VolcanoesDocument6 pagesHomework Volcanoesafnofbfqearczc100% (2)

- Oral Medication PharmacologyDocument4 pagesOral Medication PharmacologyElaisa Mae Delos SantosNo ratings yet

- Cashpor ReportDocument91 pagesCashpor ReportAnand Gautam100% (1)

- MOSFET Application Handbook PDFDocument317 pagesMOSFET Application Handbook PDFcong huongNo ratings yet

- ACE PALAWAN MGAS-UPPER GROUND FLOOR-ModelDocument1 pageACE PALAWAN MGAS-UPPER GROUND FLOOR-ModelBerlin Andrew SionNo ratings yet

- ESG FinalDocument9 pagesESG FinalLidia GutiérrezNo ratings yet

- Chapter 12Document7 pagesChapter 12Xynith Nicole RamosNo ratings yet

- Portea Home Health CareDocument17 pagesPortea Home Health CareAbhai Pratap SinghNo ratings yet

- Fra - New Format 01Document4 pagesFra - New Format 01paras pantNo ratings yet

- 2 4 3 Pringles Experiment FolioDocument8 pages2 4 3 Pringles Experiment Folioapi-308013008No ratings yet

- Transformer Sizing CalculationDocument7 pagesTransformer Sizing CalculationArunava BasakNo ratings yet

- Patient Medication Management: DRUG STUDY University of Cebu Medical CenterDocument1 pagePatient Medication Management: DRUG STUDY University of Cebu Medical CenterMemcom SolutionNo ratings yet

- Entrepreneurs Are Great WorksheetsDocument9 pagesEntrepreneurs Are Great WorksheetsSilvia MontesNo ratings yet

- Material Drive Control Systems For Wheel LoadersDocument20 pagesMaterial Drive Control Systems For Wheel LoadersJerson T. AltovarNo ratings yet

- Latihan Soal IDocument6 pagesLatihan Soal IMas GigihNo ratings yet

- DEC Design Standards for Intermediate Sized Sewerage FacilitiesDocument97 pagesDEC Design Standards for Intermediate Sized Sewerage FacilitiesMagin Idelfonso Torreblanca100% (1)

- Wireless LAN BIOS Switch HelpDocument1 pageWireless LAN BIOS Switch HelpSor CaligaganNo ratings yet

- Fresh Fruits and VegetablesDocument6 pagesFresh Fruits and VegetablesNicole LeongNo ratings yet

- A Note On Cryptocurrency Stabilisation Seigniorage SharesDocument8 pagesA Note On Cryptocurrency Stabilisation Seigniorage SharesTomy1969No ratings yet

- Lux Level Test Certificate FormDocument1 pageLux Level Test Certificate FormSandhyaRamakrishna100% (1)