Professional Documents

Culture Documents

Persulphate (Schwarz Laboratories, Inc., Mount Vernon, New York)

Uploaded by

Arnold Vitor A.0 ratings0% found this document useful (0 votes)

14 views5 pageskjnd

Original Title

Bruch Et Al-1964-Journal of the Institute of Brewing

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentkjnd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views5 pagesPersulphate (Schwarz Laboratories, Inc., Mount Vernon, New York)

Uploaded by

Arnold Vitor A.kjnd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

DISINFECTION OF BREWING YEAST WITH ACIDIFIED AMMONIUM

PERSULPHATE

By C, W. Brucx, A. Horrman, R. M, Gosine ann M. W. Brenner

(Schwarz Laboratories, Inc., Mount Vernon, New York)

Received 8th January, 1904

Acidified (pH 2:8) ammonium persulphate (0-759%) was more effective than an

acid wash at pH 28 or straight 0-75%, ammonium persulphate in the disinfection of

contaminated yeasts obtained from breweries. The contaminating bacteria in the

samples of brewery yeast were isolated and grown in mixed fermentations with

yeast. The data from disinfection trials with the contaminated yeasts showed that

acidified ammonium persulphate provided the most effective treatment, The

following patterns of bacterial resistance to the various treatments were noted:

(a) lactobacilli tend to be resistant to disinfection with 0-75%, ammonium persulphi

(b) acetic acid hacteria resist acid treatments, unless the pH Is 2-4 or lower; and

(©) flavobacteria are sensitive to acid washes and to treatments with ammonium

persulphate, but the acidified ammonium persulphate killed this bacterial type

more rapidly.

Intropuction destruction of bacteria in yeast cultures took

Tue problem of infection by undesirable

;nisms is common to all microbiological

processes in which pure cultures are used.

The practical brewer, trying to free his

itching yeast of bacterial contamination,

Taces essentially the same problem as the

virologist who attempts to secure microbe-

free tissue cultures.

‘One of the earliest methods for the

advantage of the differential sensitivity of

these organisms to low pH. Pasteur noted

that yeasts tolerate exposure to low pH

better than do bacteria, and he suggested the

disinfection of yeast by dilute solutions of

tartaric acid. “Since then, other investi-

gators have reported the use of phosphoric

acid? and sulphuric aci As Uhlig* has

pointed out, the chief disadvantage in the

Vol. 70, 1964] BRUCK ef al.: YEAST DISINFECTION WITH ACIDIFIED PERSULPHATE

use of acid washes is the possible preferential

selection of wild yeasts, if the acid wash is

not carefully controlled.

The application of other materials, such

as sodium or calcium bisulphite and

ammonium persulphate, for disinfection of

yeast suspensions has been advocated since

the turn of the century. Although there

are few data in the literature on the dis-

infecting efficiency of ammonium persulphate,

it is generally recognized in the brewing

industry that washes with dilute ammonium

persulphate solutions (0-5-1%) are usually

as effective as acid washes.

Gray & Kazin* were the first to report

disinfection of brewery yeast cultures with

antibiotics. Strandskov & Bockelmann*

have described the effectiveness of polymyxin

against gram-negative bacteria that con-

taminate yeast and beer, and the usefulness

of penicillin against gram-positive cocci and

in yeast or beer,

The present investigation of yeast disinfee-

tion is primarily a by-product of a larger

programme initiated by this laboratory to

determine the biological factors involved in

the formation of diacetyl in beer. Because it

has been shown that some beer lactobacilli

can produce diacetyl, and that lager yeasts

free of infection will yield significant amounts

of this flavour compound in some fermenta~

tions, we have been carrying out ecological

studies with mixed fermentations of beer

bacteria and lager yeast to see what inter-

relationships exist in the biological forma-

tion of diacetyl. After the beers were

removed from these fermentations, a suppl

of contaminated yeast was available whic

could be used in yeast disinfection studies,

A second motive for this investigation was

found in the repeated comments by brewers

that disinfection by acid washes or ammonium,

persulphate was not effective against the

bacteria contaminating their yeasts. Since

the bacteria used in’ these studies were

isolated from either pitching yeast or beer,

the comparative resistance of a spectrum of

lager yeast contaminants to several disinfec-

ting procedures could be evaluated,

MATERIALS AND MetHoDs

Microbial cullures.—All of the bacteria

used in this study were isolated from con-

taminated brewing yeasts or from cellar

beers high in diacetyl. They were maintained

243,

as stock cultures in hopped wort-yeast broth

and were transferred every three months.

‘The lager yeast used in the mixed fermenta-

tions was obtained in the pressed state from

abrewery. The level of bacterial contamina-

tion is very low, being usually less than one

bacterium per million yeast cells.

Of the three naturally contaminated

brewing yeasts that were treated duri

these studies, two were obtained as liquic

slurries. The remaining lager yeast (yeast B)

was received in the dried state on blotting

paper and was grown and harvested after a

normal fermentation in a 3-litre vessel,

The mixed fermentations were obtained in

the following manner. Tubes of ho}

wort-yeast, broth, were inoculated with 8%

inoculum from the broth stocks of each

bacterium. After growth had proceeded at

28°C. for 24-48 hr. 4ml. of this culture

were added to 100 mi. of hopped wort-yeast

broth, which was incubated at 28°C. for

48 hr. The 100 ml, of bacterial culture was

inoculated into 3 litres of hopped wort in an

upright Povitsky bottle. Pressed. brewer's

lager yeast (6 g.) was added to the flasks,

and the contents were fermented at 15°C.

for 5-7 days,

After fermentation, the beer was decanted

from the flask and held for diacetyl deter-

minations, About 200 ml. of beer was left

on the contaminated yeast deposit at the

bottom of each flask. “The yeast was mixed

thoroughly with the beer by vigorous shaking

of the bottles. Yeast slurry (60 ml.) was

placed in each of three 200-ml. beakers,

After the yeast slurries were chilled, 60 ml,

of cold double-strength disinfecting solution

was added to each beaker; the contents were

thoroughly mixed with a stirrer, and the

HH was adjusted with 1-0-n sulphuric acid,

Bisinfection then proceeded at the selected

temperature for the desired length of time,

Any rise in pH during disinfection was

determined after the viability assays were

performed,

The final yeast slurries had a packed cell

volume of 8-10%. The dry yeast solids of

these slurries was between 3 and 4%,

Recovery media and assays—The viability

of bacteria was determined by plating on

WL Differential Agar medium (Difco) and

the agar medium of Kissel & Dakin! The

growth of each organism was measured both

2erobically on agar plates and anaerobically

in Prickett tubes at 28°C, for 4-7 days.

BRUCH ¢t al,: YEAST DISINFECTION WITH ACIDIFIED PERSULPHATE [J. Inst. Brew.

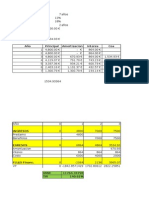

TABLE 1

SURVIVAL OF BACTERIAL CONTAMINANTS IN THREE Brewing YEASTS AFTER

DISINFECTION BY THREE PxoczDURES*

Lager yeast

culture

A

c

c

(diluted)

Survival of bacteria (%):

O-76% ammonium

persulphate +

slphuric acid to

* Cultures A and B were treated for 20 hr. at 1-2°C.; culture C was treated

for 20 hr. at 7-8°C,

‘The assays for yeast numbers were per-

formed on aerobic plates of hopped wort-agar.

Changes in the respiratory character of the

yeast were examined by colonial growth on

cies plates of WL nutrient agar (Difco).

e interpretation of the respiratory defici-

ency test has been described by Czarnecki &

van Engel

Aiter some trials, the treated yeast along

with the disinfecting solution was pitched

into 3 litres of wort." The activities of these

fermentations were visually compared with

untreated yeast fermentations. Final gravity

and pH readings were taken after @ or 7 days

at 16°C.

REsuLTs

At the request of several breweries, pilot-

geale, disinfection ‘trials were made with

infected lager yeasts furnished .

Thear breweries'had encountered ifiultas

in the purification of their yeast with a cold

0-75% ammonium persulphate wash or with

an overnight acid wash at pH 2°8 in the cold.

These two treatments were compared with

a combination of the two, #.c., acidified

ammonium persulphate. The results of these

trials are presented in Table I.

‘These data show that each infected lager

yeast had a different level of bacterial resis-

tance to these treatments. Only the acidified

ammonium persulphate treatment was con-

sistently effective in all of these trials. The

Presence of different bacterial types in each

of the cultures was indicated; accordingly,

the cultures were plated to isolate both the

aerobic and the anaerobic contaminants.

From lager yeast A, two different types of

bacteria were isolated. Culture A-2P was a

gram-positive rod form, anaerobic, slow

growing, and produced ‘acid to a pH of

about 45. Culture A-2U was a gram-

negative rod form, aerobic, and a strong

acid producer. Some diacetyl-favoured beer

TABLE It

Rusistance oF Bactenia Contaminants Isotatep prom Lacer Yeast SAMPLE A To

Distnrection IN PRESENCE or ViABLE Yeast

‘Survival (%)

pH42 | ps2

Bacterial ‘ahr | /20 hr,

isolates 12°C, | 78°C.

A-2P 00 40

A-2U 1 ‘O04

Ae 6 00

AT ca 60

'* The pH was adjusted with sulphuric acid.

Vol. 70, 1964] BRUCH et al.: YEAST DISINFECTION WITH ACIDIFIED PERSULPHATE

that had been fermented with this yeast in

the was examined; two more

bacterial types similar to, but more vigorous

than, the culture A-2P were isolated. “These

cultures were grown in mixed fermentations

with lager yeast, and results with several

disinfecting procedures are given in Table IT.

245

fermentations, harvested, and subjected to

several disinfectis lures, ‘The resulting

data are presented in Table IIT.

‘Alt of these cultures showed some resis-

tance to a short-time, low-temperature cycle

in 075% ammonium persulphate. Only

culture B-5, which is an Acetobacter type,

‘TABLE IIT

Resistance oF BACTERIAL ConTAMINANTS ISOLATED Rom LAGER YEAST SAMPLE B To

‘Disturnction 1 PRESENCE OF VianLE Yuast

075% ammonium

Survival (9%

(0-75% ammonium

pereulphate Sulphuric acid ersulphatet

pH42 | pee | pH22 pH2-8

Bacterial ‘the | Bone | "ane. 20 br.

isolates rere. | arc, | are. 78°C,

16 0

05 o

5 °

2 °

© The pH was adjusted with sulphuric acid.

The gram-positive cultures, A-2P, A-24,

and A-27, ate resistant to the ammonium

persulphate treatment. This finding con-

ed the difficulties that this particular

brewery had experienced in trying to

disinfect its yeast with ammonium per-

sulphate. The aerobic acid-producin,

culture, A-2U, tended to resist the aci

treatment at pH 28, but it was susceptible

to a pH of 2:2. Additional tests indicated

that a pH of 2-4 has to be reached before an

acid wash will be fully effective in killing this

organism.

jame preliminary taxonomic studies were

conducted with these and some of the later

isolates that will be described. Culture

A-2U is an Acetobacter type, while the other

three cultures are lactobacilli variants.

Four different types of bacteria were

isolated from lager yeast B. Culture B-3 is

a gram-positive aerobic rod that grows

vigorously in wort but does poorly in a beer

fermentation. Culture B-5 is a -

negative rod, aerobic, and a strong producer

of acid. Culture B-6 is a gram-negative

aerobe, of extremely short rod form, that

produces some acid. Culture B~7 is a gram-

negative, facultatively anaerobic, thin, long

rod form that produces little acid; it appears

to belong to the flavobacteria. These isolates

were grown with lager yeast in mixed

showed much resistance to the acid treat-

ments. As noted in Table II also, acidified

ammonium persulphate was the most effec-

tive treatment.

From lager yeast C, three related gram:

negative, facultatively anaerobic, thin rod

forms were isolated. A fourth isolate, C-9

which is similar to the three isolates from

t C, was found in almost pure culture

in the yeast from another brewery. Mixed

fermentations were carried out, and_ the

contaminated yeasts harvested and disin-

fected. The results are presented in Table IV.

‘These cultures, which are considered to be

of flavobacteria, were treated only in low-

temperature, short-time trials and were

sensitive to all of the treatments, The

highest survivals were obtained with the

straight ammonium persulphate treatment,

but a higher temperature ot a longer period.

of time would have increased the effect of

this treatment.

The levels of yeast survival were good

(over 70%) in nearly all of these trials.

me sluggishness was noted in the fermenta-

tions with most of the treated yeasts. This

difficulty can be overcome by a slightly

higher rate of pitching (or a higher pitching

temperature). No tendency to produce or

select for respiratory-deficient variants was

noted in these experiments.

248

Discussion

The standards of microbiological control

in breweries have changed over the years.

A generation ago a pitching yeast was

accepted as usable when it contained 1% of

Dacteria; more recently careful brewers were

still passing yeasts with 025%, and some

looked pained when our laboratories said

that 0-1 18 ‘was too high.

‘A contaminated yeast may harbour a

massive reservoir of troubles. Brewers who

might shudder at the thought of their cooled

wort containing 10,000 bacteria per ml., seem

untroubled by adding 10,000 bacteria per

ml. when they add 10,000,000, yeast cells

per ml. along with 10,000 bacteria as they

BRUGH ef al.: YEAST DISINFECTION WITH ACIDIFIED PERSULPHATE (J. Inst. Brew.

ammonium persulphate treatment may be

expected to reduce the viable bacteria count

to 0-0002% (2 bacteria per million yeast cells.

Taking the same example, if the yeast

{02% viable bacteria) is added to wort to

provide a normal pitching yeast count of

10,000,000 yeast cells per ml. the bacterial

count would be 20,000 per mi. "After washing

the yeast with acidified ammonium per-

sulphate, the bacterial count in the pitched

wort would very probably be Jess than

20 per ml.

‘The highest survival rate in the recorded

data was 3 per 1000; in 90% of the tests no

viable bacteria remained after exposure to

acidified ammonium persulphate.

TABLE IV

Rusistance oF BACTERIAL ConTAMINANTS ISOLATED FROM LAGER YEAST SAMPLE C TO

DISINFECTION I PRESENCE OF VIALE YEAST

Survival (%):

‘Ammonium 075% ammonium

persulphate Sulphuric acid etaulphatet

mae 20 | eee | ose | pres

Bacterial Pee Pore | Pane |e Pon.

isolates 12°C. Eve | ete. | cre te.

25 5 +3 ° ° ° °

cas 5 1 ° ° ° o

e0 1 +3 ° ° ° °

cot 1 +6 ° o1 ° 0

* The pH was adjusted with sulphuric acid.

t This bacterial culture was isolated from another brewing yeast; it is similar in character

to the isolates from yeast C.

do when they use yeast containing 0-1% of

bacteria (1 bacterium per 1000 yeast cells),

Arithmetic demonstrates that the contamina-

tions are equal. Experience teaches that

the bacteria accompanying yeast into the

wort may be more hazardous, because the

wort-contaminating organisms are usually

sty by yeast fermentation.

ith the availability of the simple yeast-

purifying technique described in this paper,

it is possible to achieve, quickly and easily,

new levels of ‘microbiological purity in

pitching yeast. The results of dozens of

experiments indicate high probability of

efiecting a 99-:0% kill of Bacteria with

acidified ammonium persulphate. Assuming

yeast crop contains 0-2% viable bacteria

(2 bacteria per 1000 yeast cells), the acidified

Acknowledgement.—The data of this paper,

and a modified version of the text, were

presented orally by Dr. Bruch at the 63rd

Annual Meeting of the American Society for

Microbiology, at Cleveland, Ohio, 5th-9th

May, 1963.

‘REFERENCES

|. Compton, J., Cronyn, J.B, & Read, W. F.,

‘allerstéin Lab. Commun., 1954, 17, 19.

. Czarnecki, H. T., & van Engel, E, L., Brewers,

Digest, Mar. i969, 62.

. Gray, & Kazin,

D., Wallerstein Lab,

‘Master Brewers Assoc. Amer., 1950, 44.

. Strandskov, F. B., & Bockelmann, J. B.,

‘J. Agric. & Food Chem., 1953, 1, 1219.

Uilig, K., ‘Amer. Beewer, Nov., i962, 41.

ee keen

ee 3

3

You might also like

- Vida util TMAR Interes Prestamo CEADocument6 pagesVida util TMAR Interes Prestamo CEAArnold Vitor A.No ratings yet

- Simio EULADocument5 pagesSimio EULARogerQuispeNo ratings yet

- Desinfeccion de VegetalesDocument13 pagesDesinfeccion de VegetalesArnold Vitor A.No ratings yet

- Effect of UV-C Disinfection of Beer - Sensory Analyses and Consumer RankingDocument6 pagesEffect of UV-C Disinfection of Beer - Sensory Analyses and Consumer RankingArnold Vitor A.No ratings yet

- Desinfeccion Con EnzimasDocument7 pagesDesinfeccion Con EnzimasArnold Vitor A.No ratings yet

- 0 C 9605166 DC 67 F 1 D 85000000Document30 pages0 C 9605166 DC 67 F 1 D 85000000Arnold Vitor A.No ratings yet

- Simultaneous Spectra Kinetic Determination of Peracetic AcidDocument6 pagesSimultaneous Spectra Kinetic Determination of Peracetic AcidArnold Vitor A.No ratings yet

- Chen Et Al-2012-Journal of The Institute of Brewing - ImportanteDocument5 pagesChen Et Al-2012-Journal of The Institute of Brewing - ImportanteArnold Vitor A.No ratings yet

- Japan - England: Student: Vitor Advincula, Arnold Percy. Code: 10170015Document1 pageJapan - England: Student: Vitor Advincula, Arnold Percy. Code: 10170015Arnold Vitor A.No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)