Professional Documents

Culture Documents

US6764542B1

Uploaded by

100liv0 ratings0% found this document useful (0 votes)

3 views7 pagesjhj

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentjhj

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views7 pagesUS6764542B1

Uploaded by

100livjhj

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

United States Patent

Lackey et al.

(54) BIODIESEL CU

ASPHALT

ie

5) Inventors

(73) Assignee

(2) Notice:

Appl. No.

Filed:

Related US.

(60) Provisional

BACK ASPHALT AND.

EMULSION

Kenneth R. Lackey, Gallatia, TN

(US); James R. Alcorn, I, Hebron,

Ky (Us)

Marathon Ashland Petroleum LLC

Findlay, OH (US)

Subject to any diselaimer the term of this

patent is extended or adjusted under 35,

USC. 154(b) by 0 days,

10/447,689

May 29, 2003,

Application Data

spplication No. 385.278, fled on May 31,

Im. C1 CosD 195/00

US. cL 106/277; 106/279; 106/280

Fleld of Search 1062277, 279,

105280

66) References Cited

US. PATENT DOCUMENTS.

287712 A * 3/1980 Hardman 106

‘norte? A 121990 Hayne ea

2033 32001 Msjrceak

6214103 BI + 42001 Kitogawe ross.

BIODIESEL

US006768542B1

0) Patent No. US 6,764,542 BL

(4s) Date of Patent: Jul. 20, 2004

6.285104 BL 82001 Chatopaihyoy etal

acing m2 area Weal

Caitise Bt ame ca

calsom BL 2002 Cu

61721 BL 72002 Yao

(OTHER PUBLICATIONS

bupslweceps gota cbit/sp42/c finaleA pl,

located on pI ine 15.

Inup/wwwsoygoll.comimany uses um, loated on p. 3,

line 15.

Inip/wwwapexnodth.comappliations), Hosted on p. 3,

lie 21

Iips/Awwwotle gowbiofels psbiodtese_from_at

a0 papi located on p 9, line 21

Ini aema ong Tocted on p12; ine 15.

Primary Examiner—David Bruasman

(78) Attorney, Agent, or Firm—Envch, Schaller, Schaub &

Porcello Co, LBA

on ABSTRACT

A cutback asphalt and an asphalt emulsion comprising

biodiesel is disclosed, Cuthack is mixed with 2 suflicient

amount of biodiesel to reduce the viscosity of the asphalt,

producing, e., a eo patch material which is fre of added

Tiguid petroleum, An asphalt emulsion of fine particles of

asphalt, water and, preferably, aa emulsifier, can be Formed

‘whieh is free of addled liquid peuoleum.

19 Claims, 1 Drawing Sheet

PRIOR ART

U.S. Patent Jul. 20, 2004 US 6,764,542 BL

PRIOR ART

Fig.1

BIODIESEL

US 6,764,542 BL

1

BIODIESEL CUTBACK ASPHALT AND

‘ASPHALT EMULSION

cro!

EFERENCE TO RELATED

‘APPLICATIONS.

‘This application claims the benefit of U.S. Provisional

Application Ser. No. 60/385,278 fled May 31, 2002.

BACKGROUND OF THE INVENTION

1. Field of the Invention

‘The invention relates to “cutback asphalis” and asphalt,

‘emulsions made with bioksel

2, Description of the Prior Art

‘A good discussion of asphalt roads, cutback asphalt and

asphalt emulsions is contained in hup:/www.epa-govitin

chiefiap42/eh04/finales05.pdf, which is incorporated

herein by reference

‘Although a considerable oversimplifcation, asphalt toad

products could be broadly grouped in three categories:

[Neat-asphalt obtained by distillation for making roads,

6g, asphalt cement,

CCutback asphals-an asphalt soflened with petroleum

solvent, eg. asphalt cement with gasoline or diesel

uel, for patching.

Asphalt emutsions-sotid particles of asphalt in water,

‘usally with an emulsifying agent

[Neat asphalt is used to make new roads and is usually

applied hot, Cutback asphalts are used for patching and

Some types of new rad construction or resurfacing, though

primarily in cooler months. Asphalt emulsions ate used in a

‘variety of thickness and applications, ranging from surface

sealers to patching material 10 new coad_ constevctios

though primarily in warmer climates.

“The present invention focuses on cutback asphalt and

asphalt emulsions and problems of repairing and restoring

road surfaces,

‘One of the most common problems encountered in main=

taining asphalt roads is potholes or chuck holes, These

tually sant off small, in arcas where there has been

freeze/thaw damage or poor surface preperation or some

assault on the road surface. Once stated, they usually grow

progressively worse, due to accumulation of water and

Pounding. Conventionally, cutback asphalt is used Tor

Patching, especialy in coote climates anlioe winter months.

‘To male the asphalt soft enough to work with, and/or reduce

fr eliminate the amount of heating needed to make the

material workable, a petroleum solvent is dissolved in the

asphall. Such “cold patch” materials ae frequently made in

advance and stockpiled to provide a source of material for

patching

‘Another method of making high softening pot asphalt,

fluid enough to process at ambient, or relatively low,

temperatue, isto form an emulsion of asphalt in Water With

an emalsifir. The asphalt retains its high melting point, but

's ground finely enough, to particles on the order of 5-10

microns, tht a relatively stable emulsion of asphalt in water

's formed which behaves as a liquid with a much lower

viscosity than the asphalt particles. The emulsion sets or

breaks when the water evaporates andior it reacts with

Particles of aggregate.

Tn some instances roads are male wit cutback asphalt of

asphalt emulsions.

‘Al cutback asphalts contain solvent. The solvent even-

tually evaporates, quickly or slowly, depending on the nature

‘of the solvent, eeal weather conditions snd the amount of

%

o

2

eating. When used to const parking foto road, the

mounts of solvent sed, apd dachanged ito the air sre

normous—from about 2 tons of hydrocahon per ace of

Parking lotup to 10-20 tons of hyrocarbon per abe oa

Meder cars, with catalic converters burning clean

fuck, generate relly low levels of HC emissions pet

nile of travel, an onde of magntae less emissions as

Compared to pesalalyic converter ears a conta, mode

éim oad building an epair mets have changed Tile nd

the amount of slate onanic compoums release. hy

taking o repairing roads using eiback asphalt or ssp

triuision tar not hanged siguiarly. Abou the ony

Sccommodstion tothe poling effet of modern roads is

ieglaton in many areas Banning se of cuback spall,

except in winter months.

“Another pecble with catback asphls, especialy the

avick sting warty is that te ge sma of ptoleom

Sydkocrbon solvent added, andthe woltity of the fec-

tions used, create a fie hard and subject workers, and

those near be oud, (0 eapesie o Lose bem

‘We discovered that i as possble to se nar

derived from vegetable, i or animal fas, a8 part of &

Cathack asphalt oe asphalt emulsion. So fara i kno,

biodiesel bas never ban used inthis wey, though tse of

Disa as ease agent as ben pote follows

Inipsvsoygold comimany uses him teaches ase of

iodiescl a ease apet for

Esfectie Release Agent

Tool Cleaning

Drag chains in pans

Paving eqipment clan up. bipavweapexnath som

"lsstinsteaches sila cs (ee amp ease

ent)

Bien, is now wellknown and widely avaiable com-

snecialy and extensively stad, 5 show by 10O¥papers

Jncluded in the repon, Bios Research Progress is.

assed above, Biodiscs are trace for fel, and some

ter sey, becie they have Hw” Vapor presse, a

ton-oxie and are sable, sper HMIS cet and J not

deteriorate or detonate pom mild heating

Although these bene (ety, oxic) may sem tobe

an cbvious prof biodiesel it wos by n0 eas Obvious

Took on bodes a suitable for iran ssphall cuback

solvent for ae in forming an asphalt culo. Asphalt

asa high molecular weight and ishighly aomati. Bioie-

scl aliphati, contain osu, has no ing rte oF

Eromatic, andi elativcy low molecular weigh, as some

Pred to tphalt,Bidise! abo contin large aroun of

bxpgen,approsching 10%, I could be argd tha inca,

‘elatvely tow molecular weight aiphtie molecule sich as

Diss would be good release agent but not suitable as

2 solvent (in bac aphal) nor for forming sable

asin in asphalt emulsions)

SUMMARY OF THE INVENTION

1. General Statement ofthe Invention

(ne embodinent ofthe presea aveation provides cut

bacle asphalt comprising phat btine fom perleun by

dilaton andor extraction an a eter solved comprising

Snester derived from vegetable cls animal fats such a

Bisel

Despite the discussed above concemns, the aliphatic

bindise cutback aspalis and asphalt emulsions worked

well and had some very unexpected eae

“The cutback aphalis othe present invention, which have

been tested extensively as a patch material ay in the

US 6,764,542 BL

7

pothole and have met with the customer approval. For

{nstance, some beneits lo using biodiesel include fre hazard

safety and low toxicity in preparing the materials also the

biodiesel is a very nice material to work with; it has no

unpleasant odor, and although it will bur, it has such a Tow

‘volatility that if will not form an explosive mixture in a

under normal processing conditions. The biodiesel i essen-

tially fre of aromatics and considered) on-toxic for skin

‘contact and is readily biodegradable, should aay spills occur

In addition, there were some very unexpected benfis to

using biodiesel in cutback asphalt

‘he biodiesel cutback asphalt is stable in storage, even

when simply left in a pile In a storage yard, which is the

Usual mellod of storing suck cold patch material, There is 0

‘observable rus-l, which can occur wher liguid petroleum

solvents are used as.a dient. There is little oF no lose of

material due to evaporation, oe perhaps drainage, in that a

pile of pateh material retained a pleasing shiny appearance

snd was readily worked, after two months in storage While

‘competitors product lost is "luster" after sbout 1 month

‘of storage. Purther surprisingly, itis now possible to make

a silisfactory culback phal with relative low amouns of

biodiesel, much less than was necessary, oF at least

‘customary forthe prior ar liquid petcoleum solvent cuback,

materials,

TInanother embodiment, the present invention provides an

asphalt emulsion comprising emulsifiable particles of

asphalt obtained from petroleum by disillation andor

‘extraction, water and a oil phase comprising an ester

‘derived from vegetable oils or animal fats

In yet another embodiment, the present invention pro-

vides'a pavement or paving composition comprising agere-

ate and from 1.0% t 10.0% of an asphalt composition

‘comprising. 2 cutback asphalt containing biodiesel or an

‘spl emulsion comprising biodiesel

[BRIEF DESCRIPTION OF THE DRAWINGS

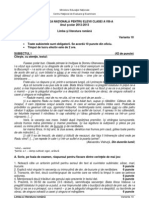

FIG. 1 is 3 photogeaph showing storage stability and

‘weathering of a cuback asphalt patch material made with

biiesel va conventional materi made with liquid hydro-

carbon eutback solvent.

DETAILED DESCRIPTION OF THE

PREFERRED EMBODIMENTS

Fog clarity, a number of terms will be defined for use

herein, using terminology consistent with that of many sate

departments of transporiation,

Asphalt

ark brown to black cementitious. material (Solid of

liquid) of whieh the main constituents ate bitumens which

‘occur naturally oF 38a residue of petroleum refining. Liquid

aspahils ae those asphalis which have been liguefied by

blending with petroleum solvents

Biodiesel

Biodiesel is generically defined s the mono alkyl eter of

Jong. chain fatty ace derived from renewable lipid sources

Suitable sources include animal fats and vegclable oils. A

preferred material is biodiesel made fom soy bean oi

Cutback Asphalt

‘Asphalt cement that has been cut back or blended with a

diluent of petroleum solvents (prior art) or with biodiesel

{avention). The types of cutback asphals are defined by

‘American Society of Testing and Materials (ASTM) speci-

fications as follows:

‘SC=Slow cure type (Road Oils): ASTM D-2026-72

‘Medium cure type: ASTM D-2027-76

RC=Rapidl eure type: ASDTM D-2028-76

%

o

4

Dust Palliative

‘Any light application of cutback asphlts forthe express

purpose of controlling Toose dust

Emulsitied Asphalt

‘An emulsion of asphalt coment and water that contains 3

small amount of emulsifying agent. An inverted emulsified

asphalt shall be considered a cutback asphalt if the liquid

spall phase was a cutback asphalt

Penetrating Prime Cost

‘Any application of asphalt to an absorptive surface 10

penetrate and bind the aggregate surface and promote auhe-

Sion between it and the new superimposed construction

Primo coats do not inchide dst paliatives oF tack coats,

Tack Coat

‘Any application of asphalt applied to an existing surface

fo provide a bond between new surfacing and existing

surfaces and to eliminate slippage planes where the new and

cexisting surfaces mec.

‘he term “asphalt (Sometimes refered to as “bitumen")

refers to all types of asphalis (bitumen), including those that

‘secur in nature an those obtained in petroleum processing.

‘The choice will depend essentially on the particular app

cation intended forthe resulting bitumen composition. Pre-

erred materials have an initial viscosity at 140° F. (60° C.)

‘of 200 to 6000 poise. The intial penctration range of the

base asphalt at 77°F. 25° C) is 30 10 350 danm, preferably

50 to 200 dim, when the intended use of the composition

Jstoad paving, Asphalt, whieh does not coatain any polymer,

sulfur, ete. may sometimes be refered to herein as a "base

asphalt”

‘Suitable asphalt componens include a variety of organic

materials, solid or semi-solid, at room temperature, Which

gradually liquefy when heated, and in which the predom

le constituents are naturally occurring bitumens, ex,

Trinidad Lake o esidues commonly obtained in petroleum,

synthetic peoleum, or shle il retin, of fom coal tar oF

the like, For example, vacuum tower bottoms produced

‘during the refining of conventional or synthetic petroleums

oils are & common residue material useful 38 asphalt com-

position, Solvent deasphalting or distillation may produce

the asphalt

‘Solvent deasphalting (SDA) bottoms may be used as part,

or all ofthe asphalt ofthe product blend. SDA bottoms are

‘obtained from Suitable feeds such as vacuum tower bottoms,

reduced crude (atmosphere), opped erude, and preferably

hydrocarbons comprising an initial boiling point of about

450° C. (850° F) or above, Preferably the solvent deasphalt-

ing_bottoms are obtained from vacuum tower bottoms,

preferably boiling above 538° C. (1000* F.), Solvent deas”

‘halting can be eartied out at temperatures of 93-148° C.

(200-300" F). After solvent deasphalting, the esulting SDA.

bottoms have a boiling point above 510° C. (950° F.),

preferably above 540° C. (1000° F.), and a penetration of 0

10 70

You might also like

- Material Test Report: Sample Details Particle Size DistributionDocument2 pagesMaterial Test Report: Sample Details Particle Size Distribution100livNo ratings yet

- Material Test Report: Sample Details Particle Size DistributionDocument1 pageMaterial Test Report: Sample Details Particle Size Distribution100livNo ratings yet

- Material Test Report: Sample Details Particle Size DistributionDocument1 pageMaterial Test Report: Sample Details Particle Size Distribution100livNo ratings yet

- 02 MAnderson MSCR ImplementationDocument39 pages02 MAnderson MSCR Implementation100liv100% (1)

- Technical White Paper FP 08 - 4-Mm DSRDocument71 pagesTechnical White Paper FP 08 - 4-Mm DSR100livNo ratings yet

- Material Test Report: Sample Details Particle Size DistributionDocument1 pageMaterial Test Report: Sample Details Particle Size Distribution100livNo ratings yet

- Us 3338849 ADocument6 pagesUs 3338849 A100livNo ratings yet

- RILEM Recommended Test Method AAR-1: Detection of Potential Alkali-Reactivity of Aggregates - Petrographic MethodDocument17 pagesRILEM Recommended Test Method AAR-1: Detection of Potential Alkali-Reactivity of Aggregates - Petrographic MethodAlvaro Pazmiño RomanNo ratings yet

- Us 5927620Document4 pagesUs 5927620100livNo ratings yet

- RILEM Recommended Test Method AAR-0: Detection of Alkali-Reactivity Potential in Concrete - Outline Guide To The Use of RILEM Methods in Assessments of Aggregates For Potential Alkali-ReactivityDocument8 pagesRILEM Recommended Test Method AAR-0: Detection of Alkali-Reactivity Potential in Concrete - Outline Guide To The Use of RILEM Methods in Assessments of Aggregates For Potential Alkali-Reactivity100livNo ratings yet

- Calculation of Measurement Uncertainty For Stiffness Modulus of Asphalt MixtureDocument9 pagesCalculation of Measurement Uncertainty For Stiffness Modulus of Asphalt Mixture100livNo ratings yet

- 162 PaliukaiteDocument7 pages162 PaliukaitePuneet SharmaNo ratings yet

- Development Crumb Rubber BitumenDocument10 pagesDevelopment Crumb Rubber Bitumen100livNo ratings yet

- Limba Romana Capacitate 2013Document2 pagesLimba Romana Capacitate 2013Ioana NicolescuNo ratings yet

- Ekingen eDocument192 pagesEkingen e100livNo ratings yet

- Jsir 68 (9) 812-816Document5 pagesJsir 68 (9) 812-816100livNo ratings yet

- Asphalt Paper DSRDocument4 pagesAsphalt Paper DSRyazqaNo ratings yet

- Wo 2013163009 A 1Document307 pagesWo 2013163009 A 1100livNo ratings yet

- 7 Hines AMAP SavannahDocument57 pages7 Hines AMAP Savannah100livNo ratings yet

- 25351Document8 pages25351100livNo ratings yet

- Perpetual Pavements in Delivering Smooth RoadDocument37 pagesPerpetual Pavements in Delivering Smooth Road100livNo ratings yet

- 992041Document47 pages992041100livNo ratings yet

- AAPAs Asphalt Pavement Solutions - For Life ProjectDocument12 pagesAAPAs Asphalt Pavement Solutions - For Life Project100livNo ratings yet

- 020-Pap 017Document17 pages020-Pap 017100livNo ratings yet

- Online Users Guide en enDocument166 pagesOnline Users Guide en en100livNo ratings yet

- ER926SB70ADocument2 pagesER926SB70A100livNo ratings yet

- 152Document6 pages152100livNo ratings yet

- Bitumen Viscosity Testing Equipment and Test ProceduresDocument6 pagesBitumen Viscosity Testing Equipment and Test ProceduresProf. Prithvi Singh Kandhal75% (4)

- Agpt T103 06 - RtfoDocument20 pagesAgpt T103 06 - Rtfo100livNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)