Professional Documents

Culture Documents

S03 Rock Drill HLX5 Maintenance

Uploaded by

Anonymous iu95trpxNCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S03 Rock Drill HLX5 Maintenance

Uploaded by

Anonymous iu95trpxNCopyright:

Available Formats

B 23710 - 3 en 0106 / TL

1 (16)

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

CONTENTS

1.

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.

TAKING A NEW ROCK DRILL IN USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1. Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2. Test run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

2

2

3.

HOSE CONNECTIONS

..............................................

4.

LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.

REMOVING THE FRONT END WITH THE ROCK DRILL ON A FEED RAIL .

5.1. Replacing the flushing housing seals and the seal housing

guide rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2. Replacing the bearings of the flushing housing . . . . . . . . . . . . . . . . .

5.3. Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4. Rotation bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5. Chuck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6. Rotation bushing bearings inside the gear housing . . . . . . . . . . . . . .

5.7. Wear limits of the shank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.

CHECKING AND TIGHTENING BOLTS AND TIE RODS . . . . . . . . . . . . . . . . . .

6.1. Tie rod tightening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2. Pressure accumulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3. Flushing housing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

11

11

12

7.

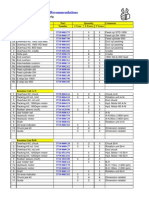

PERIODIC MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2. Field service tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3. Every day . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4. Every week . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5. Basic maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6. After rock drill service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7. Service card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8. Service follow-- up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

13

13

14

14

14

14

15

15

7

8

8

8

9

9

9

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

2 (16)

B 23710 - 3 en 0106 / TL

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

1.

GENERAL

These instructions describe in brief the main maintenance procedures for HLX5 series

hydraulic rock drills.

Service is always ready to help and give advice in all maintenance problems. The qualified

TAMROCK maintenance personnel of your TAMROCK dealer and original TAMROCK

spare parts ensure reliable operation of your drilling equipment.

2.

TAKING A NEW ROCK DRILL IN USE

2.1. Preparations

New rock drills are delivered with the pressure accumulators not

pressurized and the hose connections plugged.

CAUTION

Pressurize the accumulators according to the instructions. See Pressure accumulator

repair instructions.

Before a new rock drill is installed the drilling equipment hydraulic system must be

checked and flushed thoroughly.

2.2. Test run

Test run the rock drill and make sure that it operates properly before starting production

drilling.

During test run observe:

-- shank lubrication

-- flushing

-- pressures and temperatures

-- possible oil leakages

CAUTION

Avoid use of full percussion power if the steel is not against the rock.

This will reduce the breakage of the accumulators diaphragm, the wear

of flushing housing, drilling tools and the cavitation of the percussion

mechanism. This type of idling drilling is the most critical while drilling

upwards or cleaning the holes with pumping motion.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

B 23710 - 3 en 0106 / TL

3 (16)

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

3.

HOSE CONNECTIONS

2

3

5

4

Fig 1.

Hose connections

1. Shank lubrication

2. Percussion mechanism pressure side (H.P.)

3. Percussion mechanism return side (L.P.)

4. Rotation, pressure (H.P.)

5. Rotation, return (L.P.)

6. Flushing

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

4 (16)

B 23710 - 3 en 0106 / TL

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

4.

LUBRICATION SYSTEM

The rock drill percussion mechanism and the rotation motor are lubricated by the hydraulic

oil flowing through them.

1

Grease nipple

Fig 2.

Lubrication scheme: 1 Surface model, 2 UG model

The rotation mechanism and the shank have oil mist lubrication. The lubrication line from

the lubrication unit is connected to end of the rock drill. From there the oil mist is ducted

through piston rear end to the front end of the rock drill where the flow will lubricate the

rotation mechanism, coupling and the bushings of the flushing housing.

Leakage oil from the rear seals of the piston is also ducted to the front end of the rock drill

through a channel.

The oil that has circulated through the rock drill lubrication system is removed through the

shank lubrication collector or can be led via return channels and gear housing to the feed

rail.

Never connect the used oil mist to the hydraulic system return line.

CAUTION

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

B 23710 - 3 en 0106 / TL

5 (16)

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

1

4

2

3

Air

Fig 3.

Shank lubrication

1. Rock drill

2. SLU 1/2/3

3. Drain valve

4. Filler cap

1. The shank lubrication oil consumption can be adjusted. (See the instruction

manual for SLU 1/2/3).

2. The shank lubrication does not work if the oil level in the receiver does not lower

during drilling. (See the instruction manual for SLU 1/2/3).

3. Drain regularly the water that has collected in the receiver. The draining interval

depends on the local conditions

4. Use only oils according to lubrication recommendation.

5. Refill the receiver regularly.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

6 (16)

B 23710 - 3 en 0106 / TL

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

5.

REMOVING THE FRONT END WITH THE ROCK DRILL ON A

FEED RAIL

When you remove the flushing housing and shank, turn the rock drill to a

horizontal position. The coupling can fall out and cause injury.

WARNING

WARNING

If the shank lubrication is clogged (no air comes from the shank

lubrication return hose), stop the compressor. Before opening the

flushing housing bolts, carefully open the locking screw and let the air

pressure out. Otherwise the air pressure can blow / burst out the flushing

housing and cause injury.

By opening the bolts (4) the flushing housing (1), the shank (2), and the coupling (3) can be

pulled out without removing the rock drill from the feed rail. The lock--screw (5) holds the

rotation bushing (6) in the housing, for example while changing the shank. Check the

condition of the rotation bushing rear end (6) and the bearing (7).

6

3

2

5

1

4

Fig 4.

Dismounting of the flushing housing

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

B 23710 - 3 en 0106 / TL

7 (16)

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

5.1. Replacing the flushing housing seals and the seal housing guide

rings

Flushing housing seals (A) 5 pcs and the seal housing guide rings (B) 2 pcs must be

replaced when the flushing air or water escapes from the sides of the seal housing, and

they should be checked whenever the shank is changed. Seals are easier to install when

they are lubricated. Install the new flushing housing seals making sure they face the right

direction (shown in the figure). The use of a spare flushing housing is recommended, as

it speeds up on--site maintenance of the rock drill.

B

1

AIR FLUSHING

B

1

WATER FLUSHING

A

Fig 5.

The flushing housing seals must be installed facing the right direction, determined

by the flushing mode

In addition, a damaged seal plate (1) must be replaced due to risk of

corrosion.

CAUTION

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

8 (16)

B 23710 - 3 en 0106 / TL

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

5.2. Replacing the bearings of the flushing housing

The bearings must be replaced if the indicator groove is worn off

any place.

5.3. Coupling

Pull the coupling out from the rotation bushing. Check and

replace, if the edges of the inner teeth are worn sharp or visible

cracks are seen.

5.4. Rotation bushing

The rotation bushing must be replaced if the shoulder A is worn

to the same level with the face or damages are observed. Make

sure that also the outer surfaces of the rotation bushing are in

good conditions.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

B 23710 - 3 en 0106 / TL

9 (16)

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

5.5. Chuck

The chuck inside the rotation bushing must be changed if the

wear is over 1 mm from the original surface B or if there are some

hair cracks.

B

1 mm

5.6. Rotation bushing bearings inside the gear housing

The bearings must be changed if the wear indication--groove has

worn out from any area.

5.7. Wear limits of the shank

max 1 mm

CAUTION

The shank must be changed if the 1 mm bevel of the striking

max 1 mm head is worn out or any other wear limit is exceeded.

When installing a new shank, take care that no dirt enters inside the rock

drill with the shank. Insert the shank carefully through the flushing

housing, so that the flushing device seals are not damaged.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

10 (16)

B 23710 - 3 en 0106 / TL

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

6.

CHECKING AND TIGHTENING BOLTS AND TIE RODS

The most important maintenance task is to check the tightness of the bolts,

particularly the tie rods and mounting bolts. Loose tie rods cause rapid wear of the

body section faces, shortening the service life of the rock drill.

Following procedure is recommended for checking the bolt tightness during

normal maintenance:

1. Check the tightness of each bolt by using 10 % higher torque than specified

and the correct tightening order.

2. The joint being tested is loose if the wrench turns. In this case loosen all the

bolts being tested and retighten with the correct order.

3. If the threads are not clean the bolts cannot be tightened correctly. In such

cases the bolt must be removed, the threads checked, cleaned, and

lubricated with grease.

Use only an inspected, high---quality torque wrench.

CAUTION

2

3

2

1

Fig 6.

Rock drill bolts

1. Tie rod bolts

2. Pressure accumulator bolts

3. Flushing housing bolts

6 pcs

4+4 pcs

4 pcs

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

B 23710 - 3 en 0106 / TL

11 (16)

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

6.1. Tie rod tightening

The tools required:

-- torque wrench

-- 24 mm ring end

1. Lubricate the threads and the nut faces with grease.

2. Pretighten to 200 Nm (20 kpm). Correct tightening order is (1--2--3--4--5--6)

3. Final tightening torque is 400 Nm (40 kpm). Same tightening order

(1--2--3--4--5--6) should be used.

Fig 7.

Tie rods; tightening order

6.2. Pressure accumulators

The tools required:

-- torque wrench

-- 24 mm socket

1. Lubricate the bolt threads with grease.

2. Pretighten all four bolts to 100 Nm (10 kpm). Correct tightening order is 1--2--3--4.

3. Final tightening torque is 200 Nm (20 kpm). Same tightening order (1--2--3--4)

should be used.

Fig 8.

Pressure accumulator bolts tightening order

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

12 (16)

B 23710 - 3 en 0106 / TL

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

6.3. Flushing housing bolts

The tools required:

-- torque wrench

-- 24 mm ring end

1. Lubricate the bolt threads with grease.

2. Pretighten all four bolts to 200 Nm (20 kpm). Correct tightening order is (1--2--3--4).

3. Final tightening torque is 400 Nm (40 kpm). Same tightening order (1--2--3--4)

should be used.

1

3

4

2

Fig 9.

Flushing housing bolts

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

B 23710 - 3 en 0106 / TL

13 (16)

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

7.

PERIODIC MAINTENANCE

7.1. General

The idea of periodic maintenance is that the rock drill is serviced before any breakdown

occurs. This way expensive additional damages and unwanted production interruption

can be avoided.

The maintenance interval is 500 percussion hours, but depends on the local conditions,

and it must therefore be determined according to this experience.

Searching for the correct maintenance interval, it is advisable to start the periodic

maintenance as specified, and then lengthen the intervals until a period that suits the local

conditions has been found.

In addition the rock drill should always be taken in for service when the operator reports

of a fault on the rock drill that can cause major damage or a production interruption.

7.2. Field service tools

1.

2.

3.

4.

5.

6.

7.

Torque wrench

24 mm socket

24 mm ring end

19 mm wrench

Extension

Accumulator low pressure gauge

Accumulator high pressure gauge

4

7

3

Fig 10. Maintenance tools

Make sure that you have also the flushing seals, gaskets and the shank adapter for the

rock drill maintenance.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

14 (16)

B 23710 - 3 en 0106 / TL

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

7.3. Every day

1.

2.

3.

4.

Check the flushing housing for water and air leaks.

Check the flushing housing bolt tightness.

Check for possible oil leaks.

Check the condition of the hoses and fittings.

7.4. Every week

1.

2.

Check the hour meter reading.

Check the accumulator filling valves and their protective caps and the accumulator

bolt tightness.

3. Check the accumulator pressures

-- High pressure . . . . . 50 bar

-- Low pressure . . . . . . 4 bar

4. Check the condition of the shank, chuck, flushing housing, coupling, shank

bushing and the rotation bushing.

5. Check the tie rod tightness. If loose, tighten them up, according ch. 6.1.

7.5. Basic maintenance

Rock drill basic maintenance is recommended every 500 operating hours, Cf. Repair

Instructions. This maintenance interval can be adjusted according to local conditions and

experiences which are accumulated to the rock drill maintenance history. Do planned and

preventive maintenance rather than repairs after damages.

Monitor percussion hour meter reading and/or drilled meters/shifts between each

maintenance. Fill in the service card of the rock drill.

7.6. After rock drill service

After the rock drill service the reassembled parts will settle down to their proper position

during drilling under normal drilling loads. Especially if the parts have worn surfaces it may

result that the tie rods and the mounting bolts do not keep their tightness. Therefore a

re--tightening of these bolts is required after each rock drill service or if the rock drill has

been removed and remounted on the feed rail.

After the rock drill service and 1 round / 100--300 meters drilling:

1. re--tighten the rock drill mounting bolts on the feed rail

2. re--tighten the rock drill tie rods and flushing device bolts

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

B 23710 - 3 en 0106 / TL

15 (16)

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

7.7. Service card

Each rock drill has its own service cards. When a rock drill is taken up for maintenance,

all the earlier cards should be at hand. All relevant information about the maintenance

must be written down on the card. When the rock drill is again taken into use, the next

maintenance date should be written down on the card. Benefits of the card are:

-- Wear of every specific component of each rock drill is clearly displayed, and by

comparing the cards the effect of different circumstances and measures can be

determined.

-- The cards help in determining maintenance required to prevent major damage.

-- Properly filled cards show the complete maintenance history of the rock drill.

-- The cards help to determine the point when the rock drill should be scrapped.

-- Use service card presented on the next page.

7.8. Service follow--up

In order to follow the maintenance of a rock drill, a maintenance card presented on the

next page can be used.

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

16 (16)

B 23710 - 3 en 0106 / TL

HYDRAULIC ROCK DRILL HLX5

Operation and Maintenance

ROCK DRILL SERVICE CARD No

Equipment

Rock drill

S/n

S/n

Since previous service percusion hours

drill. shifts/rounds

drilled meters

SERVICE INFORMATION

Purpose of the service

Serviceman

Arr.date

Prev.service

Dep.date

Prev.service card No

Prev.perc.hours

Working

hours

Rep.

Dism.

Insp.

Ass.

Total

REPLACED PARTS/ PART INSPECTION

Qty

Part No

Description

Repaired

/ Batch

Replaced

/ Batch

OK

Remarks

Piston

Pilot cylinder

Front bushing

Rear bushing

Distributor

LP accumulator

HP accumulator

Spacer

Gear housing

Rotation bushing

Rot.bush.bearing

Chuck

Connecting piece

Rotation motor

Rotation shaft

Rot. shaft bearings

Front cover/ body

Flus. seal housing

Shank bearings

Remarks

Percussion

mechanism tested

Rotation

mechanism tested

E 2006 SANDVIK TAMROCK CORP., Tampere Plant

P.O.Box 100

FIN--33311 TAMPERE, Finland

Tel. +358 205 44 121

Telefax +358 205 44 120

You might also like

- Application of Optimal Control Theory to Enhanced Oil RecoveryFrom EverandApplication of Optimal Control Theory to Enhanced Oil RecoveryRating: 4.5 out of 5 stars4.5/5 (3)

- Rock DrillDocument72 pagesRock Drilljosue100% (3)

- HL 810T Omt315Document21 pagesHL 810T Omt315Alexander100% (2)

- Manual Axera 5Document92 pagesManual Axera 5Saya Coaqui100% (3)

- Tamrock HL710Document16 pagesTamrock HL710Eduardo Ariel Bernal100% (6)

- Diamec U4 PHC LRDocument126 pagesDiamec U4 PHC LRAbraham HuacasiNo ratings yet

- S06 THC 560 Axera 5Document104 pagesS06 THC 560 Axera 5Anonymous iu95trpxN100% (2)

- Hydraulic Rock Drill Spec SheetDocument2 pagesHydraulic Rock Drill Spec SheetHerd Iman100% (2)

- HL510-HL 560 Technical ManualDocument61 pagesHL510-HL 560 Technical ManualAJAYKUMAR PUND83% (6)

- 16 kW Rock Drill Technical OverviewDocument52 pages16 kW Rock Drill Technical OverviewDavis Paredes100% (3)

- COP 1838HD+ VerF Maintenance InstructionsDocument50 pagesCOP 1838HD+ VerF Maintenance Instructionshaimay118No ratings yet

- Montabert HC109Document14 pagesMontabert HC109Yiğit Erpak100% (2)

- 9853 6819 20h Spare Parts Catalog COP 1838HD+Version FDocument105 pages9853 6819 20h Spare Parts Catalog COP 1838HD+Version FARMANDO ROJO80% (5)

- Rock DrillDocument25 pagesRock DrillNilton Manrique CossioNo ratings yet

- s03 Drill Feed TurretDocument130 pagess03 Drill Feed TurretJorge Luis Pinedo Sulca100% (2)

- RANGER 500 Technical SpecsDocument4 pagesRANGER 500 Technical SpecsWilman CFNo ratings yet

- S02 Rock Drill 2014Document14 pagesS02 Rock Drill 2014Miguel Angel RicapaNo ratings yet

- HL1560T-80 CatalogoDocument38 pagesHL1560T-80 CatalogoAlma100% (3)

- Sandvik dx800Document7 pagesSandvik dx800Ozan Sahin100% (1)

- Drilling ModuleDocument119 pagesDrilling ModuleCarlos Andrés Sánchez VargasNo ratings yet

- Diamec U6 Spare PartDocument3 pagesDiamec U6 Spare PartJairo Boechat JuniorNo ratings yet

- Shanks Adapters Rock DrillDocument18 pagesShanks Adapters Rock DrillBelmondo Giulio50% (2)

- Sandvik RD414 Training Material 2015Document19 pagesSandvik RD414 Training Material 2015rolandNo ratings yet

- Boomer l2d With ExplaneDocument130 pagesBoomer l2d With ExplaneAhmad83% (6)

- COP 1838 and System FeaturesDocument11 pagesCOP 1838 and System FeaturesPercy Chero33% (3)

- Dokumen - Tips - Sandvik Mining Offering Guide (001 092)Document92 pagesDokumen - Tips - Sandvik Mining Offering Guide (001 092)Jose luis Sarayse cruz100% (1)

- Cop 1132Document11 pagesCop 1132ESRANo ratings yet

- Cabezal DHR 6RCDocument30 pagesCabezal DHR 6RCcarlos cortez100% (2)

- Boomer L2D PDFDocument4 pagesBoomer L2D PDFAndres Campusano69% (13)

- Atlas Copco Boomer L2D Operators InstructionsDocument120 pagesAtlas Copco Boomer L2D Operators InstructionsHai Van100% (14)

- 05 Circuits Diagrams - Jumbo DD321Document110 pages05 Circuits Diagrams - Jumbo DD321Stefano Russell Bravo100% (3)

- Jumbo Dl411Document426 pagesJumbo Dl411cris024No ratings yet

- dx-800 TechDocument3 pagesdx-800 TechUgurNo ratings yet

- Cop 2238Document4 pagesCop 2238Todo osodroguiNo ratings yet

- S02 Rock Drill PDFDocument14 pagesS02 Rock Drill PDFIH MedranoNo ratings yet

- FlexiRoc T35 EpirocDocument5 pagesFlexiRoc T35 EpirocDaniel Páez100% (2)

- Section7 - Service Information and Maintenance ECM 585Document26 pagesSection7 - Service Information and Maintenance ECM 585Michael A Fourie100% (1)

- Rotation Unit CS14Document26 pagesRotation Unit CS14Fordia Sonora100% (1)

- 08Document30 pages08defiunikasungti100% (1)

- Cop 4050 SeriesDocument12 pagesCop 4050 Serieskannonzk100% (4)

- 9853 1124 01 Overhauling Instructions COP2160-2560-2160EX-2560EX PDFDocument68 pages9853 1124 01 Overhauling Instructions COP2160-2560-2160EX-2560EX PDFcoelhoclaudios100% (2)

- Operators Instructions Boomer 281-DC10Document89 pagesOperators Instructions Boomer 281-DC10sivaguruk280% (10)

- Sandvik 5 range tramming with electric brake parts manualDocument86 pagesSandvik 5 range tramming with electric brake parts manualanthonycc1200100% (2)

- 9852 1007 01e Maintenance Instr COP 1840HE, HEXDocument19 pages9852 1007 01e Maintenance Instr COP 1840HE, HEXcarlosbv67100% (2)

- 1 Bolter RE77Document69 pages1 Bolter RE77scarriongalindo100% (1)

- Hammer Hlx5Document2 pagesHammer Hlx5Johnny Navarro100% (1)

- Sandvik DD320-40Document4 pagesSandvik DD320-40david100% (3)

- Axera D07Document79 pagesAxera D07Percy Chero100% (2)

- Atlas Copco CS10 Surface Drill Rig Compact DesignDocument4 pagesAtlas Copco CS10 Surface Drill Rig Compact Designmhasansharifi100% (1)

- Operator's Manual: Through The RockDocument90 pagesOperator's Manual: Through The RockJesus Fco Garcia Perez100% (1)

- UDR1000-92 Parts ManualDocument199 pagesUDR1000-92 Parts ManualBrandon WhitecrossNo ratings yet

- 9852 2462 01 Maintenance Instructions COP 1838HDDocument26 pages9852 2462 01 Maintenance Instructions COP 1838HDMario AS100% (4)

- 9852 1302 01e Maintenance Instruction COP 2150-2550 - 2150EX - 2550EXDocument22 pages9852 1302 01e Maintenance Instruction COP 2150-2550 - 2150EX - 2550EXeko sunaryo100% (4)

- 07Document133 pages07ROboii FavelaNo ratings yet

- 10Document76 pages10defiunikasungti100% (1)

- S03 Rock Drill HLX5 MaintenanceDocument16 pagesS03 Rock Drill HLX5 MaintenancereynaldoNo ratings yet

- Rockdrill HL650Document74 pagesRockdrill HL650Luis Josue100% (1)

- S01 Hydraulic Cylinders - TMKDocument8 pagesS01 Hydraulic Cylinders - TMKAnonymous iu95trpxNNo ratings yet

- Chain Feed CF 145 H + RH 714 Maintenance Instruction: C 31360 - 4 en 0904 / JT 1Document22 pagesChain Feed CF 145 H + RH 714 Maintenance Instruction: C 31360 - 4 en 0904 / JT 1cristianNo ratings yet

- Hydraulic Rock Drill HL 800 T Lifting Instructions: Incorrect CorrectDocument88 pagesHydraulic Rock Drill HL 800 T Lifting Instructions: Incorrect Correctcristian100% (2)

- Exersises QuantifiersDocument1 pageExersises QuantifiersAnonymous iu95trpxNNo ratings yet

- Homework Week 6 (1) ListoDocument2 pagesHomework Week 6 (1) ListoAnonymous iu95trpxNNo ratings yet

- Hydraulic Rock Drill Technical SpecificationsDocument10 pagesHydraulic Rock Drill Technical SpecificationsAnonymous iu95trpxNNo ratings yet

- Quasar 1FDocument72 pagesQuasar 1FAnonymous iu95trpxNNo ratings yet

- 17 - Datos Tecnicos PDFDocument4 pages17 - Datos Tecnicos PDFAnonymous iu95trpxNNo ratings yet

- 9853 6202 50d Spare Part Catalogue COP 1838 C-VersionDocument28 pages9853 6202 50d Spare Part Catalogue COP 1838 C-VersionAnonymous iu95trpxNNo ratings yet

- BoomDocument59 pagesBoomAnonymous iu95trpxN100% (1)

- Practica de FiltrosDocument210 pagesPractica de FiltrosAnonymous iu95trpxNNo ratings yet

- Spssv20 Introduction 2013Document30 pagesSpssv20 Introduction 2013Anonymous iu95trpxNNo ratings yet

- S01 General Pre-Start Check ListDocument1 pageS01 General Pre-Start Check ListAnonymous iu95trpxNNo ratings yet

- Hydraulic Rock Drill Technical SpecificationsDocument10 pagesHydraulic Rock Drill Technical SpecificationsAnonymous iu95trpxNNo ratings yet

- s05 Boom b14nvDocument20 pagess05 Boom b14nvAnonymous iu95trpxNNo ratings yet

- Compressor LE 22-75 2930 1213 04 SparePartListDocument64 pagesCompressor LE 22-75 2930 1213 04 SparePartListllllcesarllllNo ratings yet

- 9853 6202 50d Spare Part Catalogue COP 1838 C-VersionDocument28 pages9853 6202 50d Spare Part Catalogue COP 1838 C-VersionAnonymous iu95trpxNNo ratings yet

- S09 Air Circuit GeneralDocument10 pagesS09 Air Circuit GeneralAnonymous iu95trpxNNo ratings yet

- S03 AccumulatorDocument12 pagesS03 AccumulatorRaphael Ruiz RamosNo ratings yet

- S01 Hydraulic Cylinders - All CylindersDocument13 pagesS01 Hydraulic Cylinders - All CylindersAnonymous iu95trpxNNo ratings yet

- Quasar 1FDocument72 pagesQuasar 1FAnonymous iu95trpxNNo ratings yet

- S10 Water Circuit GeneralDocument13 pagesS10 Water Circuit GeneralAnonymous iu95trpxNNo ratings yet

- S00 General SafetyDocument32 pagesS00 General SafetyAnonymous iu95trpxNNo ratings yet

- S05 Rotary Actuator 360°Document14 pagesS05 Rotary Actuator 360°Anonymous iu95trpxNNo ratings yet

- S00 FrontPage Service 4092 - ENDocument2 pagesS00 FrontPage Service 4092 - ENAnonymous iu95trpxNNo ratings yet

- S01 Hydraulic Cylinders - TMKDocument8 pagesS01 Hydraulic Cylinders - TMKAnonymous iu95trpxNNo ratings yet

- Axera 5 Main Switchgear Maintenance ManualDocument22 pagesAxera 5 Main Switchgear Maintenance ManualAnonymous iu95trpxNNo ratings yet

- S04 Drill Feed TF & TFX 500Document31 pagesS04 Drill Feed TF & TFX 500Anonymous iu95trpxN100% (2)

- s10 Water Pump Grundfos Cr1 Cr3 Cr5Document8 pagess10 Water Pump Grundfos Cr1 Cr3 Cr5Anonymous iu95trpxNNo ratings yet

- s05 Boom b26f b26xlfDocument24 pagess05 Boom b26f b26xlfAnonymous iu95trpxNNo ratings yet

- s07 Axle Ford New d45Document27 pagess07 Axle Ford New d45Anonymous iu95trpxNNo ratings yet

- s07 Tramming Axera Robolt Solo 5 enDocument18 pagess07 Tramming Axera Robolt Solo 5 enAnonymous iu95trpxNNo ratings yet

- Valuation Report ExampleDocument25 pagesValuation Report ExampleKenan TemboNo ratings yet

- What Is The Column Kicker - Its Formworks, Application and AdvantagesDocument2 pagesWhat Is The Column Kicker - Its Formworks, Application and AdvantagesNaveen BansalNo ratings yet

- Alumeco Aluminum Cat 2015Document72 pagesAlumeco Aluminum Cat 2015johnknight000No ratings yet

- Tile Adhesives, Tile Grouts and Plastering SkimDocument30 pagesTile Adhesives, Tile Grouts and Plastering SkimNykha Alenton100% (1)

- Datasheet & Specification For Deluge ValveDocument2 pagesDatasheet & Specification For Deluge ValvechintanNo ratings yet

- Afa Sebf9066-00Document95 pagesAfa Sebf9066-00Edwarth MazaNo ratings yet

- Mounting On Concrete DSBDocument4 pagesMounting On Concrete DSBRolando AlvaradoNo ratings yet

- 02-04 Chap GereDocument12 pages02-04 Chap GereSri DNo ratings yet

- Contractor Design and Standard Form ContractsDocument14 pagesContractor Design and Standard Form ContractskuvjNo ratings yet

- Affordable Housing in DhakaDocument4 pagesAffordable Housing in DhakaNazmulNo ratings yet

- Concrete ON MALDIVESDocument55 pagesConcrete ON MALDIVESKãrthìçk JkrNo ratings yet

- Obo Commissioning 9Document75 pagesObo Commissioning 998257002No ratings yet

- Model UC-2 Installation InstructionsDocument8 pagesModel UC-2 Installation InstructionsWattsNo ratings yet

- Fxsq100-125a Dim 3d094917a enDocument1 pageFxsq100-125a Dim 3d094917a enDragos PicuNo ratings yet

- Ingersoll Rand AC185D Operators ManualDocument284 pagesIngersoll Rand AC185D Operators ManualAntonio Carrion100% (2)

- Api RP 5a3Document4 pagesApi RP 5a3maruc08100% (1)

- Commissioning Documentation For Final Inspection and Certificate of Occupancy 2Document1 pageCommissioning Documentation For Final Inspection and Certificate of Occupancy 2Humaid ShaikhNo ratings yet

- Catalogo BuildexDocument2 pagesCatalogo BuildexRaciel Ivan CanoNo ratings yet

- Concrete Batch Plant Control Plan PDFDocument42 pagesConcrete Batch Plant Control Plan PDFkatfy1No ratings yet

- 7B AnswerDocument6 pages7B AnswertarasasankaNo ratings yet

- Ruelco Fuse Plug LiteratureDocument3 pagesRuelco Fuse Plug Literaturenk1.testmailNo ratings yet

- Concrete Mix Design Methods, Verification StudyDocument26 pagesConcrete Mix Design Methods, Verification StudyAhmed M AminNo ratings yet

- New Cost SheetDocument5 pagesNew Cost Sheetbejay bermudezNo ratings yet

- Akpark: Cover Sheet - ElectricalDocument10 pagesAkpark: Cover Sheet - ElectricalEngr M.Arshad KhalidNo ratings yet

- Saep 309Document22 pagesSaep 309brecht1980No ratings yet

- SABP-Q-010 Mix Design and Construction of Sulfur Extended Asphalt ConcreteDocument26 pagesSABP-Q-010 Mix Design and Construction of Sulfur Extended Asphalt ConcreteMr. Moses Imagoro100% (1)

- PSI Casing End Seals Installation GuideDocument10 pagesPSI Casing End Seals Installation Guideanup_sahani100% (1)

- Maccaferri Flexible Pavement Design SpreadsheetDocument10 pagesMaccaferri Flexible Pavement Design SpreadsheetAlbaro Andres TorricoNo ratings yet

- Bengalarchitecture 151030181750 Lva1 App6891Document21 pagesBengalarchitecture 151030181750 Lva1 App6891Niriksha ShettyNo ratings yet

- 4190 HPRVDocument12 pages4190 HPRVvadivel415No ratings yet