Professional Documents

Culture Documents

1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1

Uploaded by

JithuJohnCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1

Uploaded by

JithuJohnCopyright:

Available Formats

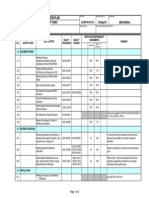

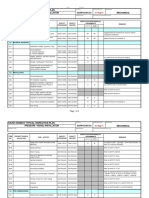

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

PRESSURE VESSEL INSTALLATION

SATIP-D-001-01

WBS/BI/JO/NO.

PROJECT TITLE:

ITEM

NO.

1.0

PROJECT PHASE &

Activity Code

APPROVED DATE

TASK / ACTIVITY

QUALITY

PROCEDURE

QUALITY

RECORD

DISCIPLINE:

25-May-05

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

RH1

RH1

REMARKS

DOCUMENT REVIEW

Review of Safety Instruction Sheet (S.I.S)

SAIC-D-2001

2.1

Verification of NMRs for Vessels and

Trays

SAIC-D-2022

2.2

Visual Inspection

a) External Inspection

b) Internal Inspection

SAIC-D-2002

SAIC-D-2003

SAIC-D-2002

SAIC-D-2003

H1

H1

2.3

Ladders, platforms, and other structural

steel attachments

SAIC-D-2004

SAIC-D-2004

W1

2.4

Storage, Handling and Preservation

SAIC-D-2005

SAIC-D-2005

H1

W1

2.5

Verification and visual inspection of

Vendor Supplied electrical and

instrumentation materials

Refer to the respective SATIPs for Electrical &

Instrumentation: ( SATIP-P-113-01, P-121-01 or P-104-02,

P-515-01, J-100-01, J-200-01, J-300-01, J-400-01, J-90203)

3.1

Concrete placement

Refer to SATIP-Q-001-02

3.2

Pre-Installation inspection

SAIC-D-2006

SAIC-D-2006

H1

W1

3.3

Equipment Installation - Alignment &

Elevation Survey (Vertical Vessel &

Horizontal Vessel)

SAIC-D-2007

SAIC-D-2007

SATR-D-2001

SATR-D-2002

H1

W1

3.4

Grouting Inspection

Refer to SATIP-Q-010-01

3.5

Inspection of Ladder, platform and other

structural attachment installations.

Refer to SATIP-M-001-01

1.1

2.0

3.0

MATERIAL RECEIVING

INSTALLATION

Page 1 of 3

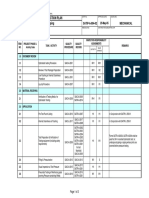

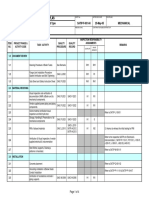

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

PRESSURE VESSEL INSTALLATION

SATIP-D-001-01

PROJECT TITLE:

ITEM

NO.

APPROVED DATE

WBS/BI/JO/NO.

PROJECT PHASE &

Activity Code

TASK / ACTIVITY

QUALITY

PROCEDURE

QUALITY

RECORD

DISCIPLINE:

25-May-05

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

SAUDI

ARAMCO

REMARKS

3.6

Inspection of Vessel Trim Installation

SAIC-D-2008

SAIC-D-2008

W1

3.7

Tray Installation

SAIC-D-2009

SAIC-D-2009

H1

W1

3.8

Tray Testing

SATR-D-2004

SATR-D-2004

H1

H1

3.9

Flange Joint- Gasket Verification & Bolt

tightening

SAIC-L-2014

SAIC-L-2014

SATR-L-2001

H1

W2

3.10

Piping inspection

Refer to SATIP-L-350-01

3.11

Steam Tracing

Refer to SATIP-L-350-06

3.12

Internal CP (galvanic) for internally coated

vessels

Refer to SATIP-X series

3.13

Lighting Installation

Refer to SATIP-P-123-02

3.14

Relief Valve Installation

Refer to SATIP-J-600-01

3.15

Grounding Installation

Refer to SATIP-P-111-01

3.16

Electrical & Instrumentation installation

Refer to the respective SATIPs for Electrical &

Instrumentation: ( SATIP-P-113-01, P-121-01 or P-121-02,

P-515-01, J-100-01, J-200-01, J-300-01, J-400-01, , J-90203)

3.17

Painting, Vessel Identification & color

Coding

Refer to SATIP-H-100-01

3.18

Insulation

Refer to SATIP-N-001-01 or SATIP-N-001-02

Page 2 of 3

See Note 1 of the General Notes , at least 10% minimum

thereafter.

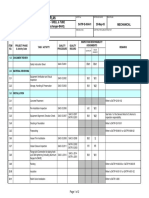

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

PRESSURE VESSEL INSTALLATION

SATIP-D-001-01

PROJECT TITLE:

ITEM

NO.

WBS/BI/JO/NO.

PROJECT PHASE &

Activity Code

QUALITY

PROCEDURE

TASK / ACTIVITY

QUALITY

RECORD

DISCIPLINE:

25-May-05

MECHANICAL

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

REMARKS

SAUDI

ARAMCO

Fireproofing

3.19

4.0

APPROVED DATE

Refer to SATIP-B-006-01 or SATIP-B-006-02

PRE-COMMISSIONING

4.1

Vessel Closure Inspection

SATR-D-2003

4.2

Instrumentation and Electrical precommissioning

Refer to the respective SATIPs for Electrical &

Instrumentation

4.3

Tightness Test

Refer to SATIP-A-004-05

4.4

Final Inspection/Punch listing for ReInstatement (by Contractor)

4.5

Mechanical Completion Punch listing

(Final MCC or Partial MCC)

SAIC-D-2012

SATR-D-2003

SAIC-D-2012

SATR-A-2011

FEIL SA-6133

H1

H1

H1

H1

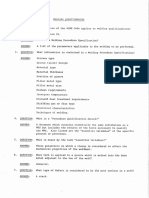

GENERAL NOTES

1

The first three incidents of each Inspection or testing activity listed require 100 % participation by Saudi Aramco Site Inspection Personnel. After this period, Saudi Aramco Inspection may adjust the levels

of Saudi Aramco participation based upon the Contractors performance.

Surveillance: QA/QC organization to monitor work in progress without notice from Construction Organization.

Witness:

QA/QC organization shall be notified of the timing of Inspection or test in advance. However, the inspection or test shall be performed as scheduled if the QA/QC

representative is not present.

Hold:

If the Main Contractor delegates the assigned responsibility to the Subcontractor, then the Main Contractor will have the same degree of responsibility as assigned to Saudi Aramco.

organization

QA/QC organization shall be notified of the timing of inspection or test in advance. Inspection or test shall not be carried out without the QA/QC organization representative in attendance.

LEGEND

W1

100% Witness Inspection/Test

H2

Sample Hold Point for QC Inspection or Test

RH1 100% Review and Approval of Documents

W2

Sample Witness Inspection/Test

R1

100% Review of Documents

RH2 Sample Review and Approval of Documents

H1

100% Hold Point for QC Inspection or Test

R2

Sample Review of Documents

Page 3 of 3

Surveillance

You might also like

- 1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1Document4 pages1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1JithuJohnNo ratings yet

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Document4 pages1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764No ratings yet

- 1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Document2 pages1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Ariel Anasco50% (2)

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- SAUDI ARAMCO SHOP FABRICATION INSPECTION PLANDocument2 pagesSAUDI ARAMCO SHOP FABRICATION INSPECTION PLANskychurch100% (1)

- SAUDI ARAMCO BOILER INSPECTION PLANDocument4 pagesSAUDI ARAMCO BOILER INSPECTION PLANAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection Plankarthi51289No ratings yet

- Saudi Aramco Typical Inspection PlanDocument2 pagesSaudi Aramco Typical Inspection PlanMAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

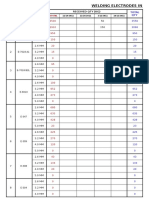

- Received Qty (KG) : SL# Electrode SizeDocument34 pagesReceived Qty (KG) : SL# Electrode Sizepadinharethil50% (2)

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioNo ratings yet

- Saudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 MechanicalDocument12 pagesSaudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 Mechanicalkarthi51289No ratings yet

- Saep 347Document27 pagesSaep 347Qaiser Mahmood100% (2)

- 1 SATIP-L-350-01 On-Plot Piping - Rev 01Document4 pages1 SATIP-L-350-01 On-Plot Piping - Rev 01zooplado75% (4)

- Juba Export Refinery Piping Quality ProcedureDocument15 pagesJuba Export Refinery Piping Quality ProcedureMd ShariqueNo ratings yet

- Saudi Aramco PMI checklist ensures alloy purityDocument5 pagesSaudi Aramco PMI checklist ensures alloy puritykarioke mohaNo ratings yet

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument6 pagesTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGAbu BindongNo ratings yet

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- Saudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalDocument11 pagesSaudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalSasi Head OfficeNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- 00 Saip 75Document72 pages00 Saip 75bazresifanniNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNo ratings yet

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Document2 pages1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyNo ratings yet

- SATIP-P-104-01 Rev 7 FinalDocument4 pagesSATIP-P-104-01 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Saep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsDocument12 pagesSaep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsShajin Mohammed Shamsudhin88% (8)

- SAIC-L-2035 Rev 6Document2 pagesSAIC-L-2035 Rev 6biplabpal2009No ratings yet

- SAIC M 2007 Struct AlignDocument1 pageSAIC M 2007 Struct AlignAnonymous S9qBDVkyNo ratings yet

- 175 320300Document1 page175 320300sridhar100% (1)

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocument15 pagesSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- 2019 - Saep-1160Document24 pages2019 - Saep-1160smdriyazbashaNo ratings yet

- Typical Inspection Plan (TIP) Title: ElectricalDocument2 pagesTypical Inspection Plan (TIP) Title: ElectricalBhaskar PitchikaNo ratings yet

- Controlling welding consumablesDocument9 pagesControlling welding consumablesMohammad RizwanNo ratings yet

- Saudi Aramco welding inspection planDocument12 pagesSaudi Aramco welding inspection planspravin231No ratings yet

- SatipDocument5 pagesSatipMuhammad Abdul Kadher100% (3)

- SATR-W-2006 Rev 6Document1 pageSATR-W-2006 Rev 6Manoj KumarNo ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Typical Inspection PlanDocument11 pagesSaudi Aramco Typical Inspection PlanAhdal NoushadNo ratings yet

- Weekly Welder ReportDocument2 pagesWeekly Welder Reportkarthi51289No ratings yet

- SAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FDocument2 pagesSAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FAnonymous S9qBDVky100% (1)

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saep 324 PDFDocument13 pagesSaep 324 PDFArvind ShakyaNo ratings yet

- Saudi Aramco Coating SpecificationsDocument25 pagesSaudi Aramco Coating SpecificationsJimlemonNo ratings yet

- Saudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalDocument11 pagesSaudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalRijwan MohammadNo ratings yet

- SAUDIPIPINGMATTRACEDocument9 pagesSAUDIPIPINGMATTRACEMAZHARULNo ratings yet

- SAIC-W-2006 Rev 0 PDFDocument4 pagesSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNo ratings yet

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDocument12 pagesSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Inspection ProcedureDocument13 pagesInspection ProcedureSantosh Kumar100% (1)

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- 01 Samss 029Document15 pages01 Samss 029Cherukunnon Jubu100% (1)

- SATIP D 001 01 (Revision 4)Document3 pagesSATIP D 001 01 (Revision 4)Anonymous 4e7GNjzGW100% (1)

- 1 SATIP-F-001-04 Boiler - Packaged Type - 1Document4 pages1 SATIP-F-001-04 Boiler - Packaged Type - 1JithuJohnNo ratings yet

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFDocument4 pages1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnNo ratings yet

- Satip e 004 01Document2 pagesSatip e 004 01Anonymous 4e7GNjzGWNo ratings yet

- 2015 Rev-Ect Feb 17 ListDocument7 pages2015 Rev-Ect Feb 17 ListJithuJohnNo ratings yet

- 2015 Rev-Ect Feb 17 ListDocument7 pages2015 Rev-Ect Feb 17 ListJithuJohnNo ratings yet

- Resume Ofjithu John (API, CSWIP & ASNT)Document6 pagesResume Ofjithu John (API, CSWIP & ASNT)JithuJohnNo ratings yet

- Hy Are Jews So SmartDocument2 pagesHy Are Jews So SmartJithuJohnNo ratings yet

- General Questions4Document31 pagesGeneral Questions4JithuJohnNo ratings yet

- 1-3 Email Nurse - Role PlayDocument2 pages1-3 Email Nurse - Role PlayJithuJohnNo ratings yet

- Pressure Vessel Exm QuestionsDocument4 pagesPressure Vessel Exm QuestionsJithuJohn100% (1)

- 21a1004 02Document1 page21a1004 02JithuJohnNo ratings yet

- Canada RN CCNDocument1 pageCanada RN CCNJithuJohnNo ratings yet

- Hy Are Jews So SmartDocument2 pagesHy Are Jews So SmartJithuJohnNo ratings yet

- General Questions4Document31 pagesGeneral Questions4JithuJohnNo ratings yet

- General Questions4Document31 pagesGeneral Questions4JithuJohnNo ratings yet

- Canada RN CCNDocument1 pageCanada RN CCNJithuJohnNo ratings yet

- Material With Electrode SelectionDocument2 pagesMaterial With Electrode SelectionJithuJohn100% (3)

- General Questions4Document31 pagesGeneral Questions4JithuJohnNo ratings yet

- Aramco QuestionDocument72 pagesAramco QuestionZuberYousuf100% (1)

- QADocument3 pagesQAJithuJohnNo ratings yet

- Aramco QuestionDocument72 pagesAramco QuestionZuberYousuf100% (1)

- Pumps API 610Document2 pagesPumps API 610JithuJohnNo ratings yet

- RGUHS MSc Nursing Exam Fee Notification April 2016Document7 pagesRGUHS MSc Nursing Exam Fee Notification April 2016JithuJohnNo ratings yet

- OET Test 3 Listening Answers - Part A and BDocument6 pagesOET Test 3 Listening Answers - Part A and BJithuJohn100% (1)

- Aramco vendor inspection for line pipe API standardsDocument3 pagesAramco vendor inspection for line pipe API standardsJithuJohnNo ratings yet

- CopyDocument2 pagesCopyJithuJohnNo ratings yet

- Welding AnswersDocument4 pagesWelding AnswersJithuJohnNo ratings yet

- Heat Exchanger-Design and ConstructionDocument46 pagesHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- Heat Exchanger-Design and ConstructionDocument46 pagesHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- Resume Ofjithu John (API, CSWIP & ASNT)Document6 pagesResume Ofjithu John (API, CSWIP & ASNT)JithuJohnNo ratings yet

- Ut Q 5Document4 pagesUt Q 5JithuJohnNo ratings yet

- Mpi Q-2Document3 pagesMpi Q-2JithuJohnNo ratings yet

- Basic 4 QDocument8 pagesBasic 4 QJithuJohnNo ratings yet

- Fluidized Bed ReactorDocument10 pagesFluidized Bed ReactorDurgesh BondeNo ratings yet

- Ieee Cts and Pts 6-10Document99 pagesIeee Cts and Pts 6-10taimoor1975No ratings yet

- SolaMAXSERIES REV5 PDFDocument2 pagesSolaMAXSERIES REV5 PDFxander1982No ratings yet

- GSR 10-8-2 Li Professional Manual 129196Document169 pagesGSR 10-8-2 Li Professional Manual 129196madmatskNo ratings yet

- 3 28 19 NtapDocument199 pages3 28 19 Ntapfikri fikriNo ratings yet

- Mixers Towable Concrete Essick EC42S Rev 8 Manual DataId 18822 Version 1Document84 pagesMixers Towable Concrete Essick EC42S Rev 8 Manual DataId 18822 Version 1Masayu MYusoffNo ratings yet

- LucentDocument14 pagesLucentDaniel ManoleNo ratings yet

- Johnson ManualDocument108 pagesJohnson Manualfirebird197286% (7)

- Safety Swivel Lifting Eye Bolts Load CapacitiesDocument1 pageSafety Swivel Lifting Eye Bolts Load CapacitiesRaul G. MartinezNo ratings yet

- Pump KnowledgeDocument17 pagesPump Knowledgesmupy_122No ratings yet

- Vlsi DesignDocument2 pagesVlsi DesignXXXNo ratings yet

- Crimper Pull Force Qualification TemplateDocument5 pagesCrimper Pull Force Qualification TemplateMatthew WaltersNo ratings yet

- Positive Displacement PumpsDocument48 pagesPositive Displacement PumpsSteve Carwell100% (5)

- Material Board: - Kadambari KarmalkarDocument5 pagesMaterial Board: - Kadambari KarmalkarKADAMBARI KARMALKARNo ratings yet

- CC TC Flat BraidDocument3 pagesCC TC Flat BraidEmul YaniNo ratings yet

- Otating Ontrol Evices: T M S ADocument11 pagesOtating Ontrol Evices: T M S ANeme VasquesNo ratings yet

- Excel Data Analytics for Engineering ApplicationsDocument1 pageExcel Data Analytics for Engineering ApplicationsK VadlamaniNo ratings yet

- ColumnShearCapacity 1Document4 pagesColumnShearCapacity 1Azhar PLNo ratings yet

- DNC MagazineDocument49 pagesDNC MagazineNizamudheen kNo ratings yet

- 078301Document8 pages078301avinashjhamechxNo ratings yet

- Idoc Extension & ProcessingDocument28 pagesIdoc Extension & Processingesameer7837No ratings yet

- Telsinex Installation Guide Ver2.0Document46 pagesTelsinex Installation Guide Ver2.0Ludgério PedroNo ratings yet

- Breathing Air System Performance QualificationDocument11 pagesBreathing Air System Performance QualificationCHALLA ANITHA100% (1)

- Doosan Solar 470LC-V Excavator Service Manual PDFDocument668 pagesDoosan Solar 470LC-V Excavator Service Manual PDFW Morales100% (1)

- Chitosan - A Versatile Semi-Synthetic Polymer in BiomedicalDocument34 pagesChitosan - A Versatile Semi-Synthetic Polymer in BiomedicalBianca Ionela DraganNo ratings yet

- FEMA 440 equivalent linearization pushover analysisDocument2 pagesFEMA 440 equivalent linearization pushover analysisAdam JrNo ratings yet

- 1999 Ford Ranger Owner's ManualDocument216 pages1999 Ford Ranger Owner's Manualtacosoft100% (6)

- Motionmountain Volume3Document318 pagesMotionmountain Volume3halojumper63No ratings yet

- Example Workpack For AodDocument63 pagesExample Workpack For Aodapi-3745449100% (3)

- Shubham Sonar CVDocument2 pagesShubham Sonar CVKuldip PardeshiNo ratings yet