Professional Documents

Culture Documents

Dockweiler BPE Spec

Uploaded by

Rey LieCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dockweiler BPE Spec

Uploaded by

Rey LieCopyright:

Available Formats

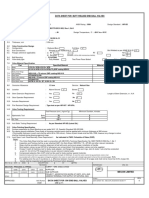

Dockw.Spezi-08-GB 15.05.

2008 15:29 Uhr Seite 9

Material TP316L, the chemical compositions in accordance to Table DT-3

ASME BPE

Chemical Composition in weights % C max. 0.035 Ni = 10.00 – 15.00

Cr = 16.00 – 18.00 P max. 0.040

Mn max. 2.00 Si max 0.75

Mo = 2.00 – 3.00 S = 0.005 – 0.017

further materials on request

Dimensions 1/4“ x 0.035 (6.35 x 0.89 mm) to 6” x 0.109 (152.40 x 2.77 mm)

Technical terms of delivery

Tubes According to ASTM A 269 / A 270, DIN EN 10217-7 / DIN EN 10216-5

Length 5900 - 6090 mm (max. 10% short lengths possible)

Fittings Tube components:

Prematerial according to ASTM A 269 / A 270, DIN EN 10217-7 / 10216-5

Machined components:

Prematerial according to ASTM A 479, DIN EN 10088-3, DIN 17440

Tolerances According to ASTM A 269 / A 270 (pharmaceutical tubes) or DIN EN ISO 1127 - D4/T3

Ends Tubes and fittings are prepared for orbital welding

Tolerances

Tubes According to ASTM A269 and A270, S2 and DIN EN ISO 1127/ D4/T3

Fittings According to ASME BPE, section DT

Surface options inner surface: As per ASME BPE, section SF, Table SF3

Tubes and fittings mechanically polished mechanically polished and electropolished

Ra max Ra max

µin µm µin µm

SF1 20 0.51 SF4 15 0.38

Outer surface: Tubes and Fittings Ra ≤ 0.80 µm (32 µin)

Inner surface treatment

Tubes Electropolishing procedure Spec. HE 175 4VN

Fittings Electropolishing procedure Spec. HE 111 4VN

Hardness max.180 HV 5/90 HRB

Test procedures • Verification of basic test certificate

• Verification of dimensions

• Visual control

• Roughness measurements

• Endoscopic inspection of bright finished tubes

Marking - Dockweiler

- ASME BPE

- Surface symbol as per ASME BPE, section SF

- Dockweiler no. (batch no.)

- Heat number

- Material type

- Dimension

Documentation Certified Test Report (3.1) as per DIN EN 10204 and ASTM A450 for the prematerial

Packaging and Delivery Ends are closed with PE/PA foils and PE caps. Tubes and fittings are individually sealed

in PE foil, marked with a white sticker „Dockweiler BPE“, electropolished parts with white

sticker „Dockweiler BPE ep“. Delivery of tubes in tubular container or wooden crate,

of fittings in strong cardboard box or wooden crate with shock absorbing filler.

C7/07/P7/07

Dockweiler AG

An der Autobahn 10/20 · D-19306 Neustadt-Glewe · Germany · Tel. +49 (0)38757 58-0 · Fax +49 (0)38757 58-222 · e-mail: info@dockweiler.com · www.dockweiler.com

You might also like

- Material Composition and Specifications for TP316L Stainless Steel TubesDocument1 pageMaterial Composition and Specifications for TP316L Stainless Steel TubesAdilson GabuNo ratings yet

- Solenoid ValveDocument2 pagesSolenoid ValveHeru PurwantoNo ratings yet

- WPS-05 TIG Welding Stainless Steel Butt and Fillet JointsDocument2 pagesWPS-05 TIG Welding Stainless Steel Butt and Fillet Jointsmurshid badshahNo ratings yet

- Technical - Specification - Group D - Tubing - 2023 07 05 13 16 29Document2 pagesTechnical - Specification - Group D - Tubing - 2023 07 05 13 16 29Chinnaraj SNo ratings yet

- Sample DS-1Document1 pageSample DS-1Sachin KumarNo ratings yet

- Pressure Measurement: Description: Media SketchDocument1 pagePressure Measurement: Description: Media SketchOpencae EngenhariaNo ratings yet

- WT Calculation - Pipelines With CRA CladDocument6 pagesWT Calculation - Pipelines With CRA CladShankar VadivelNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- Welding Procedure Specification: Material / Joints QualifiedDocument2 pagesWelding Procedure Specification: Material / Joints QualifiedFernando LlontopNo ratings yet

- Annexure-1 Magnetostrictive LT 22062020Document1 pageAnnexure-1 Magnetostrictive LT 22062020singhjyoti54.sjNo ratings yet

- Ball Valves Data SheetDocument2 pagesBall Valves Data SheetJatin Vadhera VCSP100% (1)

- Socket Weld Plug Valve Data SheetDocument1 pageSocket Weld Plug Valve Data SheetSachin KumarNo ratings yet

- Sample Valve Material CertificatesDocument18 pagesSample Valve Material CertificatesFLOW VALVE AUTOMATION100% (2)

- Brazing BPS 107-1 PDocument5 pagesBrazing BPS 107-1 Pmbe josephNo ratings yet

- Back Weld Repair Procedure QualificationDocument15 pagesBack Weld Repair Procedure QualificationFelipe Vásquez ArribasplataNo ratings yet

- Sandvik SAF 2507: Duplex Stainless SteelDocument8 pagesSandvik SAF 2507: Duplex Stainless SteelmattiaNo ratings yet

- Tornillo Hexagonal P-B Con Ara Neo 10 X 2Document1 pageTornillo Hexagonal P-B Con Ara Neo 10 X 2Miguel RubioNo ratings yet

- BoM Old ShanghaiDocument1 pageBoM Old ShanghaiMuhammad IrsyadNo ratings yet

- WIC-WPS-01 Rev. 00 - FCAW - 1.2Document2 pagesWIC-WPS-01 Rev. 00 - FCAW - 1.2murshid badshahNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- 10in 1500 MOV DatasheetDocument1 page10in 1500 MOV DatasheetkarthikNo ratings yet

- 4130wog0913 - Rev14Document3 pages4130wog0913 - Rev14Quality controller100% (1)

- Cálculo de La Silleta ParcialDocument3 pagesCálculo de La Silleta ParcialALBERTO COCOM CELAYANo ratings yet

- BPE Fittings Submittal DocumentationDocument3 pagesBPE Fittings Submittal DocumentationJeff NeurauterNo ratings yet

- WPQR Welding Procedure Qualification RecordsDocument3 pagesWPQR Welding Procedure Qualification Recordsramesh rajaNo ratings yet

- 2" To 4" E-Type Series StrainersDocument4 pages2" To 4" E-Type Series Strainershyarub9No ratings yet

- PIPELINE WELDING PROCEDURE SPECIFICATION TITLEDocument17 pagesPIPELINE WELDING PROCEDURE SPECIFICATION TITLEBenjamin Alvarez MedinaNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- SPV Seminar 11.2014 - EGMODocument62 pagesSPV Seminar 11.2014 - EGMOSumaker Lubando SitorusNo ratings yet

- TECHNIO COMMERCIAL PROPOSAL FOR WELL TEST Trailer PACKAGE R2-AWK Option1 DASDocument2 pagesTECHNIO COMMERCIAL PROPOSAL FOR WELL TEST Trailer PACKAGE R2-AWK Option1 DASslbclqrkNo ratings yet

- Medidor Caudal Kobold BGFDocument6 pagesMedidor Caudal Kobold BGFBase SistemasNo ratings yet

- Data Sheets for Oil and Gas Metering System StrainersDocument2 pagesData Sheets for Oil and Gas Metering System StrainersSales FlometriqNo ratings yet

- P 1717 Quality Certificate Lot 1Document6 pagesP 1717 Quality Certificate Lot 1Adink M AlwiNo ratings yet

- Ode Solenoid Valve 21wa3z0b130 - 21wa4z0b130Document2 pagesOde Solenoid Valve 21wa3z0b130 - 21wa4z0b130Uno MariconNo ratings yet

- Pressure Regulator ValveDocument48 pagesPressure Regulator ValveAdrian CordovaNo ratings yet

- Plate Heat Exchanger Technical SpecificationDocument1 pagePlate Heat Exchanger Technical SpecificationAsif Zahidul HaqNo ratings yet

- AstmDocument1 pageAstmGalih Prianggodo100% (1)

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Van Stone Thermowells: Data SheetDocument3 pagesVan Stone Thermowells: Data Sheetjittshong8072No ratings yet

- HS Pel02asp 000000ecDocument5 pagesHS Pel02asp 000000ecFábioNo ratings yet

- Medidor Caudal Kobold BGNDocument6 pagesMedidor Caudal Kobold BGNBase SistemasNo ratings yet

- ASME B31.8 Wall Thickness CalculationDocument23 pagesASME B31.8 Wall Thickness Calculationisrar khan100% (2)

- DT & DP - Flange Rating and Pipe Sizing R2 PDFDocument11 pagesDT & DP - Flange Rating and Pipe Sizing R2 PDFroyNo ratings yet

- A RM 105 19 18 096 SourDocument5 pagesA RM 105 19 18 096 SourGuilherme RochaNo ratings yet

- DataSheet 2 More 300# BV - FB - BW - NT-77 PDFDocument1 pageDataSheet 2 More 300# BV - FB - BW - NT-77 PDFSachin KumarNo ratings yet

- FlowBiz Double Block & Bleed Plug ValveDocument4 pagesFlowBiz Double Block & Bleed Plug ValveSHAKIR ANSARINo ratings yet

- Examples E4.16.1/E4.6.1 and E4.6.2 BPVC VIII-1: ASME PTB-4-2013Document15 pagesExamples E4.16.1/E4.6.1 and E4.6.2 BPVC VIII-1: ASME PTB-4-2013ordenador90No ratings yet

- Required Thicknesses of Pipe or Tube Per ASME B31.3 - 2012 Process Piping CodeDocument3 pagesRequired Thicknesses of Pipe or Tube Per ASME B31.3 - 2012 Process Piping CodeAlex Javier Garzon OrduñaNo ratings yet

- DIN 1628 ST 52.4Document2 pagesDIN 1628 ST 52.4Anonymous m1cSnEavoNo ratings yet

- Pipe Thickness Calculation For Internal PressureDocument12 pagesPipe Thickness Calculation For Internal PressurefsijestNo ratings yet

- Paut TestDocument2 pagesPaut TestdonoNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- BDT17-08 Clasa 0.25 PDFDocument2 pagesBDT17-08 Clasa 0.25 PDFvan_dall_2No ratings yet

- AD 424 - Shear Stud Length, November 2018Document1 pageAD 424 - Shear Stud Length, November 2018symon ellimacNo ratings yet

- MTC Elbow 6inDocument1 pageMTC Elbow 6inhenryNo ratings yet

- ENG - BD - TDS170-PN-S-GATE-PN Gate ActuatorsDocument9 pagesENG - BD - TDS170-PN-S-GATE-PN Gate Actuatorslungelo.dlaminiNo ratings yet

- Flange #: Plant: ID Code: Nomenclature: Flange Calculation According To EN 1591-1:2001 + A1:2009Document11 pagesFlange #: Plant: ID Code: Nomenclature: Flange Calculation According To EN 1591-1:2001 + A1:2009benssjNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Shipbuilding enDocument7 pagesShipbuilding enM. AguiarNo ratings yet

- PN 2300Document95 pagesPN 2300cresjohn100% (1)

- Hand-Operated Power Tool SafetyDocument2 pagesHand-Operated Power Tool SafetySanthoshKumarNo ratings yet

- SKUM Over The Top Foam Generators OFG OFGR - FDS14334 0214 LRDocument4 pagesSKUM Over The Top Foam Generators OFG OFGR - FDS14334 0214 LRValentin A.No ratings yet

- 2017 Mercedes Benz e Class 97258Document446 pages2017 Mercedes Benz e Class 97258felixwholesaleNo ratings yet

- DampavaultDocument8 pagesDampavaultchillerz69No ratings yet

- Industrial Engineering ProjectsDocument316 pagesIndustrial Engineering ProjectsbonostoreNo ratings yet

- Crop Production and Management-Solved ExercisesDocument4 pagesCrop Production and Management-Solved ExercisesSbs ReddyNo ratings yet

- SCXL004DN: Precision Compensated, Low Pressure SensorsDocument3 pagesSCXL004DN: Precision Compensated, Low Pressure Sensorsloza_2912004No ratings yet

- ISX15 / QSX15 “SOHC” SLEEVE REMOVAL & INSTALLATIONDocument8 pagesISX15 / QSX15 “SOHC” SLEEVE REMOVAL & INSTALLATIONJoseDavidSanchezYepes75% (4)

- 1 2 5 A AerodynamicforcesDocument2 pages1 2 5 A Aerodynamicforcesapi-325609547No ratings yet

- 04 PDFDocument146 pages04 PDFEli RochaNo ratings yet

- GSM Based RobotDocument232 pagesGSM Based RobotTanvi KhuranaNo ratings yet

- Tedi Atmapradhana (M16UC511) 中間発表Document22 pagesTedi Atmapradhana (M16UC511) 中間発表L Arc En TediNo ratings yet

- Automatic Voltage Regulator Installation ManualDocument10 pagesAutomatic Voltage Regulator Installation ManualDaiane MendesNo ratings yet

- Optisonic 3400: Ultrasonic Flowmeter For Liquids in All Industrial ApplicationsDocument16 pagesOptisonic 3400: Ultrasonic Flowmeter For Liquids in All Industrial ApplicationsOmar SaeedNo ratings yet

- Canon IR 2025iDocument129 pagesCanon IR 2025imboroncoi100% (1)

- Zb25 EngineDocument42 pagesZb25 Engineholsen seiner campos daga0% (1)

- (2a) Laminate & Reinforcement Mat'lDocument31 pages(2a) Laminate & Reinforcement Mat'laudheaykNo ratings yet

- SEWO high speed flap gate series install manualDocument11 pagesSEWO high speed flap gate series install manualJc GonzaNo ratings yet

- Instruction Manual: A959 1:18 4WD Offf-Road Buggy RC CarDocument6 pagesInstruction Manual: A959 1:18 4WD Offf-Road Buggy RC CarLäůrã MîrëllNo ratings yet

- European Natural Rubber Substitute From GuayuleDocument16 pagesEuropean Natural Rubber Substitute From Guayuleionus_2003No ratings yet

- HDR433M PDFDocument5 pagesHDR433M PDFMariuszChreptakNo ratings yet

- Automotive Tapered Roller and Ball Bearing Price ListDocument8 pagesAutomotive Tapered Roller and Ball Bearing Price ListAvijitSinharoyNo ratings yet

- Electrical System: General Fuses and RelaysDocument144 pagesElectrical System: General Fuses and RelaysMuhammad Ryan As-syafi'iNo ratings yet

- Man B&W Soot in EgbsDocument21 pagesMan B&W Soot in EgbsterimakabosraNo ratings yet

- Citizen CharterDocument7 pagesCitizen CharterNelson WongNo ratings yet

- Product Sheet Damen Accomodation Support Vessel 9020-02-2017Document2 pagesProduct Sheet Damen Accomodation Support Vessel 9020-02-2017Jhon GreigNo ratings yet