Professional Documents

Culture Documents

Calc Boiler Efficiency

Uploaded by

agusfaizinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calc Boiler Efficiency

Uploaded by

agusfaizinCopyright:

Available Formats

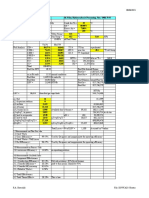

Calc 1 - Boiler Efficiency.

xls

1 of 3

http://www.exoeng.com/boilereffcalc.htm

Plant.

Performance at Tested Air Heater Leakage

Unit..

Locaon..

Furnace Data @ Tested AH Leakage:

Date..

Furnace Data @

3,476 MBtu/hr

Heat Input

Blend

Carbon

Coal A Coal B

Units

0%

Blend Fracon 100%

51.04

51.04

0.00

%

C

Total Air Flow

Hydrogen

H2

3.64

3.64

0.00

Furnace Excess Air

Sulfur

0.29

0.29

0.00

Wet Gas Flow Leaving Furnace

Oxygen

S

O2

12.74

12.74

0.00

Air Heater Exit Gas Data @ Tested AH Leakage:

Nitrogen

N2

0.66

0.66

0.00

Excess O2

Moisture

H2O

26.57

26.57

Ash

5.06

5.06

0.00

AH Gas Exit Temp Corrected (Measured)

Other

0.00

0.00

0.00

AH Gas Exit Temp Uncorrected (ie, No Leakage)

Total:

100.00

100.00

0.00

8,867

8,867

Fuel Data:

HHV

Moisture in Air

Addional Moisture

0.00

%

Btu/lb

0

m

0.0135 (lb/lb dry air)

Fuel Flow

pph

Fuel Flow

2,982,562

pph

Total Air Flow

Furnace Excess A

pph

Wet Gas Flow Le

Air Heater Exit

4.26

Excess O

Excess O

1

321

AH Gas Exit Temp

349

AH Gas Exit Temp

To correct the eciency for "Uncorrected AH Gas

To correct

Out Temp" enter "1" at right. If not, leave blank.

Out Temp"

361,584

9.97

Air Heater Leakage (%) (Mass Method)

Air Heater Leakage (%) O2 Method)

Air, Gas & Fuel Temperatures:

Steam Flow

392,027

3,625,951

Air Heater Leakage (pph)

0.0000 (lb/100lb fuel)

pph

15.56

(% by Vol)

Excess O2 Measurement Basis: 1 = Wet, 0 = Dry

Heat Input

Steam Flow

9.52

pph

Air Heater Leaka

Air Heater Leaka

Air Heater Leaka

Calculaon Reference Temp

80

We

3,987,536

pph

We

FD Fan Inlet Air Temp

Fuel Temperature (Default = Tref)

60

We

1,271,016

acfm

We

60

Flue Gas Constuents:

Oxygen (O2)

Boiler Eciency Losses, Manual Input:

Radiaon and convecon (Default = .17)

0.17

Carboc Dioxide (CO2)

Unaccounted for losses (Default = 0.50)

0.50

Sulfur Dioxide (SO2)

Ash Data:

Ash Locaon

(% by Volume)

Flue Gas Cons

Oxygen (O

4.26

12.93

Carboc Dioxi

0.02753

Sulfur Dioxid

Moisture (H2O)

11.93

Moisture (H

Nitrogen (N2)

70.85

Nitrogen (N

100.00

Total

Ash Split

(%)

20

LOI

(%)

0.26

Economizer Ash

0.26

Boiler Eciency Heat Losses @ Tested AH Leakage:

Air Heater Ash

0.00

Los

6.17

Los

75

0.26

Los

7.71

Los

Baghouse Ash

0.00

Los

0.14

Los

Dust Collector Ash

0.00

Los

0.02

Los

Boom Ash

Precipitator Ash

(Must

Total

100%)

Total Ash

100

Economizer Exit Gas Data:

2.50

Ex

Total

Boiler Ecienc

Los

0.17

Los

Ma

0.50

Ma

Tot

14.72

Tot

Boi

85.28

Boi

Fuel Flow Determinaon Data:

NOTES:

For total fuel ow determinaon enter at least one of the

yellow/red cells

following groups:

392,027

Gr

Design (or other) data set does not need to be completed. It is just available for

OR

Gr

are for input data, to be completed by user.

pph

MBtu/hr

OR

Group C: For non-reheat units, enter all of the following:

Steam Flow

pph

Steam Enthalpy

Feedwater Enthalpy

pph

pph

Fuel ow and heat input are not used to calculate boiler eciency, but are nece

Fuel Flow determinaon will aempt to access Group A data rst, Group B data s

Heat Input determinaon will aempt to access Group B data rst, Group A data

9/16/2014 4:19 PM

Calc 1 - Boiler Efficiency.xls

2 of 3

Steam Load:

http://www.exoeng.com/boilereffcalc.htm

Table 13A

Combustion Calculations - Btu Method

0 pph

Plant:

Client:

Date: 01/00/00

Location:

INPUT CONDITIONS - BY TEST OR SPECIFICATION

15.56

1 Excess air at economizer exit, % by weight

FUEL DATA - Coal

15 Ultimate An

16 Theo. Air, lb/100lb fuel

2 Entering air temperature, OF

Co

K1

60

3 Reference air temperature, F

4 Fuel temperature, OF

O

5 Flue gas temp leaving AH (including leakage), F

O

6 Flue gas temp leaving AH (excluding leakage), F

7 Moisture in air, lb/lb dry air

8 Additional moisture lb/100 lb fuel

9

10

11

12

13

14

% by wt.

80 A C

51.04

11.51

587.37

60 B S

321 C H2

0.29

4.31

1.25

3.64

34.28

124.79

349 D H2O

0.0135 E N2

26.57

0.0000

12.74

-4.32

F O2

5.06

G Ash

100.00

H Total

18 Higher heating value (HHV), Btu/lb fuel

Enthalpy of steam at 1 psi, T = [6]

Water from

fuel, as-fired Enthalpy of water at T = [3]

%

Moisture in air, %

Unburned carbon, %

Radiation and convection, %

Unaccounted for and manufacturers margin, %

40

41

42

43

44

45

46

47 Summation of losses, %

Credits

48 Heat in dry air, %

49 Heat in moisture in air, %

50 Sensible heat in fuel, %

51 Other, %

52 Summation of credits, %

53 Efficiency, %

0.0024 x [35D] x ([6] - [3])

H1 = (3.958E-5 x T + .4329) x T + 1062.2

H2 = [3] - 32

[29] x ([39] - [40]) / 100

0.0045 x [27D] x ([6] - [3])

[19] or [21] x 14,500 / [18]

ABMA curve

Summation [38] + [46]

.0024 x [26D] x ([2] - [3])

.0045 x [27D] x ([2] - [3])

(H at T[4] - H at T[3]) x 100 / [18]

Summation [48] through [51]

100 - [47] + [52]

[15] x K2

8.94

32.53

1.00

26.57

-55.04

658.37

59.10

8,867

0.02

7.42

0.01

[16H] x 100 / [18]

[19] x [18] / 14,500

COMBUSTION GAS CALCULATIONS, Quantity / 10,000 Btu Fuel Input

22 Theoretical air (corrected), lb/10,000 Btu

[20] - [21] x 1151 / [18]

23 Total Residue from fuel, lb/10,000 Btu

([15G] + [21]) x 100 / [18]

24

A At

B Leakage

C Leaving Furnace

15.559217103466114

13.826

25 Excess air, % by weight

26 Dry air, lb/10,000 Btu

(1 + [25] / 100) x [22]

0.12

27 H20 from air, lb/10,000 Btu

[26] x [7]

0.00

28 Additional Moisture, lb/10,000 Btu

[8] x 100 / [18]

0.67

29 H20 from fuel, lb/10,000 Btu

[17H] x 100 / [18]

30 Wet gas from fuel, lb/10,000 Btu

(100 - [15G] - [21]) x 100 / [18]

31

32

33 Total wet gas, lb/10,000 Btu

Summation [26] through [30]

0.78

34 Water in wet gas, lb/10,000 Btu

Summation [27] + [28] + [29]

35 Dry gas, lb/10,000 Btu

[33] - [34]

36 H20 in gas, % by weight

[100] x [34] / [33]

37 Residue, % by weight

100 x [24] / [33]

39

K2

0.66

19 Unburned carbon loss, % fuel input

20 Theoretical air, lb/10,000 Btu

21 Unburned carbon, % of fuel

EFFICIENCY CALCULATIONS, % Input from Fuel

Losses

38 Dry Gas, %

17 H20, lb/100 lb fuel

[15] x K1

7.42

0.06

D Leaving Air Heater

29.39

9.60

0.13

0.13

0.00

0.00

0.67

1.07

1.07

15.56

8.58

0.12

0.00

10.43

0.78

9.65

7.50

0.55

0.80

11.47

0.80

10.68

6.94

0.50

6.17

1,205.24

48.00

7.71

0.14

0.02

0.17

0.50

14.72

-0.461019

-0.011670

0.000000

0.000000

-0.47

84.81

9/16/2014 4:19 PM

Calc 1 - Boiler Efficiency.xls

3 of 3

Steam Load:

http://www.exoeng.com/boilereffcalc.htm

Table 13A

Combustion Calculations - Btu Method

0 pph

Plant:

Client:

Date: 01/00/00

Location:

INPUT CONDITIONS - BY TEST OR SPECIFICATION

15.56

1 Excess air at economizer exit, % by weight

FUEL DATA - Coal

15 Ultimate An

16 Theo. Air, lb/100lb fuel

2 Entering air temperature, OF

Co

K1

60

3 Reference air temperature, F

4 Fuel temperature, OF

O

5 Flue gas temp leaving AH (including leakage), F

O

6 Flue gas temp leaving AH (excluding leakage), F

7 Moisture in air, lb/lb dry air

8 Additional moisture lb/100 lb fuel

9

10

11

12

13

14

% by wt.

80 A C

51.04

11.51

587.37

60 B S

238 C H2

0.29

4.31

1.25

3.64

34.28

124.79

349 D H2O

0.0135 E N2

26.57

0.0000

12.74

-4.32

F O2

5.06

G Ash

100.00

H Total

18 Higher heating value (HHV), Btu/lb fuel

Enthalpy of steam at 1 psi, T = [6]

Water from

fuel, as-fired Enthalpy of water at T = [3]

%

Moisture in air, %

Unburned carbon, %

Radiation and convection, %

Unaccounted for and manufacturers margin, %

40

41

42

43

44

45

46

47 Summation of losses, %

Credits

48 Heat in dry air, %

49 Heat in moisture in air, %

50 Sensible heat in fuel, %

51 Other, %

52 Summation of credits, %

53 Efficiency, %

0.0024 x [35D] x ([6] - [3])

H1 = (3.958E-5 x T + .4329) x T + 1062.2

H2 = [3] - 32

[29] x ([39] - [40]) / 100

0.0045 x [27D] x ([6] - [3])

[19] or [21] x 14,500 / [18]

ABMA curve

[15] x K2

8.94

32.53

1.00

26.57

-55.04

658.37

59.10

8,867

0.02

7.42

0.01

[16H] x 100 / [18]

[19] x [18] / 14,500

COMBUSTION GAS CALCULATIONS, Quantity / 10,000 Btu Fuel Input

22 Theoretical air (corrected), lb/10,000 Btu

[20] - [21] x 1151 / [18]

23 Total Residue from fuel, lb/10,000 Btu

([15G] + [21]) x 100 / [18]

24

A At

B Leakage

C Leaving Furnace

15.559217103466114

81.174

25 Excess air, % by weight

26 Dry air, lb/10,000 Btu

(1 + [25] / 100) x [22]

0.12

27 H20 from air, lb/10,000 Btu

[26] x [7]

0.00

28 Additional Moisture, lb/10,000 Btu

[8] x 100 / [18]

0.67

29 H20 from fuel, lb/10,000 Btu

[17H] x 100 / [18]

30 Wet gas from fuel, lb/10,000 Btu

(100 - [15G] - [21]) x 100 / [18]

31

32

33 Total wet gas, lb/10,000 Btu

Summation [26] through [30]

0.78

34 Water in wet gas, lb/10,000 Btu

Summation [27] + [28] + [29]

35 Dry gas, lb/10,000 Btu

[33] - [34]

36 H20 in gas, % by weight

[100] x [34] / [33]

37 Residue, % by weight

100 x [24] / [33]

39

K2

0.66

19 Unburned carbon loss, % fuel input

20 Theoretical air, lb/10,000 Btu

21 Unburned carbon, % of fuel

EFFICIENCY CALCULATIONS, % Input from Fuel

Losses

38 Dry Gas, %

17 H20, lb/100 lb fuel

[15] x K1

7.42

0.06

D Leaving Air Heater

96.73

14.60

0.20

0.20

0.00

0.00

0.67

1.07

1.07

15.56

8.58

0.12

0.00

10.43

0.78

9.65

7.50

0.55

0.86

16.54

0.86

15.67

5.22

0.35

5.93

1,167.36

48.00

7.46

0.14

0.02

0.17

0.50

Summation [38] + [46]

14.23

.0024 x [26D] x ([2] - [3])

.0045 x [27D] x ([2] - [3])

(H at T[4] - H at T[3]) x 100 / [18]

-0.70

-0.02

0.00

0.00

-0.72

85.05

Summation [48] through [51]

100 - [47] + [52]

9/16/2014 4:19 PM

You might also like

- ENERGY PERFORMANCE ASSESSMENT OF BOILERSDocument22 pagesENERGY PERFORMANCE ASSESSMENT OF BOILERSBrijesh SrivastavNo ratings yet

- Boiler Efficiency CalculationDocument5 pagesBoiler Efficiency CalculationSuparna Bhose100% (3)

- Indirect MethodDocument6 pagesIndirect MethodFarurrodin Syah AlfahrobiNo ratings yet

- Boiler Efficiency Test: Manual InputsDocument7 pagesBoiler Efficiency Test: Manual InputsSHIVAJI CHOUDHURYNo ratings yet

- Operating Experience On Single and Three Pass BoilersDocument7 pagesOperating Experience On Single and Three Pass Boilersbonginkosi mathunjwaNo ratings yet

- Boiler Performance CalculationDocument1 pageBoiler Performance Calculationagusnnn50% (2)

- Instructions Natural Gas Boiler Calculations: AcknowledgementsDocument17 pagesInstructions Natural Gas Boiler Calculations: AcknowledgementsDavid Muñoz CastroNo ratings yet

- Steam Temp. Required Steam Temp. Initial Steam Pressure. Final Steam Pressure. Added Water TempDocument3 pagesSteam Temp. Required Steam Temp. Initial Steam Pressure. Final Steam Pressure. Added Water TempBrijesh SrivastavNo ratings yet

- Efficiency Calculations of BagasseDocument4 pagesEfficiency Calculations of BagasseOmar Ahmed ElkhalilNo ratings yet

- Condenser CalculationDocument6 pagesCondenser Calculationgreenenergykolkata100% (2)

- Heat saving calculation guideDocument64 pagesHeat saving calculation guideKhurram ShahzadNo ratings yet

- PTC 4.1 Boiler Test EficiencyDocument11 pagesPTC 4.1 Boiler Test EficiencyPra Tiwi100% (2)

- Coal-Fired Power Plant Financing DataDocument241 pagesCoal-Fired Power Plant Financing DatanardoNo ratings yet

- Boiler Cost Per Hour CalculationDocument1 pageBoiler Cost Per Hour Calculationsreelu100% (1)

- Waste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobDocument30 pagesWaste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobMoriyasuNguyen100% (1)

- Achieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015Document25 pagesAchieveing Zero Liquid Discharge Through Mechanical Vapour Recompression-2015ansarNo ratings yet

- Thermal Calculations - WHRSDocument10 pagesThermal Calculations - WHRSshani5573No ratings yet

- Boiler Efficiency Improvement Through Analysis of Losses PDFDocument5 pagesBoiler Efficiency Improvement Through Analysis of Losses PDFTambun BerdikariNo ratings yet

- Falling Film Evaporator Performance Results From Two Reunion Island Factories - ZI - 2009 PDFDocument5 pagesFalling Film Evaporator Performance Results From Two Reunion Island Factories - ZI - 2009 PDFFajar KurniawanNo ratings yet

- Boiler Efficiency Calculations SheetDocument5 pagesBoiler Efficiency Calculations Sheetkalyanm20351578% (9)

- Sugarcane ComputeDocument12 pagesSugarcane ComputeJun Burias Padilla100% (1)

- Boiler EfficiencyDocument10 pagesBoiler Efficiencyromi_hamdani100% (4)

- Boiler Efficiency-An AnalysisDocument18 pagesBoiler Efficiency-An AnalysisDebasish ChowdhuryNo ratings yet

- Steam Turbine EfficiencyDocument71 pagesSteam Turbine EfficiencyAnonymous LjE1R12CasNo ratings yet

- Principles of Steam GenerationDocument30 pagesPrinciples of Steam GenerationAnil KumarNo ratings yet

- Flash Drum CalculationDocument2 pagesFlash Drum CalculationjnmanivannanNo ratings yet

- Indirect Boiler Efficiency Method Heat BalanceDocument8 pagesIndirect Boiler Efficiency Method Heat BalanceMohsin MajeedNo ratings yet

- Calculation of Heat Rate and Efficiency 04 Desember 2017 CFK #2Document1 pageCalculation of Heat Rate and Efficiency 04 Desember 2017 CFK #2Nur Ali SaidNo ratings yet

- Steam Heat Consumption CalculationsDocument12 pagesSteam Heat Consumption CalculationsshailendraraneNo ratings yet

- BB VerticalTrayDeaerator Jan11Document16 pagesBB VerticalTrayDeaerator Jan11GHEZELASHEGHINo ratings yet

- Thermopack Heat Generation CalculationDocument8 pagesThermopack Heat Generation CalculationAyush AgrawalNo ratings yet

- Boiler CalculationsDocument24 pagesBoiler Calculationsgkdora574100% (1)

- Economizer Design Calculations 1Document11 pagesEconomizer Design Calculations 1Mohsin Ali Khan50% (2)

- Combustion CalculationsDocument6 pagesCombustion CalculationsMauro FerrareseNo ratings yet

- Verification of Capacity of Secondary Air Fan For Bagasse Fired BoilerDocument2 pagesVerification of Capacity of Secondary Air Fan For Bagasse Fired BoilerAu TagolimotNo ratings yet

- 1a Natural Circulation BoilersDocument44 pages1a Natural Circulation BoilersFraser LamontNo ratings yet

- Note - All Yellow Cells Are Manditory To Be FilledDocument2 pagesNote - All Yellow Cells Are Manditory To Be FilledPrashant SinghNo ratings yet

- Boiler Equipment DesignDocument6 pagesBoiler Equipment DesignTots Holares100% (1)

- Boiler CalcDocument420 pagesBoiler Calczamijaka50% (2)

- Blowdown Economizer CalculationDocument2 pagesBlowdown Economizer CalculationSajjad AhmedNo ratings yet

- Properties by Correlation For Process SimulationDocument4 pagesProperties by Correlation For Process SimulationSuryakant RanderiNo ratings yet

- Boiler Efficiency CalculationsDocument8 pagesBoiler Efficiency CalculationsmanishxlriNo ratings yet

- Furnace EfficiencyDocument1 pageFurnace EfficiencySteve WanNo ratings yet

- Boiler CalcDocument92 pagesBoiler CalcPrasanta Kumar BeheraNo ratings yet

- Triple Effect EvaporatorDocument9 pagesTriple Effect Evaporatorjnmanivannan100% (1)

- Boilers, Boiler Fuel andDocument7 pagesBoilers, Boiler Fuel andVivek RamnohurNo ratings yet

- Boiler CalculationDocument4 pagesBoiler Calculationmohsin husen BargirNo ratings yet

- CONDENSATE AND STEAM TRAP IN STEAM LINEDocument16 pagesCONDENSATE AND STEAM TRAP IN STEAM LINEreach_arindomNo ratings yet

- Aux Power CalculationDocument22 pagesAux Power Calculationssheart_mindNo ratings yet

- BoilerCalcSteamPropDocument4 pagesBoilerCalcSteamPropMarc EdwardsNo ratings yet

- Steam Calculation 2008 0326Document53 pagesSteam Calculation 2008 0326Myungkwan HaNo ratings yet

- AH BLR PerformanceDocument96 pagesAH BLR PerformanceDeepak JayNo ratings yet

- 1987 - Magasiner - The Effect of FuelDocument4 pages1987 - Magasiner - The Effect of Fuelflitzzz100% (1)

- (Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingDocument32 pages(Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingLisa SeptidianaNo ratings yet

- Plant EfficiencyDocument51 pagesPlant EfficiencyknsaravanaNo ratings yet

- 4.10.4 Performance Evaluation of BoilersDocument7 pages4.10.4 Performance Evaluation of BoilersGanti AsegarNo ratings yet

- Brayton CycleDocument4 pagesBrayton CyclePriambudi Pujihatma0% (1)

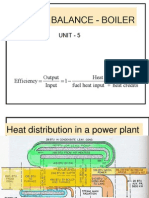

- HEAT BALANCE BOILER UNIT 5Document18 pagesHEAT BALANCE BOILER UNIT 5hafidhrahadiyan2No ratings yet

- Draft, Performance indicators, efficiency evaluation of furnaces and boilersDocument59 pagesDraft, Performance indicators, efficiency evaluation of furnaces and boilersmujeebmehar100% (3)

- 4B. BOILER Efficency-D, ID Oil FiredDocument10 pages4B. BOILER Efficency-D, ID Oil Firedalokbdas100% (1)

- Quality Management for IT ProjectsDocument53 pagesQuality Management for IT ProjectsEnsha AnwashNo ratings yet

- QM PMP CH8Document67 pagesQM PMP CH8Aygun ShukurovaNo ratings yet

- Boiler Tube Failure Due To Opening A Drain ValveDocument3 pagesBoiler Tube Failure Due To Opening A Drain ValveagusfaizinNo ratings yet

- Cold End Corrosion in A Boiler and Its PreventionDocument3 pagesCold End Corrosion in A Boiler and Its PreventionagusfaizinNo ratings yet

- Boiler Performance TestDocument5 pagesBoiler Performance TestagusfaizinNo ratings yet

- Low Drum Level in BoilersDocument3 pagesLow Drum Level in BoilersagusfaizinNo ratings yet

- Boiler Water Treatment - Why Is It ImportantDocument3 pagesBoiler Water Treatment - Why Is It ImportantSandeep MishraNo ratings yet

- Energy Equivalent ConversionsDocument3 pagesEnergy Equivalent ConversionsagusfaizinNo ratings yet

- Once Through and Drum Type Boiler Designs ComparedDocument3 pagesOnce Through and Drum Type Boiler Designs ComparedagusfaizinNo ratings yet

- CFB Design DescriptionDocument10 pagesCFB Design DescriptionagusfaizinNo ratings yet

- Estimated Avg Rate ElecDocument1 pageEstimated Avg Rate ElecSrihari DukkipatiNo ratings yet

- Build & Class Accommodation Barges GuideDocument1 pageBuild & Class Accommodation Barges GuideagusfaizinNo ratings yet

- Types of HRSGDocument2 pagesTypes of HRSGagusfaizinNo ratings yet

- P91Document3 pagesP91agusfaizinNo ratings yet

- Water Quality in High Pressure BoilersDocument3 pagesWater Quality in High Pressure BoilersagusfaizinNo ratings yet

- Accommodation Barge Guide To ColorsDocument1 pageAccommodation Barge Guide To ColorsagusfaizinNo ratings yet

- Rules for building steel bargesDocument1 pageRules for building steel bargesagusfaizinNo ratings yet

- Steel Barges 2015: Rules For Building and ClassingDocument1 pageSteel Barges 2015: Rules For Building and ClassingagusfaizinNo ratings yet

- Barge Guide To ColorsDocument1 pageBarge Guide To ColorsCarlos GutierrezNo ratings yet

- Anx B Specification Dovra-2-2013Document33 pagesAnx B Specification Dovra-2-2013agusfaizinNo ratings yet

- 249 Barrel Oil Storage Barge SpecificationsDocument1 page249 Barrel Oil Storage Barge SpecificationsagusfaizinNo ratings yet

- Biju Patnaik University of Technology MCA SyllabusDocument18 pagesBiju Patnaik University of Technology MCA SyllabusAshutosh MahapatraNo ratings yet

- Domestic Ro Price List 2021Document6 pagesDomestic Ro Price List 2021den oneNo ratings yet

- Hydro Skimming Margins Vs Cracking MarginsDocument78 pagesHydro Skimming Margins Vs Cracking MarginsWon Jang100% (1)

- Kimwa Compound, Baloy 04/01/2023 03/27/2023 LYL Development Corporation 006430292000Document1 pageKimwa Compound, Baloy 04/01/2023 03/27/2023 LYL Development Corporation 006430292000Maricel IpanagNo ratings yet

- Meltdown: The New Normal Call of The Wild Gear of The YearDocument93 pagesMeltdown: The New Normal Call of The Wild Gear of The YearAppaeommasaranghaeNo ratings yet

- Spo2 M1191aDocument247 pagesSpo2 M1191ashashibiya33No ratings yet

- NFL 101 Breaking Down The Basics of 2-Man CoverageDocument10 pagesNFL 101 Breaking Down The Basics of 2-Man Coveragecoachmark285No ratings yet

- Ngos' Due Diligence and Risk Mitigation: A Holistic ApproachDocument54 pagesNgos' Due Diligence and Risk Mitigation: A Holistic ApproachMichel KozahNo ratings yet

- Delta Ia-Mds VFDB I TC 20070719Document2 pagesDelta Ia-Mds VFDB I TC 20070719homa54404No ratings yet

- Grader 14 M Caterpillar BrouchorDocument2 pagesGrader 14 M Caterpillar Brouchorjude tallyNo ratings yet

- To Revision of DDPMAS-2002: Centre For Military Airworthiness and Certification (CEMILAC)Document11 pagesTo Revision of DDPMAS-2002: Centre For Military Airworthiness and Certification (CEMILAC)Jatinder Singh100% (1)

- Nanotechnology Applications in Viscoelastic Surfactant Stimulation FluidsDocument10 pagesNanotechnology Applications in Viscoelastic Surfactant Stimulation FluidsNircarlomix OrtegaNo ratings yet

- Communicating Corporate Social Responsibility: Perspectives and PracticeDocument26 pagesCommunicating Corporate Social Responsibility: Perspectives and PracticeAndiMuhammadIrwanNo ratings yet

- Actividad 3-Semana2-DécimoDocument7 pagesActividad 3-Semana2-DécimoAmaury VillalbaNo ratings yet

- PNMT (Pasolink) Operation ManualDocument52 pagesPNMT (Pasolink) Operation ManualAsrar Zaffar50% (2)

- The Strategies of Coca-Cola'S Expansion in The Globalization EraDocument12 pagesThe Strategies of Coca-Cola'S Expansion in The Globalization EraFathan MubinaNo ratings yet

- Prasanna Bhangdia PDFDocument3 pagesPrasanna Bhangdia PDFBHANGDIA PRASANNA ARUNNo ratings yet

- Safety Breach NoticeDocument3 pagesSafety Breach NoticeMohamed HadjkacemNo ratings yet

- An Internship Report on Customer Service of Prabhu BankDocument48 pagesAn Internship Report on Customer Service of Prabhu BankKaran PandeyNo ratings yet

- 43 CSeT F Mock - 240818 PDFDocument26 pages43 CSeT F Mock - 240818 PDFben romdhane ahmedNo ratings yet

- MJ1000-Motorola IncDocument4 pagesMJ1000-Motorola IncFrancisco DiazNo ratings yet

- Charles L. Mader - Numerical Modeling of The Deflagration-to-Detonation TransitionDocument21 pagesCharles L. Mader - Numerical Modeling of The Deflagration-to-Detonation TransitionSteemWheelNo ratings yet

- ZRO List 3.17Document4 pagesZRO List 3.17Com22No ratings yet

- North American Series 4762 Immersion Tube Burners 4762 - BULDocument4 pagesNorth American Series 4762 Immersion Tube Burners 4762 - BULedgardiaz5519No ratings yet

- 131b0314 - Im Danffos VLT ManualDocument108 pages131b0314 - Im Danffos VLT ManualMery Helen Barraza DelgadoNo ratings yet

- QSF HRM F03 Job Application FormDocument2 pagesQSF HRM F03 Job Application Formjohn MNo ratings yet

- PAS Install Lab Guide - v11.2Document145 pagesPAS Install Lab Guide - v11.2Muhammad Irfan Efendi SinulinggaNo ratings yet

- Dan John Case Study - Scaling with Facebook AdsDocument5 pagesDan John Case Study - Scaling with Facebook AdsZeynep ÖzenNo ratings yet

- Verilog HDL Lab ManualDocument68 pagesVerilog HDL Lab ManualParag Parandkar80% (25)

- Nadig Reporter Newspaper Chicago June 19 2013 EditionDocument20 pagesNadig Reporter Newspaper Chicago June 19 2013 EditionchicagokenjiNo ratings yet