Professional Documents

Culture Documents

Polyjet Materials Data Sheet

Uploaded by

Rodriguez ArthursCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polyjet Materials Data Sheet

Uploaded by

Rodriguez ArthursCopyright:

Available Formats

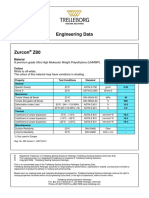

PolyJet Materials Data Sheet

MATERIALS SIMULATING ENGINEERING PLASTICS

DIGITAL ABS, GREEN (RGD5160-DM, RGD5161-DM) MADE OF RGD515 & RGD535 |DIGITAL

ABS, IVORY (RGD5130-DM, RGD5131-DM) MADE OF RGD515 & RGD531

ASTM

UNITS

METRIC

UNITS

IMPERIAL

Tensile strength

D-638-03

MPa

70-80

psi

10,000-11,500

8000-8700

Elongation at break

D-638-05

10-15

10-15.

25-40

Modulus of elasticity

D-638-04

MPa

3200-3500

psi

465,000-510,000

psi

375,000-435,000

Flexural Strength

D-790-03

MPa

110-130

psi

16,000-19,000

65-75

psi

9,500-11,000

Flexural Modulus

D-790-04

MPa

3100-3500

psi

450,000-510,000

MPa

1700-2200

psi

245,000-320,000

HDT, oC @ 0.45MPa

D-648-06

63-67

145-163

D-648-06

58-68

136-154

D-648-06

75-80

167-176

D-648-06

82-90

180-194

HDT, oC @ 0.45MPa after thermal

post treatment procedure A

HDT, oC @ 1.82MPa

D-648-07

55-57

131-135

Izod Notched Impact

D-256-06

J/m

14-16

ft lb/inch

0.262-0.300

Water Absorption, %

D-570-98 24hr

1.2-1.4

1.2-1.4

Tg

DMA, E

62-65

144-149

ASTM

UNITS

METRIC

UNITS

IMPERIAL

Tensile strength

D-638-03

MPa

55-60

psi

Elongation at break

D-638-05

25-40

Modulus of elasticity

D-638-04

MPa

2600-3000

Flexural Strength

D-790-03

MPa

Flexural Modulus

D-790-04

HDT, C @ 0.45MPa

HDT, oC @ 0.45MPa after thermal

post treatment procedure A

HIGH TEMPERATURE MATERIAL (RGD525)

HDT, C @ 0.45MPa after thermal

post treatment procedure B

D-648-06

92-95

198-203

HDT, oC @ 1.82MPa

D-648-07

51-55

124-131

Izod Notched Impact

D-256-06

J/m

65-80

ft lb/inch

1.22-1.50

Shore Hardness D

Scale D

Scale D

87-88

Scale D

87-88

Tg

DMA, E

47-53

117-127

Rockwell Hardness

Scale M

Scale M

78-83

Scale M

78-83

Shore Hardness (D)

Scale D

Scale D

85-87

Scale D

85-87

Polymerized density

ASTM D792

g/cm3

1.17-1.18

Rockwell Hardness

Scale M

Scale M

67-69

Scale M

67-69

Ash content

USP281

0.38-0.42

0.38-0.42

Polymerized density

ASTM D792

g/cm3

1.17-1.18

MATERIALS SIMULATING STANDARD PLASTICS

TRANSPARENT MATERIALS

TRANSPARENT MATERIALS

VEROCLEAR RGD810

RGD720

ASTM

UNITS

METRIC

UNITS

IMPERIAL

ASTM

UNITS

METRIC

UNITS

IMPERIAL

Tensile strength

D-638-03

MPa

50-65

psi

7250-9450

Tensile strength

D-638-03

MPa

50-65

psi

7250-9450

Elongation at break

D-638-05

15-25

15-25

Elongation at break

D-638-05

10-25

10-25

Modulus of elasticity

D-638-04

MPa

2000-3000

psi

290,000-435,000

Modulus of elasticity

D-638-04

MPa

2000-3000

psi

290,000-435,000

Flexural Strength

D-790-03

MPa

80-110

psi

12000-16000

Flexural Strength

D-790-03

MPa

75-110

psi

11000-16000

Flexural Modulus

D-790-04

MPa

2700-3300

psi

390,000-480,000

Flexural Modulus

D-790-04

MPa

2200-3200

psi

320,000-465,000

HDT, oC @ 0.45MPa

D-648-06

45-50

113-122

HDT, oC @ 0.45MPa

D-648-06

45-50

113-122

HDT, oC @ 1.82MPa

D-648-07

45-50

113-122

HDT, oC @ 1.82MPa

D-648-07

45-50

113-122

Izod Notched Impact

D-256-06

J/m

20-30

ft lb/inch

0.375-0.562

Izod Notched Impact

D-256-06

J/m

20-30

ft lb/inch

0.375-0.562

Water Absorption

D-570-98 24hr

1.5-2.2

1.5-2.2

Water Absorption

D-570-98 24hr

1.1-1.5

1.1-1.5

Tg

DMA, E

48-50

118-122

Tg

DMA, E

52-54

126-129

Shore Hardness (D)

Scale D

Scale D

83-86

Scale D

83-86

Shore Hardness (D)

Scale D

Scale D

83-86

Scale D

83-86

Rockwell Hardness

Scale M

Scale M

73-76

Scale M

73-76

Rockwell Hardness

Scale M

Scale M

73-76

Scale M

73-76

Polymerized density

ASTM D792

g/cm3

1.18-1.19

Polymerized density

ASTM D792

g/cm3

1.18-1.19

Ash content

USP281

0.01-0.02

Ash content

USP281

0.02-0.06

0.02-0.06

Find material properties for color materials on the Color Digital Materials Data Sheet.

0.01-0.02

RIGID OPAQUE MATERIALS

RIGID OPAQUE MATERIALS

VEROGRAY RGD850, VEROBL ACKPLUS RGD875, VEROWHITEPLUS RGD835,

VEROYELLOW RGD836, VEROCYAN RGD841 , VEROMAGENTA RGD851

VEROBLUE RGD840

Tensile strength

Elongation at break

Modulus of elasticity

Flexural Strength

Flexural Modulus

HDT, C @ 0.45MPa

HDT, C @ 1.82MPa

Izod Notched Impact

Water Absorption

Tg

Shore Hardness (D)

Rockwell Hardness

Polymerized density

Ash content VeroGray,

VeroWhitePlus

Ash content VeroBlackPlus

ASTM

UNITS

METRIC

UNITS

IMPERIAL

D-638-03

D-638-05

D-638-04

D-790-03

D-790-04

D-648-06

D-648-07

D-256-06

D-570-98 24hr

DMA, E

Scale D

Scale M

ASTM D792

USP281

MPa

%

MPa

MPa

MPa

C

C

J/m

%

C

Scale D

Scale M

g/cm3

%

50-65

10-25

2000-3000

75-110

2200-3200

45-50

45-50

20-30

1.1-1.5

52-54

83-86

73-76

1.17-1.18

0.23-0.26

psi

%

psi

psi

psi

F

F

ft lb/inch

%

F

Scale D

Scale M

7250-9450

10-25

290,000-435,000

11000-16000

320,000-465,000

113-122

113-122

0.375-0.562

1.1-1.5

126-129

83-86

73-76

0.23-0.26

USP281

0.01-0.02

0.01-0.02

DURUS WHITE RGD430

ASTM

UNITS

METRIC

UNITS

IMPERIAL

Tensile strength

Elongation at break

Modulus of elasticity

Flexural Strength

Flexural Modulus

HDT, C @ 0.45MPa

HDT, C @ 1.82MPa

Izod Notched Impact

Water Absorption

Tg

Shore Hardness (D)

Rockwell Hardness

Polymerized density

Ash content

MPa

%

MPa

MPa

MPa

C

C

J/m

%

C

Scale D

Scale M

g/cm3

%

20-30

40-50

1000-1200

30-40

1200-1600

37-42

32-34

40-50

1.5-1.9

35-37

74-78

no data

1.15-1.17

0.10-0.12

psi

%

psi

psi

psi

F

F

ft lb/inch

%

F

Scale D

Scale M

2900-4350

40-50

145,000-175,000

4350-5800

175,000-230,000

99-108

90-93

0.749-0.937

1.5-1.9

95-99

74-78

no data

0.1-0.12

RIGUR RGD450

Tensile strength

Elongation at break

Modulus of elasticity

Flexural Strength

Flexural Modulus

HDT, C @ 0.45MPa

HDT, C @ 1.82MPa

Izod Notched Impact

Tg

Shore Hardness (D)

Rockwell Hardness

Polymerized density

Ash content

ASTM

UNITS

METRIC

UNITS

IMPERIAL

D-638-03

MPa

50-60

psi

7250-8700

Elongation at break

D-638-05

15-25

15-25

Modulus of elasticity

D-638-04

MPa

2000-3000

psi

290,000-435,000

Flexural Strength

D-790-03

MPa

60-70

psi

8700-10200

Flexural Modulus

D-790-04

MPa

1900-2500

psi

265,000-365,000

HDT, C @ 0.45MPa

D-648-06

45-50

113-122

HDT, C @ 1.82MPa

D-648-07

45-50

113-122

Izod Notched Impact

D-256-06

J/m

20-30

ft lb/inch

0.375-0.562

Water Absorption

D-570-98 24hr

1.5-2.2

1.5-2.2

Tg

DMA, E

48-50

118-122

Shore Hardness (D)

Scale D

Scale D

83-86

Scale D

83-86

Scale M

73-76

0.21-0.22

Rockwell Hardness

Scale M

Scale M

73-76

Polymerized density

ASTM D792

g/cm3

1.18-1.19

Ash content

USP281

0.21-0.22

RUBBER-LIKE MATERIALS

SIMUL ATED POLYPROPYLENE MATERIALS

D-638-03

D-638-05

D-638-04

D-790-03

D-790-04

D-648-06

D-648-07

D-256-06

D-570-98 24hr

DMA, E

Scale D

Scale M

ASTM D792

USP281

Tensile strength

ASTM

UNITS

METRIC

UNITS

IMPERIAL

D-638-03

D-638-05

D-638-04

D-790-03

D-790-04

D-648-06

D-648-07

D-256-06

DMA, E

Scale D

Scale M

ASTM D792

USP281

MPa

%

MPa

MPa

MPa

C

C

J/m

C

Scale D

Scale M

g/cm3

%

40-45

20-35

1700-2100

52-59

1500-1700

49-54

45-50

30-35

48-52

80-84

58-62

1.20-1.21

0.3-0.4

psi

%

psi

psi

psi

F

F

ft lb/inch

F

Scale D

Scale M

5800-6500

20-35

246,000 305,000

7500 - 8500

217,000 246,000

120-129

113-122

0.561-0.656

118-126

80-84

58-62

0.3-0.4

TANGOBL ACKPLUS FL X980 AND TANGOPLUS FL X930

ASTM

UNITS

METRIC

Tensile strength

D-412

MPa

0.8-1.5

UNITS

IMPERIAL

psi

115-220

Elongation at break

D-412

170-220

170-220

Compressive set

D-395

4-5

4-5

Shore Hardness (A)

D-2240

Scale A

26-28

Scale A

26-28

Tensile Tear resistance

D-624

Kg/cm

2-4.

Lb/in

18-22

Polymerized density

ASTM D792

g/cm3

1.12-1.13

TANGOBL ACK FL X973

Tensile strength

ASTM

UNITS

METRIC

UNITS

IMPERIAL

D-412

MPa

1.8-2.4

psi

115-350

Elongation at break

D-412

45-55

45-55

Compressive set

D-395

0.5-1.5

0.5-1.5

Shore Hardness (A)

D-2240

Scale A

60-62

Scale A

60-62

Tensile Tear resistance

D-624

Kg/cm

3-5

Lb/in

18-24

Polymerized density

ASTM D792

g/cm3

1.14-1.15

TANGOGRAY FL X950

ASTM

UNITS

METRIC

UNITS

IMPERIAL

Tensile strength

D-412

MPa

3-5

psi

435-725

Elongation at break

D-412

45-55

45-55

Compressive set

D-395

0.5-1.5

0.5-1.5

Shore Hardness (A)

D-2240

Scale A

73-77

Scale A

73-77

Tensile Tear resistance

D-624

Kg/cm

8-12

Lb/in

50-60

Polymerized density

ASTM D792

g/cm3

1.16-1.17

The data included in this brochure is for your information purposes only and should not be considered specific advice to any particular customer project. Each customer is responsible for the design, functioning and all other decisions with regards to its particular projects and systems. The sale and provision of the products described

in this brochure are subject to terms and conditions outlined in Stratasys selling policies, contracts between the parties or Stratasys Terms and Conditions of Sale. This brochure is not intended to and does not enlarge or add to any such contract or terms.

2014, 2015 Stratasys Ltd. All rights reserved. Stratasys, Stratasys logo, Objet, For a 3D World, Objet24,Objet30, Objet 30 Pro, Objet30 OrthoDesk, Objet Studio, Quadra, QuadraTempo, FullCure, SHR, Eden, Eden250, Eden260, Eden260V, Eden 330, Eden350, Eden350V, Eden500V, Job Manager, CADMatrix,Connex, Objet260

Connex, Connex350, Connex500, Objet1000, Rigur, Alaris, Alaris30, PolyLog, TangoBlack,TangoGray, TangoPlus, TangoBlackPlus, VeroBlue, VeroBlack, VeroBlackPlus, VeroClear, VeroDent,VeroGray, VeroWhite, VeroWhitePlus, Durus, Digital Materials, PolyJet, Polyjet Matrix, Digital ABS and ObjetGreen are trademarks or registered

trademarks of Stratasys Ltd. and/or its subsidiaries or affiliates and may be registered in certain jurisdictions. All other trademarks belong to their respective owners. MSS_PJ_PJMaterialsDataSheet_EN_0815

You might also like

- MSS PJ PJMaterialsDataSheetDocument2 pagesMSS PJ PJMaterialsDataSheetAndreNo ratings yet

- RT-Duroid 5880 PropertiesDocument2 pagesRT-Duroid 5880 PropertiesJesus GarciaNo ratings yet

- ALATHON L5005 y CERTENE 122DDocument4 pagesALATHON L5005 y CERTENE 122DJuan Carlos Otero JaramilloNo ratings yet

- Global's New High Performance PE4710 MaterialDocument5 pagesGlobal's New High Performance PE4710 MaterialIván López PavezNo ratings yet

- SPECSPEADM5370Document1 pageSPECSPEADM5370nicolas yoris marcoglieseNo ratings yet

- SCH 40Document12 pagesSCH 40haithamNo ratings yet

- Projet 6000 & 7000: Step Up To The Gold Standard in 3D Printing With Genuine Sla®Document4 pagesProjet 6000 & 7000: Step Up To The Gold Standard in 3D Printing With Genuine Sla®Ldi LerielNo ratings yet

- Ficha Tecnica Agru - Geotextil NT Ambiental (2018)Document1 pageFicha Tecnica Agru - Geotextil NT Ambiental (2018)Edward Jose Quispe BaldarragoNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- Wepp Cas52gDocument1 pageWepp Cas52gArthur Sanda LayukNo ratings yet

- Idemitsu SM CF 10w 30Document2 pagesIdemitsu SM CF 10w 30DIDIT HERDIATNANo ratings yet

- Screw-In RTD Temperature Probe With Plug Connector: Approvals/approval Marks (See "Technical Data")Document5 pagesScrew-In RTD Temperature Probe With Plug Connector: Approvals/approval Marks (See "Technical Data")guruh anindraNo ratings yet

- Castrol EDGE Professional TWS 10W-60: DescriptionDocument2 pagesCastrol EDGE Professional TWS 10W-60: DescriptionElieNo ratings yet

- ELITE 5401G: Blown Film ResinDocument2 pagesELITE 5401G: Blown Film ResinEndayenew MollaNo ratings yet

- EDGE Extended Performance: DescriptionDocument3 pagesEDGE Extended Performance: DescriptionMuhNo ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- Compounding Guide StruktolDocument154 pagesCompounding Guide Struktoldusik007100% (6)

- Lexan F2104 SHEET: Product DatasheetDocument2 pagesLexan F2104 SHEET: Product DatasheetFrank RamirezNo ratings yet

- Rhodia - Tds - Technylstar S 218 v30 Black 31 N - enDocument5 pagesRhodia - Tds - Technylstar S 218 v30 Black 31 N - ennimonhNo ratings yet

- Wrapid Sleeve PDSDocument2 pagesWrapid Sleeve PDSjayhuacat7743No ratings yet

- Bpxe AbjfycDocument2 pagesBpxe AbjfycMuhNo ratings yet

- Castrol EDGE 5W-40: DescriptionDocument2 pagesCastrol EDGE 5W-40: Descriptionvicky kNo ratings yet

- Idemitsu Diesel CF-4 SG 10W-30 15W-40 PDFDocument2 pagesIdemitsu Diesel CF-4 SG 10W-30 15W-40 PDFGILANG KASNo ratings yet

- Low Density Polyethylene LD7000A: DescriptionDocument1 pageLow Density Polyethylene LD7000A: DescriptionJaime222No ratings yet

- Bpxe B5arw3Document1 pageBpxe B5arw3Arthur Sanda LayukNo ratings yet

- 440Document3 pages440Magabata GoguNo ratings yet

- Idemitsu 4T SL/MB 10W-30: Lubricant Product InformationDocument2 pagesIdemitsu 4T SL/MB 10W-30: Lubricant Product InformationYandiNo ratings yet

- Trirex 3020HF: Polycarbonate ResinDocument5 pagesTrirex 3020HF: Polycarbonate ResinAlbert FortunatoNo ratings yet

- Blown Film Resin - ELITE 5400G Enhanced PolyethyleneDocument2 pagesBlown Film Resin - ELITE 5400G Enhanced PolyethyleneEndayenew MollaNo ratings yet

- Cold Shrink 8420Document3 pagesCold Shrink 8420PringetteNo ratings yet

- Idemitsu 4T SJ/MB 10W-30: Lubricant Product InformationDocument2 pagesIdemitsu 4T SJ/MB 10W-30: Lubricant Product InformationKhadafiNo ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayelecompinnNo ratings yet

- MPI Seals Catalog CTS-1000Document6 pagesMPI Seals Catalog CTS-1000Anurag JainNo ratings yet

- Selective Laser SinteringDocument12 pagesSelective Laser SinteringMihai CitcauanNo ratings yet

- 203-010 Griswold 6100 Family Product Data SheetDocument1 page203-010 Griswold 6100 Family Product Data Sheetjuan davidNo ratings yet

- Repsol Maker Super TauroDocument2 pagesRepsol Maker Super Tauroibrahim maulanaNo ratings yet

- Idemitsu CVTF: Lubricant Product InformationDocument2 pagesIdemitsu CVTF: Lubricant Product InformationArdy LauNo ratings yet

- Datasheets E FDMDocument5 pagesDatasheets E FDMAlireza YaghoubiNo ratings yet

- HDPE Geomembrane - AlvatechDocument10 pagesHDPE Geomembrane - AlvatechshgsuhermanNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- Gazguard 026: Units Typical Value Initial PropertyDocument2 pagesGazguard 026: Units Typical Value Initial PropertyTeguh SetionoNo ratings yet

- Petronas Ambra Multi G 10W-30: Technical Data SheetDocument1 pagePetronas Ambra Multi G 10W-30: Technical Data SheetCarlos GuerreroNo ratings yet

- RO3000 Laminate Data Sheet - RO3003, RO3006, RO3010Document4 pagesRO3000 Laminate Data Sheet - RO3003, RO3006, RO3010Juliano Rodrigues BrianezeNo ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayFilipe BrendlerNo ratings yet

- Property ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalDocument1 pageProperty ASTM or UL Test Extruded NYLON 6/6 Cast Nylon Physical MechanicalEktor RamirzNo ratings yet

- Teslin: Quick OverviewDocument3 pagesTeslin: Quick OverviewDewiNo ratings yet

- Manual GL-4 80W-90: DescriptionDocument1 pageManual GL-4 80W-90: DescriptionSugianto DoankNo ratings yet

- Araldite LY556 - Aradur 917 - Accelarator DY 070 - TDSDocument6 pagesAraldite LY556 - Aradur 917 - Accelarator DY 070 - TDSjbd170352No ratings yet

- Zurcon Z80 PDFDocument1 pageZurcon Z80 PDFLuz SmithNo ratings yet

- CP 191-enUS-ASTMDocument1 pageCP 191-enUS-ASTMAndersonNo ratings yet

- DB Transmax DUALDocument2 pagesDB Transmax DUALleshyjNo ratings yet

- rammer_demolitiontoolsDocument36 pagesrammer_demolitiontoolsoguzhan.akselNo ratings yet

- GP100ORXP enUS ASTMDocument1 pageGP100ORXP enUS ASTMRaul ArmendarizNo ratings yet

- DN Turbine OilDocument2 pagesDN Turbine OilPrapat SabsinthaweelapNo ratings yet

- PETRONAS Akcela NEXPLORE Gear OilDocument1 pagePETRONAS Akcela NEXPLORE Gear OilCleniltonAndreGomesNo ratings yet

- F 720 362 Rev. A Sensors For KomatsuDocument2 pagesF 720 362 Rev. A Sensors For KomatsucdeliusiiiNo ratings yet

- The PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustryDocument2 pagesThe PE4710 - PE 100 Is A Special Black Polyethylene Material For The Pipe IndustrysreeNo ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- PDS Edge 5w-50Document2 pagesPDS Edge 5w-50epesanoNo ratings yet

- SP19416圖式20161104Document3 pagesSP19416圖式20161104Rodriguez ArthursNo ratings yet

- Solar Power Pesticides SprayerDocument4 pagesSolar Power Pesticides SprayerRodriguez Arthurs100% (1)

- Combustion and Flame: Kyung Ju Kim, Myung Hoon Cho, Soo Hyung KimDocument9 pagesCombustion and Flame: Kyung Ju Kim, Myung Hoon Cho, Soo Hyung KimRodriguez ArthursNo ratings yet

- National Cheng Kung University student examines causes and impacts of landslides in IndiaDocument17 pagesNational Cheng Kung University student examines causes and impacts of landslides in IndiaRodriguez ArthursNo ratings yet

- Nafems Conference BroucherDocument4 pagesNafems Conference BroucherRodriguez ArthursNo ratings yet

- Ijsetr Vol 3 Issue 5 1453 1457Document5 pagesIjsetr Vol 3 Issue 5 1453 1457Rodriguez ArthursNo ratings yet

- Implementation of A Skating Motion On A Spider Robot: Bachelor ThesisDocument55 pagesImplementation of A Skating Motion On A Spider Robot: Bachelor ThesisRodriguez ArthursNo ratings yet

- Mems Report JournalDocument4 pagesMems Report JournalRodriguez ArthursNo ratings yet

- Mos Fabrication Content BsDocument11 pagesMos Fabrication Content BsarumugamNo ratings yet

- 3D Printing TechnologyDocument5 pages3D Printing Technologyvasu088No ratings yet

- Optimization CrankShaft MechanismDocument22 pagesOptimization CrankShaft MechanismLakshman ReddyNo ratings yet

- FIBER OPTICS Workshop BrouchureDocument15 pagesFIBER OPTICS Workshop BrouchureRodriguez ArthursNo ratings yet

- A356.0 Alloy DetailDocument2 pagesA356.0 Alloy DetailAdrian LimantoNo ratings yet

- Automobile Crank ShaftDocument8 pagesAutomobile Crank ShaftRodriguez ArthursNo ratings yet

- Volume 3 Issue 9 Paper 1Document21 pagesVolume 3 Issue 9 Paper 1Rodriguez ArthursNo ratings yet

- Aiaa 2010 1018Document11 pagesAiaa 2010 1018Rodriguez ArthursNo ratings yet

- Skill Development Program for Employability EnhancementDocument15 pagesSkill Development Program for Employability EnhancementRodriguez ArthursNo ratings yet

- Design Optimization TutorialDocument13 pagesDesign Optimization TutorialRodriguez ArthursNo ratings yet

- V Tail MAV ReportDocument46 pagesV Tail MAV ReportRodriguez ArthursNo ratings yet

- LS-PrePost Forming Aug1stDocument240 pagesLS-PrePost Forming Aug1stRodriguez ArthursNo ratings yet

- Access Global Online Research Ag ResourcesDocument2 pagesAccess Global Online Research Ag ResourcesRodriguez ArthursNo ratings yet

- Report ProjectDocument53 pagesReport ProjectRodriguez ArthursNo ratings yet

- CAEA v145 Update ACTDocument22 pagesCAEA v145 Update ACTRodriguez ArthursNo ratings yet

- UAV Design TrainingDocument17 pagesUAV Design TrainingPritam AshutoshNo ratings yet

- Trends in Aerospace EngineeringDocument21 pagesTrends in Aerospace EngineeringRodriguez ArthursNo ratings yet

- XFLR5 Tut v1Document40 pagesXFLR5 Tut v1spandaglis0% (1)

- ABAQUS Tutorial Schedule and Access InfoDocument2 pagesABAQUS Tutorial Schedule and Access InfoAmit RajputNo ratings yet

- Ramesh S TalkDocument21 pagesRamesh S TalkRodriguez ArthursNo ratings yet

- NAL Workshop April8 VeenaDocument37 pagesNAL Workshop April8 VeenaRodriguez ArthursNo ratings yet