Professional Documents

Culture Documents

Handbook of PVC Pipe

Uploaded by

samirbendre117%(6)17% found this document useful (6 votes)

5K views6 pagesThe Uni-Bell PVC Pipe Association Handbook of PVC Pipe: design and Construction is the definitive guide to gasketed-joint PVC pipe. A group of responsible PVC pipe producers created the non-profit in 1971. Today the Uni-bell is working for all PVC pipe users and potential pipe users.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Uni-Bell PVC Pipe Association Handbook of PVC Pipe: design and Construction is the definitive guide to gasketed-joint PVC pipe. A group of responsible PVC pipe producers created the non-profit in 1971. Today the Uni-bell is working for all PVC pipe users and potential pipe users.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

17%(6)17% found this document useful (6 votes)

5K views6 pagesHandbook of PVC Pipe

Uploaded by

samirbendre1The Uni-Bell PVC Pipe Association Handbook of PVC Pipe: design and Construction is the definitive guide to gasketed-joint PVC pipe. A group of responsible PVC pipe producers created the non-profit in 1971. Today the Uni-bell is working for all PVC pipe users and potential pipe users.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

The Uni-Bell PVC Pipe Association

Handbook

of

PVC Pipe

Design and Construction

Uni-Bell PVC Pipe Association

2655 Villa Creek Drive, Suite 155

Dallas, Texas 75234

$40.00

© Uni-Bell PVC Pipe Association, 2001

Copyright © 1977, 1979, 1982, 1991, 2001

by

Uni-Bell PVC Pipe Association

Dallas, Texas

All rights reserved.

This book, or parts thereof, may not be reproduced

in any form without permission of the publishers.

First Edition, October 1977

Second printing, February 1978

Third printing, May 1979

Fourth printing, June 1980

Fifth printing, April 1981

Second Edition, March 1982

Second printing, October 1983

Third printing, October 1986

Third Edition, September 1991

Second printing, December 1993

Third printing, December 1997

Fourth printing, September 1999

Fourth Edition, August 2001

Printed in the United States of America

© Uni-Bell PVC Pipe Association, 2001

PREFACE

In 1971 a group of responsible PVC pipe producers had the foresight to

recognize that the exceptional qualities of performance and value would eventually

make gasketed-joint PVC pipe the product of choice for buried water, sewer,

drainage and irrigation piping. To properly service the future design and technical

information needs associated with such a large scale and growing industry, these

leaders combined their resources to create a non-profit technical, educational and

research-oriented organization known today as the Uni-Bell PVC Pipe Association.

Since it was organized, Uni-Bell has served the engineering, regulatory,

public health and standardization communities with integrity and considerable

measures of both time and resources. Whenever questions or problems have arisen

relative to PVC pipe performance, Uni-Bell members, through their Association,

have responded. Uni-Bell sponsored research in the areas of buried pipe deflection,

durability, ultraviolet aging, direct tapping and cyclic surge performance has

provided pipe designers and installers with much needed practical information.

Today Uni-Bell is working for all PVC pipe users and potential pipe users,

helping to assure proper product application and performance through research and

education. Uni-Bell's highly qualified professional staff work to provide users with

the information they need concerning gasketed-joint PVC pipe. In addition, Uni-Bell

continues to develop useful technical publications and recommended standards

recognized around the world.

The Uni-Bell Handbook of PVC Pipe: Design and Construction is the

Association’s preeminent publication. It has been prepared with the objective of

being the most comprehensive reference text on PVC pipe and fittings. This

handbook provides practical engineering and construction information together with

recommendations applicable to the design and use of primarily underground PVC

piping systems in both pressure and non-pressure applications.

Handbook users are invited to contact Uni-Bell's staff of qualified engineers

for additional technical support or to clarify information contained within the book.

Technical services are available on request through member companies or upon

direct request to Uni-Bell. A directory of the current membership of the Uni-Bell

PVC Pipe Association is available by contacting Uni-Bell.

The statements contained in this Handbook are those of the Uni-Bell PVC

Pipe Association and are not warranties, nor are they intended to be such. Inquiries

for information on specific products, product attributes and the manufacturer's

warranty should be directed to member companies.

iiv

© Uni-Bell PVC Pipe Association, 2001

Handbook of PVC Pipe

TABLE OF CONTENTS

Preface ...................................................................................................... i

Chapter I, Polyvinyl Chloride (PVC) Pipe ...............................................1

PVC -- An Engineered Thermoplastic..........................................3

Historical Background ..................................................................3

A Rational Choice.........................................................................5

PVC Pipe Technology...................................................................9

Chapter II, Raw Materials.......................................................................11

PVC Pipe Compounds ................................................................12

Gasket Materials .........................................................................20

Chapter III, Resistance to Aggressive Environments .............................23

Corrosion ....................................................................................25

Chemical Attack..........................................................................26

Permeation ..................................................................................56

Biological Attack ........................................................................57

Weathering..................................................................................61

Abrasion......................................................................................62

Soil Movement............................................................................66

Repetitive Fatigue .......................................................................66

Chapter IV, PVC Pipe Manufacturing and Testing ................................71

Manufacturing Processes ............................................................72

Manufacturing of Profile Wall Pipe............................................78

Manufacturing of Injection Molded PVC Fittings......................80

Fabricated PVC Fittings..............................................................84

Standard Specifications...............................................................87

Testing ......................................................................................105

Qualification Tests ....................................................................106

Quality Control Tests and Inspection .......................................113

Quality Assurance Testing........................................................116

Test Certification and Warranty ...............................................116

Packaging and Shipping............................................................117

Manufacturing of PVCO...........................................................117

ii

© Uni-Bell PVC Pipe Association, 2001

Table of Contents

Table of Contents (cont.)

Chapter V, Pressure Pipe and Fittings, Design and Selection ..............121

Pressure Pipe Design and Selection..........................................122

Internal Hydrostatic Pressure....................................................122

Distribution Mains ....................................................................132

Transmission Mains ..................................................................133

Transmission Pipe Design Example .........................................137

Design of Molded PVC Pressure Fittings.................................144

Fabricated PVC Pressure Fittings .............................................148

Surge Pressures In PVC Pipe....................................................148

Sewage Force Mains .................................................................157

Pressure Pipe Longevity ...........................................................166

Molecularly Oriented PVC Pressure Pipe (PVCO) ..................168

Chapter VI, Superimposed Loads on Buried Pipe ................................173

Earth Loads ...............................................................................174

Live Loads ................................................................................207

Design Software........................................................................212

Chapter VII, Design of Buried PVC Pipe.............................................217

Sewer Pipe Longevity ...............................................................257

Alternative Design Methods .....................................................258

Chapter VIII, Special Design Applications ..........................................275

Longitudinal Bending ...............................................................276

Support Spacing ........................................................................295

Expansion and Contraction.......................................................302

Molecularly Oriented PVC Pipe (PVCO).................................306

Chapter IX, Hydraulics .........................................................................311

Flow of Water in PVC Pressure Pipes ......................................312

Gravity Flow in PVC Sewer Pipe .............................................356

Molecularly Oriented PVC Pipe (PVCO).................................375

iv iii

© Uni-Bell PVC Pipe Association, 2001

Handbook of PVC Pipe

Table of Contents (cont.)

Chapter X, Construction .......................................................................383

Receiving, Storage and Handling .............................................384

PVC Pipe Joint Assembly.........................................................389

Casings......................................................................................393

Sliplining Applications .............................................................397

PVC Pressure Pipe Installation. ................................................398

PVC Non-Pressure Pipe............................................................427

Published Design Guides and Recommendations.................................471

PVC Pipe Dimensions...........................................................................475

Unit Conversion Tables ........................................................................505

Index ...................................................................................................513

iv

© Uni-Bell PVC Pipe Association, 2001

You might also like

- PVC CompoundDocument11 pagesPVC Compoundhoneydoll67% (3)

- Handbook For PVC PipesDocument158 pagesHandbook For PVC PipesWaleed Rahmat50% (2)

- Foam Core PVC PipeDocument9 pagesFoam Core PVC Pipe7140220No ratings yet

- Polyvinyl Chloride Pipe CompositionDocument2 pagesPolyvinyl Chloride Pipe Compositionmacnoms100% (1)

- (PVC) PVC TechnologyDocument1,250 pages(PVC) PVC TechnologyMinh Triều Huỳnh95% (19)

- Project Report On CPVC Pipe and Fitting PlantDocument10 pagesProject Report On CPVC Pipe and Fitting PlantEIRI Board of Consultants and PublishersNo ratings yet

- Design of Extrusion HeadsDocument64 pagesDesign of Extrusion HeadsMohamed HassanNo ratings yet

- CIT PVC ProcessingDocument45 pagesCIT PVC ProcessingThao Nguyen Van100% (1)

- W. V. Titow M. Phil., PH.D., C. Chem., F. R. S. C., F. P. R. I., C. Text., A.T.I. (Auth.) - PVC Plastics - Properties, Processing, and Applications-Springer Netherlands (1990) PDFDocument919 pagesW. V. Titow M. Phil., PH.D., C. Chem., F. R. S. C., F. P. R. I., C. Text., A.T.I. (Auth.) - PVC Plastics - Properties, Processing, and Applications-Springer Netherlands (1990) PDFNguyễn Viết Lương50% (2)

- Ingredients Used in Rigid PVC Compounding: ResinDocument5 pagesIngredients Used in Rigid PVC Compounding: Resinsprabhat2005100% (5)

- PVC PipesDocument35 pagesPVC Pipespratikgarg03No ratings yet

- Technology of PVC Compounding and Its ApplicationsDocument21 pagesTechnology of PVC Compounding and Its ApplicationsBibhu Ranjan Bihari100% (1)

- Polyvinyl Chloride (PVC)Document46 pagesPolyvinyl Chloride (PVC)Kapil Rathi0% (1)

- Pipe ExtrusionDocument21 pagesPipe ExtrusionSummer Spencer100% (2)

- Effect of Stabilizers On Properties of PVC (Polymer) 1Document52 pagesEffect of Stabilizers On Properties of PVC (Polymer) 1DIPAK VINAYAK SHIRBHATE100% (5)

- PVC-recycling Technologies: Environmental ConcernsDocument2 pagesPVC-recycling Technologies: Environmental ConcernsFA AyNo ratings yet

- Promains PVC Pipe and Fittings Product Guide Jan 2012 2Document16 pagesPromains PVC Pipe and Fittings Product Guide Jan 2012 2NaeemSiddiquiNo ratings yet

- CPVC Pipes and FittingsDocument4 pagesCPVC Pipes and FittingsCA Gokul Vadapalli100% (1)

- PVC Technology: Chapter 11Document80 pagesPVC Technology: Chapter 11Andri0% (1)

- Project Introduction PipeDocument3 pagesProject Introduction Pipepankaj24x7No ratings yet

- Thermal Stabilizers For PVC A ReviewDocument8 pagesThermal Stabilizers For PVC A ReviewDarshan ShahNo ratings yet

- ISCO HDPE Full Line CatalogDocument252 pagesISCO HDPE Full Line Catalogpvsreddy2002100% (1)

- (Two-Component Polyurethane Systems) ContentsDocument8 pages(Two-Component Polyurethane Systems) ContentsCong ChinhNo ratings yet

- Waxes For PVC ProcessingDocument33 pagesWaxes For PVC ProcessingFrancisco Venegas Zuñiga100% (1)

- PVC, CPVC Solvent, Primer and CleanerDocument12 pagesPVC, CPVC Solvent, Primer and CleanerUmarSeddiqueNo ratings yet

- Overview of PET ProcessingDocument5 pagesOverview of PET ProcessingSwagat R Pyakurel50% (2)

- Baerlocher PVC Stabilisers Asian Technical Seminar 2013Document37 pagesBaerlocher PVC Stabilisers Asian Technical Seminar 2013Jen Chavez100% (1)

- Pressure Piping Systems Design: Municipal Technical Manual SeriesDocument86 pagesPressure Piping Systems Design: Municipal Technical Manual SerieschokNo ratings yet

- Fiberglass Piping Engineering Design ManualDocument36 pagesFiberglass Piping Engineering Design ManualdestresscallNo ratings yet

- Kraloy Fittings CatalogDocument46 pagesKraloy Fittings CatalogPedro A Ocanto BNo ratings yet

- Elements of Pipe DesignDocument49 pagesElements of Pipe DesignAnonymous 4rMVkArNo ratings yet

- Handbook of PVC Pipe Design and Construction: (First Industrial Press Edition)From EverandHandbook of PVC Pipe Design and Construction: (First Industrial Press Edition)No ratings yet

- Engineering Piping Design Guide Fiberglass Reinforced Piping SystemsDocument36 pagesEngineering Piping Design Guide Fiberglass Reinforced Piping Systemsoscarhdef100% (1)

- Pressure Piping Systems Technical ManualDocument82 pagesPressure Piping Systems Technical ManualNirob MahmudNo ratings yet

- Modern Sewer Design Book For Storm Water SewerDocument348 pagesModern Sewer Design Book For Storm Water Sewersawmag123No ratings yet

- F-6000 Tapered Joint InstallationDocument78 pagesF-6000 Tapered Joint InstallationDavid Luna MolinaNo ratings yet

- 68372617-Concrete-Pipe ÇATLAKLAR PDFDocument64 pages68372617-Concrete-Pipe ÇATLAKLAR PDFözkan DemirNo ratings yet

- NEMA WC-71-1999-icea-71-1999icea-s-96-659-1999Document10 pagesNEMA WC-71-1999-icea-71-1999icea-s-96-659-1999jan carlos martinezNo ratings yet

- Classes of PipesDocument81 pagesClasses of PipesSalley BukhariNo ratings yet

- GRP Pipe Socket JointDocument80 pagesGRP Pipe Socket JointMAGUNAM100% (1)

- Bell & Spigot Hand Book PDFDocument90 pagesBell & Spigot Hand Book PDFkasvikrajNo ratings yet

- 2006 Structural Seismic Design Manual 1Document32 pages2006 Structural Seismic Design Manual 1Julio Rafael Terrones Vásquez100% (1)

- Concrete Pipe Design ManualDocument555 pagesConcrete Pipe Design Manualv100% (5)

- F6000Document90 pagesF6000sandbadbahriNo ratings yet

- Final Report FRC Coupling BeamsDocument120 pagesFinal Report FRC Coupling BeamsHansV.HuamaníCamargoNo ratings yet

- Technical Catalogue For Submarine Installations of Polyethylene PipesDocument84 pagesTechnical Catalogue For Submarine Installations of Polyethylene Pipesvictor salvadorNo ratings yet

- Dokumen - Tips - GRP Pipe Socket JointDocument86 pagesDokumen - Tips - GRP Pipe Socket Jointmai huy tânNo ratings yet

- Wavistrong Engineering GuideDocument86 pagesWavistrong Engineering Guidepiping1522No ratings yet

- Tr-33 Generic Butt Fusion Joining Gas PipeDocument32 pagesTr-33 Generic Butt Fusion Joining Gas PipeLuis QuinoNo ratings yet

- Manual para Tuberia de Doble ContencionDocument98 pagesManual para Tuberia de Doble ContencionPedro RodriguezNo ratings yet

- 014732Document208 pages014732Vitelio PinzonNo ratings yet

- Ansi 9.8 1998 PDFDocument82 pagesAnsi 9.8 1998 PDFProposals PPDNo ratings yet

- Handbook of Polymer-Modified Concrete and Mortars: Properties and Process TechnologyFrom EverandHandbook of Polymer-Modified Concrete and Mortars: Properties and Process TechnologyRating: 5 out of 5 stars5/5 (2)

- CSPI - Handbook of Steel Drainage Highway - Construction - Products 2008 PDFDocument636 pagesCSPI - Handbook of Steel Drainage Highway - Construction - Products 2008 PDFkhalil mamiNo ratings yet

- Engg & Piping Design Guide (FRP Pipe)Document36 pagesEngg & Piping Design Guide (FRP Pipe)karuna346No ratings yet

- Concrete PipeDocument64 pagesConcrete PipeAzvember100% (1)

- Trenchless Applications Installation GuideDocument33 pagesTrenchless Applications Installation GuideItay Bar-LevNo ratings yet

- Fsa HandbookDocument35 pagesFsa Handbookargari19No ratings yet

- HIS For Vertical PumpDocument72 pagesHIS For Vertical PumpVaibhavSharma100% (2)

- Structural Audit of BridgeDocument3 pagesStructural Audit of Bridgesamirbendre10% (1)

- D K Stadium. G.ADocument3 pagesD K Stadium. G.Asamirbendre1No ratings yet

- Design of Plate GirderDocument85 pagesDesign of Plate Girdersamirbendre1100% (2)

- Major Bridge Levels - Mar 01,2019Document13 pagesMajor Bridge Levels - Mar 01,2019samirbendre1No ratings yet

- Preliminary Column SizingDocument2 pagesPreliminary Column Sizingsamirbendre1100% (1)

- Bus WashDocument10 pagesBus Washsamirbendre1No ratings yet

- Ornamental Fishery Shed Estimate1Document1 pageOrnamental Fishery Shed Estimate1samirbendre1No ratings yet

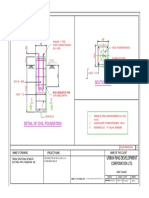

- Electrical Poles Foundation - 3mDocument1 pageElectrical Poles Foundation - 3msamirbendre1100% (1)

- Electrical Poles Foundation - 3mDocument1 pageElectrical Poles Foundation - 3msamirbendre1100% (1)

- VVVMC Ring Road Rob Structural Quantities NalasoparaDocument4 pagesVVVMC Ring Road Rob Structural Quantities Nalasoparasamirbendre1No ratings yet

- Electrical Poles Foundation - 3mDocument1 pageElectrical Poles Foundation - 3msamirbendre1100% (1)

- Electrical Poles Foundation - 3mDocument1 pageElectrical Poles Foundation - 3msamirbendre1100% (1)

- Electrical Poles Foundation - 3mDocument1 pageElectrical Poles Foundation - 3msamirbendre1100% (1)

- PT I Girder Design 20mDocument18 pagesPT I Girder Design 20msamirbendre1No ratings yet

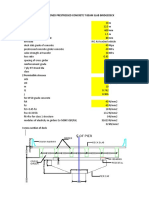

- Design of Class of Pipe As Per Layout of Zone 1Document8 pagesDesign of Class of Pipe As Per Layout of Zone 1samirbendre1No ratings yet

- Tapi River Bridge Cost20022018Document1 pageTapi River Bridge Cost20022018samirbendre1No ratings yet

- Geotech Surat ReportDocument104 pagesGeotech Surat Reportsamirbendre167% (3)

- Cost Summary For Strcutures of 90m - ORR - 17.02.2018Document1 pageCost Summary For Strcutures of 90m - ORR - 17.02.2018samirbendre1No ratings yet

- PT Slab Bridge Deck 20 MDocument8 pagesPT Slab Bridge Deck 20 Msamirbendre1No ratings yet

- GAD - 1 - Major Bridge On Tapi RiverDocument1 pageGAD - 1 - Major Bridge On Tapi Riversamirbendre1No ratings yet

- GAD - 2 - Major Bridge On Tapi RiverDocument1 pageGAD - 2 - Major Bridge On Tapi Riversamirbendre1No ratings yet

- 22-03-2013 19:29:08, Gbanerjee, DWG To PDF - Pc3, Iso Full Bleed A3 (297.00 X 420.00 MM), 1:1.42178, GbaDocument4 pages22-03-2013 19:29:08, Gbanerjee, DWG To PDF - Pc3, Iso Full Bleed A3 (297.00 X 420.00 MM), 1:1.42178, Gbasamirbendre1No ratings yet

- KBMC Sewerage Scheme - Wier Design ReportDocument6 pagesKBMC Sewerage Scheme - Wier Design Reportsamirbendre1No ratings yet

- Water Tank Side Wall 12x6x16Document2 pagesWater Tank Side Wall 12x6x16samirbendre1No ratings yet

- O and MDocument37 pagesO and Msamirbendre1No ratings yet

- Pier Jacketing ReportDocument5 pagesPier Jacketing Reportsamirbendre1100% (1)

- Weir DesignDocument1 pageWeir Designsamirbendre1No ratings yet

- FRP 1Document1 pageFRP 1samirbendre1No ratings yet

- ALCON EstimateDocument2 pagesALCON Estimatesamirbendre1No ratings yet

- Phytorid STPDocument4 pagesPhytorid STPsamirbendre1No ratings yet

- Ultraviolet Flame Detector: Omniguard Model 660Document2 pagesUltraviolet Flame Detector: Omniguard Model 660carlosNo ratings yet

- Burnay, Bushman & Laroi - 2019Document10 pagesBurnay, Bushman & Laroi - 2019TinyjurshNo ratings yet

- Module 1 Inclusive Education Lecture 1 & Introduction - OnlineDocument32 pagesModule 1 Inclusive Education Lecture 1 & Introduction - OnlineSharon ShenNo ratings yet

- Sheet Metal Cutting Using Geneva MechanismDocument27 pagesSheet Metal Cutting Using Geneva MechanismsingamNo ratings yet

- Fuses f150Document7 pagesFuses f150ORLANDONo ratings yet

- TCS3400 DS000411 4-00Document34 pagesTCS3400 DS000411 4-00Miguel_Angel92No ratings yet

- Viva 15jun2008Document347 pagesViva 15jun2008garth.whitakerNo ratings yet

- Propositional LogicDocument41 pagesPropositional LogicMuneeb Javaid100% (1)

- Generic StructureDocument6 pagesGeneric StructureAndre AlvarezNo ratings yet

- Thursday / January 2019 Thursday / January 2019Document572 pagesThursday / January 2019 Thursday / January 2019Zie EikinNo ratings yet

- PCBDocument5 pagesPCBarampandey100% (4)

- Ficha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux LedDocument5 pagesFicha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux Ledluis perdigonNo ratings yet

- Individual Performance Commitment and Review Form (Ipcrf) : Annex EDocument8 pagesIndividual Performance Commitment and Review Form (Ipcrf) : Annex Emenzi magnoNo ratings yet

- PTN Guide Compilation by EmeraldchowDocument24 pagesPTN Guide Compilation by EmeraldchowMirzaNo ratings yet

- Empowerment TechnologyDocument15 pagesEmpowerment Technologysxhan gwenNo ratings yet

- SPECIFIC ENERGY, ENERGY DENSITY OF FUELS and PRIMARY ENERGY SOURCESDocument17 pagesSPECIFIC ENERGY, ENERGY DENSITY OF FUELS and PRIMARY ENERGY SOURCESPranavBalarajuNo ratings yet

- PC Engineering Undergr 2014Document94 pagesPC Engineering Undergr 2014Austin JamesNo ratings yet

- Which Will Weigh The Least Without AnswerDocument7 pagesWhich Will Weigh The Least Without AnswerumeshNo ratings yet

- Module 14-Area ComputationsDocument5 pagesModule 14-Area ComputationsGerovic Parinas50% (2)

- The Aerodynamics of ParachutesDocument78 pagesThe Aerodynamics of Parachutesstevehuppert50% (2)

- Budget of Work Inquiries Investigations and Immersion 19 20Document1 pageBudget of Work Inquiries Investigations and Immersion 19 20alma florNo ratings yet

- Analisa AgriculturalDocument6 pagesAnalisa AgriculturalFEBRINA SARLINDA, STNo ratings yet

- Advanced Office Add-In DevelopmentDocument40 pagesAdvanced Office Add-In DevelopmentReadoneNo ratings yet

- Delonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Document21 pagesDelonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Luis AlbertoAlmeidaSilva100% (1)

- Hilfswerk Wien-Salzburg - 11. Meio 2018Document9 pagesHilfswerk Wien-Salzburg - 11. Meio 2018FreieEnergieNo ratings yet

- Lab Report 1Document23 pagesLab Report 1hadri arif0% (1)

- 1506a E88tag3 PDFDocument5 pages1506a E88tag3 PDFmohammad javad golNo ratings yet

- 50+ MATLAB Projects For Engineering StudentsDocument5 pages50+ MATLAB Projects For Engineering StudentsaamyaNo ratings yet

- PUP 200 Quizzes 6Document47 pagesPUP 200 Quizzes 6Nam TranNo ratings yet

- Fire Alarm SymbolsDocument6 pagesFire Alarm Symbolscarlos vasquezNo ratings yet