Professional Documents

Culture Documents

ACFrOgCHIjqeoQQIJ8eqdI7l8XMyJSzb1Wm v77urE8SxY5Ix0K0L31BNIr5QhvdCuusiAvbA7Ku54z-xSpUV7dWF yHE-sPlJPTPRVk9W1M5GvEfhqj qunY0RAvxM PDF

Uploaded by

Abdikarim ObahleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACFrOgCHIjqeoQQIJ8eqdI7l8XMyJSzb1Wm v77urE8SxY5Ix0K0L31BNIr5QhvdCuusiAvbA7Ku54z-xSpUV7dWF yHE-sPlJPTPRVk9W1M5GvEfhqj qunY0RAvxM PDF

Uploaded by

Abdikarim ObahleCopyright:

Available Formats

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

STUDENTCODEOFETHIC

(SCE)

DEPARTMENTOFGEOTECHNICALAND

TRANSPORTATIONENGINEERING

FACULTYOFCIVIL&ENVIRONMENTAL

ENGINEERING

UTHM

I,herebyconfessthatIhavepreparedthisreportonmyowneffort.Ialsoadmitnotto

receiveorgiveanyhelpduringthepreparationofthisreportandpledgethat

everythingmentionedinthereportistrue.

___________________________

StudentSignature

Name:MOHDFARISBINABDULLRAHIM

MatricNo.:DF090099

Date:17MARCH2011

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

STUDENTCODEOFETHIC

(SCE)

DEPARTMENTOFGEOTECHNICALAND

TRANSPORTATIONENGINEERING

FACULTYOFCIVIL&ENVIRONMENTAL

ENGINEERING

UTHM

I,herebyconfessthatIhavepreparedthisreportonmyowneffort.Ialsoadmitnotto

receiveorgiveanyhelpduringthepreparationofthisreportandpledgethat

everythingmentionedinthereportistrue.

___________________________

StudentSignature

Name:MOHAMADNORHAFIZULBINMOHDARIF

MatricNo.:DF090157

Date:17MARCH2011

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

STUDENTCODEOFETHIC

(SCE)

DEPARTMENTOFGEOTECHNICALAND

TRANSPORTATIONENGINEERING

FACULTYOFCIVIL&ENVIRONMENTAL

ENGINEERING

UTHM

I,herebyconfessthatIhavepreparedthisreportonmyowneffort.Ialsoadmitnotto

receiveorgiveanyhelpduringthepreparationofthisreportandpledgethat

everythingmentionedinthereportistrue.

___________________________

StudentSignature

Name:MOHAMADFADZLIBINMOHDSARIB

MatricNo.:DF090099

Date:17MARCH2011

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

STUDENTCODEOFETHIC

(SCE)

DEPARTMENTOFGEOTECHNICALAND

TRANSPORTATIONENGINEERING

FACULTYOFCIVIL&ENVIRONMENTAL

ENGINEERING

UTHM

I,herebyconfessthatIhavepreparedthisreportonmyowneffort.Ialsoadmitnotto

receiveorgiveanyhelpduringthepreparationofthisreportandpledgethat

everythingmentionedinthereportistrue.

___________________________

StudentSignature

Name:NURATIQAHBINTIAHMADKAMARUDIN

MatricNo.:AF080242

Date:17MARCH2011

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

STUDENTCODEOFETHIC

(SCE)

DEPARTMENTOFGEOTECHNICALAND

TRANSPORTATIONENGINEERING

FACULTYOFCIVIL&ENVIRONMENTAL

ENGINEERING

UTHM

I,herebyconfessthatIhavepreparedthisreportonmyowneffort.Ialsoadmitnotto

receiveorgiveanyhelpduringthepreparationofthisreportandpledgethat

everythingmentionedinthereportistrue.

___________________________

StudentSignature

Name:NURFADILAHBINTIKAMALUDIN

MatricNo.:AF080203

Date:17MARCH2011

ALLMEMBERPERSONALPROFILE

5

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

MOHDFARISBINABDULLRAHIM

DF090071

MOHAMADNORHAFIZULBINMOHDARIF

DF090157

MOHAMADFADZLIBINMOHDSARIB

DF090099

NURFADILAHBINTIKAMALUDIN

AF080203

NURATIQAHBINTIAHMADKAMARUDIN

AF080242

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

CONTENT

1.0 INTRODUCTION

01

2.0 OBJECTIVE

02

3.0 APPARATUS

02

4.0 PROCEDURE

04

5.0 RESULTANDDATAANALYSIS

06

6.0 DISCUSSION

13

7.0 CONCLUSION

14

8.0 REFERENCES

14

9.0 APPENDIX

15

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

TITLE:CALIFORNIABEARINGRATIOTEST

________________________________________________________________________

1.0

INTRODUCTION

The California Bearing Ratio (CBR) was developed by California division of

highways as a method of classifying and evaluating soilsubgrade and base

course materials for flexible pavements. The CBR test is currently used in

pavementdesignforbothroadsandairfieldpavement.InsomemethodsCBRis

used directly and in some others it is converted to Resilient Modulus MR using

thefollowingrelationshipsareMR=1500xCBR(ibs/in2),MR=10340xCBR

(Kpa)

The laboratory CBR test measures the shearing resistance of a crushed

aggregate/soil under controlled moisture and density conditions. The test yields

bearing ratio number that is applicable for the state of crushed aggregate/soil as

tested. The CBR is obtained as the ratio of the unit stress required of effect a

certaindepthofpenetrationofthepiston(1935mm)intoacompactedspecimen

of crushed aggregate/soil at some water content and density to the standard unit

stress required to obtain the same depth of penetration on a standard sample of

crushedstone.Thus.CBR=**100TheCBRisusuallybaseontheloadratiofor

thepenetrationof25mm.IftheCBRvalueatthepenetrationof5.0mmislarger,

the test should be repeated. If a second test yields a larger value of CBR at 5.0

mmpenetrationthenthislargervalueshouldbeadopted.TheCBRtestareusually

made on test specimens at optimum moisture content (OMC) for the crushed

aggregate/soilasdeterminedfrommodifiedcompactiontest.

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

CBRisusedtoratetheperformancesofsoilsusedasbasesandsubgrade.The

followingtablegivestypicalrating:

2.0

CBR

GENERALRATING

USES

0.3

Verypoor

Subgrade

37

Poortofair

Subgrade

720

Fair

Subbase

2050

Good

Baseofsubbase

>50

Excellence

Base

OBJECTIVE

TodeterminetheCBRvalueofthegivencrushedaggregate/soilsample.

3.0

APPARATUS

3.1

CBRequipmentconsistingof152.4mmdiameterand178mmheight,An

extension collar of a diameter 51 mm, spacer disk of 150.8mm diameter

and61.4mmheight.

3.2

Mechanicalcompactionrammer50.8mmdie,2.49kgandcapableoffree

fallof305mm.

3.3

Surchargeweighttosimulatetheeffectofoverlayingpavementweight.

3.4

CBR machine: A compression machine, which can operate at a constant

rateof1.3mm/min.Ametalpistonof1935mm2isattachedtoit.

Mechanical

compaction

rammer

Gaugereader

9

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

Surchargeweight

Cbrmould

Clampingand

baseplateof

CBRmould

Rodplat

10

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

4.0

PROCEDURE

1. CBR equipment consisting of 152.4 mm

diameterand178mmheight,Anextension

collar of diameter 51 mm, spacer disk of

150.8mmdiameterand61.4mmheight.

2. Mechanical compaction rammer 50.8 mm

die,2.49kgandcapableoffreefallof305

mm.

2. The representative crushed aggregate/soil

sample is sieved through 20 mm sieve.

About 5kg of crushed aggregate/soil is

taken and mixed with optimum moisture

content(OMC).

11

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

2. Compact the aggregate /soil water mixture into

the world in 3 equal layers to give a height of

127mmcompacteachlayerinthe10blows,30

blowsand65blowsforeachsample.

2. Place the mold with crushed aggregate/soil on

the CBR machine and place the surcharge

weight .seat the penetration piston, set the dial

gaugesforloadandpenetration.

2. Determine the water content of the

crushedaggregate/soilmixture.

12

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

5.0

RESULTANDANALYSISDATA

CBR:Plottheloaddeformationcurveforeachspecimen.Insomecasestheinitial

penetration takes place without a proportional increase in the resistance to

penetration and the curve may be concave upward. To obtain the true stressstrain

relationships, correct the curve having concave upward shape near the origin by

adjustingthelocationoftheoriginbyextendingthestraighttheportionofthestress

straincurvedownwarduntilitintersectswithxaxis.

Determinethecorrectedloadvaluesat2.5mmand5.0mmanddeterminetheCBR

bythefollowingrelationship.

Standardloadat2.5mmistaken13.2kNandat5.0mmitison20kN

DryDensity:

Weightoftheemptymold

=Agm

Weightofthemold+soil

=Bgm

Volumeofsoilsample

=V

Weightdensity

WaterContentw

DryDensity

PlottheCBRvsDrydensityanddeterminetheCBRat95%ofmaximumdrydensity

andrepeatthisvalueofCBR.

CBRTESTPENETRATIONDATA

Load

13

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

Sample1

Penetration

Sample2

Sample3

(mm)

Div.

Corrected

Div.

Corrected

Div.

Corrected

0.0

0.00

0.00

0.00

0.5

0.00

0.00

0.13

1.0

0.00

0.00

18

0.80

1.5

21

0.93

0.22

38

1.69

2.0

45

2.00

33

1.47

61

2.71

2.5

65

2.89

70

3.12

97

4.32

3.0

83

3.69

108

4.81

142

6.32

3.5

100

4.45

146

6.50

198

8.81

4.0

117

5.21

187

8.32

269

11.97

4.5

133

5.92

234

10.41

335

14.91

5.0

149

6.63

272

12.10

400

17.80

5.5

162

7.21

309

13.75

468

20.83

6.0

175

7.79

345

15.35

545

24.25

EXAMPLEOFCALCULATION

Usesample1,penetration1.5

Corrected

=0.0445dialgauge

=0.044521

=0.93

*Calculationforsample2andsample3issameasabove

GraphLoad(kN)versusPenetration(mm)hasbeenplottedinappendix.

DATASHEET(CBRTEST)

14

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

TypeoftheTest:Soaked/Unsoaked

OMCDate:17/03/2011

OMC:5.0% max:2151kg/cm3

Sample

No.ofBlows

10

30

65

Emptywt.ofmould,W1(g)

16726

16839

16707

Wtofmould+wetsample,W2(g)

21210

21582.0

21544

Volumeofsample,V(cm3)

2127

2127

2127

Wetdensity=(W2W1)/V(g/cm3)

2.108

2.230

2.274

10

30

65

Wt.ofemptycan,A(g)

10.10

17.00

9.80

Wt.ofcan+wetsample,B(g)

110.10

117.00

109.80

Wt.ofcan+drysample,C(g)

104.60

111.70

104.80

Watercontent,W%=[(BC)/(CA)]*100

5.82

5.60

5.26

DryDensity,=/(1+W)(g/cm3)

1.992

2.112

2.160

Canno.

GraphDryDensity(g/cm3)versusMoistureContent(%)hasbeenplottedinappendix.

EXAMPLEOFCALCULATION

15

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

Sample1(10blows)

WeightofMould,W1

=16726g

WeightofMould+wetsample,W2

=21210g

Volume,V

=j2t

=x7.622x11.66

=2127cm3

Wetdensity,

Weightofcan,A

=10.10g

Weightofcan+wetsample,B

=110.10g

Weightofcan+drysample,C

=104.60g

Watercontent,W

DryDensity,d

Sample2(30blows)

WeightofMould,W1

=16839g

WeightofMould+wetsample,W2

=21582g

Volume,V

=j2t

=x7.622x11.66

=2127cm3

Wetdensity,

Weightofcan,A

=17.00g

Weightofcan+wetsample,B

=117.00g

Weightofcan+drysample,C

=111.70g

Watercontent,W

16

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

DryDensity,d

Sample3(65blows)

WeightofMould,W1

=16707g

WeightofMould+wetsample,W2

=21544g

Volume,V

=j2t

=x7.622x11.66

=2127cm3

Wetdensity,

Weightofcan,A

=9.80g

Weightofcan+wetsample,B

=109.80g

Weightofcan+drysample,C

=104.80g

Watercontent,W

DryDensity,d

SummaryofTestResults

Sample

No.

1

No.of

Blows

(gm/cm3)

CBR2.5(%)

CBR5.0(%)

10

1.992

21.89

33.15

30

2.112

23.64

60.50

17

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

65

2.160

32.73

89.00

CBRat0.95max:100%

ThegraphDryDensity(g/cm3)versusCBR(%)hasbeenplottedasshowninappendix.

EXAMPLEOFCALCULATION

Usesampleno.1

CBR2.5=penetrationdatax100

13.2

=2.89x100

13.2

=21.89

CBR5.0=penetrationdatax100

20

=6.63x100

20

=33.15

*Calculationforsample2andsample3issameasabove

Refergraph,

Optimummoisturecontent=5.33%

Maxdrydensity=2.160gm/cm3

CBRat0.95dmax=45%(baseofsubbase)

6.0

DISCUSSION

TheCaliforniaBearingRatioiscarriedouttodeterminetheCBRvalueof

the given crushed aggregate or soil sample. The value of the experiment is

comparedwiththestandardvalueofCBR.

18

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

IntheCBRtest,thesampleisseparatedinto3typeswhichconsistof10

blows, 30 blows and 65 blows. Every sample is compacted to 3 layers for each

blow.

The compacted soil will be tested with the depth of penetration of the metal

piston.Thevalueofpenetrationisrecordedintothetable.Thecompactionthatis

carriedoutcausesthesoiltobecomemorecompact.

Fromthegraphload(kN)versuspenetration(mm)thatisbeenplotted,the

value of the corrected load at 2.5mm and 5.0mm is obtained. The CBR2.5 and

CBR5.0valueforsample1is21.89%and33.15%,sample2is23.64%and60.50%

andsample3is32.73%and89.00%.Accordingtotheresult,sample3issoilwith

goodcompactionthatgivesahighervalueofCBR.

ThegraphofCBRversusDrydensityhasbeenplottedasappendicesand

wehavedeterminedthevalueofCBRat0.95drydensitymaximumis45%.This

showsthatthesampleissuitable(good)tobeusedasthebaseofsubbaselayer

becausethevalueisbetween2050%.

Precautions

Cleantheholesofthebaseplateandthatofperforateddiscthoroughly.

Alignthesurchargeweightwiththeplungersothattheplungerpenetratesfreely

intothesoil.

7.0

CONCLUSSION

The objective of this experiment is to determine the California Bearing

Ratio(CBR)valueofthegivencrushedaggregateorsoilsample.TheCBRtest

19

BFC3121Geotechnical&TransportationLab(CBRtest)

Group5(Section7)

areveryimportanttesttomakesureofpavementdesignfulfilltherequirementso

thatitnotfailureinourdesigntimelater.

Fromthisexperiment,thevalueofCBRisusedforroadpavementdesign.

Itincludesthethicknessofthepavementlayer.

There are 4 graphs plotted. Pavement layer functions to support and

separate load from vehicles. So, CBR is important in design to make sure the

recordisabletosupport.

We can conclude that our experiment is successful. It is because the

aggregate value of CBR is 95%, more than 50%, which is excellent in general

rating.Itcanbeuseasroadbaseandsubbaselayer.Byusingthisaggregatefor

roadconstruction,itissafeforvehiclesbecausehasagoodstrength.

8.1

REFERENCES

8.2 Trafficengineeringandsafety,BFC2082,UniversitiTunHusseinOnnMalaysia

8.3 Nicholars J. Garber; Lester A.Hoel; Traffic & Highway Engineering (3rd Edition),

UniversityofVirginia,1995.

8.4 Paul H.wright & Radnor J.Paquette; Higway Engineering (5th Edition), Georgia

InstituteofTechnology,1979.

8.5 BentTagesen;HighwayEngineering&Traffic(1stEdition),TechnicalUniversityof

Denmark.

8.6 www.wikipedia.com

9.0

APPENDIX

CBRequipment

20

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Cover ReportDocument2 pagesCover ReportkhairulazharkNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- BS en 1377-1997 - (2014-11-26 - 03-14-20 PM)Document12 pagesBS en 1377-1997 - (2014-11-26 - 03-14-20 PM)Abdikarim ObahleNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Model For Appraising The Sustainability of BridgesDocument8 pagesA Model For Appraising The Sustainability of BridgesAbdikarim ObahleNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Maths4 Tuturial7Document8 pagesMaths4 Tuturial7Abdikarim ObahleNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Power Experiment 3Document7 pagesPower Experiment 3Abdikarim ObahleNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Maintain Safe Systems with Maintenance Free EarthingDocument12 pagesMaintain Safe Systems with Maintenance Free EarthingRavi Shankar ChakravortyNo ratings yet

- (Advances in Biochemical Engineering - Biotechnology 119) Takayuki Nishizaka (Auth.), Isao Endo, Teruyuki Nagamune (Eds.) - Nano - Micro Biotechnology (2010, Springer-Verlag Berlin Heidelberg) PDFDocument271 pages(Advances in Biochemical Engineering - Biotechnology 119) Takayuki Nishizaka (Auth.), Isao Endo, Teruyuki Nagamune (Eds.) - Nano - Micro Biotechnology (2010, Springer-Verlag Berlin Heidelberg) PDFAlejandra EscalonaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Automatic Temperature Controlled FanDocument27 pagesAutomatic Temperature Controlled Fankannan100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Dmr-Es10Eb Dmr-Es10Ec Dmr-Es10Eg Dmr-Es10Ep Dmr-Es10Ebl: DVD Video RecorderDocument71 pagesDmr-Es10Eb Dmr-Es10Ec Dmr-Es10Eg Dmr-Es10Ep Dmr-Es10Ebl: DVD Video RecorderWILIAM RODRIGUEZNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Assignment 5 - AirportDocument2 pagesAssignment 5 - AirportSaroj AcharyaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- DMCR Protection Relay For Oil TransformerDocument9 pagesDMCR Protection Relay For Oil TransformerDawn HernandezNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- AEON BINH DUONG CANARY - CONSTRUCTION SCHEDULE 2014Document5 pagesAEON BINH DUONG CANARY - CONSTRUCTION SCHEDULE 2014LantNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- C# Abstract Classes and Interfaces ExplainedDocument20 pagesC# Abstract Classes and Interfaces ExplainedshubhamNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Samsung ML-1710 Recarga PDFDocument6 pagesSamsung ML-1710 Recarga PDFarkittoNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- ASTM E164 2019 Standard Practice For Contact Ultrasonic TestingDocument24 pagesASTM E164 2019 Standard Practice For Contact Ultrasonic TestingCesar RodriguezNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ATAL FDP On The Role of Materials in Electric Vehicles Workshop - ReportDocument12 pagesATAL FDP On The Role of Materials in Electric Vehicles Workshop - ReportPuneet Mohan SharmaNo ratings yet

- Codigos Ford Escape ReneDocument1 pageCodigos Ford Escape ReneKandy KnNo ratings yet

- ANA Cordon and Search TTP DeliverableDocument33 pagesANA Cordon and Search TTP DeliverablejpgvenancioNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- TNEB vacancy cut-off datesDocument7 pagesTNEB vacancy cut-off dateswinvenuNo ratings yet

- Igv Check Sheets: Maintenance Department Dr2 - Instrumentation Date: Shift: Shift in ChargeDocument12 pagesIgv Check Sheets: Maintenance Department Dr2 - Instrumentation Date: Shift: Shift in Chargesangeeth85No ratings yet

- Glossary of Heat Exchanger TerminologyDocument2 pagesGlossary of Heat Exchanger Terminologypvwander100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MiVoice Office 400 Products BR enDocument12 pagesMiVoice Office 400 Products BR enWalter MejiaNo ratings yet

- Ligaya NG Buhay EnsembleDocument2 pagesLigaya NG Buhay EnsembleFrinzess VelascoNo ratings yet

- Elizabeth Hokanson - Resume - DB EditDocument2 pagesElizabeth Hokanson - Resume - DB EditDouglNo ratings yet

- Star Burst EffectDocument22 pagesStar Burst EffectDexter AlcantaraNo ratings yet

- Steam Condensate Pot SizingDocument1 pageSteam Condensate Pot SizingSaeid Rahimi MofradNo ratings yet

- Vietnam ProjosDocument271 pagesVietnam Projosjbart252No ratings yet

- Data FNC BatteriesDocument20 pagesData FNC BatteriessalmanahmedmemonNo ratings yet

- Is 9459Document13 pagesIs 9459Anonymous mcHqIfbnV1No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Slice 3 Choice BoardDocument3 pagesSlice 3 Choice Boardapi-463991923No ratings yet

- Medium Voltage Surge Arresters Catalog HG 31.1 2017 Low Resolution PDFDocument79 pagesMedium Voltage Surge Arresters Catalog HG 31.1 2017 Low Resolution PDFAnkur_soniNo ratings yet

- Ideal Institute of Engineering: Industrial RoboticsDocument10 pagesIdeal Institute of Engineering: Industrial RoboticsSoumik DasNo ratings yet

- Group 6 - Chapter 1 RevisedDocument15 pagesGroup 6 - Chapter 1 RevisedJAMES ELIJAH BALDERRAMANo ratings yet

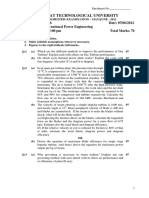

- GTU BE- Vth SEMESTER Power Engineering ExamDocument2 pagesGTU BE- Vth SEMESTER Power Engineering ExamBHARAT parmarNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)