Professional Documents

Culture Documents

MasterKure 106 (Masterkure 106) - ZA

Uploaded by

Kiran ReddyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MasterKure 106 (Masterkure 106) - ZA

Uploaded by

Kiran ReddyCopyright:

Available Formats

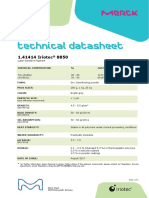

MasterKure 106

(Formerly known as Masterkure 106)

Wax based concrete curing compound / bond breaker

DESCRIPTION

MasterKure 106 is a solvent free, membrane

forming wax emulsion, suitable for spray

application to freshly poured concrete.

The resultant film retains sufficient moisture in the

concrete to ensure full hydration of the cement;

essential for optimum strength development.

Membrane cured concrete is typically harder and

exhibits a dust free surface with a reduced

incidence of drying shrinkage cracks.

The film can also act as a bond breaker between

initial and subsequent concrete pours.

PRIMARY USES

As a more effective and economical alternative to

hessian and water and polythene curing regimes.

Suitable for use on all concrete surfaces.

As a bond breaking film for the vertical face of

precast bridge segments during match casting.

ADVANTAGES

Eliminates the need for water.

Single application.

Promotes a harder dust free surface.

Cured film is clear and water repellent.

Reduces drying shrinkage.

High curing efficiency.

Reduced labour costs.

Water based.

PACKAGING

MasterKure 106 is available in 25 litre or 200

litre drums.

STANDARDS

ASTM C309 Type 1 Class A

AASHTO M-148 Type 1 Class A

DIRECTIONS FOR USE AS A CURING

COMPOUND

The compound should be spray applied as evenly

as possible on to the freshly placed concrete.

For horizontal surfaces MasterKure 106 should

be applied as soon as the initial surface sheen

has disappeared from the concrete surface. In

the case of formed concrete, the MasterKure

106 should be applied immediately on removal of

the formwork. To assist breakdown of the

MasterKure 106 film on vertical and formed

surfaces, it is essential to dampen down the

concrete with clean water prior to application.

DIRECTIONS FOR USE AS A BOND BREAKER

The compound should be spray applied to form an

even film covering the entire surface against which

the subsequent segment will be cast.

If necessary more than one coat should be

applied. The actual coverage and number of coats

will be dependent on texture and porosity of the

surface. The recommended application rate when

used as a bond breaker is 4 square meters per

litre.

COVERAGE

The recommended rate of application is 5-6

square metres per litre. This corresponds to that

at which MasterKure 106 has been tested, and

at which it attains the claimed degree of curing

efficiency. In favourable conditions such as

shaded interior surfaces, adequate curing can be

achieved with extended coverage rates.

TYPICAL PROPERTIES

Appearance:

Specific gravity:

Flashpoint:

Finish appearance:

Water retention

ASTM C156:

Drying time

ASTM C309:

White liquid

1.00

Not applicable

Clear; tack free

water repellent film

Pass

FILM BREAKDOWN

The time for deterioration of the membrane is

dependent on a number of variables, which

include film thickness, degree of exposure to

weathering, traffic, UV light, and the porosity of the

substrate concrete.

Less than 4 hours

MasterKure 106

(Formerly known as Masterkure 106)

SUBSEQUENT SURFACE FINISHES

It is important that the complete removal of the

MasterKure 106 should be ensured prior to the

application of any surface finish or additional

treatment. It is recommended that where the

concrete is to receive a coating or the application

of tiles, the use of MasterKure 106 is considered.

MasterKure 106 is a resin based non-degrading

curing membrane meeting the requirements of

ASTM C-309 Type 1 Class B. It is additionally

formulated to act as a primer for many finishes or

to seal concrete surfaces and provide a degree of

abrasion to flatwork.

SPECIFICATION CLAUSE

Where indicated, concrete shall be cured by

application of MasterKure 106,

membrane

forming wax emulsion manufactured by BASF or

similar approved; to the following specification:

Specification type:

ASTM C309: Type 1 Class A

AASHTO M-148

NOTE

Field service, where provided, does not constitute

supervisory responsibility. For additional

information contact your local BASF

representative.

BASF reserves the right to have the true cause of

any difficulty determined by accepted test

methods.

QUALITY AND CARE

All products originating from BASF Construction

Chemicals South Africa are manufactured under a

management system independently certified to

conform to the requirements of the quality,

environmental and occupational health & safety

standards ISO 9001, 2008.

* Properties listed are based on laboratory controlled tests.

= Registered trademark of the BASF-Group in many countries.

MasterKure 106 is to be applied at a coverage

rate of 5 to 6 square metres per litre and strictly in

accordance with the manufacturers instructions.

STORAGE

Shelf life is up to 6 months when stored under

cover, out of direct sunlight and protected from

extremes of temperature.

HEALTH AND SAFETY

As with all chemical products, care should be

taken during use and storage to avoid contact with

eyes, mouth, skin and foodstuffs. Treat splashes

to eyes and skin immediately. If accidentally

ingested, seek medical attention. Reseal

containers after use. Use in well ventilated areas

and avoid inhalation.

The technical information and application advice given in this BASF publication are based on the present state of

STATEMENT OF our best scientific and practical knowledge. As the information herein is of a general nature, no assumption can be

RESPONSIBILITY made as to a product's suitability for a particular use or application and no warranty as to its accuracy, reliability or

completeness either expressed or implied is given other than those required by law. The user is responsible for

checking the suitability of products for their intended use.

NOTE

Field service where provided does not constitute supervisory responsibility. Suggestions made by

BASF either orally or in writing may be followed, modified or rejected by the owner, engineer or contractor since

they, and not BASF, are responsible for carrying out procedures appropriate to a specific application.

BASF Construction Chemicals South Africa (Pty) Ltd

852 Sixteenth Road, Midrand

PO Box 2803, Halfway House, 1685

Tel: +27 11 203 2405

Fax: +27 11 203 2679

www.master-builders-solutions.basf.co.za

You might also like

- TDS - Masterkure 107Document2 pagesTDS - Masterkure 107Venkata Rao100% (1)

- TDS - Masterseal 410Document2 pagesTDS - Masterseal 410Venkata RaoNo ratings yet

- TDS - Masterkure 106Document2 pagesTDS - Masterkure 106Venkata RaoNo ratings yet

- Expancure 90Document3 pagesExpancure 90Amar Wadood KhanNo ratings yet

- Sign Installation Method Statement Risk Assessment PDFDocument21 pagesSign Installation Method Statement Risk Assessment PDFAbdirhman YusufNo ratings yet

- Aggregate: Aggregate Is NOT Just An "Inert Filler" Sources of Natural AggregateDocument8 pagesAggregate: Aggregate Is NOT Just An "Inert Filler" Sources of Natural AggregateSumit SrivastavaNo ratings yet

- Lecture 10-Hot & Cold Weather ConcretingDocument13 pagesLecture 10-Hot & Cold Weather ConcretingSyed Azmat Ali ShahNo ratings yet

- QA - QC Engineer - Hill International, Inc. - LinkedIn PDFDocument3 pagesQA - QC Engineer - Hill International, Inc. - LinkedIn PDFAbdul-Azim OntokNo ratings yet

- SEOT JSA For Installation of Project Sign BoardDocument3 pagesSEOT JSA For Installation of Project Sign BoardArchana SoorajNo ratings yet

- What Is ISO 31000Document3 pagesWhat Is ISO 31000Kaushal SutariaNo ratings yet

- Self Compacting ConcreteDocument13 pagesSelf Compacting ConcreteShiv.Dayal BhartiNo ratings yet

- TDS Concure WB IndiaDocument2 pagesTDS Concure WB IndiaipoNo ratings yet

- Design and Application of Self Compacting ConcreteDocument38 pagesDesign and Application of Self Compacting ConcreteAby AnjaliseNo ratings yet

- Aci 10 - 08Document62 pagesAci 10 - 08maNo ratings yet

- Chemcure WPDocument2 pagesChemcure WPICPL-RWPNo ratings yet

- 214 JetCureDocument2 pages214 JetCureNSunNo ratings yet

- Self Compacting ConcreteDocument18 pagesSelf Compacting ConcreteKannan KandappanNo ratings yet

- Nitocote EN901Document4 pagesNitocote EN901ArieIndrawanNo ratings yet

- Common Defects in Concrete Form Work SystemsDocument4 pagesCommon Defects in Concrete Form Work Systemsvenkateswara rao pothinaNo ratings yet

- Masterkure 128: Polymeric Emulsion Based, Concrete Curing CompoundDocument2 pagesMasterkure 128: Polymeric Emulsion Based, Concrete Curing CompoundDoby YuniardiNo ratings yet

- Method For Installation of PEHD ManholesDocument14 pagesMethod For Installation of PEHD ManholesPipeline EngineerNo ratings yet

- Aci 318R-14Document36 pagesAci 318R-14JibonGhoshPritomNo ratings yet

- Previews ACI 314R 11 PreDocument6 pagesPreviews ACI 314R 11 PreTavio TavioTavio0% (1)

- Gradation FormatDocument15 pagesGradation Formatajit karandikarNo ratings yet

- Percent Air Voids in Compacted Dense and Open Asphalt MixturesDocument4 pagesPercent Air Voids in Compacted Dense and Open Asphalt MixturesAhmad KhreisatNo ratings yet

- Method of Statement For Hollowness RepairDocument3 pagesMethod of Statement For Hollowness RepairSumedhaSampath0% (1)

- SCC Guide: Self-Compacting Concrete Mix Design and PropertiesDocument27 pagesSCC Guide: Self-Compacting Concrete Mix Design and PropertiesAbsiye Aden0% (1)

- Concrete Curing CompoundDocument6 pagesConcrete Curing CompoundEngr AhmadNo ratings yet

- International Sieve Chart ComparisonDocument1 pageInternational Sieve Chart ComparisonSimanchal KarNo ratings yet

- ACI 304.6R-91 Guide For The Use of Volumetric-MeasuringDocument14 pagesACI 304.6R-91 Guide For The Use of Volumetric-MeasuringMihai BanateanuNo ratings yet

- MasterSeal 610Document2 pagesMasterSeal 610Gavriel NgNo ratings yet

- Curing Concrete 2013 0Document2 pagesCuring Concrete 2013 0ThobiasNo ratings yet

- (UJS-CON-E-30029 V0) MS For Concreting WorksDocument7 pages(UJS-CON-E-30029 V0) MS For Concreting WorksSiegfred RaccaNo ratings yet

- ShotcreteDocument39 pagesShotcreteLloyd R. Ponce50% (2)

- Causes of Defects in Concrete StructuresDocument3 pagesCauses of Defects in Concrete StructuresSyed Mohd MehdiNo ratings yet

- Materials TestingDocument391 pagesMaterials TestingChristopher Gibbs50% (2)

- Customer Satisfaction SurveyDocument2 pagesCustomer Satisfaction SurveyAnindam BanerjeeNo ratings yet

- ETABS Software Verifies Reinforced Concrete Beam DesignDocument5 pagesETABS Software Verifies Reinforced Concrete Beam DesignVILCANo ratings yet

- Essential Concrete Curing MethodsDocument4 pagesEssential Concrete Curing MethodsrmdarisaNo ratings yet

- MBS - BASF - Flooring ProductsDocument2 pagesMBS - BASF - Flooring ProductsPrayogo Ibnu WicaksonoNo ratings yet

- Türk Standardi: TS EN 933-4Document13 pagesTürk Standardi: TS EN 933-4end_muhNo ratings yet

- ANGELIQUE INTERNATIONAL LTD MIX DESIGN CALCULATIONDocument10 pagesANGELIQUE INTERNATIONAL LTD MIX DESIGN CALCULATIONChetan SohalNo ratings yet

- SCC Guideline MixDesign May 2008 ISBN 87 7756 769 2Document22 pagesSCC Guideline MixDesign May 2008 ISBN 87 7756 769 2Hafidh Mulyadi Hst100% (1)

- Hot Weather ConcretingDocument21 pagesHot Weather ConcretingDr Yousif HummaidaNo ratings yet

- Pasal Penting CRSI - Technical Note For Field Inspection-Pages-1,3Document2 pagesPasal Penting CRSI - Technical Note For Field Inspection-Pages-1,3Anonymous OA6TwORv3No ratings yet

- Wa0001 PDFDocument26 pagesWa0001 PDFAnonymous 5uPEDI6No ratings yet

- William Edwards DemingDocument21 pagesWilliam Edwards DemingmasahinNo ratings yet

- Proper Use of The Rebound Hammer Updated To Reflect The Changes To ASTM C805Document6 pagesProper Use of The Rebound Hammer Updated To Reflect The Changes To ASTM C805Niroshan PereraNo ratings yet

- Method of Statement (Concrete Repair)Document3 pagesMethod of Statement (Concrete Repair)Sa3id HassanNo ratings yet

- Curing ConcreteDocument8 pagesCuring ConcreteJay AquinoNo ratings yet

- Causes and Solutions of Cracks in BuildingsDocument9 pagesCauses and Solutions of Cracks in Buildingsmohamad arifuddin bin mohdNo ratings yet

- DR Fixit Powder WaterproofDocument2 pagesDR Fixit Powder Waterprooflokeshras12No ratings yet

- Masterkure 106 TdsDocument2 pagesMasterkure 106 TdsEmre ErdoğanNo ratings yet

- Curing Compound MasterKure 106JDocument2 pagesCuring Compound MasterKure 106JMebepure GazeNo ratings yet

- Master Kure 181Document2 pagesMaster Kure 181aahtagoNo ratings yet

- Basf Masterkure 107 Tds PDFDocument2 pagesBasf Masterkure 107 Tds PDFHaseeb ShadNo ratings yet

- masterkure_106j_tdsDocument2 pagesmasterkure_106j_tdsmh8188339No ratings yet

- Masterkure 181: Description Typical PropertiesDocument2 pagesMasterkure 181: Description Typical PropertiesMg Lu HlaNo ratings yet

- Masterkure 107: Water Based Concrete Curing Compound, White Pigmented For Solar ReflectanceDocument2 pagesMasterkure 107: Water Based Concrete Curing Compound, White Pigmented For Solar ReflectanceNidDouNo ratings yet

- Masterkure 181Document3 pagesMasterkure 181Haresh BhavnaniNo ratings yet

- MasterRheobuild 1122AP AF28715Document1 pageMasterRheobuild 1122AP AF28715Kiran ReddyNo ratings yet

- Manufacturer test certificate for GI metal productsDocument1 pageManufacturer test certificate for GI metal productsKiran ReddyNo ratings yet

- Gypsum Plaster Testing LetterDocument1 pageGypsum Plaster Testing LetterKiran ReddyNo ratings yet

- RS ReportDocument1 pageRS ReportKiran ReddyNo ratings yet

- 4885-4889 Testing of Conrete CubesDocument3 pages4885-4889 Testing of Conrete CubesKiran ReddyNo ratings yet

- Rural Urban 2011Document17 pagesRural Urban 2011Kiran ReddyNo ratings yet

- A.dimension and Surface Quality Tests To Be Performed On TilesDocument1 pageA.dimension and Surface Quality Tests To Be Performed On TilesKiran ReddyNo ratings yet

- Cash DepartmentDocument3 pagesCash DepartmentKiran ReddyNo ratings yet

- 9013Document14 pages9013Sujoy RoyNo ratings yet

- Test Results for 53 Grade CementDocument1 pageTest Results for 53 Grade CementKiran Reddy86% (7)

- Daily Bulk Receipt Master File As On 09 08 2013Document538 pagesDaily Bulk Receipt Master File As On 09 08 2013Kiran ReddyNo ratings yet

- Is 516 Method of Test For Strength of ConcreteDocument25 pagesIs 516 Method of Test For Strength of Concreteselva_65195078% (9)

- SMA Ref Guide V61Document63 pagesSMA Ref Guide V61Kiran ReddyNo ratings yet

- Inspect suspended scaffold checklistDocument2 pagesInspect suspended scaffold checklistKiran Reddy100% (2)

- Tube Coupler Poster1Document1 pageTube Coupler Poster1Kiran Reddy100% (1)

- Self-Compacting ConcreteDocument68 pagesSelf-Compacting ConcreteMisgun SamuelNo ratings yet

- Mensuration & Quantity Survey PDFDocument21 pagesMensuration & Quantity Survey PDFShareenMuneebNo ratings yet

- Work 181Document28 pagesWork 181Sandeep RuchandaniNo ratings yet

- Ulcra 1976Document46 pagesUlcra 1976Ar Kunal PatilNo ratings yet

- Kloppers Critical 2003 PDFDocument363 pagesKloppers Critical 2003 PDF조기현No ratings yet

- 4.6.intermolecular ForcesDocument27 pages4.6.intermolecular Forcesspareacc9823No ratings yet

- The Neurohistological TechniquesDocument4 pagesThe Neurohistological Techniquesapi-3846255100% (2)

- Suitable dimensions, performance requirements, and processes for optical transmittersDocument1 pageSuitable dimensions, performance requirements, and processes for optical transmittersshruti soniNo ratings yet

- Sika®-1: Product Data SheetDocument2 pagesSika®-1: Product Data SheetKhin Sandi KoNo ratings yet

- Carbobond 3028 1Document1 pageCarbobond 3028 1Yan TengNo ratings yet

- Reanna DixonDocument10 pagesReanna DixonElvin BucknorNo ratings yet

- Coal Preparation Technologies Sep 2019 Indpnesia (JCOAL)Document23 pagesCoal Preparation Technologies Sep 2019 Indpnesia (JCOAL)ErwinLBudiNo ratings yet

- R9907 Algorithm MethaneDocument29 pagesR9907 Algorithm MethanemxnoxnNo ratings yet

- Pamphlet TG-X SeriesDocument2 pagesPamphlet TG-X SeriesrajeshNo ratings yet

- SOFTENING POINTDocument8 pagesSOFTENING POINTSusi MulyaniNo ratings yet

- 11 Chemistry Eng 2018Document216 pages11 Chemistry Eng 2018Deepanjali PalNo ratings yet

- Kinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Document15 pagesKinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Luigi MazzuccoNo ratings yet

- 管径计算表Document11 pages管径计算表Ascend032No ratings yet

- Physics 12 CH 2 MCQsDocument18 pagesPhysics 12 CH 2 MCQsAdeela UmarNo ratings yet

- 0157 - TI - MG - REBOX HLL - SYS - Customer - Reference - A4 - RZ - VIEW - tcm17-526907Document2 pages0157 - TI - MG - REBOX HLL - SYS - Customer - Reference - A4 - RZ - VIEW - tcm17-526907Văn Tuấn NguyễnNo ratings yet

- Beza Air Mineral RO & Alkali Coway Coway OfficialDocument1 pageBeza Air Mineral RO & Alkali Coway Coway OfficialNurhajarah KhamisahNo ratings yet

- As NZS 1865 1997 Aluminium and Aluminium Alloys Drawn Wire Rod Bar and StripDocument7 pagesAs NZS 1865 1997 Aluminium and Aluminium Alloys Drawn Wire Rod Bar and StripYasser Hammad MohamedNo ratings yet

- Synthesis and Characterization of Some Novel Polyfunctionally Substituted Indeno (2,1-b) Thiophene Compounds Derived From IndanonesDocument6 pagesSynthesis and Characterization of Some Novel Polyfunctionally Substituted Indeno (2,1-b) Thiophene Compounds Derived From IndanonesWalid Ebid ElgammalNo ratings yet

- Porphyrins PDFDocument17 pagesPorphyrins PDFPk JaatNo ratings yet

- Nanotechnology: Yung Liou P601 Yung@phys - Sinica.edu - TW Institute of Physics Academia SinicaDocument58 pagesNanotechnology: Yung Liou P601 Yung@phys - Sinica.edu - TW Institute of Physics Academia SinicaPragyaNo ratings yet

- Achillea Millefolium L.Document5 pagesAchillea Millefolium L.Miroslav IlicNo ratings yet

- Iriotec - 8850 - Merck - TDS (For Rest of The World) PDFDocument2 pagesIriotec - 8850 - Merck - TDS (For Rest of The World) PDFxy2zjgNo ratings yet

- Chem Book-1Document216 pagesChem Book-1Ergi HoxhaNo ratings yet

- Process Analysis of Refinery Crude Charge HeaterDocument21 pagesProcess Analysis of Refinery Crude Charge HeaterNicholas RiveraNo ratings yet

- Tic Reinforced AmcDocument27 pagesTic Reinforced AmcarlyNo ratings yet

- Fluid Mechanics Tutorial on Fluid Properties and CalculationsDocument2 pagesFluid Mechanics Tutorial on Fluid Properties and CalculationsGabrielNo ratings yet

- Cell Communication Practice TestDocument5 pagesCell Communication Practice Testapi-237801056100% (2)

- Operating Manual SIRIUS 1000-2000 LIN Storage Vessel Art. No 78211329 Da...Document29 pagesOperating Manual SIRIUS 1000-2000 LIN Storage Vessel Art. No 78211329 Da...Bogdan CorbescuNo ratings yet

- Dielectric Constants Chart: How To Use This GuideDocument10 pagesDielectric Constants Chart: How To Use This GuideDewet VirmondNo ratings yet