Professional Documents

Culture Documents

Canon IR2535 Trouble Error Codes

Uploaded by

nafeesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Canon IR2535 Trouble Error Codes

Uploaded by

nafeesCopyright:

Available Formats

1

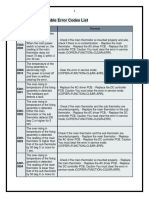

Canon iR2535 Trouble Error Codes List

Code

Description

Remedy

1.Go through the following to clear the error:

CLEAR > ENGIN > ERRCLR; and then turn

Fixing temperature abnormal rise

OFF and then ON the power. 2.Check

The temperature detected by the

connection of the Connectors (Thermistor

E000main thermistor does not rise to

Connector and AC Connector). 3.Replace the

0001

the specified value during startup

Fixing Main Thermistor (Film Unit). 4.Replace

control.

the Fixing Assembly. 5.Replace the DC

Controller PCB (PCB4).

Fixing unit temperature rise

detection

E001The reading of the main

0000

thermistor is 250 deg C or more

continuously for 200 msec.

1.Go through the following to clear the error:

CLEAR > ENGIN > ERRCLR; and then turn

OFF and then ON the power. 2.Check

connection of the Connectors (Thermistor

Connector and AC Connector). 3.Replace the

Fixing Main Thermistor (Film Unit). 4.Replace

the Fixing Assembly. 5.Replace the DC

Controller PCB (PCB4).

Fixing unit temperature rise

detection

E001The hardware circuit detects

0001

overheating of the main or sub

thermistor for 200 msec.

1.Go through the following to clear the error:

CLEAR > ENGIN > ERRCLR; and then turn

OFF and then ON the power. 2.Replace the

DC Controller PCB (PCB4).

1.Go through the following to clear the error:

CLEAR > ENGIN > ERRCLR; and then turn

Fixing unit temperature rise

OFF and then ON the power. 2.Check

detection

connection of the Connectors (Thermistor

E001The reading of the sub thermistor

Connector and AC Connector). 3.Replace the

0002

is 295 deg C or more

Fixing Main Thermistor (Film Unit). 4.Replace

continuously for 200 msec.

the Fixing Assembly. 5.Replace the DC

Controller PCB (PCB4).

Fixing unit temperature

insufficient rise

1.The reading of the main

thermistor is less than 115 deg C

continuously for 400 msec 1.3

E002sec after it has indicated 100 deg

0000

C.

2.The reading of the main

thermistor is less than 150 deg C

continuously for 400 msec 1.3

sec after it has indicated 140 deg

1.Go through the following to clear the error:

CLEAR > ENGIN > ERRCLR; and then turn

OFF and then ON the power. 2.Check

connection of the Connectors (Thermistor

Connector and AC Connector). 3.Replace the

Fixing Main Thermistor (Film Unit). 4.Replace

the Fixing Assembly. 5.Replace the DC

Controller PCB (PCB4).

C.

1.Go through the following to clear the error:

Low fixing temperature detection CLEAR > ENGIN > ERRCLR; and then turn

after standby

OFF and then ON the power. 2.Check

connection of the Connectors (Thermistor

E003- The reading of the main

0000 thermistor is less than 140 deg C Connector and AC Connector). 3.Replace the

continuously for 400 msec or

Fixing Main Thermistor (Film Unit). 4.Replace

more.

the Fixing Assembly. 5.Replace the DC

Controller PCB (PCB4).

Thermistor disconnection

detection error

E004When disconnection is detected

0000

with connector (J214) for 30 sec

continuously.

1.Check connection of the Connector (J214).

2.Replace the Film Unit. 3.Replace the Fixing

Assembly. 4.Replace the DC Controller PCB

(PCB4).

Unstable rotation of the Main

Motor (M1)

Detection is executed every 100

E010msec after the start of motor

0001

rotation; however, the drive

detection signal is absent for 2

sec.

1.Replace the Main Motor (M1). 2.Replace the

DC Controller PCB (PCB4).

Unstable rotation of the Main

Motor (M1)

E010- During motor rotation, detection

0002 is executed every 100 msec;

however, the drive signal is

absent 5 times in sequence.

1.Replace the Main Motor (M1). 2.Replace the

DC Controller PCB (PCB4).

Unstable rotation of the Fixing

Motor (M2)

Detection is executed every 100

E014msec after the start of motor

0001

rotation; however, the drive

detection signal is absent for 2

sec.

1.Replace the Fixing Motor (M2). 2.Replace

the DC Controller PCB (PCB4).

Unstable rotation of the Fixing

Motor (M2)

E014- During motor rotation, detection

0002 is executed every 100 msec;

however, the drive signal is

absent 5 times in sequence.

1.Replace the Fixing Motor (M2). 2.Replace

the DC Controller PCB (PCB4).

Error in Waste Toner Sensor

E019(S17)

0000

Warning when the sensor goes

1.Replace the Waste Toner Sensor (S17).

2.Replace the DC Controller PCB (PCB4).

on for 2000 consecutive sheets,

and error when the sensor goes

on for 100 consecutive sheets.

* Error occurs after the delivery if

a paper in passage exists.

The path between the sub

hopper and the developing

assembly is clogged with toner.

The Developing Assembly Toner

Sensor (TS1) detects the

absence of toner,while the Sub

Hopper Toner Sensor (TS2)

detects the presence of toner.

E020- With the Developing Cylinder

0000 Clutch (CL3) turned on, the

hopper feedscrew motor (M7) is

rotated for 1 sec intermittently

194 times; still, theDeveloping

Assembly Toner Sensor (TS1)

does not detect the presence of

toner.

* Error occurs after the delivery if

a paper in passage exists.

1.Check the rotation of hopper motor gear. (If

rotating, false detection by the sensor is

doubted. Feed the toner to the developing unit

in service mode: CLEAR>ENGIN>TNRINST.)

2.Replace the Developing Assembly Toner

Sensor (TS1). 3.Replace the Sub Hopper

Toner Sensor (TS2). 4.Replace the DC

Controller PCB (PCB4).

The connector (J207) of

Developing Assembly Toner

Sensor (TS1) is disconnected.

The Developing Assembly Toner

E024Sensor (TS1) connection

0000

detection signal is absent for 100

msec 10 times in sequence. *

Error occurs after the delivery if a

paper in passage exists.

1.Check connection of the Connector (J207).

2.Replace the Developing Assembly Toner

Sensor (TS1). 3.Replace the DC Controller

PCB (PCB4).

The Developing Assembly Toner

Sensor (TS1) is disconnected

<At LOW SPEED> - The

developing assembly toner

sensor (TS1) ON counter is

checked every 2.5 seconds, and 1.Check connection of the Connector (J207).

E024the counter increments 1 count

2.Correct the cable. 3.Replace the Developing

0001

every 25 times when the sensor Assembly Toner Sensor (TS1).

goes on, and 300 counts are

reached.

<At HIGH SPEED> - The

developing assembly toner

sensor (TS1) ON counter is

checked every 1.5 seconds, and

the counter increments 1 count

every 15 times when the sensor

goes on, and 300 counts are

reached.

Code

Description

Remedy

The connector (J207) of Sub

Hopper Toner Sensor (TS2) is

disconnected.

The Sub Hopper Toner Sensor

E025(TS2) connection detection signal is

0000

absent for 100 msec 10 times in

sequence.

* Error occurs after the delivery if a

paper in passage exists.

1.Check connection of the Connector

(J207). 2.Replace the Sub Hopper Toner

Sensor (TS2). 3.Replace the DC Controller

PCB (PCB4).

Failure of the Bottle Motor (M6)

The bottle motor (M6) is unlocked

E025- when it goes on for 12 consecutive

0001 times at 0.1 sec. intervals.

* Error occurs after the delivery if a

paper in passage exists.

1.Replace the Bottle Motor (M6).

2.Replace the DC Controller PCB (PCB4).

Failure of the Scanner Motor (M21)

The Scanner Motor (M21) speed

lock signal does not indicate a

1.Check the cable. 2.Replace the Laser

E110- locked state a specific period of

Scanner Unit. 3.Replace the DC Controller

0001 time after the Scanner Motor (M21)

PCB (PCB4).

has been started.

* The same condition is detected

after the error retry is performed.

Failure of the Scanner Motor (M21)

The speed lock signal indicates a

deviation 10 times in sequence at

1.Check the cable. 2.Replace the Laser

E110intervals of 100 msec after the

Scanner Unit. 3.Replace the DC Controller

0002

signal has indicated a locked state. PCB (PCB4).

* The same condition is detected

after the error retry is performed.

Failure of the Scanner Motor (M21)

The scanner motor (M21) speed

1.Check the cable. 2.Replace the Laser

E110lock signal does not indicate a

Scanner Unit. 3.Replace the DC Controller

0003

locked state for 6.5 sec. after a

PCB (PCB4).

switchover is made from low to

normal speed or for 8 sec. after a

switchover is made from normal to

low speed.

* The same condition is detected

after the error retry is performed.

Error in EEPROM access

20 retries failed after error occurred

E196- during communication with

1.Replace the DC Controller PCB (PCB4).

0000 EEPROM.

* Error occurs after the delivery if a

paper in passage exists.

Error in communication of Laser

E197- Driver PCB (PCB14)

0000 Communication error 1 with image

PCB

1.Check the cable. 2.Replace the Laser

Scanner Unit. 3.Replace the DC Controller

PCB (PCB4).

Error in communication of Laser

E197- Driver PCB (PCB14)

0001 Communication error 2 with image

PCB

1.Check the cable. 2.Replace the Laser

Scanner Unit. 3.Replace the DC Controller

PCB (PCB4).

There is an error in the detection of

the CIS home position.

1.The attempt to detect the home

E202- position fails when the CIS is

0000 moved forward.

2.The attempt to detect the home

position fails when the CIS is

moved back.

1.Disconnect and then connect the flexible

cable(Relay PCB (PCB2)-Main Controller

PCB (PCB1) 64pin). 2.Replace the flexible

cable. 3.Replace the CCD HP sensor

(S22). 4.Replace the Scanner Motor (M21).

5.Replace the Relay PCB (PCB2).

6.Replace the Main Controller PCB

(PCB1).

The light intensity of the CCD is

faulty.

E225The light intensity of the CCD

0000

during shading is under the

specified level.

1.Disconnect and then connect the flexible

cable. 2.Replace the flexible cable.

3.Replace the CCD Unit. 4.Replace the

Relay PCB (PCB2). 5.Replace the Main

Controller PCB (PCB1).

The reader unit power supply (24V)

is faulty.

1.At time of power-on, the 24V port

is off.

1.Disconnect and then connect the power

E227- 2.At the start of a job, the 24V port

supply harness connector. 2.Replace the

0000 is off.

Power Supply PCB (PCB3).

3.At the end of a job, the 24V port is

off.

4.When a load is being driven, the

24V port is off.

E240- Error in controller communication

1.Check the Connectors. 2.Replace the DC

0000

The serial communication error

Controller PCB (PCB4).

such as parity error or overrun error

is constantly detected.

Error in controller communication

1.Check the Connectors. 2.Replace the DC

E240- The serial communication error

0001 such as parity error or overrun error Controller PCB (PCB4).

is detected while printing.

1.Disconnect and then connect the flexible

cable(Relay PCB (PCB2)-Main Controller

EEPROM error

PCB (PCB1) 50pin). 2.Disconnect and then

1.An error has occurred at powerconnect the flexible cable(CCD unit- Relay

on.

PCB (PCB2)). 3.Disconnect and then

E2482.An error has occurred during write connect the power supply harness

0000

operation.

connector. 4.Replace the flexible cable.

3.An error has occurred during read 5.Replace the CCD Unit. 6.Replace the

operation following write operation. Relay PCB (PCB2). 7.Replace the Power

Supply PCB (PCB3). 8.Replace the Main

Controller PCB (PCB1).

Error in Zero Cross

Zero Cross failed to be detected for

E261- 500ms or more while the relay was 1.Check the Connectors. 2.Replace the DC

Controller PCB (PCB4).

0000 ON.

* The same condition is detected

after the error retry is performed.

Code

Description

Reading unit communication

E280error

0000

Reading error after writing.

Remedy

1.Disconnect and then connect the flexible

cable(Relay PCB (PCB2)-Main Controller PCB

(PCB1) 50pin). 2.Disconnect and then connect

the flexible cable(Relay PCB (PCB2)-Main

Controller PCB (PCB1) 64pin). 3.Disconnect

and then connect the flexible cable(CCD unitRelay PCB (PCB2)). 4.Replace the flexible

cable. 5.Replace the Relay PCB (PCB2).

6.Replace the Main Controller PCB (PCB1).

Release Motor (M2) error

The sensing level of the

1.Replace the Release Motor HP Sensor

E413- release motor HP sensor

(SR11). 2.Replace the Release Motor (M2).

0000 (SR11) does not change within

3.Replace the ADF Driver PCB.

a specified period when the

release motor (M2) is driven.

E500- Communication error

1.Check the cable. 2.Replace the Finisher

0000

The communication with the

host machine is interrupted.

EEPROM error

E505The checksum for the

0001

EEPROM data has an error.

Controller PCB (PCB1). 3.Replace the DC

Controller PCB.

1.Replace the Finisher Controller PCB (PCB1).

Shift Motor (M4) error

The shift roller does not leave 1. Replace the Shift Roller HP Sensor (S2). 2.

E520the shift roller home position

Replace the Shift Motor (M4). 3.Replace the

0001

when the Shift Motor (M4) has Finisher Controller PCB (PCB1).

been driven for 1.2 seconds.

Shift Motor (M4) error

The shift roller does not return 1. Replace the Shift Roller HP Sensor (S2). 2.

E520to the shift roller home position Replace the Shift Motor (M4). 3.Replace the

0002

when the Shift Motor (M4) has Finisher Controller PCB (PCB1).

been driven for 1.2 seconds.

Stapler Motor (M10) error

The stapler does not leave the

E531staple home position when the

8001

Staple Motor (M10) has been

driven for 0.5 sec.

1.Check the wiring between the Finisher

Controller PCB and Stapler. 2.Replace the

Stapler. 3.Replace the Finisher Controller PCB

(PCB1).

Stapler Motor (M10) error

The stapler does not return to

E531the staple home position when

8002

the Stapler Motor (M10) has

been driven for 0.5 sec.

1.Check the wiring between the Finisher

Controller PCB and Stapler. 2.Replace the

Stapler. 3.Replace the Finisher Controller PCB

(PCB1).

STP Move Motor (M1) error

The stapler does not leave the

E532- stapler move home position

0001 when the STP Move Motor

(M1) has been driven for 0.25

sec.

1.Replace the Stapler Move HP Sensor (S10).

2.Check the wiring between the Finisher

Controller PCB and the STP Move Motor.

3.Check the stapler shift base. 4.Replace the

STP Move Motor (M1). 5.Replace the Finisher

Controller PCB (PCB1).

STP Move Motor (M1) error

The stapler does not return to

E532- the stapler move home

0002 position when the STP Move

Motor (M1) has been driven for

2.8 sec.

1.Replace the Stapler Move HP Sensor (S10).

2.Check the wiring between the Finisher

Controller PCB and the STP Move Motor.

3.Check the stapler shift base. 4.Replace the

STP Move Motor (M1). 5.Replace the Finisher

Controller PCB (PCB1).

Tray Lift Motor (M11) time out

E540- error

0001 The stack tray does not move

within a specified time period.

1.Replace the Tray Lift Motor (M11). 2.Replace

the Finisher Controller PCB (PCB1).

E540- Tray Lift Motor (M11) closing

1.Replace the Stack Tray Clock Sensor (S13).

0005

detect switch error

The FG input cannot be

detected when the Tray Lift

Motor (M11) has been driven

for 0.1 second.

2.Replace the Tray Lift Motor (M11). 3.Replace

the Finisher Controller PCB (PCB1).

Additional Tray Lift Motor

E542- (M12) time out error

0001 The stack tray does not move

within a specified time period.

1.Replace the Additional Tray Lift Motor (M12).

2.Replace the Finisher Controller PCB (PCB1).

Additional Tray Lift Motor

(M12) closing detect switch

error

E542The FG input cannot be

0005

detected when the Additional

Tray Lift Motor (M12) has been

driven for 0.1 second.

1.Replace the Additional Tray Clock Sensor

(S23). 2.Replace the Additional Tray Lift Motor

(M12). 3.Replace the Finisher Controller PCB

(PCB1).

Shift Roller Release Motor

(M5) error

The shift roller does not leave

E567the shift roller release home

0001

position when the Shift Roller

Release Motor (M5) has been

driven for 0.1 sec.

1.Replace the Shift Roller Release Sensor (S3).

2.Replace the Shift Roller Release Motor (M5).

3.Replace the Finisher Controller PCB (PCB1).

ode

Description

Remedy

Shift Roller Release Motor (M5) error

The shift roller does not return to the

E567shift roller release home position when

0002

the Shift Roller Release Motor (M5) has

been driven for 0.06 sec.

1.Replace the Shift Roller Release

Sensor (S3). 2.Replace the Shift

Roller Release Motor (M5). 3.Replace

the Finisher Controller PCB (PCB1).

Gripper Open/Close Motor (M7) error

The gripper unit does not leave the

E571gripper unit home position when the

0001

Gripper Open/Close Motor (M7) has

been driven for 0.25 seconds.

1.Replace the Grip Arm Sensor

(S13). 2.Replace the Gripper

Open/Close Motor (M7). 3.Replace

the Finisher Controller PCB (PCB1).

Gripper Open/Close Motor (M7) error

The gripper unit does not return to the

E571gripper unit home position when the

0002

Gripper Open/Close Motor (M7) has

been driven for 0.15 seconds.

1.Replace the Grip Arm Sensor

(S13). 2.Replace the Gripper

Open/Close Motor (M7). 3.Replace

the Finisher Controller PCB (PCB1).

E575- Gripper Unit Move Motor (M2) error

1.Replace the Gripper Unit HP

0001

The gripper unit does not leave the

Sensor (S7). 2.Replace the Gripper

gripper unit home position when the

Unit Move Motor (M2). 3.Replace the

Gripper Unit Move Motor (M2) has been Finisher Controller PCB (PCB1).

driven for 3.8 seconds.

Gripper Unit Move Motor (M2) error

The gripper unit does not return to the

E575gripper unit home position when the

0002

Gripper Unit Move Motor (M2) has been

driven for 0.1 seconds.

1.Replace the Gripper Unit HP

Sensor (S7). 2.Replace the Gripper

Unit Move Motor (M2). 3.Replace the

Finisher Controller PCB (PCB1).

E602The built-in SD card is not detected

0001

E602Access to the built-in SD card failed

1105

Error in UFDI communication

E711- The communication system error (such

0001 as reception timeout or checksum error)

occurred.

1.Check and Replace the cable.

2.Replace the DC Controller PCB

(PCB4). 3.Replace the Finisher

Controller PCB.

Erroneous communication with finisher

E713- The communication does not restart by

0000 the error retry after the communication

failure with the finisher.

1.Check the cable. 2.Replace the DC

Controller PCB (PCB4). 3.Replace

the Finisher Controller PCB.

Erroneous communication with optional

cassette or 2-way unit

E716- After the presence of a cassette

0000 pedestal or a 2-way unit has been

detected, the communication fails to be

normal for 5 sec.

1.Check the cable. 2.Replace the DC

Controller PCB (PCB4). 3.Replace

the Cassette Pedestal Driver PCB.

4.Replace the 2-way unit driver PCB.

Failure of the communication with the 2way unit

E716When the communication with the 2-way

0010

unit is faulty after detecting the

connection with the finisher.

1.Install the 2-way unit. 2.Check the

cable. 3.Replace the DC Controller

PCB (PCB4). 4.Replace the 2-way

unit driver PCB.

E719- Erroneous communication with New

0000 Card Reader (serial communication)

E719- Erroneous communication with Coin

0002 Vendor (serial communication)

E736- Erroneous communication between

0000 CCU and controller.

E744- Mismatched version between the

0001 language file and the Bootable

10

ode

Description

Remedy

Shift Roller Release Motor (M5) error

The shift roller does not return to the

E567shift roller release home position when

0002

the Shift Roller Release Motor (M5) has

been driven for 0.06 sec.

1.Replace the Shift Roller Release

Sensor (S3). 2.Replace the Shift

Roller Release Motor (M5). 3.Replace

the Finisher Controller PCB (PCB1).

Gripper Open/Close Motor (M7) error

The gripper unit does not leave the

E571gripper unit home position when the

0001

Gripper Open/Close Motor (M7) has

been driven for 0.25 seconds.

1.Replace the Grip Arm Sensor

(S13). 2.Replace the Gripper

Open/Close Motor (M7). 3.Replace

the Finisher Controller PCB (PCB1).

Gripper Open/Close Motor (M7) error

The gripper unit does not return to the

E571gripper unit home position when the

0002

Gripper Open/Close Motor (M7) has

been driven for 0.15 seconds.

1.Replace the Grip Arm Sensor

(S13). 2.Replace the Gripper

Open/Close Motor (M7). 3.Replace

the Finisher Controller PCB (PCB1).

Gripper Unit Move Motor (M2) error

The gripper unit does not leave the

E575gripper unit home position when the

0001

Gripper Unit Move Motor (M2) has been

driven for 3.8 seconds.

1.Replace the Gripper Unit HP

Sensor (S7). 2.Replace the Gripper

Unit Move Motor (M2). 3.Replace the

Finisher Controller PCB (PCB1).

Gripper Unit Move Motor (M2) error

The gripper unit does not return to the

E575gripper unit home position when the

0002

Gripper Unit Move Motor (M2) has been

driven for 0.1 seconds.

1.Replace the Gripper Unit HP

Sensor (S7). 2.Replace the Gripper

Unit Move Motor (M2). 3.Replace the

Finisher Controller PCB (PCB1).

E602The built-in SD card is not detected

0001

E602Access to the built-in SD card failed

1105

Error in UFDI communication

E711- The communication system error (such

0001 as reception timeout or checksum error)

occurred.

1.Check and Replace the cable.

2.Replace the DC Controller PCB

(PCB4). 3.Replace the Finisher

Controller PCB.

Erroneous communication with finisher

E713- The communication does not restart by

0000 the error retry after the communication

failure with the finisher.

1.Check the cable. 2.Replace the DC

Controller PCB (PCB4). 3.Replace

the Finisher Controller PCB.

Erroneous communication with optional

E716cassette or 2-way unit

0000

After the presence of a cassette

1.Check the cable. 2.Replace the DC

Controller PCB (PCB4). 3.Replace

the Cassette Pedestal Driver PCB.

11

pedestal or a 2-way unit has been

detected, the communication fails to be

normal for 5 sec.

4.Replace the 2-way unit driver PCB.

Failure of the communication with the 2way unit

E716When the communication with the 2-way

0010

unit is faulty after detecting the

connection with the finisher.

1.Install the 2-way unit. 2.Check the

cable. 3.Replace the DC Controller

PCB (PCB4). 4.Replace the 2-way

unit driver PCB.

E719- Erroneous communication with New

0000 Card Reader (serial communication)

E719- Erroneous communication with Coin

0002 Vendor (serial communication)

E736- Erroneous communication between

0000 CCU and controller.

E744- Mismatched version between the

0001 language file and the Bootable

Canon iR6570 Trouble Error Codes List

Code

Description

Remedy

The heater fails to heat. After

correcting the fault, be sure to reset the

error.

- Replace the main/shutter thermistor. E000(COPIER>FUNCTION>CLEAR>ERR)

Replace the DC controller PCB.

0000

After power-on, the reading of the main

thermistor does not increase to 70 deg

C or higher within 20 sec.

The heater fails to heat. After

correcting the fault, be sure to reset the

- Reset the error.

E000- error.

0010 (COPIER>FUNCTION>CLEAR>ERR) (COPIER>FUNCTION>CLEAR>ERR)

The power has been turned off and

then on without resetting the error.

There is an abnormal rise in

temperature. After correcting the fault,

be sure to reset the error.

E001(COPIER>FUNCTION>CLEAR>ERR)

0001

There is an error or an open circuit in

the main thermistor, shutter thermistor,

or sub thermistor.

- Check the connector of each

thermistor for any fault in connection

and wiring. - Replace the thermistor in

question. - Replace the DC controller

PCB.

12

There is an abnormal rise in

temperature. After correcting the fault,

be sure to reset the error.

E001(COPIER>FUNCTION>CLEAR>ERR)

0002

The reading of the main thermistor,

shutter thermistor, or sub thermistor is

230 deg C or higher for 2 sec.

- Replace the thermistor in question. Replace the DC controller PCB.

There is an abnormal rise in

temperature. After correcting the fault,

E001- be sure to reset the error.

0003 (COPIER>FUNCTION>CLEAR>ERR)

The reading is not 150 deg C or higher

or 210 deg C or lower within 30 sec.

-Cheak the connecting of the main/ sub/

shutter thermistors. -Check the

mounting of the main/ sub/ shutter

thermistors. -Exchange the main/ sub/

shutter thermistors. -Exchange the DC

controller PCB.

There is an abnormal rise in

temperature. After correcting the fault,

be sure to reset the error.

E001(COPIER>FUNCTION>CLEAR>ERR)

0010

The power has been turned off and

then back on without resetting the

error.

- Reset the error.

(COPIER>FUNCTION>CLEAR>ERR)

There is an abnormal rise in

temperature. After correcting the fault,

be sure to reset the error.

E002(COPIER>FUNCTION>CLEAR>ERR)

0000

The reading of the main thermistor is

not 100 deg C 12 sec after it has

exceeded 70 deg C.

- Check the connector of the

main/shutter thermistor for any fault in

connection and wiring. - Check the

main/shutter thermistor for mounting

condition. - Replace the main/shutter

thermistor. - Replace the fixing heater

unit. - Replace the DC controller PCB.

There is an abnormal rise in

temperature. After correcting the fault,

be sure to reset the error.

E002(COPIER>FUNCTION>CLEAR>ERR)

0001

The reading of the main thermistor is

not 150 deg C 15 sec after it has

exceeded 100 deg C.

- Check the connector of the

main/shutter thermistor for any fault in

connection and wiring. - Check the

main/shutter thermistor for mounting

condition. - Replace the main/shutter

thermistor. - Replace the fixing heater

unit. - Replace the DC controller PCB.

There is an abnormal rise in

temperature. After correcting the fault,

- Reset the error.

E002- be sure to reset the error.

0010 (COPIER>FUNCTION>CLEAR>ERR) (COPIER>FUNCTION>CLEAR>ERR)

The power has been turned off and

then back on without resetting the error

There is an abnormal rise in

E003temperature. After correcting the fault,

0000

be sure to reset the error.

connection and wiring. - Check the

main/shutter thermistor for mounting

condition. - Replace the main/shutter

13

(COPIER>FUNCTION>CLEAR>ERR)

The reading of the main thermistor is

lower than 70 deg C for 2 sec or more

after it has exceeded 100 deg C.

There is an abnormal rise in

temperature. After correcting the fault,

be sure to reset the error.

E003(COPIER>FUNCTION>CLEAR>ERR)

0010

The power has been turned off and

then back on without resetting the

error.

thermistor. - Replace the fixing heater

unit. - Replace the DC controller PCB.

- Reset the error.

(COPIER>FUNCTION>CLEAR>ERR)

The IH power supply is faulty/the IH

control mechanism is faulty. After

correcting the fault, be sure to reset the

- Reset the error.

E004- error.

0010 (COPIER>FUNCTION>CLEAR>ERR) (COPIER>FUNCTION>CLEAR>ERR)

The power has been turned off and

then back on without resetting the

error.

The IH power supply is faulty/the IH

control mechanism is faulty. After

correcting the fault, be sure to reset the Replace the fixing heater power supply

E004error.

with one designed for the country of

0101

(COPIER>FUNCTION>CLEAR>ERR) installation (voltage).

There is a mismatch between the input

voltage and the IH power supply ID.

The IH power supply is faulty/the IH

control mechanism is faulty. After

correcting the fault, be sure to reset the

E004error.

0102

(COPIER>FUNCTION>CLEAR>ERR)

The IH current is faulty. (current

leakage)

- Check the connector for any fault in

connection. - Replace the fixing heater

power supply. - Replace the DC

controller PCB.

The IH power supply is faulty/the IH

control mechanism is faulty. After

E004- correcting the fault, be sure to reset the

0103 error.

(COPIER>FUNCTION>CLEAR>ERR)

The IH current is faulty. (no current)

- Check the connector for any fault in

connection. - Replace the fixing heater

power supply. - Replace the DC

controller PCB.

Code

Description

E004- The IH power supply is faulty/the IH

Remedy

- Check the connector for any fault in

14

0104

control mechanism is faulty. After

correcting the fault, be sure to reset the

error.

(COPIER>FUNCTION>CLEAR>ERR)

There is an IH over-current.PCB.

connection. - Replace the fixing heater

power supply. - Replace the DC

controller PCB.

The IH power supply is faulty/the IH

control mechanism is faulty. After

E004- correcting the fault, be sure to reset the

0105 error.

(COPIER>FUNCTION>CLEAR>ERR)

The IH input voltage is too high.

- Check the connector for any fault in

connection. - Replace the fixing heater

power supply. - Replace the DC

controller PCB.

The IH power supply is faulty/the IH

control mechanism is faulty. After

E004- correcting the fault, be sure to reset the

0106 error.

(COPIER>FUNCTION>CLEAR>ERR)

The IH input voltage is too low.

- Check the connector for any fault in

connection. - Replace the fixing heater

power supply. - Replace the DC

controller PCB.

The IH power supply is faulty/the IH

control mechanism is faulty. After

correcting the fault, be sure to reset the

E004- error.

0201 (COPIER>FUNCTION>CLEAR>ERR)

At power-on (or, when IH is at reset), the

IH control mechanism is not in an initial

state.

- Check the connector for any fault in

connection. - Replace the fixing heater

power supply. - Replace the DC

controller PCB.

The IH power supply is faulty/the IH

control mechanism is faulty. After

correcting the fault, be sure to reset the

E004- error.

0202 (COPIER>FUNCTION>CLEAR>ERR)

At IH start-up, the IH control enable flag

is not set within 1 sec after the start flag

is set.

- Check the connector for any fault in

connection. - Replace the fixing heater

power supply. - Replace the DC

controller PCB.

The IH power supply is faulty/the IH

control mechanism is faulty. After

correcting the fault, be sure to reset the

E004error.

0203

(COPIER>FUNCTION>CLEAR>ERR)

With IH at rest, the IH control flag is not

released.

- Check the connector for any fault in

connection. - Replace the fixing heater

power supply. - Replace the DC

controller PCB.

The IH power supply is faulty/the IH

E004control mechanism is faulty. After

0204

correcting the fault, be sure to reset the

- Check the connector for any fault in

connection. - Replace the fixing heater

power supply. - Replace the DC

15

error.

(COPIER>FUNCTION>CLEAR>ERR)

The 12-V power supply (IH relay) is

identified as being off.

The IH power supply is faulty/the IH

control mechanism is faulty. After

correcting the fault, be sure to reset the

E004error.

0205

(COPIER>FUNCTION>CLEAR>ERR)

At IH start-up, the PWM/ON data is

faulty ('0' or 'FFFF')

controller PCB.

- Replace the DC controller PCB.

- Replace the fixing web. - Replace the

There is no fixing web/there is an error in fixing web length sensor. - Replace the

the detection of web solenoid

DC controller PCB. After correcting the

E005connection.

fault, be sure to reset the fixing web

0000

The absence of the fixing web has been counter reading.

detected for 5 sec or more.

(COPIER>COUNTER>MISC>FIXWEB)

There is no fixing web/there is an error in

the detection of web solenoid

- Check the connector for any fault in

E005connection.

connection. - Replace the solenoid.

0001

At power-on, the connection of the web

solenoid is not detected.

There is no fixing web/there is an error in

the detection of web solenoid

- Reset the fixing web counter.

E005connection.

(COPIER>COUNTER>MISC>FIX0010

The power has been turned off and then WEB)

back on without resetting the error.

There is a feed motor error.

E010- The FG signal of the feed motor does

0000 not arrive for 2 sec or more even when

the feed motor has been turned on.

- Check the connector for any fault in

connection. - Replace the motor

There is a drum motor error.

E012- The FG signal of the drum motor does

0000 snot arrive for 2 sec or more even when

the drum motor has been turned on.

- Check the connector for any fault in

connection. - Replace the motor.

The waste toner pipe is clogged.

E013The waste toner pipe is identified as

0000

being clogged for 4 sec or more.

- Check the connector for any fault in

connection. - Replace the waste toner

feedscrew lock detecting switch. Replace the waste toner feed unit. Replace the DC controller PCB.

E013- The waste toner pipe is clogged.

- Check the connector for any fault in

16

0010

Code

The power has been turned off and then connection. - Replace the waste toner

back on without resetting the error.

feedscrew lock detecting switch. Replace the waste toner feed unit. Replace the DC controller PCB.

Description

Remedy

There is a fixing motor error.

- Check the connector for

E014- The Phase lock signal of the fixing motor does not

any fault in connection. 0000 arrive for 2 sec even when the fixing motor has

Replace the motor.

been turned on.

There is no toner in the developing assembly;

there is an error in the detection of developing

toner sensor connection; there is an error in the

detection of hopper toner sensor connection.

E020- The presence of toner is detected inside the sub

0000 hopper and, in addition, the absence of toner is

detected inside developing assembly for 120 sec

continuously even when operation has been

under way for the supply of toner to the

developing assembly.

- Check the connector of the

developing toner sensor for

any fault in connection. Replace the developing toner

sensor. - Replace the hopper

toner sensor.

There is no toner in the developing assembly;

there is an error in the detection of developing

E020- toner sensor connection; there is an error in the

0001 detection of hopper toner sensor connection.

At power-on, the connection of the developing

assembly toner sensor is not detected.

- Check the connector for

any fault in connection. Replace the sensor.

There is no toner in the developing assembly;

there is an error in the detection of developing

E020- toner sensor connection; there is an error in the

0002 detection of hopper toner sensor connection.

At power-on, the connection of the developing

hopper toner sensor is not detected.

- Check the connector for

any fault in connection. Replace the sensor.

There is a toner feed motor over-current detection

error, there is a toner bottle motor connection

- Check the connector for

E025detection error.

any fault in connection. 0001

An over-current has been detected in the toner

Replace the motor.

feed motor.

There is a toner feed motor over-current detection

error, there is a toner bottle motor connection

- Check the connector for

E025detection error.

any fault in connection. 0002

An over-current has been detected in the toner

Replace the motor.

bottle motor.

17

There is a toner feed motor over-current detection

error, there is a toner bottle motor connection

- Check the connector for

E025detection error.

any fault in connection. 0003

At power-on, the connection of the toner bottle

Replace the motor.

motor is not detected.

The NE controller counter has malfunctioned.

E032An open circuit has been detected for the count

0001

pulse signal.

Turn off the main power, and

check for an open circuit in

the cable; then, turn the main

power back on.

There is a potential control error/there is an APC

error.

E061As a result of potential control, the drum surface

0001

potential (VL2) of the background is 200 V or

higher (i.e., causing a solid black image).

- Replace the potential

sensor unit. - Replace the

laser scanner unit. - Replace

the DC controller PCB.

There is a potential control error/there is an APC

error.

E061- The primary charging output used at time of

0002 printer output and the drum surface potential after

laser output is identified as being 200 V or more

(i.e., causing a solid black image).

- Replace the potential

sensor unit. - Replace the

laser scanner unit. - Replace

the DC controller PCB.

There is a BD error.

A check is made of VLOCK at intervals of 100

E100msec while the laser is on. An error will be

0001

identified if it is not detected 10 times in

sequence.

- Replace the laser scanner

unit. - Replace the DC

controller PCB.

There is a laser verify error.

E102The machine model ID that has been read from

0001

the laser scanner EEPROM is not correct.

There is a polygon motor error.

- Although the polygon motor has been turned on,

VLOCK is not detected at all within 76.5 sec. - At

time of a shift from full-speed to half-speed

- Replace the laser scanner

E110control, VLOCK is not detected at all for 7.5 sec. - unit. - Replace the DC

0001

At time of half-speed control, a check is made of controller PCB.

VLOCK at intervals of 100 msec. An error will be

identified if it is not detected 10 times

continuously.

There is a controller cooling fan error.

E121- Even though the controller cooling fan has been

0001 turned on, the controller cooling fan stop signal

has been detected for 5 sec or more.

E193- There is a gate array error.

- Check the connector for

any fault in connection. Replace the fan.

18

0001

Code

The add-on through setting of the IMGI cannot

correctly be done (it is not correctly set 10

continuous times)

Description

Remedy

The EEPROM is faulty.

There is a mismatch between the data that has - Initialize the RAM. - Replace

E196been written in EEPROM and the data that has the EEPROM. - Replace the

1abb

been read. (a: chip No. 0 through 5; bb: chip

DC controller PCB.

faulty address)

The EEPROM is faulty.

The ID in EEPROM that has been read and the - Initialize the RAM. - Replace

E196ID in ROM are compared. An error will be

the EEPROM. - Replace the

2abb

identified if they do not match. (a: chip No. 0

DC controller PCB.

through 5; bb: chip faulty address)

The EEPROM is faulty.

When the main power is turned on, the ID in

E196- EEPROM and the ID in ROM are compared.

3abb An error will be identified if they do not match.

(a: chip No. 0 through 5; bb: chip faulty

address)

There is an error in communication between

the DC controller PCB and the video PCB/an

error in communication of the DC controller

E197PCB.

0000

An error in the communication between the DC

controller PCB and the video PCB has

occurred.

There is an error in communication between

the DC controller PCB and the video PCB/an

error in communication of the DC controller

E197PCB.

0001

An error in the communication with the laser

driver module of the DC controller PCB has

occurred.

Error in CIS Unit (DADF)

- The error is cleared by turning off/on the

power switch. This triggers function-restricted

E225mode. - CIS unit suspends its functions; only

1010

CCD unit performs duplexing reading. Functions will be automatically restored by

replacing CIS unit.

- Check the position and

condition of the EEPROM. Initialize the RAM. - Replace

the EEPROM. - Replace the

DC controller PCB.

19

The communication between the main

controller PCB and the DC controller PCB is

E240- faulty.

0000 There is an error in the communication

between the main controller PCB and the CPU

of the DC controller PCB.

- Check the connector for any

fault in connection. - Replace

the DC controller PCB. Replace the main controller

PCB.

E315- There is a fault in the image data.

0007 There is a JIBIG encode error.

- Turn off and then back on the

power.

E315- There is a fault in the image data.

000d There is a JBIG decode error.

- Turn off and then back on the

power.

There is a fault in the image data.

E315- CRC error detected in OpenI/F (image transfer - Replace the external controller

connection PCB

0200 from the external controller); retried but failed

to restore.

E315- There is a fault in the image data.

0300 Cubic timeout

- Turn off/on the power switch.

Replace the PCB for frequent

error occurrence.

E315- There is a fault in the image data.

0400 Shift device A timeout

- Turn off/on the power switch.

Replace the PCB for frequent

error occurrence.

E315- There is a fault in the image data.

0401 Shift device B timeout

- Turn off/on the power switch.

Replace the PCB for frequent

error occurrence.

There is an error in the finisher internal

E503- communication (finisher).

0002 There is an error in the communication

between the finisher and the saddle unit.

- Check the connection

between the saddle stitcher

controller PCB and the finisher

controller PCB.

There is an error in the finisher internal

E503- communication (finisher).

0003 There is an error in the communication

between the finisher and the punch unit.

- Check the communication

between the saddle stitcher

controller PCB and the finisher

controller PCB.

Code

Description

Remedy

There is a finisher backup

memory error (finisher).

E505An error has occurred in

0001

the data stored in the

backup memory.

- Turn off the main power; check the DC controller

PCB and the finisher controller PCB for wiring;

check the 24-V system fuse; then, turn the main

power back on.

E505- There is a finisher backup

0002 memory error (finisher).

- Turn off the main power; check the DC controller

PCB and the puncher controller PCB for wiring;

20

There is an error in the

then, check the 24-V system fuse; then, turn the

punch unit EEPROM data. main power back on.

There is a trailing edge

assist motor error

(finisher).

E514- The home position sensor

8001 does not go off even when

the trailing edge assist

motor has rotated for a

specific period of time.

1. Check the trailing edge assist home position

sensor. Is the sensor normal? 2. Check the wiring

between the finisher controller PCB and the trailing

edge assist motor. Is it normal? 3. Check the trailing

edge assist mechanism. Is there a fault? 4. Try

replacing the trailing edge assist motor. Is the

problem corrected?

There is a trailing edge

assist motor error

(finisher).

E514- The home position sensor

8002 does not go on even when

the trailing edge assist

motor has rotated for a

specific period of time.

1. Check the trailing edge assist home position

sensor. Is the sensor normal? 2. Check the wiring

between the finisher controller PCB and the trailing

edge assist motor. Is it normal? 3. Check the trailing

edge assist mechanism. Is there a fault? 4. Try

replacing the trailing edge assist motor. Is the

problem corrected?

There is a gear change

motor error (finisher).

The home position sensor

E519does not go on even when

0002

the gear change motor has

rotated for a specific

period of time.

1. Check the gear change home position sensor. Is

the sensor normal? 2. Check the wiring between the

finisher controller PCB and the change motor. Is it

normal? 3. Check the gear change mechanism. Is

there a fault? 4. Try changing the gear change

motor. Is the problem corrected?

There is a gear change

motor error (finisher).

The home position sensor

E519does not go off even when

8001

the gear change motor has

rotated for a specific

period of time.

1. Check the gear change home position sensor. Is

the sensor normal? 2. Check the wiring between the

finisher controller PCB and the change motor. Is it

normal? 3. Check the gear change mechanism. Is

there a fault? 4. Try changing the gear change

motor. Is the problem corrected?

There is a gear change

motor error (finisher).

The home position sensor

E519does not go on even when

8002

the front alignment motor

has rotated for a specific

period of time.

1. Check the gear change home position sensor. Is

the sensor normal? 2. Check the wiring between the

finisher controller PCB and the change motor. Is it

normal? 3. Check the gear change mechanism. Is

there a fault? 4. Try changing the gear change

motor. Is the problem corrected?

There is a front alignment

E530- error. (finisher)

8001 The home position sensor

does not go off even when

1. Check the aligning plate home position sensor. Is

it normal? 2. Check the wiring between the finisher

controller PCB and the aligning plate front motor. Is

it normal? 3. Is there any mechanical obstacle in the

21

the front alignment motor

has rotated for a specific

period of time.

path in which the aligning plate moves? 4. Try

replacing the aligning plate front motor. Is the

problem corrected?

There is a stapling error.

(finisher)

The home position sensor 1. Check the wiring between the finisher controller

E531does not go off even when PCB and the stapler. Is it normal? 2. Try replacing

0001

the stapler motor has

the stapler. Is the problem corrected?

rotated for a specific

period of time.

There is a stapling error.

(finisher)

The home position sensor 1. Check the wiring between the finisher controller

E531does not go on even when PCB and the stapler. Is it normal? 2. Try replacing

0002

the stapler motor has

the stapler. Is the problem corrected?

rotated for a specific

period time.

There is a stapler shift

error. (finisher)

The home position sensor

E532does not go off even when

8001

the stapler shift motor has

rotated for a specific

period of time.

1. Check the stapler shift home position sensor. Is

the sensor normal? 2. Check the wiring between the

finisher controller PCB and the stapler shift motor.

Is it normal? 3. Is there any mechanical obstacle in

the path of the stapler shift base? 4. Try replacing

the stapler shift motor. Is the problem corrected?

There is a stapler shift

error. (finisher)

The home position sensor

E532does not go on even when

8002

the stapler shift motor has

rotated for a specific

period of time.

1. Check the stapler shift home position sensor. Is

the sensor normal? 2. Check the wiring between the

finisher controller PCB and the stapler shift motor.

Is it normal? 3. Is there any mechanical obstacle in

the path of the stapler shift base? 4. Try replacing

the stapler shift motor. Is the problem corrected?

There is a swing error.

(finisher)

The home position sensor

E535does not go off even when

8001

the swing motor has

rotated for a specific

period of time.

1. Check the swing home position sensor. Is it

normal? 2. Check the wiring between the finisher

controller PCB and the swing motor. Is it normal? 3.

Is there a fault in the swing mechanism? 4. Try

replacing the swing motor. Is the problem

corrected?

There is a swing error.

(finisher)

E535The home position sensor

8002

does not go on even when

the swing motor has

1. Check the swing home position sensor. Is it

normal? 2. Check the wiring between the finisher

controller PCB and the swing motor. Is it normal? 3.

Is there a fault in the swing mechanism? 4. Try

replacing the swing motor. Is the problem

22

rotated for a specific

period of time.

There is a rear alignment

error. (finisher)

The home position sensor

E537does not go off even when

8001

the swing motor has

rotated for a specific

period of time.

Code

corrected?

1. Check the aligning plate rear home position

sensor. Is it normal? 2. Check the wiring between

the finisher controller PCB and the aligning plate

rear motor. Is it normal? 3. Is there a mechanical

obstacle in the path of the aligning plate? 4. Try

replacing the aligning plate rear motor. Is the

problem corrected?

Description

Remedy

There is a rear alignment error.

(finisher)

E537- The home position sensor does

8002 not go on even when the swing

motor has rotated for a specific

period of time.

1. Check the aligning plate rear home

position sensor. Is it normal? 2. Check the

wiring between the finisher controller PCB

and the aligning plate rear motor. Is it

normal? 3. Is there a mechanical obstacle in

the path of the aligning plate? 4. Try

replacing the aligning plate rear motor. Is the

problem corrected?

There is an upper tray

ascent/decent error. (finisher)

- If the tray does not return to

E540- home position when the tray 1

8001 shift motor is driven for 20

seconds. - If the tray does not

move to other area when tray 1

shift motor is driven for 4 seconds.

1. Check the No. 1 tray area sensors 1

through 3. Are they normal? 2. Check the

wiring between the finisher controller PCB

and the No. 1 tray shift motor. Is it normal?

3. Is there a fault in the tray ascent/descent

mechanism? 4. Try replacing the No. 1 tray 1

paper surface sensor tray shift motor. Is the

problem corrected?

There is an upper tray

ascent/decent error. (finisher)

- The dangerous area is reached

E540- before the tray 1 paper surface

8002 sensor detects paper surface

during the paper surface detection

operation. - A discontinuous area

is detected during tray operation

1. Check the No. 1 tray area sensors 1

through 3. Are they normal? 2. Check the

wiring between the finisher controller PCB

and the No. 1 tray shift motor. Is it normal?

3. Is there a fault in the tray ascent/descent

mechanism? 4. Try replacing the No. 1 tray 1

paper surface sensor tray shift motor. Is the

problem corrected?

1. Check the No. 1 tray area sensors 1

There is an upper tray

through 3. Are they normal? 2. Check the

ascent/decent error. (finisher)

wiring between the finisher controller PCB

E540The tray 1 closing detect switch is and the No. 1 tray shift motor. Is it normal?

8003

activated while the tray 1 is

3. Is there a fault in the tray ascent/descent

operating.

mechanism? 4. Try replacing the No. 1 tray 1

paper surface sensor tray shift motor. Is the

23

problem corrected?

There is an upper tray

ascent/decent error. (finisher)

E540- Clock signal input cannot be

8004 detected when the tray 1 shift

motor has been driven for 0.2

second.

1. Check the No. 1 tray area sensors 1

through 3. Are they normal? 2. Check the

wiring between the finisher controller PCB

and the No. 1 tray shift motor. Is it normal?

3. Is there a fault in the tray ascent/descent

mechanism? 4. Try replacing the No. 1 tray 1

paper surface sensor tray shift motor. Is the

problem corrected?

There is an upper tray

ascent/decent error. (finisher)

E540The lock detection signal turns

8005

OFF 150 ms after the lock

detection signal turned ON

1. Check the No. 1 tray area sensors 1

through 3. Are they normal? 2. Check the

wiring between the finisher controller PCB

and the No. 1 tray shift motor. Is it normal?

3. Is there a fault in the tray ascent/descent

mechanism? 4. Try replacing the No. 1 tray 1

paper surface sensor tray shift motor. Is the

problem corrected?

1. Check the No. 1 tray area sensors 1

There is an upper tray

through 3. Are they normal? 2. Check the

ascent/decent error. (finisher)

wiring between the finisher controller PCB

E540- The lock detection signal does not and the No. 1 tray shift motor. Is it normal?

3. Is there a fault in the tray ascent/descent

8006 turn ON when the tray 1 shift

motor has been driven for 1

mechanism? 4. Try replacing the No. 1 tray 1

second.

paper surface sensor tray shift motor. Is the

problem corrected?

1. Check the No. 1 tray area sensors 1

through 3. Are they normal? 2. Check the

There is an upper tray

wiring between the finisher controller PCB

ascent/decent error. (finisher)

and the No. 1 tray shift motor. Is it normal?

E540The lock detection signal does not

3. Is there a fault in the tray ascent/descent

8007

turn OFF when the tray 1 shift

mechanism? 4. Try replacing the No. 1 tray 1

motor is at a stop.

paper surface sensor tray shift motor. Is the

problem corrected?

There is a lower tray

E542ascent/descent error. (finisher)

0003

The safety switch has activated

1. Check the No. 2 tray area sensors 1

through 3. Are the sensors normal? 2. Check

the wiring between the finisher controller

PCB and the No. 2 tray shift motor. Is it

normal? 3. Is there a fault in the tray

ascent/descent mechanism? 4. Try replacing

the No. 2 tray shift motor. Is the problem

corrected?

E542- There is a lower tray

8001 ascent/descent error. (finisher)

1. Check the No. 2 tray area sensors 1

through 3. Are the sensors normal? 2. Check

24

There is a fault in the lower tray

ascent/descent motor clock

signal.

There is a lower tray

E542ascent/descent error. (finisher)

8002

There is an area error.

the wiring between the finisher controller

PCB and the No. 2 tray shift motor. Is it

normal? 3. Is there a fault in the tray

ascent/descent mechanism? 4. Try replacing

the No. 2 tray shift motor. Is the problem

corrected?

1. Check the No. 2 tray area sensors 1

through 3. Are the sensors normal? 2. Check

the wiring between the finisher controller

PCB and the No. 2 tray shift motor. Is it

normal? 3. Is there a fault in the tray

ascent/descent mechanism? 4. Try replacing

the No. 2 tray shift motor. Is the problem

corrected?

1. Check the shutter home position sensor.

Is it normal? 2. Check the wiring between the

There is a shutter unit error.

finisher controller PCB and the stack feeding

(finisher)

motor and between the finisher controller

E584The shutter open sensor does not PCB and the shutter open/close clutch. Is it

0002

go on. (The shutter does not

normal? 3. Is there a fault in the shutter

open.)

mechanism? 4. Try replacing the stack

edging motor and the shutter open/close

clutch. Is the problem corrected?

There is a shutter unit error.

(finisher)

E584The shutter open sensor fails to

8001

go off. (The shutter does not

close.)

1. Check the shutter home position sensor.

Is it normal? 2. Check the wiring between the

finisher controller PCB and the stack feeding

motor and between the finisher controller

PCB and the shutter open/close clutch. Is it

normal? 3. Is there a fault in the shutter

mechanism? 4. Try replacing the stack

edging motor and the shutter open/close

clutch. Is the problem corrected?

There is a punch motor error.

(punch unit)

E590- The punch home position sensor

8001 is not detected even when the

punch motor has been driven for

200 msec.

- Check the punch home position sensor,

horizontal registration motor, and punch

driver PCB; thereafter, turn off and then back

on the main power.

There is a punch motor error.

(punch unit)

E590- The puncher does not detect the

8002 punch home position sensor while

the motor is at rest at time of

punch motor initialization.

- Check the punch home position sensor,

horizontal registration motor, and punch

driver PCB; thereafter, turn off and then back

on the main power.

25

26

Code

Description

Remedy

There is a punch dust sensor error. (punch unit)

E591The incoming light voltage is faulty in the

8001

presence of light.

- Turn off and then back on

the main power.

There is a punch dust sensor error. (punch unit)

E591The incoming light voltage is faulty in the

8002

absence of light.

- Turn off and then back on

the main power.

There is a punch horizontal registration sensor

E592- error. (punch unit)

8001 The incoming light voltage is faulty in the

presence of light. (trailing edge sensor)

- turn off and then back on

the main power.

There is a punch horizontal registration sensor

E592- error. (punch unit)

8002 The incoming light is faulty in the absence of

light and voltage. (trailing edge sensor)

- turn off and then back on

the main power.

There is a punch horizontal registration sensor

error. (punch unit)

E592The incoming light voltage is faulty in the

8003

presence of light. (horizontal registration sensor

1)

- turn off and then back on

the main power.

There is a punch horizontal registration sensor

error. (punch unit)

E592The incoming light voltage is faulty in the

8004

absence of light. (horizontal registration sensor

1)

- turn off and then back on

the main power.

There is a punch horizontal registration sensor

error. (punch unit)

E592The incoming light voltage is faulty in the

8005

presence of light. (horizontal registration sensor

2)

- turn off and then back on

the main power.

There is a punch horizontal registration sensor

error. (punch unit)

E592The incoming light voltage is faulty in the

8006

absence of light. (horizontal registration sensor

2)

- turn off and then back on

the main power.

There is a punch horizontal registration sensor

error. (punch unit)

E592The incoming light voltage is faulty in the

8007

presence of light. (horizontal registration sensor

3)

- turn off and then back on

the main power.

E592- There is a punch horizontal registration sensor

- turn off and then back on

27

8008

error. (punch unit)

The incoming light voltage is faulty in the

absence of light. (horizontal registration sensor

3)

the main power.

There is a punch horizontal registration sensor

error. (punch unit)

E592The incoming light voltage is faulty in the

8009

presence of light. (horizontal registration sensor

4)

- turn off and then back on

the main power.

There is a punch horizontal registration sensor

error. (punch unit)

E592The incoming light voltage is faulty in the

800A

absence of light. (horizontal registration sensor

4)

- turn off and then back on

the main power.

There is a punch shift motor error. (punch unit)

E593In the presence of light, the incoming light

8001

voltage HP sensor does not go off.

- Turn off and the back on

the main power.

There is a punch shift motor error. (punch unit)

E593In the absence of light, the incoming light

8002

voltage HP sensor does not go on.

- Turn off and the back on

the main power.

There is a saddle paper positioning error.

The paper positioning plate home position

E5F0- sensor does not go on even when the paper

0001 positioning plate motor has been driven for 1.33

sec. paper positioning plate motor (M4S), paper

positioning plate home position sensor (PI7S)

- Check the paper

positioning plate motor

(M4S) and the paper

positioning plate home

position sensor (PI7S).

Code

Description

Remedy

There is a saddle paper positioning error.

The paper positioning plate home position

E5F0- sensor does not go off even when the paper

0002 positioning plate motor has been driven for 1

sec. paper positioning plate motor (M4S), paper

positioning plate home position sensor (PI7S)

- Check the paper

positioning plate motor

(M4S) and the paper

positioning plate home

position sensor (PI7S).

There is a saddle paper folding error.

The number of detection pulses of the paper

E5F1folding motor clock sensor is lower than a

0001

specific value. paper folding motor (M2S), paper

folding motor clock sensor (PI4S)

- Check the paper folding

motor (M2S) and the paper

folding motor clock sensor

(PI4S).

E5F1- There is a saddle paper folding error.

0002 The state of the paper folding home position

- Check the paper folding

motor (M2S) and the paper

28

sensor does not change even when the paper

folding motor has been driven for 3 sec. paper

folding motor (M2S), paper folding motor clock

sensor (PI4S)

folding motor clock sensor

(PI4S).

There is a saddle guide error.

The guide home position sensor does not go on - Check the guide motor

E5F2even when the guide motor has been driven for (M3S) and the guide home

0001

0.455 sec. guide motor (M3S), guide home

position sensor (PI13S).

position sensor (PI13S)

There is a saddle guide error.

The guide home position sensor does not go off - Check the guide motor

E5F2even when the guide motor has been driven for (M3S) and the guide home

0002

1 sec. guide motor (M3S), guide home position position sensor (PI13S).

sensor (PI13S)

There is a saddle alignment error.

The aligning plate home position sensor does

E5F3- not go on even when the aligning motor has

0001 been driven for 0.5 sec. (if at time of

initialization, 1.67 sec) alignment motor (M5S),

aligning plate home position sensor (PI5S)

- Check the alignment

motor (M5S) and the

aligning plate home

position sensor (PI5S).

There is a saddle alignment error.

The aligning plate home position sensor does

E5F3not go off even when the aligning motor has

0002

been driven for 1 sec. alignment motor (M5S),

aligning plate home position sensor (PI5S)

- Check the alignment

motor (M5S) and the

aligning plate home

position sensor (PI5S).

There is a saddle rear stapler error.

The stitching home position sensor does not go

E5F4- on even when the stitching motor (rear) has

0001 been driven in reverse for 0.5 sec or more.

stitching motor (rear, M6S), stitching home

position sensor (rear, MS5S)

- Check the stitching motor

(rear, M6S) and the

stitching home position

sensor (rear, MS5S).

There is a saddle rear stapler error.

The stitching home position sensor does not go

E5F4- off even when the stitching motor (rear) has

0002 been driven in normal direction for 0.5 sec or

more. stitching motor (rear, M6S), stitching

home position sensor (rear, MS5S)

- Check the stitching motor

(rear, M6S) and the

stitching home position

sensor (rear, MS5S).

There is a saddle front stapling error.

The stitching home position sensor does not go

E5F5- on even when the stitching motor (front) has

0001 been driven in reverse for 0.5 sec or more.

stitching motor (front, M7S), stitching home

position sensor (front, MS7S)

- Check the stitching motor

(front, M7S) and the

stitching home position

sensor (front, MS7S).

29

There is a saddle front stapling error.

The stitching home position sensor does not go

E5F5- off even when the stitching motor (front) has

0002 been driven in normal direction for 0.5 sec or

more. stitching motor (front, M7S), stitching

home position sensor (front, MS7S)

- Check the stitching motor

(front, M7S) and the

stitching home position

sensor (front, MS7S).

There is a saddle butting error.

The paper pushing plate home position sensor

E5F6- does not go on even when the paper pushing

8001 plate motor has been driven for 0.3 sec or more.

paper pushing plate motor (M8S), paper

pushing plate home position sensor (PI14S)

- Check the paper pushing

plate motor (M8S) and the

paper pushing plate home

position sensor (PI14S).

There is a saddle butting error.

The paper pushing plate home position sensor

E5F6- does not go off even when the paper pushing

8002 plate motor has been driven for 80 msec. paper

pushing plate motor (M8S), paper pushing plate

home position sensor (PI14S)

- Check the paper pushing

plate motor (M8S) and the

paper pushing plate home

position sensor (PI14S).

There is a saddle butting error.

The number of detection pulses of the paper

E5F6- pushing plate motor clock sensor is lower than a

8003 specific value. paper pushing plate motor

(M8S), paper pushing plate motor clock sensor

(PI1S)

- Check the paper pushing

plate motor (M8S) and the

paper pushing plate motor

clock sensor (PI1S).

There is a saddle butting error.

The paper pushing plate leading edge sensor

E5F6- does not go off even when the paper pushing

8004 plate motor has been driven for 80 msec. paper

pushing plate motor (M8S), paper pushing plate

leading edge position sensor (PI15S)

- Check the paper pushing

plate motor (M8S) and the

paper pushing plate leading

edge position sensor

(PI15S).

Code

Description

Remedy

There is a saddle butting error.

The paper pushing plate leading edge

position sensor does not go on even when

E5F6the paper pushing plate has been driven for

8005

0.3 sec or more. paper pushing plate motor

(M8S), paper pushing plate leading edge

position sensor (PI15S)

- Check the paper pushing plate

motor (M8S) and the paper

pushing plate leading edge

position sensor (PI15S).

There is a saddle switch error.

E5F9With any of the sensor identifying its

0001

respective cover as being closed, the inlet

- Check the inlet cover switch

(MS1S), front cover switch

(MS2S), and the delivery cover

30

cover switch is identified as being open for

1 sec from the start of initial rotation or

printing: - inlet cover sensor (PI9S) - front

cover open/closed sensor (PI2S) - delivery

cover sensor (PI3S) Or, the front cover

switch (MS2S) or the delivery cover switch

(MS3S) is open. inlet cover switch (MS1S),

front cover switch (MS2S), delivery cover

switch (MS3S)

switch (MS3S).

There is a saddle switch error.

With any of the following sensors identifying

its respective cover as being closed, the

front cover switch is identified as being

- Check the front cover switch

E5F9- open for 1 sec or more after the start of

(MS2S) and the delivery cover

0002 initial rotation or printing. - inlet cover

switch (MS3S).

sensor (PI9S) - front cover open/closed

sensor (PI2S) - delivery cover sensor (PI3S)

- front cover switch (MS2S), delivery cover

switch (MS3S)

There is a saddle switch error.

With any of the following sensors identifying

its respective cover as being closed, the

delivery cover switch is identified as being

- Check the delivery cover switch

E5F9open for 1 sec or more from the start of

(MS3S).

0003

initial rotation or printing: - inlet cover

sensor (PI9S) - front cover open/closed

sensor (PI2S) - delivery cover sensor (PI3S)

- delivery cover switch (MS3S)

E602

error in hard disk or HDD encryption board

E604- The image memory is faulty or inadequate.

0000 The memory is inadequate for the model.

- Add memory.

The hard disk is faulty.

E609- At time of start-up, the HDD fails to reach a - Replace the hard disk. - Replace

0008 specific temperature within a specific period the DC controller PCB.

of time.

The hard disk is faulty.

E609At time of a sleep shift, the temperature is

0009

below a specific level.

E610

The HDD encryption key is faulty.

(hardware composition error, initialization

error, ID key error, ID processing error)

E611- retried reboot due to SRAM crash and the

- Replace the hard disk. - Replace

the DC controller PCB.

- Check the hardware composition.

- Turn off and then on the main

power.

Clear SRAM to cancel the

31

0000

E612

like during the shutdown recovery job

shutdown recovery job.

execution

SRAM data were broken and the stored job

information cannot be read; this causes the

repeated reboot trials to recover the power

shutdown, and thus the redundant job

transmission. This phenomenon triggers E

code.

Write the correct license and new

error in postponement Timing: when starting serial numbers and turn off/on the

the host machine

power switch. - Turn off and then

on the main power.

- Check the connection of the

cable between the fax controller

There is a fault in the communication

PCB (2-line) and the main

between the fax controller PCB (2-line) and

controller PCB. - Replace the ROM

E674the main controller PCB.

DIMM of the fax controller PCB (20001

An attempt to set fax device mode has

line). - Replace the fax controller

failed.

PCB (2-line). - Replace the main

controller PCB.

There is a fault in IPC initialization.

E710- At time of power-on, the communications IC - Check the connection of the

cable.

0001 on the main controller PCB does not

become ready within 3 sec after start-up.

There is a fault in IPC initialization.

E710At power-on, the machine communication

0002

IC has detected an error.

- Check the connection of the

cable.

There is a fault in the IPC communication.

After power-on, the occurrence of an error

E711has been written 4 times in 1.5 sec to the

0001

error register of the communications IC on

the main controller PCB.

- Check the connection of the

cable

Code

Description

Remedy

There is a fault in the IPC communication.

E711After power-on, the machine communication IC

0002

has detected an error.

- Check the connection of the

cable.

There is a sorter IPC error.

E713An error has been detected in the sorter

0000

communication IC.

- Check the connection of the

cable. - Replace the finisher

controller PCB. - Replace the

DC controller PCB.

32

There is a fault in the communication with the NE

controller. After correcting the fault, be sure to

reset the error.

- Check the connection of the

E717(COPIER>FUNCTION>CLEAR>ERR)

cable.

0001

An error has occurred at time of NE controller

start-up. The NE controller that was connected

before power-off is not connected at power-on.

There is a fault in the communication with the NE

controller. After correcting the fault, be sure to

reset the error.

- Check the connection of the

E717(COPIER>FUNCTION>CLEAR>ERR)

cable.

0002

There is an IP error while the NE controller is in

operation. The IPC may have an open circuit or

the IPC communication cannot be recovered.

There is a fault in the coin vendor. After

correcting the fault, be sure to reset the error.