Professional Documents

Culture Documents

Daikin VRV III (Selection Installation Proceedure) Technical Data Book PDF

Uploaded by

Harveen SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daikin VRV III (Selection Installation Proceedure) Technical Data Book PDF

Uploaded by

Harveen SinghCopyright:

Available Formats

technical data

air conditioning systems

Air-cooled selection procedure

Air-cooled selection procedure

TABLE OF CONTENTS

1 Air-cooled selection procedure

Selection procedure VRVIII system based on cooling load . . . 2

Indoor unit selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outdoor unit selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Actual performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selection example based on cooling load . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

2

3

3

Capacity correction ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

VRVIII-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

VRVIII cooling only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

VRVIII heat pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

VRVIII heat recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Integrated heating capacity coefficient . . . . . . . . . . . . . . . . . . . . . . . . .

Refnet pipe systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Example of Refnet piping layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refrigerant pipe selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

VRVIII-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VRVIII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VRVIII heat recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piping thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VRV Systems Air-cooled selection procedure

36

47

48

49

51

54

Air-cooled selection procedure

Selection procedure VRVIII system based on cooling load

1-1

Indoor unit selection

Enter indoor unit capacity tables at given indoor and outdoor temperature.

Select the unit that the capacity is the nearest to and higher than the given load.

NOTE

1

1

Individual indoor unit capacity is subject to change by the combination. Actual capacity has to be calculated according to the combination by using

outdoor units capacity table.

1-2

Outdoor unit selection

Allowable combinations are indicated in indoor unit combination total capacity index table.

In general, oudoor units can be selected as follows though the location of the unit, zoning and usage of the rooms should be considered.

The indoor and outdoor unit combination is determined that the sum of indoor unit capacity index is nearest to and smaller than the capacity index at

100 % combination ratio of each outdoor unit. Up to 16 indoor units can be connected to one outdoor unit. It is recommended to choose a larger

outdoor unit if the installation space is large enough.

If the combination ratio is higher than 100 %, the indoor unit selection will have to be reviewed by using actual capacity of each indoor unit.

Indoor unit combination total capacity index table

Outdoor unit

RXYSQ4PV / RXYSQ4PY1

RXYSQ5PV / RXYSQ5PY1

RXYSQ6PV / RXYSQ6PY1

Outdoor unit

RX(Y)Q5P

RX(Y)Q8P/REYQ8P

RX(Y)Q10P/REYQ10P

RX(Y)Q12P/REYQ12P

RX(Y)Q14PA/REYQ14P

RX(Y)Q16PA/REYQ16P

RX(Y)Q18PA/REYQ18P

RXYQ20P(A)/REYQ20P

RXYQ22P(A)/REYQ22P

RXYQ24P(A)/REYQ24P

RXYQ26P(A)/REYQ26P

RXYQ28P(A)/REYQ28P

RXYQ30P(A)/REYQ30P

RXYQ32P(A)/REYQ32P

RXYQ34P(A)/REYQ34P

RXYQ36P(A)/REYQ36P

RXYQ38P(A)/REYQ38P

RXYQ40P(A)/REYQ40P

RXYQ42P(A)/REYQ42P

RXYQ44P(A)/REYQ44P

RXYQ46P(A)/REYQ46P

RXYQ48P(A)/REYQ48P

RXYQ50P(A)

RXYQ52P(A)

RXYQ54P(A)

130 %

130

162.5

182

120 %

120

150

168

110 %

110

137.5

154

100 %

100

125

140

Indoor unit combination ratio

90 %

90

112.5

126

80 %

80

100

112

70%

70

87.5

98

60 %

60

75

84

50 %

50

62.5

70

130 %

162.5

260

325

390

455

520

585

650

715

780

845

910

975

1,040

1,105

1,170

1,235

1,300

1,365

1,430

1,495

1,560

1,625

1,690

1,755

120 %

150

240

300

360

420

480

540

600

660

720

780

840

900

960

1,020

1,080

1,140

1,200

1,260

1,320

1,380

1,440

1,500

1,560

1,620

110 %

137.5

220

275

330

385

440

495

550

605

660

715

770

825

880

935

990

1,045

1,100

1,155

1,210

1,265

1,320

1,375

1,430

1,485

100 %

125

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

950

1,000

1,050

1,100

1,150

1,200

1,250

1,300

1,350

Indoor unit combination ratio

90 %

112.5

180

225

270

315

360

405

450

495

540

585

630

675

720

765

810

855

900

945

990

1,035

1,080

1,125

1,170

1,215

80 %

100

160

200

240

280

320

360

400

440

480

520

560

600

640

680

720

760

800

840

880

920

960

1,000

1,040

1,080

70%

87.5

140

175

210

245

280

315

350

385

420

455

490

525

560

595

630

665

700

735

770

805

840

875

910

945

60 %

75

120

150

180

210

240

270

300

330

360

390

420

450

480

510

540

570

600

630

660

690

720

750

780

810

50 %

62.5

100

125

150

175

200

225

250

275

300

325

350

375

400

425

450

475

500

525

550

575

600

625

650

675

Indoor unit capacity index

Model

Capacity index

20

20

25

25

32

31.25

40

40

50

50

63

62.5

71

71

VRV Systems Air cooled selection procedure

80

80

100

100

125

125

200

200

250

250

Air-cooled selection procedure

Selection procedure VRVIII system based on cooling load

1-3

Actual performance data

Use outdoor unit capacity tables

Determine the correct table according to the outdoor unit model and combination ratio.

Enter the table at given indoor and outdoor temperature and find the outdoor capacity and power input. The individual indoor unit capacity (power

input) can be calculated as follows:

ICA = OCA x INX

TNX

ICA: Individual indoor unit capacity (power input)

OCA: Outdoor unit capacity (power input)

INX: Individual indoor unit capacity index

TNX: Total capacity index

1

1

Then, correct the indoor unit capacity according to the piping length.

If the corrected capacity is smaller than the load, the size of indoor unit has to be increased. Repeat the same selection procedure.

1-4

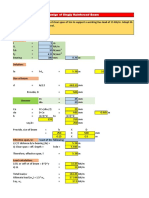

Selection example based on cooling load

Given

Design condition

Cooling: indoor 20CWB, outdoor 33CDB

Cooling load

Room

Load (kW)

A

2.9

Power supply: 3-phase 380V/50Hz

Indoor unit selection

B

2.7

C

2.5

D

4.3

E

4.0

F

4.0

G

3.9

H

4.2

B

2.7

25

3.0

C

2.5

25

3.0

D

4.3

40

4.8

E

4.0

40

4.8

F

4.0

40

4.8

G

3.9

40

4.8

H

4.2

40

4.8

Enter indoor unit capacity table at:

20CWB indoor temperature

33CDB outdoor air temperature.

Selection results are as follows:

Room

Load (kW)

Unit size

Capacity

A

2.9

25

3.0

Outdoor unit selection

Assume that the indoor and outdoor unit combination is as follows.

Outdoor unit: RXYQ10P

Indoor unit:

FXCQ25M8 x 3, FXCQ40M8 x 5

Indoor unit combination total capacity index

25 x 3 + 40 x 5 = 275 (110 %)

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Selection procedure VRVIII system based on cooling load

1-4

Selection example based on cooling load

Actual performance data (50Hz)

Outdoor unit cooling capacity: 30.5kW (RXYQ10P, 110 %)

Individual capacity

Capacity of FXCQ25M

= 30.5 x

Capacity of FXCQ40M

= 30.5 x

25

275

40

275

= 2.77kW

= 4.44kW

Actual combination capacity

Room

Load (kW)

Unit size

Capacity

1

1

A

2.9

25

2.77

B

2.7

25

2.77

C

2.5

25

2.77

D

4.3

40

4.44

E

4.0

40

4.44

F

4.0

40

4.44

G

3.9

40

4.44

H

4.2

40

4.44

The unit size for room A has to be increased from 25 to 32 because the capacity is less than the load. For new combination, actual capacity is calculated

as follows.

Indoor unit combination total capacity index

(25 x 2) +31.25 + (40 x5) = 281.25 (112.5 %)

Outdoor unit cooling capacity:

27,610 kcal/h (direct interpolation between 110 % and 120 % in the table)

Individual capacity

Capacity of FXCQ25M

Capacity of FXCQ32M

Capacity of FXCQ40M

25 = 2.7kW

281.25

= 30.0 x 32 = 3.4kW

281.25

= 30.0 x 40 = 4.3kW

281.25

= 30.0 x

Actual capacity of new combination

Room

Load (kW)

Unit size

Capacity

A

2.9

32

3.4

B

2.7

25

2.7

C

2.5

25

2.7

D

4.3

40

4.3

E

4.0

40

4.3

F

4.0

40

4.3

G

3.9

40

4.3

H

4.2

40

4.3

Then, the capacities have to be corrected for actual piping length according to the location of indoor and outdoor units and the distance between them.

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Capacity correction ratio

2-1

VRVIII-S

RXYSQ4,5PV/RXYSQ4,5PY1

1. Rate of change in cooling capacity

2. Rate of change in heating capacity

1

2

3D045710C

NOTES

1. These figures illustrate the rate of change in capacity of a standard indoor unit system at maximum load (with the thermostat set to maximum) under standard conditions.

Moreover, under partial load conditions there is only a minor deviation from the rate of change in capacity shown in the above figures.

2. With this outdoor unit, evaporating pressure constant control when cooling, and condensing pressure constant control when heating is carried out.

3. Method of calculating cooling / heating capacity (max. capacity for combination with standard indoor unit).

Cooling / heating capacity = cooling / heating capacity obtained from performance characteristics table x each capacity rate of change

In the case length of piping differs depending on the indoor unit, maximum capacity of each unit during simultaneous operation is:

Cooling / heating capacity = cooling / heating capacity of each unit x capacity rate of change for each piping length

<As for RXYSQ4,5P7V3B>

4. When overall equivalent pipe length is 90m or more, the diameter of the main gas pipes (outdoor unit-branch sections) must be increased.

[Diameter of above case]

Model

RXYSQ4, 5P7V3B

RXYSQ4, 5P7Y1B

Gas

Liquid

Not increased

J19.1

5. When the main sections of the interunit gas pipe diameters are increased the overall equivalent length should be calculated as follows.

Overall equivalent length = Equivalent length to main pipe x 0.5 + Equivalent length after branching

Example:: RXYSQ4, 5P7V3B

: RXYSQ4, 5P7Y1B

Equivalent length

Equivalent length

Indoor unit

Outdoor unit

Size increase

Branch

In the above case (Cooling)

Overall equivalent length = 80m x 0.5 + 40m = 80m

The correction factor in capacity when Hp=0m is thus approximately 0.78.

Explanation of symbols

Hp : Level difference (m) between indoor and outdoor units where indoor in inferior position.

HM : Level difference (m) between indoor and outdoor units where indoor in superior position.

L

: Equivalent pipe length (m)

: Capacity correction factor

[Diameter of pipes]

Model

RXYSQ4, 5P7V3B

RXYSQ4, 5P7Y1B

Gas

Liquid

J15.9

J9.5

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Capacity correction ratio

2-1

VRVIII-S

RXYSQ6PV/RXYSQ6PY1

1. Rate of change in cooling capacity

2. Rate of change in heating capacity

1

2

3D045961C

NOTES

1. These figures illustrate the rate of change in capacity of a standard indoor unit system at maximum load (with the thermostat set to maximum) under standard conditions.

Moreover, under partial load conditions there is only a minor deviation from the rate of change in capacity shown in the above figures.

2. With this outdoor unit, evaporating pressure constant control when cooling, and condensing pressure constant control when heating is carried out.

3. Method of calculating cooling / heating capacity (max. capacity for combination with standard indoor unit).

Cooling / heating capacity = cooling / heating capacity obtained from performance characteristics table X each capacity rate of change

In the case length of piping differs depending on the indoor unit, maximum capacity of each unit during simultaneous operation is:

Cooling / heating capacity = cooling / heating capacity of each unit X capacity rate of change for each piping length

<As for RXYSQ6P7V3B>

4. When overall equivalent pipe length is 90m or more, the diameter of the main gas pipes (outdoor unit-branch sections) must be increased.

[Diameter of above case]

Model

RXYSQ6P7V3B

RXYSQ6P7Y1B

Gas

Liquid

Not increased

J22.2

5. When the main sections of the interunit gas pipe diameters are increased the overall equivalent length should be calculated as follows.

Overall equivalent length = Equivalent length to main pipe x 0.5 + Equivalent length after branching

Example:: RXYSQ6P7V3B

: RXYSQ6P7Y1B

Equivalent length

Equivalent length

Indoor unit

Outdoor unit

Size increase

Branch

In the above case (Cooling)

Overall equivalent length = 80m x 0.5 + 40m = 80m

The correction factor in capacity when Hp=0m is thus approximately 0.86.

Explanation of symbols

Hp : Level difference (m) between indoor and outdoor units where indoor in inferior position.

HM : Level difference (m) between indoor and outdoor units where indoor in superior position.

L

: Equivalent pipe length (m)

: Capacity correction factor

[Diameter of pipes]

Model

RXYSQ6P7V3B

RXYSQ6P7Y1B

Gas

Liquid

J19.1

J9.5

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Capacity correction ratio

2-2

VRVIII cooling only

RXQ5P

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

60

50

40

30

20

10

0

0

-10

-20

-30

-40

-50

0.86

1.00

0.98

10

1.00

0.96

0.94

0.90

0.92

20

0.98

0.96

30

0.94

0.84

0.82

50

60

0.80

0.78

0.76

80

90

0.74

0.88

40

70

100

110

0.92

0.90 0.88 0.86 0.84

0.82

0.80

0.78

0.76

Equivalent piping length

3TW27302-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

gas pipe

19.1

RXQ5P

5

Model

gas pipe

15.9

liquid pipe

9.5

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size.

Correction factor

Standard size

Size increase

1.0

0.5

Cooling (gas pipe)

7

liquid pipe

9.5

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

RXQ5P

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.78

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Capacity correction ratio

2-2

VRVIII cooling only

RXQ8P

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

60

0.90

50

0.82

0.94

30

0.96

20

0.98

1.00

10

0 0.75

0

10

1.00

20

-10

-20

30

40

50

60

0.94

0.92

0.90

70

80

90

100

110

0.98

-30

0.96

-40

-50

0.84

0.86

0.88

0.92

40

0.88

0.86

0.84

Equivalent piping length (m)

3TW27302-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

gas pipe

22.2

RXQ8P

5

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

gas pipe

19.1

RXQ8P

6

liquid pipe

9.5

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size.

Correction factor

Standard size

Size increase

1.0

0.5

Cooling (gas pipe)

7

liquid pipe

12.7

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.86

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Capacity correction ratio

2-2

VRVIII cooling only

RXQ10P

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

60

0.90 0.88 0.86 0.84

0.82

0.80

50

0.92

40

0.94

30

0.96

20

0.98

10 1.00

0

0

40

60

80

100

120

140

160

20

-10

1.00

-20

0.98

-30

0.96

-40

0.94 0.92 0.90 0.88 0.86 0.84

0.82

0.80

-50

Equivalent piping length (m)

0.78

180

0.78

3TW27302-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXQ10P

gas pipe

25.4*

liquid pipe

12.7

* If not available on site, do not increase. If not increased, no correction factor should be applied to the equivalent length (see note 6).

5

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXQ10P

gas pipe

22.2

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size.

Correction factor

Standard size

Size increase

1.0

0.5

Cooling (gas pipe)

7

liquid pipe

9.5

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.87

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Capacity correction ratio

2-2

VRVIII cooling only

RXQ12,14P

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

60

0.92

0.90

0.88

0.86

0.94

50

0.96

40

30

0.98

20

10 1.00

0

40

60

80

0

100

120

140

160

20

-10

1.00

-20

-30

0.98

-40

0.96 0.94

0.92

0.90

0.88

0.86

-50

Equivalent piping length (m)

0.84

180

0.84

3TW27302-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXQ12-14P

gas pipe

28.6

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXQ12-14P

gas pipe

28.6

liquid pipe

12.7

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size.

Correction factor

Standard size

Size increase

1.0

0.5

Cooling (gas pipe)

7

liquid pipe

15.9

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 1.0 + 40m x 1.0 = 120m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.89

10

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Capacity correction ratio

2-2

VRVIII cooling only

RXQ16P

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

60

0.92 0.90 0.88

50

0.86

0.94

40

0.96

30

0.98

20

10 1.00

00

20

40

60

80

-10

1.00

-20

0.98

-30

0.96

-40

0.94 0.92 0.90 0.88

-50

0.84

100

0.80

0.82

120

140

0.86 0.84

0.82

Equivalent piping length

0.78

160

0.80

180

0.78

3TW27302-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

gas pipe

31.8*

RXQ5P

5

Model

gas pipe

28.6

liquid pipe

12.7

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size.

Correction factor

Standard size

Size increase

1.0

0.5

Cooling (gas pipe)

7

liquid pipe

15.9

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

RXQ5P

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.88

VRV Systems Air cooled selection procedure

11

Air-cooled selection procedure

Capacity correction ratio

2-2

VRVIII cooling only

RXQ18P

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

60

0.84

0.82

0.92 0.90 0.88 0.86

50

0.94

40

0.96

30

0.98

20

10 1.00

0

20

100

0

120

140

80

40

60

-10

1.00

-20

0.98

-30

0.96

-40

0.94 0.92 0.90 0.88 0.86 0.84

0.82

-50

Equivalent piping length

0.80

160

0.80

0.78

180

0.78

3TW27302-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXQ18P

gas pipe

31.8*

liquid pipe

19.1

* If not available on site, do not increase. If not increased, no correction factor should be applied to the equivalent length (see note 6).

5

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXQ18P

gas pipe

28.6

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size

.

Correction factor

Standard size

Size increase

1.0

0.5

Cooling (gas pipe)

7

liquid pipe

15.9

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 1.0 + 40m x 1.0 = 120m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.83

12

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Capacity correction ratio

2-3

VRVIII heat pump

RXYQ5P

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

60

0.86

50

40

30

20

1.00

10

0.98

0.96

0.94

0.92

0.90

0.84

0.82

0.80

0.78

0.76

60

0.74

0.88

0

-10 0

10

1.00

-20

20

0.98

-30

-40

0.96

30

0.94

40

50

60

70

80

90

100

110

0.92

0.90 0.88 0.86

-50

0.84

0.82

0.80

0.78

Correction ratio for heating capacity

0.76

Height difference between outdoor and farest indoor (m)

50

40

30

20

10

0

-10

-10

1.00

10

1.00

30

50

70

90

110

130

150

170

190

-20

-30

-40

-50

Equivalent piping length (m)

Equivalent piping length

3TW27232-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling and constant condensing pressure control when heating is carried out.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXYQ5P

gas pipe

19.1

gas pipe

15.9

liquid pipe

9.5

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size

When heating capacity is calculated: liquid pipe size.

Cooling (gas pipe)

Heating (liquid pipe)

7

liquid pipe

9.5

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXYQ5P

Correction factor

Standard size

Size increase

1.0

0.5

1.0

0.5

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

(Heating) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 120m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.78

heating capacity when height difference = 0 is thus approximately 1.0

VRV Systems Air cooled selection procedure

13

Air-cooled selection procedure

Capacity correction ratio

2-3

VRVIII heat pump

RXYQ8P

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

Correction ratio for heating capacity

60

60

0.90

50

0.88

0.84

0.86

0.82

0.92

40

0.94

30

0.96

20

0.98

1.00

10

0 0.70

0

-10

-20

20

10

30

40

50

60

70

80

90

100

110

1.00

0.98

-30

0.96

-40

0.94

-50

0.92

0.90

0.88

Equivalent piping length

0.86

0.84

Height difference between outdoor and farest indoor (m)

50

40

30

20

1.00

10

0

-10

-20

10

1.00

20

40

50

60

70

80

90

100

110

-30

-40

-50

Equivalent piping length (m)

3TW27232-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling and constant condensing pressure control when heating is carried out.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXYQ8P

gas pipe

22.2

gas pipe

19.1

liquid pipe

9.5

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size

When heating capacity is calculated: liquid pipe size.

Cooling (gas pipe)

Heating (liquid pipe)

7

liquid pipe

12.7

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXYQ8P

Correction factor

Standard size

Size increase

1.0

0.5

1.0

0.5

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

(Heating) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.86

heating capacity when height difference = 0 is thus approximately 1.0

14

30

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Capacity correction ratio

2-3

VRVIII heat pump

RXYQ10P

Correction ratio for cooling capacity

60

0.90 0.88 0.86 0.84

0.82

0.80

50

0.92

40

0.94

30

0.96

0.98

20

10 1.00

0

40

60

80

20

100

120

140

160

0

-10

1.00

-20

0.98

-30

0.96

-40

0.94 0.92 0.90 0.88 0.86 0.84

0.82

0.80

-50

Equivalent piping length

Correction ratio for heating capacity

60

0.78

180

0.78

Height difference between outdoor and farest indoor (m)

Height difference between outdoor and farest indoor (m)

0.98 0.96 0.94 0.92 0.90 0.88 0.86 0.84 0.82 0.80

50

40

30

20

1.00

10

0

-10

-20

10

1.00

20

30

40

50

60

70

80

90

100

110

-30

-40

-50

0.98 0.96 0.94 0.92 0.90 0.88 0.86 0.84 0.82 0.80

Equivalent piping length (m)

3TW27232-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling and constant condensing pressure control when heating is carried out.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXYQ10P

gas pipe

25.4*

liquid pipe

12.7

* If not available on site, do not increase. If not increased, no correction factor should be applied to the equivalent length (see note 6).

5

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXYQ10P

gas pipe

22.2

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size

When heating capacity is calculated: liquid pipe size.

Cooling (gas pipe)

Heating (liquid pipe)

7

liquid pipe

9.5

Correction factor

Standard size

Size increase

1.0

0.5

1.0

0.5

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

(Heating) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.87

heating capacity when height difference = 0 is thus approximately 0.90

VRV Systems Air cooled selection procedure

15

Air-cooled selection procedure

Capacity correction ratio

2-3

VRVIII heat pump

RXYQ12,14,24,36P

Correction ratio for heating capacity

1

2

Heigth difference between outdoor

and farest indoor (m)

Heigth difference between outdoor and

farest indoor (m)

Correction ratio for cooling capacity

Equivalent piping length (m)

Equivalent piping length (m)

Notes

1. These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to maximum) under

standard conditions.

Moreover, under partial load conditions there is only a minor deviation from the rate of change in capacity shown in the above figures.

2. With this outdoor unit, evaporating pressure constant control when cooling, and condensing pressure constant control when heating is carried out.

3. Method of calculating the capacity of the outdoor units

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned below, whichever is

smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units

Capacity of outdoor units from capacity table at 100% connection ratio

Correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units

Capacity of outdoor units from capacity table at installed connection ratio

Correction ratio of piping to farest indoor

4. When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased.

For new diameters, see below.

model

RXYQ12+14P

RXYQ24P

RXYQ36P

Gas pipe

28,6

34,9

41,3

Liquid pipe

15,9

19,1

22,2

5. When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also to installation manual).

model

RXYQ12+14P

RXYQ24P

RXYQ36P

Gas pipe

28,6

34,9

41,3

Liquid pipe

12,7

15,9

19,1

6. Equivalent length used in the above figures is based upon the following equivalent length

Equivalent piping length

=

X

Correction factor

+

Equivalent length of branch pipes X

Correction factor

Equivalent length of main pipe

Choose the correction factor from the following table.

When cooling capacity is calculated: gas pipe size

When heating capacity is calculated: liquid pipe size

Cooling (Gas pipe)

Heating (Liquid pipe)

Correction factor

Standard size

Size increase

1,0

0,5

1,0

0,5

Example

Main gas pipe size increase

Main liquid pipe size increase

Branch gas pipe size increase

Branch liquid pipe size increase

In the above case

(Cooling) Overall equivalent length = 80mx1,0 + 40mx1,0 = 120m

(Heating) Overall equivalent length = 80mx0,5 + 40mx1,0 = 80m

The rate of change in:

Cooling capacity when heigth difference = 0 is thus approximately 0,89

Heating capacity when heigth difference = 0 is thus approximately 1,0

16

VRV Systems Air cooled selection procedure

3TW27232-6A

Air-cooled selection procedure

Capacity correction ratio

2-3

VRVIII heat pump

RXYQ16P

60

0.80 0.79

0.92 0.90 0.88 0.86 0.84 0.82

50

0.94

40

0.96

30

0.98

20

10 1.00

0

20

40

60

80

100

120

140

160

180

0

-10

1.00

-20

0.98

-30

0.96

-40

0.94 0.92 0.90 0.88 0.86 0.84

0.82

0.80 0.79

-50

Equivalent piping length

Correction ratio for heating capacity

60

Height difference between outdoor and farest indoor (m)

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

0.99 0.97 0.95 0.93

50

40

30

20

1.00

10

0

-10

-20

10

1.00

20

30

40

50

60

70

80

90

100

110

-30

-40

-50

0.99 0.97 0.95 0.93

Equivalent piping length (m)

3TW27232-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling and constant condensing pressure control when heating is carried out.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXYQ16P

gas pipe

31.8*

liquid pipe

15.9

* If not available on site, do not increase. If not increased, no correction factor should be applied to the equivalent length (see note 6).

5

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXYQ16P

gas pipe

28.6

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size

When heating capacity is calculated: liquid pipe size.

Cooling (gas pipe)

Heating (liquid pipe)

7

liquid pipe

12.7

Correction factor

Standard size

Size increase

1.0

0.5

1.0

0.5

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

(Heating) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.88

heating capacity when height difference = 0 is thus approximately 0.99

VRV Systems Air cooled selection procedure

17

Air-cooled selection procedure

Capacity correction ratio

2-3

VRVIII heat pump

RXYQ18,26,28,30,38,40,42,44P

60

0.80 0.79

0.92 0.90 0.88 0.86 0.84 0.82

50

0.94

40

0.96

30

0.98

20

1.00

10

0

40

60

80

100

120

140

160

180

0

20

-10

1.00

-20

0.98

-30

0.96

-40

0.94 0.92 0.90 0.88 0.86 0.84

0.82

0.80 0.79

-50

Equivalent piping length

Correction ratio for heating capacity

60

Height difference between outdoor and farest indoor (m)

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

50

40

30

20

1.00

10

0

-10

-20

10

1.00

20

30

40

50

60

70

80

90

100

110

-30

-40

-50

Equivalent piping length (m)

3TW27232-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling and constant condensing pressure control when heating is carried out.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXYQ18P

RXYQ26-30P

RXYQ38-44P

gas pipe

31.8*

38.1*

41.3

liquid pipe

19.1

22.2

22.2

* If not available on site, do not increase. If not increased, no correction factor should be applied to the equivalent length (see note 6).

5

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXYQ18P

RXYQ26-30P

RXYQ38-44P

gas pipe

28.6

34.9

41.3

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size

When heating capacity is calculated: liquid pipe size.

Cooling (gas pipe)

Heating (liquid pipe)

7

liquid pipe

15.9

19.1

19.1

Correction factor

Standard size

Size increase

1.0

0.5

1.0

0.5

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 1.0 + 40m x 1.0 = 120m

(Heating) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.83

heating capacity when height difference = 0 is thus approximately 1.0

18

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Capacity correction ratio

2-3

VRVIII heat pump

RXYQ20,32,34P

60

0.80

0.78

50

0.92 0.90 0.88 0.86 0.84 0.82

40

0.94

30

0.96

20

0.98

10 1.00

0

20

40 60

80

100

120 140 160 180

0

-10

1.00

-20

0.98

-30

0.96

-40

0.94 0.92 0.90 0.88 0.86 0.84 0.82

0.80

0.78

-50

Equivalent piping length

Correction ratio for heating capacity

60

Height difference between outdoor and farest indoor (m)

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

50

40

30

20

1.00

10

0

-10

-20

10

1.00

20

30

40

50

60

70

80

90

100

110

-30

-40

-50

Equivalent piping length (m)

3TW27232-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling and constant condensing pressure control when heating is carried out.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXYQ20P

RXYQ32-34P

gas pipe

31.8*

38.1*

liquid pipe

19.1

22.2

* If not available on site, do not increase. If not increased, no correction factor should be applied to the equivalent length (see note 6).

5

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXYQ20P

RXYQ32-34P

gas pipe

28.6

34.9

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size

When heating capacity is calculated: liquid pipe size.

Cooling (gas pipe)

Heating (liquid pipe)

7

liquid pipe

15.9

19.1

Correction factor

Standard size

Size increase

1.0

0.5

1.0

0.5

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

(Heating) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.88

heating capacity when height difference = 0 is thus approximately 1.0

VRV Systems Air cooled selection procedure

19

Air-cooled selection procedure

Capacity correction ratio

2-3

VRVIII heat pump

RXYQ22P

60

0.80

0.92 0.90 0.88 0.86 0.84 0.82

50

0.94

40

0.96

30

0.98

20 1.00

10

0 0.70

20

40

60

80 100

120 140

160

0

-10

-20

1.00

-30

0.98

-40

0.96 0.94 0.92 0.90 0.88 0.86 0.84 0.82

0.80

-50

Equivalent piping length

0.78

180

Correction ratio for heating capacity

Height difference between outdoor and farest indoor (m)

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

60

50

40

30

20

10

0

0

-10

-20

-30

-40

-50

1.00

10

1.00

20

30

40

50

60

70

80

90

100

110

Equivalent piping length (m)

3TW27232-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling and constant condensing pressure control when heating is carried out.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXYQ22P

gas pipe

31.8*

liquid pipe

19.1

* If not available on site, do not increase. If not increased, no correction factor should be applied to the equivalent length (see note 6).

5

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXYQ22P

gas pipe

28.6

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size

When heating capacity is calculated: liquid pipe size.

Cooling (gas pipe)

Heating (liquid pipe)

7

liquid pipe

15.9

Correction factor

Standard size

Size increase

1.0

0.5

1.0

0.5

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

(Heating) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.88

heating capacity when height difference = 0 is thus approximately 1.0

20

VRV Systems Air cooled selection procedure

Air-cooled selection procedure

Capacity correction ratio

2-3

VRVIII heat pump

RXYQ46P

60

0.90 0.88 0.86 0.84 0.82

0.80

0.78

50

0.92

40

0.94

30

0.96

0.98

20

10 1.00

0

40 60

80

100 120 140

160 180

0

20

-10

1.00

-20

0.98

-30

0.96

-40

0.78

0.94 0.92 0.90 0.88 0.86 0.84 0.82

0.80

-50

Equivalent piping length

Correction ratio for heating capacity

Height difference between outdoor and farest indoor (m)

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

60

50

40

30

20

10

0

0

-10

-20

-30

-40

-50

0.99 0.97 0.95

1.00

10

1.00

20

30

40

50

60

70

Equivalent piping length (m)

80

90

100

110

0.99 0.97 0.95

3TW27232-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling and constant condensing pressure control when heating is carried out.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXYQ46P

gas pipe

41.3

gas pipe

41.3

liquid pipe

19.1

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size

When heating capacity is calculated: liquid pipe size.

Cooling (gas pipe)

Heating (liquid pipe)

7

liquid pipe

22.2

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXYQ46P

Correction factor

Standard size

Size increase

1.0

0.5

1.0

0.5

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 1.0 + 40m x 1.0 = 120m

(Heating) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in:

cooling capacity when height difference = 0 is thus approximately 0.83

heating capacity when height difference = 0 is thus approximately 1.0

VRV Systems Air cooled selection procedure

21

Air-cooled selection procedure

Capacity correction ratio

2-3

VRVIII heat pump

RXYQ48P

60

0.90 0.88 0.86 0.84 0.82

0.80

0.78

50

0.92

40

0.94

30

0.96

0.98

20

10 1.00

0

40 60

80

100

120

140

160 180

0

20

-10

1.00

-20

0.98

-30

0.96

-40

0.78

0.94 0.92 0.90 0.88 0.86 0.84 0.82

0.80

-50

Equivalent piping length

Correction ratio for heating capacity

Height difference between outdoor and farest indoor (m)

Correction ratio for cooling capacity

Height difference between outdoor and farest indoor (m)

60

50

40

30

20

10

0

0

-10

-20

-30

-40

-50

0.99 0.97 0.95 0.93 0.91 0.89

1.00

10

1.00

20

40

50

60

70

Equivalent piping length (m)

80

90

100

110

0.99 0.97 0.95 0.93 0.91 0.89

3TW27232-6

NOTES

These figures illustrate the correction ratio for piping length in capacity for a standard indoor unit system at maximum load (with the thermostat set to

maximum) under standard conditions.

Moreover, under partial load conditions, there is only a minor deviation from the capacity correction ratio, shown in the above figures.

With this outdoor unit, constant evaporating pressure control when cooling and constant condensing pressure control when heating is carried out.

Method of calculating the capacity of the outdoor units:

The maximum capacity of the system will be either the total capacity of the indoor units or the maximum capacity of the outdoor units as mentioned

below, whichever is smaller.

Condition: Indoor connection ratio does not exceed 100%

Maximum capacity of outdoor units = capacity of outdoor units from capacity table at 100% connection ratio

x correction ratio of piping to farest indoor

Condition: Indoor connection ratio exceeds 100%

Maximum capacity of outdoor units = capacity of outdoor from capacity table at installed connection ratio

x correction ratio of piping to farest indoor

When the overall equivalent pipe length is 90m or more, main gas and liquid pipe diameters must be increased..

For new diameters see below.

Model

RXYQ48P

gas pipe

41.3

gas pipe

41.3

liquid pipe

19.1

Equivalent length used in the above figures is based upon the following equivalent length.

Equivalent piping length = Equivalent length of main pipe x Correction factor +

Equivalent length of branch pipes x Correction factor

Choose a correction factor from the following table.

When cooling capacity is calculated: gas pipe size

When heating capacity is calculated: liquid pipe size.

Cooling (gas pipe)

Heating (liquid pipe)

7

liquid pipe

22.2

When the pipe length after the first refrigerant branch kit is more than 40m, pipe size between first and final branch kit must be increased (refer also

to installation manual).

Diameter of main pipes (standard size)

Model

RXYQ48P

Correction factor

Standard size

Size increase

1.0

0.5

1.0

0.5

Example

Main gas pipe size increase

Main liquid pipe size increase

80 m

Branch gas pipe size increase

Branch liquid pipe size increase

40 m

In the above case

(Cooling) Overall equivalent length = 80m x 1.0 + 40m x 1.0 = 120m

(Heating) Overall equivalent length = 80m x 0.5 + 40m x 1.0 = 80m

The rate of change in: