Professional Documents

Culture Documents

Frosio 17A Inspection Work & Equipment

Uploaded by

Saiful LizanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frosio 17A Inspection Work & Equipment

Uploaded by

Saiful LizanCopyright:

Available Formats

Use of instruments

Frosio 17A Inspection work & equipment slide # 1

Inspection Equipment

Utstyr utlagt

Frosio 17A Inspection work & equipment slide # 2

Inspection after application

After application

the following must be checked

Climatic conditions (Ventilation,

Temperature and humidity)

Curing / drying of the film

Dry film thickness (DFT)

Adhesion

Holiday detection (if required)

Frosio 17A Inspection work & equipment slide # 3

ISO 2808 - 97 Method No.1

Wet film measuring comb

Microns Wet paint

250 225 200 175 150 125 100 75 50 25

Steel

Frosio 17A Inspection work & equipment slide # 4

ISO 2808

Wet film thickness gauge

• Measure wet paint film

• Here: 25 microns between the teeth

0459-21

4932-81

Frosio 17A Inspection work & equipment slide # 5

Using “PIG” Universal on a

ship’s hull

• PIG = Paint

Inspection Gauge

• Destructive test

method

• Possible to verify

the number of coats

applied Cd-4932-100

• Possible to measure

the thickness of

each individual coat

Frosio 17A Inspection work & equipment slide # 6

PIG Paint Inspection Gauge

Mainly for laboratory use

4932-100

Frosio 17A Inspection work & equipment slide # 7

ISO 2808 - 97

Determination of film thickness

Method No. 6: Magnetic method

• Magnetic induction principle (Method 6 A)

• Permanent magnetic principle (Method 6 B)

• Instruments for magnetic, metallic substrates

• Calibration must be done in accordance

with instructions from the manufacturer

• Before testing the paint system

must be properly cured.

Frosio 17A Inspection work & equipment slide # 8

ISO 2808 - 97

Determination of film thickness

Method No. 7 - Eddy current method

• High frequency electromagnetic

instrument

• For non-magnetic substrates

• Calibration in accordance with the

manufacturers instruction

Frosio 17A Inspection work & equipment slide # 9

ISO 2808 - 97

Determination of film thickness

Method No. 10 - On blast cleaned steel substrates

• Electromagnetic instruments

• Calibration on a smooth steel surface min. 1,2 mm

thick

• For DFT measurement, not less than 25 and

preferably above 50 microns

• Number of readings, as a guide:

– 1 reference area: At least 3 readings evenly

– 2 reference areas for every square meter for flat plates

– 4 reference areas for every length for a web

– 2 reference areas every metre length for a flange

– 2 reference areas every metre length for a pipe

Frosio 17A Inspection work & equipment slide # 10

ISO 2808 - Magnetic and electromagnetic

Dry film thickness gauges

• Dry film thickness gauge

• Calibrate on smooth

surface to zero and to

thickness similar to be

measured

• Check with your

calibration foil frequently

• Plastic material foils wear

easily. Replace

Cd-4932-82

frequently.

• No internal memory in

gauge

Frosio 17A Inspection work & equipment slide # 11

ISO 2808 - Magnetic and electromagnetic

Dry film thickness gauges

• Dry film thickness gauge

• Calibrate on smooth

surface to zero and to

thickness similar to be

measured

• Check with your calibration

foil frequently

• Plastic material foils wear

easily. Replace frequently.

• No internal memory in

gauge

Inspection \ Dryfilmthickness1

Frosio 17A Inspection work & equipment slide # 12

Magnetic and Electromagnetic

Dry Film Thickness Gauges

• ISO 2808

• Dry film thickness gauge

• Calibrate on smooth

surface to zero and to

thickness similar to be

measured

• Check with your

calibration foil frequently

• Plastic material foils Tørrfilm målere Elektr.

wear easily. Replace Magn.

frequently.

• Some models have

internal memory.

Frosio 17A Inspection work & equipment slide # 13

SSPC - PA 2

Measuring DFT on small areas

Procedure

1. Area of 10 m2: 5 spot measurements

2. Each spot measurement: The average of 3 individual

readings made on one small area

3. The average of 5 spot measurements must be within

specified range of film thickness

4. Single spot measurements may be as low as 80% of

specified minimum film thickness

5. Individual readings included in the spot

measurements may be less than 80% of minimum

thickness

Frosio 17A Inspection work & equipment slide # 14

SSPC - PA 2

Number of film thickness measurements

Case Area Selection of Measurements

1. 10 m2 5 spots (on each spot: 3 measurements)

2. 30 m2 As for case 1 for each 10 m2

3. Up to100 m2 Select 3 areas, each of 10 m2

4. Above 100 m2 The first 100 m2 as for case 3

For each following 100 m2 select randomly

one area of 10 m2

Note: If measurements outside the specification for any 10 m2 in case 3 or

4 above are found, then each 10 m2 shall be measured

Frosio 17A Inspection work & equipment slide # 15

Instruments for measuring

surface roughness

• Stylus instruments

• Elcometer Mod. 123

• Testex Press-O-film

• Microscope

• Comparator

–Rugotest No. 3

–ISO 8503 etc.

Frosio 17A Inspection work & equipment slide # 16

Surface Roughness acc. to

ISO 8503

• Example of a reference

comparator: Clemco

• Surface profile comparator

comprising four segments.

• Clemco - grit

• Clemco shot also available

Clemco

• Check if the profile is

according to specification Compartor

and the paint

manufacturer’s

recommendation

Frosio 17A Inspection work & equipment slide # 17

Using Inspection Tools: Mirror and

Flash light

• Visual inspection

• Important tools to be

able to inspect areas

difficult to access

Jan, speil, lykt

Frosio 17A Inspection work & equipment slide # 18

ISO 8502 – 4 Humidity

Guidance on the estimation of the probability

of condensation prior to paint application

1. Air temperature

2. % Relative humidity

3. Steel temperature

4. Dew point

Steel temperature min. 3 oC above the dew point

Frosio 17A Inspection work & equipment slide # 19

Contact Thermometer

• Electronic instrument

for measuring the steel

temperature

• Steel temperature

must be min. 3oC

above the dew point

• Other types of

thermometers are also

available. E.g.

magnetic Steel temperature

thermometers

Frosio 17A Inspection work & equipment slide # 20

Measuring the Relative Humidity

• ISO 8502 - 4

• Photo: Sling hygrometer

for measuring:

- Dry temperature

- Wet temperature

• Measure the temperature

in the vicinity of the work

• Calculate the relative

humidity

• Use together with dew

point calculator

Frosio 17A Inspection work & equipment slide # 21

Dew Point Calculator

• ISO 8502 - 4

• For calculation of dew

point

• To be used together with

surface temperature

thermometer and sling

hygrometer.

• Use this frequently during

pre-treatment, application

and drying of the paint.

• Recommendation: Every 6

hours and when weather

conditions are changing

Frosio 17A Inspection work & equipment slide # 22

Salt Test Equipment - Bresle Test

• ISO 8502 - 6

(Sampling)

• ISO 8502 - 9

(Conductivity)

• Equipment for

sampling and

measuring content of

water soluble salt on

substrate

• Bresle method Bresle sett

Frosio 17A Inspection work & equipment slide # 23

How to measure the salt level on

a surface

• Water soluble salts will be

removed by water jetting

• Here: The substrate is

cleaned at a pressure of

2000 bar

• Salt level is measured by

the Bresle method

• Dissolve the salt inside

the frame of the patch For 15 ml sample size, multiply

• Measure the conductivity conductivity measured in μS by a

of the water sample factor of 6 to get mg salt per m2

Pre-treatment: Wj_saltlevel1

Frosio 17A Inspection work & equipment slide # 24

Calculating salt level on the

substrate

Formula: (L2 – L1) x 6 = mg salt per m2

L2 = μS after cleaning

L1 = μS before cleaning

Water sample, ml: 10 15 20 50

Constant in formula: 4 6 8 20

Frosio 17A Inspection work & equipment slide # 25

Assessment of Dust on Steel Surfaces

Prepared for Painting. ISO 8502-3

Tape Blast cleaned steel

Approved

Not approved

Frosio 17A Inspection work & equipment slide # 26

Frosio 17A Inspection work & equipment slide # 27

ASTM D 4752-87

Curing test of Zinc - ethylsilicate with MEK.

Glove MEK Rag

Rubbing 50 x

No Zinc on the Rag: A lot of Zinc on Rag:

Cured Not cured

Approved Further curing / Reblasting

Frosio 17A Inspection work & equipment slide # 28

ASTM D 4752-87

MEK curing test of zinc ethyl silicate

• Left: One cured and uncured test plate

• Right: Uncured zinc over coated. Result: Delamination

0807-2

A-4

Frosio 17A Inspection work & equipment slide # 29

ASTM D 4752-87

Curing test of Zinc – ethyl silicate with MEK.

Glove

MEK

Inspection / Zincsilicate_curing1

Rag

Frosio 17A Inspection work & equipment slide # 30

ASTM D 3359-87

Adhesion testing by knife and adhesive tape

• There are two test methods

• The method to select depends on the DFT

Method A: DFT above 125 microns

Method B: DFT below 125 microns

(Above 125 if wider cuts are used)

Method A: X - cut. Tape test

Method B: Cross - cut. Tape test

Frosio 17A Inspection work & equipment slide # 31

ASTM 3359-87. Method B

Adhesion testing

• < 50 microns = 1 mm apart (11 cuts)

• 50 - 125 microns = 2 mm apart (6 cuts)

• > 125 microns = Method A

1. Cuts: 20 mm long

2. Brush with a soft brush

3. Examine

4. Cuts: 20 mm long at 90o on the original cuts

5. Brush with...

6. Tape 75 mm

7. Within 90 + 30 sec. remove tape

Frosio 17A Inspection work & equipment slide # 32

Classification of adhesion test results.

Method B. (Example for six parallel cuts).

5B None 5B The edges of the cuts are completely

smooth; none of the lattice is detached

4B 4B Small flakes of the coating is detached at

intersections: 5% of the area is affected

3B Small flakes of the coating are detached

along edges and at intersections of cuts.

3B The area affected is 5 to 15% of the

lattice.

2B The coating has flaked along the edges

2B and on parts of the squares. The area

affected is 15 to 35% of the lattice.

1B The coating has flaked along the edges of

1B cuts in large ribbons and whole squares

have detached. The area affected is 35 to

65 % of the lattice.

0B Flaking and detachment worse than Grade

0B Greater than 65% 1B.

Frosio 17A Inspection work & equipment slide # 33

ISO 2409

Cross-cut test

Cutting tool

Single bladed knife

or

Multi-blade cutting tool with 6 cutting

edges spaced 1 mm or 2 mm apart

Spacing of cuts

0 - 60 microns: 1 mm spacing, hard substrates

0 - 60 microns: 2 mm spacing, soft substrates

60 - 120 microns: 3 mm spacing, hard/soft substrates

121 - 250 microns: 3 mm spacing, hard/soft substrates

Frosio 17A Inspection work & equipment slide # 34

ISO 2409

Cross-cut test

Procedure:

• Make 6 parallel cuts with defined space in the

coating.

• Repeat operation, crossing original cuts at 90o

so that a grid pattern is formed.

• Brush with soft brush.

• Apply adhesive tape and pull off.

• Classify results in accordance with table 1.

Frosio 17A Inspection work & equipment slide # 35

ISO 2409

Cross cut adhesion test

• Cross cut adhesion

test

• Cut vertical and

horizontal lines to

form a grid

• Apply a strong tape

• Pull off the tape Cd-4932-91

• Evaluate according to

the standard

Frosio 17A Inspection work & equipment slide # 36

ISO 2409

Cross-cut adhesion test

• Left: A good type of cross-cut tool

• Right: Evaluation of performed test

0002-002

0002-001

Frosio 17A Inspection work & equipment slide # 37

Classification of Adhesion Test Results.

(Example for six parallel cuts).

5B None 5B The edges of the cuts are completely

smooth; none of the lattice is detached

4B 4B Small flakes of the coating is detached at

intersections: 5% of the area is affected

3B Small flakes of the coating are detached

along edges and at intersections of cuts.

3B The area affected is 5 to 15% of the

lattice.

2B The coating has flaked along the edges

2B and on parts of the squares. The area

affected is 15 to 35% of the lattice.

1B The coating has flaked along the edges of

1B cuts in large ribbons and whole squares

have detached. The area affected is 35 to

65 % of the lattice.

0B Flaking and detachment worse than Grade

0B Greater than 65% 1B.

Frosio 17A Inspection work & equipment slide # 38

ISO 2409

Classification of Cross-cut test

Classi- Appearance of surface

Description

fication Six parallel cuts

0 Completely smooth: none of the squares detached

1 Small flakes at the Intersections. Area affected 5 %

Flaked along the edges and/or at the

2 Intersections. Area affected: 5-15%

Flaked along the edges, wholly in large ribbons,

3 and/or partly or wholly on different parts of

the squares. Area affected: 15-35%

Flaked along the edges in large ribbons and/or

4 some squares have detached partly or wholly.

Area affected: 35-65%

5 Any degree of flaking that cannot even be classified by 4.

Frosio 17A Inspection work & equipment slide # 39

ISO 2409

Cross cut adhesion test

• Cross cut adhesion

test

• Cut vertical and

horizontal lines to form

a grid

• Apply a strong tape

• Pull off the tape

• Evaluate according to

the standard

Inspection / Adhesion_crosscut1

Frosio 17A Inspection work & equipment slide # 40

ISO 4624

Pull-off test for adhesion

Instruments:

• Elcometer Adhesion Tester

• Saeberg Adhesion Tester (pneumatic)

• Hate Adhesion Tester (hydraulic)

• PAT

• Other

Failure:

Adhesion failure: Between coats or between or substrate and 1st coat

Cohesion failure: Inside a coat

Frosio 17A Inspection work & equipment slide # 41

ISO 4624

Pull-off test for adhesion

Procedure:

• Test dollies glued onto the coating

• Adhesive: Cyano-acrylate or solvent free epoxy

• Remove adhesive and coating around the dollies

• Pull off test-dollies vertical to the surface

• Read adhesion value and report the type of fracture

Fractures:

• Adhesion failure - fracture between coats or substrate and 1.

coat

• Cohesion failure - fracture within a coat

Frosio 17A Inspection work & equipment slide # 42

ISO 4624

Pull-off dollies glued to the structure

• Pull off adhesion

test

• Dollies are glued to

the structure with a

strong glue

• Prior to pull-off:

Cut around the Cd-4932-102

dolly, through the

paint film and down

to the substrate

material

Frosio 17A Inspection work & equipment slide # 43

ISO 4624

Pull-off testing of paint on a structure

• Pull off adhesion test.

• Destructive test method

• Here, connecting of the

device for pulling off the

dollies

• Read and note the value

• Several types of Cd-4932-101

instruments are

available

Frosio 17A Inspection work & equipment slide # 44

ISO 4624

Area after pull-off testing

• Pull off adhesion test

• The adhesive failure -

fracture between coats -

or between coating and

substrate must be

evaluated Cd-4932-103

• Note adhesion failure, %

• The cohesive failure -

fracture within the

coating- must be

evaluated.

• Note cohesion failure, %

• Also: Note glue failure, %

Frosio 17A Inspection work & equipment slide # 45

ISO 4624

Pull-off dollies glued to the

structure

• Pull off adhesion test

• Dollies are glued to the

structure with a strong

glue

• Prior to pull-off:

Cut around the dolly,

through the paint film

and down to the

substrate material

• Record the pull-off

value Inspection / Adhesion_pulloff1

• Evaluate the failure

Frosio 17A Inspection work & equipment slide # 46

ASTM G 62 - 85 Method A

Pinhole detection. Low voltage.

• Low voltage: < 75 V DC

• To detect pinholes, voids or metal particles to

be in the range of 25-250 microns.

• Effective for paint films up to a DFT of 500

microns if a wetting agent is used in the

water.

• This is a non-destructive test.

Frosio 17A Inspection work & equipment slide # 47

ASTM G-62-85, method A

Low voltage holiday detector

• Photo: Low voltage

pinhole detector

• Detecting pinholes, voids

or metal particles in paint

film up to 250 microns

• Non destructive test

method

• Will only detect defects Cd-4932-92

down to bare metal

• The sponge must be

wetted

• Do not use excessive

water

Frosio 17A Inspection work & equipment slide # 48

ASTM G-62-85, method A

Low voltage pinhole detector

• Photo: Low voltage pinhole

detector

• Detecting pinholes, voids

or metal particles in paint

film up to 250 microns

• Non destructive test

method

• Will only detect defects

down to bare metal 0002-004

• The sponge must be

wetted

• Do not use excessive water

Frosio 17A Inspection work & equipment slide # 49

ASTM G-62-85, method A

Low voltage pinhole detector

• Detecting pinholes,

voids or metal particles

in paint film up to 250

microns

• Non destructive test

method

• Will only detect defects

down to bare metal

• The sponge must be

wetted

• Do not use excessive Inspection / Pore_detection1

water

Frosio 17A Inspection work & equipment slide # 50

ASTM G 62 Method B

Holiday detection. High voltage.

High voltage: 900 - 20.000 V

Used to detect pinholes, voids and

areas with thin paint films

This is a destructive test.

Frosio 17A Inspection work & equipment slide # 51

ASTM G-62-85, method B

High voltage holiday detector

• Destructive test method

for detecting pinholes,

voids and thin spots in

paint film

• Adjust voltage according to

the film thickness or the

paint manufacturers Cd-4932-93

recommendation

• Gives a light or signal when

pinhole or weak point is

detected

Frosio 17A Inspection work & equipment slide # 52

ASTM G-62-85, method B

High voltage holiday detector

• Destructive test method

for detecting pinholes,

voids and thin spots in

paint film

• Adjust voltage according to

the film thickness or the

• 0002-005

paint manufacturers

recommendation

• Gives a light or signal when

pinhole or weak point is

detected

Frosio 17A Inspection work & equipment slide # 53

ASTM G 62 Method B

Holiday detection. High voltage.

• High voltage: 900 - 20.000

V

• Used to detect pinholes,

voids and

• areas with thin paint films

• This is a destructive test.

Inspection / Holiday_detection1

Frosio 17A Inspection work & equipment slide # 54

ISO 12944

General standard for corrosion protection:

Paints and varnishes - Corrosion protection

of steel structures by protective paints systems.

Part 1 General introduction.

Part 2 Classification of environments.

Part 3 Design considerations.

Part 4 Types of surface and surface preparation.

Part 5 Protective paint systems.

Part 6 Laboratory performance test methods.

Part 7 Execution and supervision of paint work.

Part 8 Development of specifications for new work

and maintenance.

Frosio 17A Inspection work & equipment slide # 55

ISO 8504 - 1

General principles

Selection of methods

Frosio 17A Inspection work & equipment slide # 56

ISO 8504

Surface preparation methods:

Part 1: General principles.

Part 2: Abrasive blast-cleaning.

Part 3: Hand- and power-tool

cleaning.

Frosio 17A Inspection work & equipment slide # 57

ISO 8504 - 2

Abrasive blast-cleaning

• Methods

• Effectiveness

• Fields of

application

Frosio 17A Inspection work & equipment slide # 58

ISO 8504 - 3

Hand and Power-tool Cleaning

• Methods

• Equipment to be used

• Procedure to be followed

Frosio 17A Inspection work & equipment slide # 59

Using solvents to determine

generic type of paint

Paint dissolves:

Rag soaked

Physically drying

with solvent

No reaction:

Chemically curing

Steel

Lifting/Wrinkling:

2 coat paint Oxidatively curing

Frosio 17A Inspection work & equipment slide # 60

Using solvents to determine

generic type of paint

Use a rag soaked

with solvent

No reaction:

Chemically curing

Paint dissolves:

Physically drying

Lifting/Wrinkling: Inspection / Determine_generic1

Oxidatively curing

Frosio 17A Inspection work & equipment slide # 61

Standards relating to mechanical properties

Property Standard / Test method

Adhesion (Cross cut) ISO 2409, DIN 53251, BS 3900-E6, ASTM 3359

Adhesion (Pull-off) ISO 4624, ASTM 4541, BS 3900 - E10

Adhesion ASTM D 1002 (Specified for Chartek)

(Shear strength)

Hardness ISO 2815 (Buchholz - methode)

Hardness ISO 1522 (Kønig - pendel)

Hardness Barchol

Elasticiy ISO 1520 (Cupping test)

Flexibility ISO 6860 ASTM D 522

BS 3900 - E11 (Conical mandrel)

Impact resistance ISO/TR 6272 - 79E ASTM D 2794 - 84

DIN 55669 BS 3900 - E3

Frosio 17A Inspection work & equipment slide # 62

Testing and evaluation.

marine atmosphere (1 of 2)

Test method Standards Comments

Physical testing

Adhesion ISO 2409 Before and after exposure

Adhesion ISO 4624 Before and after exposure

Flexibility ISO 1510 Before and after exposure

Elasticity ISO 1520 Before and after exposure

Hardness ISO 2815

Impact resistance ISO 6272

Gloss ISO 2813

Abrasion resistance ASTM D 4060

Exposure conditions:

Saltspray ISO 7253 or ASTM B 117

Prohesion test

UV-cabinet ASTM G 53

Condensation chamber ISO 6270

Humidity chamber BS 3900

Weathering ISO 2810

Resistance to liquids ISO 2812 Oil, petroleum , etc.

Frosio 17A Inspection work & equipment slide # 63

Testing and evaluation.

marine atmosphere (2 of 2)

Test method Standards Comments

Evaluation of paint films

Blistering ISO 4628/2

Rust ISO 4628/3

Cracking ISO 4628/4

Flaking ISO 4628/5

Chalking ISO 4628/6

Scribe ASTM D 1654

Evaluation of the liquid paint

Appearance in tin ISO 2431 “Flow time”

Viscosity ISO 2884

Application properties

Frosio 17A Inspection work & equipment slide # 64

Abrasion resistance

• Weigh the painted

sample

• Install it in the apparatus

and run 1000 cycles

• Measure the weight loss

Testing paints \ Abrasion resistance1

Frosio 17A Inspection work & equipment slide # 65

Flexibility test

• Use a thin test panel

• Measure the paint film

thickness

• Carry out the impact test

on the rear side of the

test panel

• Determine the highest

level of impact load

before any crack or

defect in the paint film

occurs

Testing paints \ Flexibility_test1

Frosio 17A Inspection work & equipment slide # 66

Impact test

• Use a thick test panel

• Measure the paint film

thickness

• Carry out the impact test

on the painted side of the

test panel

• Determine the highest

level of impact load

before any crack or

defect in the paint film

occurs

Testing paints \ Impact_test1

Frosio 17A Inspection work & equipment slide # 67

Reference area should:

• be representative to the remaining

area coated with the same system.

• be available for inspection at any time.

• be marked thoroughly to indicate

"ref.area"

• not be overcoated

Frosio 17A Inspection work & equipment slide # 68

Controlled application

• Inspection of:

» steelwork

» cleaning

» surface preparation (blastcleaning)

» painting

» curing

» completed system

Frosio 17A Inspection work & equipment slide # 69

Number of reference areas

Size of structure Recommended maximum Recommended maximum Recommended maximum

(painted area) Number of reference percentage of reference total area of reference

m2 areas area relative to total area areas

of structure m2

< 2000 3 0,6 12

2000 to 5000 5 0,5 25

5000 to 10000 7 0,5 50

10000 to 25000 7 0,3 75

25000 to 50000 9 0,2 100

>50000 9 0,2 200

Frosio 17A Inspection work & equipment slide # 70

You might also like

- 08 Inspection & QCDocument92 pages08 Inspection & QCAntony Bruno GenewinNo ratings yet

- Standards Specs and Procedures PDFDocument33 pagesStandards Specs and Procedures PDFe.vicente.caballeroNo ratings yet

- Dry Film Thickness Measurements How Many Are EnoughDocument11 pagesDry Film Thickness Measurements How Many Are EnoughSds Mani SNo ratings yet

- Compatibility of PaintsDocument1 pageCompatibility of Paintslonglong3003100% (1)

- SURFACE TREATMENT GUIDEDocument4 pagesSURFACE TREATMENT GUIDEGanesh R NairNo ratings yet

- Importance of Certified Coating Inspectors for IMO RulesDocument21 pagesImportance of Certified Coating Inspectors for IMO Rulesigeorge7950% (2)

- CIP Work Experience FINALDocument2 pagesCIP Work Experience FINALDeepak YadavNo ratings yet

- Examp and HSEDocument46 pagesExamp and HSElonglong3003No ratings yet

- Surfacepreparation StandardDocument11 pagesSurfacepreparation StandardAri SupramonoNo ratings yet

- Hempadur Avantguard 750 1736g - Product DatasheetDocument2 pagesHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- Inspections/full Package, Frosio-Nace Certified InspectorsDocument8 pagesInspections/full Package, Frosio-Nace Certified InspectorsZiom Ziomek100% (1)

- 2 - 06 FROSIO Pre - CertificationDocument167 pages2 - 06 FROSIO Pre - CertificationHamza Al Amin100% (1)

- BGAS Grade 1 CourseDocument71 pagesBGAS Grade 1 Course9440864459No ratings yet

- FROSIO - Flash QuesDocument4 pagesFROSIO - Flash QuesAnte BosancicNo ratings yet

- Daily Painting Report System P 01ndDocument49 pagesDaily Painting Report System P 01ndArung IdNo ratings yet

- 1-Frosio Chapter 1 Inspector Duties and BehaviourDocument84 pages1-Frosio Chapter 1 Inspector Duties and BehaviourtaiNo ratings yet

- SES Amercoat Dimetcote 9Document4 pagesSES Amercoat Dimetcote 9kamalkashNo ratings yet

- Painting Inspector Hand BookDocument5 pagesPainting Inspector Hand BookAmaan Khan100% (7)

- CatalogueDocument59 pagesCataloguengtchungNo ratings yet

- FinalExamSheet 4663 1495206384Document28 pagesFinalExamSheet 4663 1495206384Gabriel Pana100% (2)

- FROSIO PresentationDocument36 pagesFROSIO PresentationSatish100% (3)

- OLD BGAS Grade-1 - Revision Questions - 2007Document11 pagesOLD BGAS Grade-1 - Revision Questions - 2007Alex joseph alexNo ratings yet

- Painting Inspection Grade 2/3 Exam: Unit Test - 4Document1 pagePainting Inspection Grade 2/3 Exam: Unit Test - 4AjeetKumar0% (1)

- QADocument21 pagesQAms rooNo ratings yet

- Technical-service-Role-of-Coating-Advisor 2010 - tcm189-80199 PDFDocument14 pagesTechnical-service-Role-of-Coating-Advisor 2010 - tcm189-80199 PDFBADIUZZAMA AZMINo ratings yet

- Lead Supervising or 3rd Party Nace Peer Review/level 3 CertifiedDocument3 pagesLead Supervising or 3rd Party Nace Peer Review/level 3 Certifiedapi-77735589No ratings yet

- Pretreatment Paint TrainingDocument143 pagesPretreatment Paint TrainingIslam Fawzy100% (1)

- Painting ReportDocument2 pagesPainting ReportgstketutNo ratings yet

- BGAS PaperDocument9 pagesBGAS PaperMuhammad AsifNo ratings yet

- Painting Inspection Report Angle Bars PDFDocument1 pagePainting Inspection Report Angle Bars PDFpstechnical_43312697No ratings yet

- Nace Cip Level 3 Qtpcqtpcqapdfnace Cip Level 3pdfpdf FilenaceDocument2 pagesNace Cip Level 3 Qtpcqtpcqapdfnace Cip Level 3pdfpdf FilenaceNimish Pavan100% (1)

- Sponge Jet Blasting PDFDocument5 pagesSponge Jet Blasting PDFamirthraj74100% (1)

- Paint film defects and failures guideDocument49 pagesPaint film defects and failures guideDaison PaulNo ratings yet

- Coating Interview QuestionDocument1 pageCoating Interview QuestionMatthew Baker100% (3)

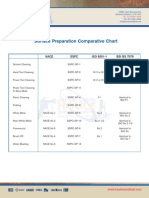

- Surface Preparation Comparative ChartDocument1 pageSurface Preparation Comparative Chartcmms88No ratings yet

- Ly Thuyet Tham Khao Cho Thi Trac Nghiem.Document11 pagesLy Thuyet Tham Khao Cho Thi Trac Nghiem.Lâm Thanh100% (1)

- Diferrence Between Nace and FrosioDocument1 pageDiferrence Between Nace and FrosioOscarNo ratings yet

- Marathon XHBDocument4 pagesMarathon XHBeskim00No ratings yet

- Question & Answer Ofhomework1Document9 pagesQuestion & Answer Ofhomework14romi89100% (2)

- 3855 ICorr Coating Inspector Assessment Guidelines 0821Document6 pages3855 ICorr Coating Inspector Assessment Guidelines 0821aliNo ratings yet

- Paint Inspection BasicDocument6 pagesPaint Inspection BasicmaddyNo ratings yet

- Senior Painting Coating & Insulation Inspector CVDocument4 pagesSenior Painting Coating & Insulation Inspector CVHoàng Nguyên Võ100% (1)

- SSPC Trainthepainter WebinarDocument64 pagesSSPC Trainthepainter WebinarFreddy Carl Fredricksen100% (2)

- Painting Question and AnswerDocument38 pagesPainting Question and AnswerRamdas100% (4)

- Painting Inspector Reviewer1Document5 pagesPainting Inspector Reviewer1ishaq_khanNo ratings yet

- Aban Constructions Pvt. LTD: Procedure For PaintingDocument4 pagesAban Constructions Pvt. LTD: Procedure For PaintingAkhilesh KumarNo ratings yet

- Essential Coating Inspection QuestionnaireDocument11 pagesEssential Coating Inspection Questionnairerajesh100% (1)

- Coating DefectDocument36 pagesCoating DefectDILIP VELHAL100% (1)

- Surveillance of Painting Activity RecordsDocument2 pagesSurveillance of Painting Activity RecordsAravind KNo ratings yet

- CorrisionDocument56 pagesCorrisionUsab GamalNo ratings yet

- 6 Sigma PaintDocument38 pages6 Sigma PaintAnonymous fvO1W3No ratings yet

- 1 Insulation SupervisorDocument2 pages1 Insulation Supervisorrsamim0% (1)

- Paint - Inspections Work and Equiptment ### PDFDocument35 pagesPaint - Inspections Work and Equiptment ### PDFDaison PaulNo ratings yet

- Latihan NacecongratulationsDocument13 pagesLatihan NacecongratulationsPadma Pangreksa75% (4)

- Qstns 1Document29 pagesQstns 1Shawn Leo100% (2)

- C Ti P Ti Coating Practices: International Association of Oil & Gas Producers Coatings Workshop June 10, 2008Document28 pagesC Ti P Ti Coating Practices: International Association of Oil & Gas Producers Coatings Workshop June 10, 2008kelvinc256No ratings yet

- INTERNATIONAL PERMEATION STANDARDS GUIDEDocument15 pagesINTERNATIONAL PERMEATION STANDARDS GUIDEemre sönmezNo ratings yet

- Frosio 03 Inspector DutiesDocument36 pagesFrosio 03 Inspector DutiesThien Van Le100% (1)

- TP913Document5 pagesTP913jmpateiro1985No ratings yet

- Einschlaganker Drop in Anchor: Çakma DübelDocument16 pagesEinschlaganker Drop in Anchor: Çakma DübelSuphi YükselNo ratings yet

- 34801Document1 page34801Suphi YükselNo ratings yet

- Fransız Elektrot Firması Seçim TablosuDocument60 pagesFransız Elektrot Firması Seçim TablosuSuphi Yüksel100% (2)

- Gupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Document108 pagesGupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Suphi YükselNo ratings yet

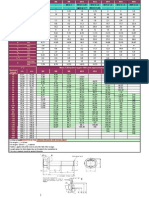

- P (Auxiliary Dimension) C: Min. Max. Max. Max. Max. Nominal SizeDocument1 pageP (Auxiliary Dimension) C: Min. Max. Max. Max. Max. Nominal SizeSuphi YükselNo ratings yet

- DIN 928 Kare Kaynak Somunlari Square Weld Nuts: (D) M5 M6 M8 M10 M12 Thread Size (D XP)Document1 pageDIN 928 Kare Kaynak Somunlari Square Weld Nuts: (D) M5 M6 M8 M10 M12 Thread Size (D XP)Suphi YükselNo ratings yet

- Fiberli Flanşli Altiköşe İnce Diş Somunlar With Flange and With Non-Metallic Insert With Metric Fine Thread Prevaling Torque Type Hexagon Nuts EN 1666Document1 pageFiberli Flanşli Altiköşe İnce Diş Somunlar With Flange and With Non-Metallic Insert With Metric Fine Thread Prevaling Torque Type Hexagon Nuts EN 1666Suphi YükselNo ratings yet

- EN ISO 10513 Sikmali Altiköşe İnce Diş Stil 2 Somunlar All-Metal Prevailing Torque Type Hexagon Nuts Style 2 With Metric Fine ThreadDocument1 pageEN ISO 10513 Sikmali Altiköşe İnce Diş Stil 2 Somunlar All-Metal Prevailing Torque Type Hexagon Nuts Style 2 With Metric Fine ThreadSuphi YükselNo ratings yet

- 10512Document1 page10512Suphi YükselNo ratings yet

- DIN 6926 Fiberli Flanşli Altiköşe Somunlar Prevaling Torque Type Hexagon Nuts With Flange and With Non-Metallic InsertDocument1 pageDIN 6926 Fiberli Flanşli Altiköşe Somunlar Prevaling Torque Type Hexagon Nuts With Flange and With Non-Metallic InsertSuphi YükselNo ratings yet

- Thread Size Chart for Metric Hex Nuts (M6 to M20Document1 pageThread Size Chart for Metric Hex Nuts (M6 to M20Suphi YükselNo ratings yet

- P B Ref.: Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinDocument1 pageP B Ref.: Min. Max. Max. Max. Min. Min. Min. Max. Min. Max. Min. Max Max. MinSuphi YükselNo ratings yet

- DIN 982 Fiberli AltiKöşe Yüksek Somunlar SpecificationsDocument1 pageDIN 982 Fiberli AltiKöşe Yüksek Somunlar SpecificationsSuphi YükselNo ratings yet

- DIN 929 Altiköşe Kaynak Somunlari Hexagon Weld Nuts: - M8 X 1 M10 X 1,25 M12 X 1,25 - M10 X 1 M12 X 1,5Document1 pageDIN 929 Altiköşe Kaynak Somunlari Hexagon Weld Nuts: - M8 X 1 M10 X 1,25 M12 X 1,25 - M10 X 1 M12 X 1,5Suphi YükselNo ratings yet

- DIN 6915 High-Strenght Hexagon Nuts With Large Widths Across Flats Geniş Anahtar Ağizli Altiköşe SomunlarDocument1 pageDIN 6915 High-Strenght Hexagon Nuts With Large Widths Across Flats Geniş Anahtar Ağizli Altiköşe SomunlarSuphi YükselNo ratings yet

- M8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Document1 pageM8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Suphi YükselNo ratings yet

- Max. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinDocument1 pageMax. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinSuphi YükselNo ratings yet

- Outokumpu Stainless Steel HandbookDocument92 pagesOutokumpu Stainless Steel HandbookcutefrenzyNo ratings yet

- Ref. Max. Theor - Max. Actual Min. Max. Min. Min. Max. Max. Min. Nom. Max.) Max.) Min. Min. MinDocument1 pageRef. Max. Theor - Max. Actual Min. Max. Min. Min. Max. Max. Min. Nom. Max.) Max.) Min. Min. MinSuphi YükselNo ratings yet

- Max. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinDocument1 pageMax. Min. Max. Max. Min. Min. Max. Min. Min. Nom. Max. Min. Min. MinSuphi YükselNo ratings yet

- 1665Document1 page1665Suphi YükselNo ratings yet

- Thread Size Chart for Metric Bolts M5 to M16Document1 pageThread Size Chart for Metric Bolts M5 to M16Suphi YükselNo ratings yet

- 6921Document1 page6921Suphi YükselNo ratings yet

- Mass (7,85 KG/DM: Products in The Green Region Are Available As Full ThreadDocument1 pageMass (7,85 KG/DM: Products in The Green Region Are Available As Full ThreadSuphi YükselNo ratings yet

- Solutions Guide: The Choice of Master CraftsmenDocument20 pagesSolutions Guide: The Choice of Master CraftsmenSuphi YükselNo ratings yet

- A Max. P: - M8 X 1 M10 X 1,25 - M10 X 1Document1 pageA Max. P: - M8 X 1 M10 X 1,25 - M10 X 1Suphi YükselNo ratings yet

- Thread Size Dimensions Chart for M12, M16, M20 BoltsDocument1 pageThread Size Dimensions Chart for M12, M16, M20 BoltsSuphi YükselNo ratings yet

- SKF Bearing Installation and MaintenanceDocument146 pagesSKF Bearing Installation and MaintenanceDefinal ChaniagoNo ratings yet

- Storage Tanks Made of SteelDocument6 pagesStorage Tanks Made of SteelHakan Şahinoğlu100% (1)

- SMAW PowerpointDocument28 pagesSMAW PowerpointShankar Gurusamy100% (3)