Professional Documents

Culture Documents

MO - NO. H11/504: Manufacturing Instructions MHKXTLS607X5

Uploaded by

maruti_gbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MO - NO. H11/504: Manufacturing Instructions MHKXTLS607X5

Uploaded by

maruti_gbCopyright:

Available Formats

MHKXTLS607X5

MANUFACTURING INSTRUCTIONS REVISION 3

DATE 11/03/2011

INDENT DETAILS NAMEPLATE DETAIL BEARINGS

Branch Kw (HP) 7.5(10) RPM / Pole 970/6 DE 6309 2Z

Indent no Volt 415±10% Amp 15.6 NDE 6309 2Z

Date Ins Class F DUTY S4 Relub Hrs.

Quantity Conn. Diag. DELTA AMB 45ºc

Customer Frame 160L MTG B3

M/c No. MHKXTLS607X5 IP 55 MO.NO.

PO no. BATCH No. Freq 50Hz±5%

Del.Date Cat Ref 150S/H-40%CDF

H11/504

CONSTRUCTION NO: CORE LENGTH : 165mm

ROTOR / SHAFT ORDER :- STATOR WINDING ORDER :- NON-STD

Stampings LM6 Stamping H-LMS0029------------------S_160-6-54-165

Shaft Winding Group 18-3 Coils / Group 3

Extension Wdg.Diag. AV0154 Connections DELTA

ROTOR DETAILS Winding Pitch 1-6-8-10 Insul. Class F

Type Wire Size(mm) 1x0.80/2x0.75 No. of Leads 6 As Per Dwg.

Drg.no No. of Turns / Coil 15/S Lead Size 2.5mm² No. TC/TL007

RFD Socket M5 TB. Position Top

Skew Angle R,20 / between 1.327±5% R,20 / Phase 2.010±5%

Cu Wt (Kg) O/H Doc.

SPECIAL INSTRUCTION:-

MACHINED COMPONENT ORDER STD

1. Crane Duty Motor.

Stator case 2. 150S/H-40%CDF, to be written in Cat Ref Column of Name Plate.

E/S with insert(RM) NDE 3. Epxoy Gel Coat "B-6-665: on Overhang.

E/S NDE (m/ced) 4. LM6 Rotor to be used.

E/S with insert(RM) DE 5. Rotor to be pressed as per "160L".

E/S DE(m/ced)

FOOT (Left)

FOOT (Right)

ADDITIONAL INFORMATION STD

Bearing locking at DE Side : Internal circlip Hardware List QUANTITY

Bearing DE NDE

Carton Box Term. Box

Size

Details Position

Sealing Box T.Box base

Aux. Box T.Box Cvr

Paint Shade T B CVR Gasket

V – Ring T B Base Gasket

Cable size Fan

T.box E.T. Size Fan Cvr.

Online Greasing Arr. Extn. Key

Two Opp. Earthing Terminals. On Stator Shell

Comp. Gland No.s

INSPECTION PERFORMANCE DESIGN VALUE TESTED VALUES COMMITMENT TO CUSTOMER

N L Current 8.0 Amp at 415V FL 3/4 F L 1/2 F L

Rotor Finished Dia : mm L R Current 24.5 Amp at 105V Speed 970

INSPECTION Yes / No Rated Input ------ Efficiency 88.00%

Insp. Auth. : NO F L Torque Power Factor 0.76

Heat Run Reqd. : YES / NO L R Torque Start Torque P O Trque :

T C Reqd.: YES R U Torque Start Current

Copies : 1 P O Torque Temp. rise 75ºC

Revision Details

01 Shaft pressing details added

Inspected By : Prepared By: Mech.Check By: Winding Checked by: Final Motor Inspected By:

Sahil Maruti

APPROVED BY: Assly. Checked by :

Kishore Gupta

SAP Activity person name Date

BOM Uplaod Maruti Bilgoji

Routing, Production version, Costing

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Pt. Bayer Motor 3.7 KWDocument20 pagesPt. Bayer Motor 3.7 KWhamzah naoreyNo ratings yet

- Emergency Servicing Reconditioning of 3 Phase Induction Motor Sumitomo Cyclo Drive. 22kwDocument4 pagesEmergency Servicing Reconditioning of 3 Phase Induction Motor Sumitomo Cyclo Drive. 22kwHazelNo ratings yet

- Low Voltage Motor Insulation SystemDocument2 pagesLow Voltage Motor Insulation SystemzdrahalNo ratings yet

- Permissible Loading of Generators and Large MotorsDocument19 pagesPermissible Loading of Generators and Large MotorsrohitctppNo ratings yet

- Vibration Sources Identification GuideDocument1 pageVibration Sources Identification GuideMURALINo ratings yet

- Evaluation of Service Failure of Three Phase Induction Motor Using Failure Mode and Effects Analysis (FMEA)Document17 pagesEvaluation of Service Failure of Three Phase Induction Motor Using Failure Mode and Effects Analysis (FMEA)CHINEDU CHIEJINENo ratings yet

- Feb 05 MotorsDocument62 pagesFeb 05 MotorsdediekosNo ratings yet

- Low and Medium Voltage Motor Repair Shop Selection GuidelineDocument10 pagesLow and Medium Voltage Motor Repair Shop Selection GuidelineGunadevan ChandrasekaranNo ratings yet

- SurgeTesting EARbasics 0716Document2 pagesSurgeTesting EARbasics 0716pcastro_temNo ratings yet

- Motor and Motor ControlDocument126 pagesMotor and Motor ControlAhmed Farahat0% (1)

- SM AtexDocument12 pagesSM AtexnelsonacuaNo ratings yet

- Diagnostic Insulation TestingDocument5 pagesDiagnostic Insulation TestingkarthikumarNo ratings yet

- Service Failure Analysis of D C Motor Co PDFDocument6 pagesService Failure Analysis of D C Motor Co PDFOmar QatawnehNo ratings yet

- Jawaharlal Nehru Technological University Anantapur AndhrapradeshDocument30 pagesJawaharlal Nehru Technological University Anantapur AndhrapradeshJagaNo ratings yet

- Day 2C 1100-1200 John Allen EASA Rewind Study1203Document0 pagesDay 2C 1100-1200 John Allen EASA Rewind Study1203mariogp4542No ratings yet

- Motor Test Report SummaryDocument15 pagesMotor Test Report SummaryKholis JaimonNo ratings yet

- Examples of Premature Stator Winding Failure in Recently Manufactured Motors and GeneratorsDocument4 pagesExamples of Premature Stator Winding Failure in Recently Manufactured Motors and GeneratorsstarkopeteNo ratings yet

- Testing Methods for Predicting Electrical Failures in MotorsDocument5 pagesTesting Methods for Predicting Electrical Failures in Motorsamk2009No ratings yet

- AlternatorWindingData 0510Document4 pagesAlternatorWindingData 0510faraidunNo ratings yet

- Motor CleaningMethods Bishop 0620Document21 pagesMotor CleaningMethods Bishop 0620Rolando LoayzaNo ratings yet

- Tavner PeterDocument303 pagesTavner PeterManigandanNo ratings yet

- Investigative Fault Analysis of 11KV Slip-Ring Induction MotorsDocument12 pagesInvestigative Fault Analysis of 11KV Slip-Ring Induction MotorsInternational Journal of Innovative Science and Research Technology100% (1)

- Test Procedure PB273 - CDocument12 pagesTest Procedure PB273 - Cadi yudhaNo ratings yet

- SEAA 2032 - ELECTRICAL and MECHANICAL SYSTEM PART 2: INDUCTION MOTOR PRINCIPLESDocument33 pagesSEAA 2032 - ELECTRICAL and MECHANICAL SYSTEM PART 2: INDUCTION MOTOR PRINCIPLESHanis SyafiqNo ratings yet

- AMEU Technical Convention Bushings FailuresDocument4 pagesAMEU Technical Convention Bushings FailuresDunstan AmaratungaNo ratings yet

- Vdocument - in Generator Maintenance Frame 6 Users Groupframe 6 Users Grouporgwp Contentuploads2018096bDocument27 pagesVdocument - in Generator Maintenance Frame 6 Users Groupframe 6 Users Grouporgwp Contentuploads2018096bMahesh MishraNo ratings yet

- Bearing damage classification ISO standardDocument6 pagesBearing damage classification ISO standardPraveen PaviNo ratings yet

- PCS-902 X Instruction Manual en Overseas General X R1.03 (En XLBH5102.0086.0014)Document416 pagesPCS-902 X Instruction Manual en Overseas General X R1.03 (En XLBH5102.0086.0014)Arief Sandy AnggoroNo ratings yet

- GVPI Assessment-EASA 2014 v2Document7 pagesGVPI Assessment-EASA 2014 v2mersiumNo ratings yet

- Motor DatasheetDocument1 pageMotor DatasheetMuzzamilNo ratings yet

- Prevention and Protection of Generator Rotor Earth Faults Ogn-Ops-Elect-007Document10 pagesPrevention and Protection of Generator Rotor Earth Faults Ogn-Ops-Elect-007Nitin SinghNo ratings yet

- Bhel HaridwarDocument51 pagesBhel HaridwarBKBMTHNo ratings yet

- P34amk039510 enDocument109 pagesP34amk039510 enColesha BarukaNo ratings yet

- AC Motor Name Plate - Terms & MeaningsDocument2 pagesAC Motor Name Plate - Terms & Meaningsavandetq15No ratings yet

- 12 - 2006 PorofabDocument16 pages12 - 2006 PorofabsalekojicNo ratings yet

- Importance of Insulation Resistance Testing2Document25 pagesImportance of Insulation Resistance Testing2FaisalNo ratings yet

- CCJ - How To Prevent Collector-Ring FiresDocument7 pagesCCJ - How To Prevent Collector-Ring Firesabdulyunus_amirNo ratings yet

- Dry Type Transformer Test Report: Page 1 of 2Document2 pagesDry Type Transformer Test Report: Page 1 of 2erwin5sambas5aryanaNo ratings yet

- Brush Wear GuideDocument3 pagesBrush Wear GuideSomkene MbakweNo ratings yet

- Ii2Geexiaiict6: Device Group Ignition Prote-Ction Class Temperature Class Explosion Group Category IdentifierDocument7 pagesIi2Geexiaiict6: Device Group Ignition Prote-Ction Class Temperature Class Explosion Group Category IdentifierClaudio GonzalezNo ratings yet

- BR PR PartsDocument18 pagesBR PR PartsKrishna KumarNo ratings yet

- A PROVEN ELECTRIC MOTOR REGREASING PROGRAMDocument6 pagesA PROVEN ELECTRIC MOTOR REGREASING PROGRAMhamidkarimi_zpcNo ratings yet

- Generator Products GEA13489A PDFDocument16 pagesGenerator Products GEA13489A PDFMadusanka WeebeddaNo ratings yet

- Testing of Turbo GeneratorsDocument4 pagesTesting of Turbo Generatorsemmanuel akaNo ratings yet

- A Generator - Our Experience 23042016Document10 pagesA Generator - Our Experience 23042016Chilamkurti Siva Sankara RaoNo ratings yet

- DC Motor PrimerDocument26 pagesDC Motor PrimerastroltravlerNo ratings yet

- Baker Surge Testing Electric Motors WPDocument8 pagesBaker Surge Testing Electric Motors WPBisto MasiloNo ratings yet

- Easa Currents - February 2007Document0 pagesEasa Currents - February 2007maheshNo ratings yet

- Form - Wound - Repair - Specification Rewinding PDFDocument10 pagesForm - Wound - Repair - Specification Rewinding PDFBenjie CallantaNo ratings yet

- Determining The Efficiency of Induction Machines, Converters and SoftstartersDocument8 pagesDetermining The Efficiency of Induction Machines, Converters and Softstarterssadeq03No ratings yet

- MaintainingMotorEfficiency 1107 PDFDocument3 pagesMaintainingMotorEfficiency 1107 PDFnasrunNo ratings yet

- General Purpose Slip-Ring Induction Motors: Product CatalogueDocument12 pagesGeneral Purpose Slip-Ring Induction Motors: Product Catalogueرضوان محمد مرعي كاملNo ratings yet

- Manufacturing and System Design of Insulation For Air Cooled Turbo Generator by V.P.I ProcessDocument54 pagesManufacturing and System Design of Insulation For Air Cooled Turbo Generator by V.P.I Processapi-3834081100% (1)

- M/s. BASAI STEELS PVT. LTD. boiler parts data sheetsDocument79 pagesM/s. BASAI STEELS PVT. LTD. boiler parts data sheetsBurra DayanandamNo ratings yet

- ESP installation reportDocument3 pagesESP installation reportrahulNo ratings yet

- Motores de Rotación ParkerDocument26 pagesMotores de Rotación ParkerSam MarmorNo ratings yet

- Article 145TTFR16035 DataPack 9Document7 pagesArticle 145TTFR16035 DataPack 9Edgar Gabriel Sanchez DominguezNo ratings yet

- PE184TC-5-4 NEMA Premium Efficiency Totally Enclosed Fan Cooled C-Flange Electric MotorDocument2 pagesPE184TC-5-4 NEMA Premium Efficiency Totally Enclosed Fan Cooled C-Flange Electric MotorSreekanthNo ratings yet

- Eddy Current BrakesDocument26 pagesEddy Current BrakesAbrar Ahmed100% (1)

- Observer Based Nonlinear ControlDocument7 pagesObserver Based Nonlinear ControlJavier FontalvoNo ratings yet

- AIR-X Circuit Replacement InstructionsDocument9 pagesAIR-X Circuit Replacement InstructionsscabdNo ratings yet

- AP PGECET 2016 EE Question Paper Answer KeyDocument32 pagesAP PGECET 2016 EE Question Paper Answer KeyD J BravoNo ratings yet

- Week 3 B 2 Electric MotorsDocument59 pagesWeek 3 B 2 Electric MotorsCharlton S.InaoNo ratings yet

- Part BDocument10 pagesPart BVenkat ManiNo ratings yet

- Fundamental Studies of Variable-Voltage Hybrid-Electric PowertrainsDocument21 pagesFundamental Studies of Variable-Voltage Hybrid-Electric PowertrainsOliver RailaNo ratings yet

- Unit 66 Three Phase Motors and DrivesDocument9 pagesUnit 66 Three Phase Motors and DrivesAmatek Teekay 特克纳No ratings yet

- 2018, - Altair - Multi-Physics Electric Motor Optimization For Noise ReductionDocument5 pages2018, - Altair - Multi-Physics Electric Motor Optimization For Noise ReductionburchandadiNo ratings yet

- The Life and Inventions of Nikola TeslaDocument6 pagesThe Life and Inventions of Nikola Teslaapi-235866788No ratings yet

- Motor TheoryDocument20 pagesMotor TheorydomcristiniNo ratings yet

- Industrial Power Systems Handbook PDFDocument987 pagesIndustrial Power Systems Handbook PDFpadmajasivaNo ratings yet

- ELECTRICAL QUESTIONS AND ANSWERS-MCQ-8-ETO - Electro Technical OfficerDocument11 pagesELECTRICAL QUESTIONS AND ANSWERS-MCQ-8-ETO - Electro Technical Officeramit100% (3)

- Eccentricity Measurement in STGDocument7 pagesEccentricity Measurement in STGKarthick Velayutham100% (1)

- EE 4PM4 Quiz 1 Solutions - 2016-17Document4 pagesEE 4PM4 Quiz 1 Solutions - 2016-17PreethamNo ratings yet

- Ee09 704 - Electrical Machine Design Model QPDocument2 pagesEe09 704 - Electrical Machine Design Model QPGīřïşh McNo ratings yet

- Analysis of Slot Leakage Reactance of Submersible Motor With Closed Slots During Starting Transient OperationDocument8 pagesAnalysis of Slot Leakage Reactance of Submersible Motor With Closed Slots During Starting Transient OperationAli HashemiNo ratings yet

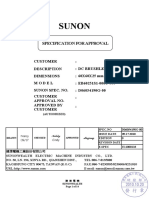

- Sunon Specification Approval for DC Brushless FanDocument14 pagesSunon Specification Approval for DC Brushless FanVictor Mihai Oglinda ElivicNo ratings yet

- Switchgear, Cables & AlternatorDocument24 pagesSwitchgear, Cables & AlternatorVinay KumarNo ratings yet

- Alternator MaterialDocument12 pagesAlternator MaterialveeranjaneyulugopuNo ratings yet

- Ijsrp p3626 PDFDocument4 pagesIjsrp p3626 PDFMohamed Taleb100% (1)

- An Extended Modeling of Synchronous Generators For Internal Fault Evaluation and Protection AssessmentDocument8 pagesAn Extended Modeling of Synchronous Generators For Internal Fault Evaluation and Protection AssessmentR0B0T2013No ratings yet

- Overall Summary of Motors' Condition at Various Plants (January 2004)Document1 pageOverall Summary of Motors' Condition at Various Plants (January 2004)kishan14175No ratings yet

- Electric Car: GE109 Lab ReportDocument15 pagesElectric Car: GE109 Lab ReportSujal BansalNo ratings yet

- Automatic Speed Control and Accident Avoidance of Vehicle UsingDocument34 pagesAutomatic Speed Control and Accident Avoidance of Vehicle UsingK HariNo ratings yet

- Aesv AesuDocument32 pagesAesv AesuAzisNo ratings yet

- 2ALTERNATORDocument56 pages2ALTERNATORlilya mohNo ratings yet

- Survey of Insulation Systems in Electrical MachinesDocument19 pagesSurvey of Insulation Systems in Electrical Machinesyeprem82No ratings yet

- Determination of Single Phase Induction Motor ParametersDocument6 pagesDetermination of Single Phase Induction Motor ParametersBook4AllNo ratings yet