Professional Documents

Culture Documents

Volvo ETM Replacement

Uploaded by

Michael LoucasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Volvo ETM Replacement

Uploaded by

Michael LoucasCopyright:

Available Formats

Magnetti Marelli ETM (electronic throttle management) sensor replacement by Precision Ph 1300 886 955 (Australia)

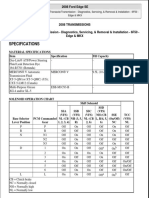

Part numbers of modules affected: 8644347 36001822 8644346 9136793 9186793 9207831 9497244 Fitment: Volvo S70, V70, XC70, S80 1999-2001 C70 1999-2002 S60 Turbo 2001 Part numbers of modules affected: 8644344 36001821 8644345 Fitment: Volvo S60 2001-2002 without Turbo V70 2001-2002 without Turbo

What are the symptoms of a failed or failing ETM?

Poor idle or idle speed which is hunting or going up and down without pressing the accelerator pedal. The ETS light is illuminated on the dash display. Car goes into limp home mode and accelerates poorly. Also when the car is diagnosed by computer at a dealer or independent mechanic various throttle position codes are displayed. Once the cars ECU receives erratic signals or an open circuit due to the wear in this strip it goes into Limp Home mode and the ETS light on the dash display will be illuminated. In many cases various error codes associated with throttle position will also be read by the cars ECU. The check Engine light may also be illuminated. The cars speed will then be restricted to around 65kp/h or 40mp/h

What fails in the ETM?

The photo on the left shows a potentiometer strip which has become badly worn through contact with the sweeping arm which rubs across this strip many thousands of times during acceleration/deceleration of the throttle plate during normal driving over an extended period. Even though the materials that the sweeping arm is made from are relatively soft, the sweeping arms contacts will eventually wear through the carbon resistive track. Volvos 2nd generation yellow stickered ETMs used slightly softer wiping arms and a thicker carbon coating. Also Volvo released new software that would prolong the inevitable failure of the ETM. In fact you can visit your local friendly Volvo dealer and you can have the software upgrade fitted to your ETM which will only prolong the inevitable failure. In the USA lobby groups fought with Volvo America to extend the warranty to 10 years or 200,000 miles (320,000 kms). In other world markets this has not happened and cases were assessed on an individual basis. In Australia dealers are not replacing the ETM under warranty.

So Whats the Solution?

An accomplished electronic design company with a track record of excellence was commissioned to design and manufacture an improved end cap with contact less design and two angle detecting chips which would replace both sensors on the Magnetti Marelli unit. It uses Hall Effect technology similar to many cam and crank sensor applications in motor vehicles. The reliability of this sensor is far greater than the contact version it replaces and is expected to last the life of the vehicle.

Why is this better than a new throttle body?

As Volvo has not changed the basic design of the ETM a new Volvo throttle body will have the same flawed carbon resistive film which caused the ETM to fail. Documented failures have been reported with as little as 90,000 kms (56,000 miles) even after the latest software updates have been fitted. Imagine fitting a new part and not being able to assure your client it will last longer than the car.

Why this suits all budgets

If youre an independent Volvo repairer or an experienced DIYer you will find that it is far less expensive than a new ETM and when you factor in the cost of a ETM reload at the dealer (towing to the dealer may be necessary as the car might not start with a new ETM) Also because we are using your cars own ETM there is no need for a reload so this cost is saved. New ETMs from Volvo will cost around $625 if imported from the USA plus shipping and delays (locally sourced ETMs in Australia will cost around $1,300) Also the new ETM will need to be matched to your cars VIN (vehicle identification number) at extra cost which will need to be done at a dealer with special software.

What does Precision do to the ETM?

First we clean the ETM housing, and the throttle body if necessary. Then we open the casing to reveal the sensor connection points. We then remove the old sensor while retaining the wiring points so a new sensor may be fitted. We then fit the sensing magnet. Next we disengage the other throttle sensor on the opposite side, so the new throttle sensor only is recognised, then solder the new TPS in place. A high grade putty is then used to reseal the connectors to avoid corrosion. Then the case is resealed again with high grade putty to seal the unit from moisture. Finally the wiring loom is inspected for wear, repaired where necessary and a new split tubing is fitted for safety.

Cleaning out the housing

The new magnet is fitted with thread lock compound

Resealing the housing

The finished product with new sensor and new split tubing.

Warranty Conditions

-Evidence of damage either by accident of vehicle or tampering of the casing or a broken warranty seal -Evidence of natural disasters such as fire, flood or lightning -ETM was installed in another vehicle prior to return -Vehicle was used in motor sport or competitive racing -Other electrical short or overcharging of electrical system which has directly affected the ETM -The ETM was returned in such a way that damage has occurred during transit. -Original core was not returned within 12 months from the date of purchase

You might also like

- Portals Raybestos Files PM 1340 TCCcatalogDocument32 pagesPortals Raybestos Files PM 1340 TCCcatalogrobertoperez525No ratings yet

- Winserver2 Volvo Viewinglibrary ST 160 2012 07 10 PDFDocument29 pagesWinserver2 Volvo Viewinglibrary ST 160 2012 07 10 PDFLuis JesusNo ratings yet

- VOLVO V70 2001 User ManualDocument243 pagesVOLVO V70 2001 User Manualkir0iNo ratings yet

- Jeep KK DTC LISTDocument6 pagesJeep KK DTC LISTHenry SilvaNo ratings yet

- BBS Wheel Hardware GuideDocument47 pagesBBS Wheel Hardware GuideJuan VasquezNo ratings yet

- Getrag Special Tools 6DCT250 (DPS6, DC4) : L K Basic Tool KitDocument4 pagesGetrag Special Tools 6DCT250 (DPS6, DC4) : L K Basic Tool KitHumberto Cadori Filho100% (1)

- Denon AVR-1906Document70 pagesDenon AVR-1906bsambNo ratings yet

- 2015 Ford Escape Specs ComparisonDocument1 page2015 Ford Escape Specs ComparisontouchvikrantNo ratings yet

- Fully Autonomous Vehicles: Visions of the future or still reality?From EverandFully Autonomous Vehicles: Visions of the future or still reality?No ratings yet

- Parts ManualDocument142 pagesParts ManualAlexandru AlistarhNo ratings yet

- VW T4 Automatic Gearbox Adapter Kit InstallationDocument2 pagesVW T4 Automatic Gearbox Adapter Kit InstallationLuke HazelgroveNo ratings yet

- MP12 Probe System Installation and User's GuideDocument146 pagesMP12 Probe System Installation and User's GuideleonNo ratings yet

- 1008AE Specification SummaryDocument11 pages1008AE Specification Summarynovram novNo ratings yet

- Volvo Penta Aquamatic80 HandbookDocument49 pagesVolvo Penta Aquamatic80 HandbookautobritaiNo ratings yet

- Implementing the J1850 Protocol for Vehicle CommunicationDocument15 pagesImplementing the J1850 Protocol for Vehicle CommunicationMikeNo ratings yet

- Converter Lining CatalogDocument76 pagesConverter Lining CatalogMarianoNo ratings yet

- TCM (Remanufactured) : 6T45 (Code 6524)Document1 pageTCM (Remanufactured) : 6T45 (Code 6524)belchiorNo ratings yet

- JF 015Document6 pagesJF 015danielNo ratings yet

- New Product Announcement: Zf6Hp19A / Audi 09LDocument1 pageNew Product Announcement: Zf6Hp19A / Audi 09LFSR1407No ratings yet

- Range Rover P38 MY99 - TV & Video System (LRL0344ENG)Document15 pagesRange Rover P38 MY99 - TV & Video System (LRL0344ENG)Riahi RezegNo ratings yet

- Ja Jf016e VBLDocument1 pageJa Jf016e VBLEdersonNo ratings yet

- 15-1025 1st 2nd Gear Jumps Out MMT6 GrboxDocument29 pages15-1025 1st 2nd Gear Jumps Out MMT6 GrboxBogdan Stefan100% (1)

- Volvo s80 Owners Manual 2004Document216 pagesVolvo s80 Owners Manual 2004Edijs AlksnisNo ratings yet

- 960 - 1996 Owner's ManualDocument254 pages960 - 1996 Owner's ManualhucnNo ratings yet

- Service Training: The Audi Q7 Power TransmissionDocument41 pagesService Training: The Audi Q7 Power TransmissionHuy Trần QuốcNo ratings yet

- 4 L 60 EgroundDocument2 pages4 L 60 EgroundDavid RosadoNo ratings yet

- Auto TransmissionDocument444 pagesAuto TransmissionCicerón RomeroNo ratings yet

- DiCE SetupguideDocument11 pagesDiCE SetupguideLuis JesusNo ratings yet

- GEARS March 2014 PDFDocument76 pagesGEARS March 2014 PDFpapipapiiNo ratings yet

- Plug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideFrom EverandPlug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideNo ratings yet

- Frame Contained PDF File, Click To ViewDocument263 pagesFrame Contained PDF File, Click To ViewArtur ArturowskiNo ratings yet

- 722dot6 Valvebody LayoutDocument2 pages722dot6 Valvebody LayoutDanijel AspanNo ratings yet

- 4t40e - 4t45eDocument6 pages4t40e - 4t45eJD DionisioNo ratings yet

- Transmision Automatica Altima Bolletin.Document19 pagesTransmision Automatica Altima Bolletin.Brian MorenoNo ratings yet

- Earlham Park: Edith Cavell Building University VillageDocument1 pageEarlham Park: Edith Cavell Building University VillageGiang BuiNo ratings yet

- ETKA Skoda Transmission CodesDocument16 pagesETKA Skoda Transmission CodesglistridaNo ratings yet

- Volvo XC70 Power Brake Booster ReplacementDocument12 pagesVolvo XC70 Power Brake Booster ReplacementMarilyn MaxwellNo ratings yet

- AC Product Update November 2014Document1 pageAC Product Update November 2014Raca ZivkovicNo ratings yet

- BMW - zf6 6r60 Zip inDocument11 pagesBMW - zf6 6r60 Zip inBartłomiej Kilian100% (1)

- 01M VW Cat PDFDocument16 pages01M VW Cat PDFferber107eNo ratings yet

- Toyota Evap Series: Understanding Non-Intrusive SystemsDocument2 pagesToyota Evap Series: Understanding Non-Intrusive SystemsMNo ratings yet

- Lucas OPUS ignition system for Jaguar V12 enginesDocument9 pagesLucas OPUS ignition system for Jaguar V12 enginesBo BoboNo ratings yet

- 6T40 Gen III - Start StopDocument3 pages6T40 Gen III - Start Stopchoco84No ratings yet

- TD 201102Document68 pagesTD 201102Transmisiones Automáticas Chepe50% (2)

- 4 R 44 eDocument4 pages4 R 44 eArmando Kalel AlmanzaNo ratings yet

- Sentra 2008 Trasmision Cvt.Document606 pagesSentra 2008 Trasmision Cvt.Brian MorenoNo ratings yet

- AlfaFiatLancia 19JTD EDC15Document3 pagesAlfaFiatLancia 19JTD EDC15crnisaleNo ratings yet

- Rostra Precision Controls Transmission Products CatalogDocument64 pagesRostra Precision Controls Transmission Products CatalogMaría Martz De García67% (3)

- Peugeot 308 Specifications Brochure PDFDocument12 pagesPeugeot 308 Specifications Brochure PDFLuis PanaoNo ratings yet

- Bumper RemovalDocument7 pagesBumper RemovalRoberts ObkeNo ratings yet

- Mechatronik SealDocument3 pagesMechatronik SealMihai Serban OlariuNo ratings yet

- Rondo 2.7L 2007 Service ManualDocument2,489 pagesRondo 2.7L 2007 Service ManualĐạt ThànhNo ratings yet

- C (2) CosengDocument32 pagesC (2) CosengCristhian RiosNo ratings yet

- Dragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)From EverandDragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)No ratings yet

- Audi A4 B6 1.8T Troubleshooting GuideDocument8 pagesAudi A4 B6 1.8T Troubleshooting GuideM Hazwan Wahab33% (3)

- Evaporative Cooler ChampionsDocument12 pagesEvaporative Cooler Championswa yangNo ratings yet

- 1000+ Free Ebooks and DVDs Download at www.gitara1.comDocument96 pages1000+ Free Ebooks and DVDs Download at www.gitara1.comoscar calvete100% (3)

- Generating Business IDEASDocument25 pagesGenerating Business IDEASAnshul YadavNo ratings yet

- Approved Module Phil Tourism Geographyamp Culture Printed Modular v3 Converteddocx PDF FreeDocument56 pagesApproved Module Phil Tourism Geographyamp Culture Printed Modular v3 Converteddocx PDF FreeKevin Angelo ManaloNo ratings yet

- Plant QRQC FormDocument1 pagePlant QRQC FormjaninaNo ratings yet

- Weedeater One Service ManualDocument20 pagesWeedeater One Service ManualBrandon HarveyNo ratings yet

- You Can Access All These Resources From Home or School!Document1 pageYou Can Access All These Resources From Home or School!2026Alizabith HaskinsNo ratings yet

- PROJECTDocument4 pagesPROJECTMAHESH VNo ratings yet

- 242641how To Get Hired in The Softether IndustryDocument2 pages242641how To Get Hired in The Softether IndustryvoadilixthNo ratings yet

- SQL Labsheet 2 - DML Part 1Document1 pageSQL Labsheet 2 - DML Part 1Hirdesh RamjutunNo ratings yet

- Indus Motor Company SWOT AnalysisDocument3 pagesIndus Motor Company SWOT AnalysishammadmajeedNo ratings yet

- Logcat Prev CSC LogDocument196 pagesLogcat Prev CSC LogAzeneth Ashley CleaningNo ratings yet

- Communications Systems - PLM-8CS PLENA Matrix 8 Zone Call StationDocument3 pagesCommunications Systems - PLM-8CS PLENA Matrix 8 Zone Call StationSaad KhNo ratings yet

- Falling From Grace by S L Naeole PDFDocument2 pagesFalling From Grace by S L Naeole PDFDeniseNo ratings yet

- Legitimate Interests Assessment FormDocument6 pagesLegitimate Interests Assessment FormRenataNo ratings yet

- BTS Training Ciena 6500 Maintenance and TroDocument9 pagesBTS Training Ciena 6500 Maintenance and TroShaneej Kumar Tiwary100% (1)

- Reset Printer Canon MP140Document7 pagesReset Printer Canon MP140bim2009No ratings yet

- Dissertation La Juridiction AdministrativeDocument6 pagesDissertation La Juridiction AdministrativeScientificPaperWritingServicesUK100% (1)

- READING 2 UNIT 11 Old-Inventions-Reading-ComprehensionDocument2 pagesREADING 2 UNIT 11 Old-Inventions-Reading-ComprehensionDavid Isaac Ruiz ChaconNo ratings yet

- Teleperformance AssessmentDocument4 pagesTeleperformance AssessmentKristine Razonabe80% (5)

- Java vs Python: When to Use Each Programming LanguageDocument1 pageJava vs Python: When to Use Each Programming Languageprominence123No ratings yet

- European Reference Document On Best Available Techniques (BREF) - Bianca-Maria ScaletDocument23 pagesEuropean Reference Document On Best Available Techniques (BREF) - Bianca-Maria ScaletmjbotelhoNo ratings yet

- Roga NidanDocument555 pagesRoga NidanKristina BabicNo ratings yet

- Variocontrol Lineardrive 180D: 4/6/24 A Full-Colour Dimmable Led DriverDocument5 pagesVariocontrol Lineardrive 180D: 4/6/24 A Full-Colour Dimmable Led DriversanjuNo ratings yet

- R-Business Continuity Plan Examining of Multi-Usable FrameworkDocument8 pagesR-Business Continuity Plan Examining of Multi-Usable FrameworkJosé Manuel Sánchez Murga100% (1)

- ITN Module 9Document27 pagesITN Module 9Salma AhmedNo ratings yet

- FSFR1800USDocument15 pagesFSFR1800USДмитрий КопышевNo ratings yet

- Case - Texas Eastman PDFDocument17 pagesCase - Texas Eastman PDFahmad wildan100% (1)

- Third Industrial Revolution May Sharply Reduce JobsDocument3 pagesThird Industrial Revolution May Sharply Reduce JobsMelissa Salaverry CamposNo ratings yet

- UTS - The Virtual Self PDFDocument2 pagesUTS - The Virtual Self PDFSHAIRA PAMAYLAONNo ratings yet