Professional Documents

Culture Documents

210 MW Boiler Construction 1

Uploaded by

Vipul DabreOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

210 MW Boiler Construction 1

Uploaded by

Vipul DabreCopyright:

Available Formats

MAHAGENCO

Presentation on 210 MW Boiler Construction

Presented by Uddhao G. Manapure K-57, Batch Koradi Training Centre Koradi

1. INTRODUCTION

Boiler is any closed vessel exceeding 22.75 liters in capacity used for steam generation under pressure. First boiler was developed in 1725 and its working pressure was 6 to 10 kg/cm2 and was called Wagon Boiler

There are mainly two types of Boilers 1. Fire Tube Boiler 2. Water tube Boiler The boiler used for generation of power is somewhat different in construction than the boilers used in other industrial applications. The boiler used for power generation is constructed by the four walls called water walls. These walls are made up of long tubes called water wall tubes through which water flows and the combustion of fuel takes place inside the boiler. The flue gases so formed passes through two passes of the boiler.

1. First Pass 2. Second Pass

Boiler used in Thermal Power Plant are again subdivided into 1. Natural Circulation 2. Forced Circulation - operating pressure approaches

to critical pressure

According to working pressure 1. Sub critical Pressure Boiler: - working press. Range 130 to 180 kg/cm2 2. Critical Pressure Boiler: - pressure 221.2 kg/cm2 3. Supercritical pressure Boiler or Once Through Boiler: - working pressure 240 kg/cm2

Boiler design Considerations:Following factors are taken into consideration: Lowest capital cost, easy in construction, simplicity safety, good working condition, easy in maintenance. Availability of auxiliaries Efficient operation, effective for heat transfer well insulate of casings, ability to deliver pure steam with effective drum internals, to genrate steam of full capacity.

1.1 Boiler Construction :Main parts of Boiler used in Thermal power plant 1) Boiler Drum 2) Down corners 3) Water wall 4) Furnace Superheater 5) Primary Superheater 6) Platen superheater 7) Final Superheater 8) Reheater 9) Economizer 10) Burners 11) Ignitors 12) Windbox 13) Soot Blowers The flue gas formed by combustion of a fuel in the furnace passes through two passes I) II) 1) 2) 3) 4) First Pass Second Pass

First pass consist of Furnace water wall Platen super heater Reheater Water wall screen tubes

Second pass consist of 1) Final super heater 2) LTSH 3) Economizer After second pass flue gases flows through air preheater where it gives heat to air then passes through ESP & blown out to atmosphere through chimney.

1.1.1.Boiler Drum :1) Drum is a pressure vessel 2) It is made of special carbon steel plate Material of SA-299 grade A1 Or SA- 515 Grade 70 Plates thickness having 132 mm 3) The function of Boiler Drum is to separate water & steam from the mixture generated in the furnace wall. 4) It also provides a water storage for preventing the starvation of tubes.

Parts :1) Turbo separator 2) Screen dryer 3) Feed pipe 4) Baffle Plate 5) Drum level gauge (lower) 6) Riser tube (Water walls Tubes) i.e 6 x 23 rows on drum 7) Chemical dosing pipe 8) Main hole & main hole cover 9) Safety Valve 10) Sampling line 11) Vents Technical specification of 210 MW boiler drum is given below. Length 15700 mm Weight 123 Tonnes Internal Diameter 1676 mm Outside Diameter 1942 mm Thickness of Metal 132 mm Material Carbon Steel SA 515 Gr. 70 or S.A. 299 A1 Pressure in Drum 149.7 Kg. /cm2 (LMW Unit) 168 Kg. /cm2 (KWU Unit) Total Number of Turboseprater in each row 50 Location :Boiler drum is located at height of 53 Mtr. from a ground level. The main supporting structure of a boiler consist of 18 main column & 12 auxilary column. The main columns supported the main boiler components.

1.1.2 Down comers

1) 2) 3) There are 6 to 8 down comer from drum and are jointed to ring headers to provide water to water walls. The Two down comers joined to Platen water wall header. platter water wall header are not provided to every boiler. Rear Left

Bottom Ringheader

Right

Front 1) 2) 3) 4) 5) Two down comer to front side of Bottom Ringheader Two down comer - to rear side of Bottom Ringheader One down comer to left side of Bottom Ringheader One down corner To right side of Bottom Ringheader Two down comer Tow water wall platen inletheader.

1.1.3 Water walls

1) Water wall tubes also called as riser tubes. 2) furance made up of 4 water walls I) front water wall II) LHS water wall III) IV) rear water wall RHS water wall

I)

Front water wall :-

Connections made up of water tubes from the front portion of Bottom Ringheader to front top header are shown. 1) Platen water walls :There are four platen water walls located at the top of the combustion chamber to increase the heating surface without increasing the volume of the boiler furnace. 2) L.H.S. water walls :The left side water wall connections from Bottom Ringheader to left top headers as shown.

3) R.H.S. Water walls:The right side water wall connections from the right portion of bottom ring headers to the right top header as shown. 4) The rear water wall :Connections from bottom ring headers to rear top headers as shown. About 60% rear water wall tubes form goose neck and are connected to the rear top most header. A goose neck helps in maintaining a better distribution of the flue gas steam in the transition zone i.e. In between first & second pass. And about 30% of rear water wall tubes go straight to the top rear header which is exactly above the rear portion of the Ringheader. About 10% of the water wall tube from rear side rear side bottom Ringheader are connected to the extended water wall inlet headers located below the goose neck. From the extended water wall inlet headers water gooses to righ & Left top headers Riser tube connection from boiler top header to drum are shown there are 6 x 23 rows of riser tube connections on the drum as shown, in fig The fig. shows the complete assembly of a) Water walls from bottom ring headers to top headers. b) Riser tube connections from top headers to drum as shown in fig.

1.1.4 Furnace : The tall rectangular raident type furnace or used in modern design of pulverized fuel boiler. Height of modern boiler is increased to lower gas temp & reduced sagging. Furnace is of two passes In front pass combustion of fuel takes place & hence this is the most hot zone of the boiler called is firing zones. The temp of firing zone is about 12000c to 14000c this type of furnace is called water cooled furnace After second pass flue gases passess through Air Preheater where it gives heat to air then passes through ESP and blown out to atmosphere through chimney.

Superheaters:1.1.5 1) primary super Heater (LTSH) Steam from drum comes to LTSH, It has two stages i) Upper bank & Lower bank Each bank has 134 assemblies of pitch 102 mm Material of the tubes are SA 209 T, SA 210 Gr. A, SA 213 T11 Size of the tubes is 44.5 x 4.5 mm Temprerature with standing range 4500c to 4800c

1.1.6 2) Platen superheater :- (Radient superheather)

Steam from LTSH comes to platen superheater It is situated in furnace vertically. It has 29 assemblies having pitch of 457 mm Material of the tube is alloy steel SA 213 T11 SA 213 T22 Size of the tubes are 51 x 7.1 mm & 51 x 8.6 mm

1.1.7 3) Final superheaters: It is situated vertically behind reheater having 119 assemblies at a pitch of 114 mm Size of tubes 51 x 7.6 mm Final superheater tubes are made up of SA 213 T22 alloy steel This material can with stand temperature upto 5800c

1.1.8 REHEATER :Reheater is located behind the platen superheater. It is Two parts front & rear Front reheater has 59 assemblies at a pitch of 229 mm & Rear Reheater has 89 assemblies at a pitch of 152mm Material of Tubes SA 213 T1 alloy steel. Tube size 54 x 3.6 mm Tube material can withstand temp. upto 5500c.

1.1.9 :- Economizer : It is located between LTSH & Air Preheaters in second pass of furnace. Feed water after HP Heater passes through economizer. After this it is goes to drum. Economizer is in two banks, lower banks & upear Bank It has 270 assemblies at a pitch of 102mm Material of tubes SA 210 Gr A1 Size of tubes 44.5 x 4.5 mm Tubes material can withstand tamp. Upto 450 0c

1.1.10 Burners & Igniters: Coal is used as primary fuel & oil is used as a secondary fuel during start up of boilers & for flame stability at loads & other transient operating conditions. Burner is to automise fuel, penetrate & mixed with proper proportions for complete combustion. Burner are stituated at 3 elevations called AB,CD & EF At every there are four burners. Fo/LSHS can be fired at all elevations but LDO can be taken at AB elevations only startup of boiler. For every burner weather LDO/FO there is one igniter to ignite the burner. Now igniters are being changed from HSD/LDO to HEA (High energy arc igniters, purly electrical)

1.1.11 wind box : The wind box is situated at 11mtr level of boiler it is in two parts. One is in LHS & other is in RHS of Boiler. There are thirteen compartments in it on each corners out of which 1) 3 for oil burners 2) 6 for coal mills. 3) 4 for auxiliary air. These compartment are connected to burner tilt mechanism which is operated +/-30 as per require according to final temp of steam. The secondary air after Airpreheater come to windbox and is given to furnace along with fuel for complete combustion.

1.1.12 Soot blowers : About 78 soot blowers are provide at different zones to remove the accumulated soot on boiler tubes for effective heat transfer.

Types of soot blower :Water wall soot Blowers : LRSB : Long retractable soot blowers are 20 in nos. These are used to clean S.H. & R.H. & are located in 2nd pass of the furnace. There are situated on the furnace & are 56 in nos These are driven by electric motors. Super heated steam is blown through them to clean the disignated area of the water wall. Two soot blowers are located on air heaters to clean the baskets of A.H. Steam from PRDS is taken for this purpose.

You might also like

- Presentation APHDocument35 pagesPresentation APHKr SantoshNo ratings yet

- Griffon2000TDX Manual rel-01OLDocument17 pagesGriffon2000TDX Manual rel-01OLHassan MohmedNo ratings yet

- The Layout of Fluid Mechanics and Hydraulic Machinery LabDocument4 pagesThe Layout of Fluid Mechanics and Hydraulic Machinery LabAhmad RazaNo ratings yet

- 500 MW BOILER SALIENT FEATURESDocument8 pages500 MW BOILER SALIENT FEATURESKeyur PatelNo ratings yet

- Boiler 210mwDocument15 pagesBoiler 210mwishakNo ratings yet

- 500mw Boiler Operating InstructionsDocument8 pages500mw Boiler Operating InstructionsRavindrababu Banothu100% (1)

- KWU Steam Turbine Governing System 210 X 4 MW HtpsDocument86 pagesKWU Steam Turbine Governing System 210 X 4 MW HtpsAneesh CR100% (1)

- Cold Start Up - CSTPS PDFDocument19 pagesCold Start Up - CSTPS PDFAhemadNo ratings yet

- 210 MW BoilerDocument25 pages210 MW BoilerAhemadNo ratings yet

- HP & LPBP SystemDocument47 pagesHP & LPBP SystemKana Padmaja50% (2)

- Boiler Q ADocument26 pagesBoiler Q AGnanaSekar100% (1)

- NPTI (SR) Scheme Tracing Report TSIIDocument62 pagesNPTI (SR) Scheme Tracing Report TSIIiwantinthatve75% (4)

- Design Aspects of Supercritical Power PlantsDocument33 pagesDesign Aspects of Supercritical Power PlantsSankar Achary100% (1)

- BHEL SupercriticalDocument87 pagesBHEL SupercriticalBottle ManiNo ratings yet

- A Quick Guide For TDBFP Rolling.: Prepared by Group-4Document7 pagesA Quick Guide For TDBFP Rolling.: Prepared by Group-4Rajanish BiswasNo ratings yet

- Turbine Rolling Startup GuideDocument39 pagesTurbine Rolling Startup GuideSarah Frazier100% (2)

- Indian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionDocument7 pagesIndian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionAlok DoshiNo ratings yet

- HeatersDocument9 pagesHeatersDevidutta PandaNo ratings yet

- 02.case Study On Boiler Tube Failure at JPLDocument8 pages02.case Study On Boiler Tube Failure at JPLAnonymous XBq5J84No ratings yet

- Mill Interlocks GuideDocument6 pagesMill Interlocks GuideNikhilNo ratings yet

- Higher Capacity 500 MW Boiler: Key Features and Design FactorsDocument34 pagesHigher Capacity 500 MW Boiler: Key Features and Design Factorsdreamboy87No ratings yet

- Secondary Air Damper Control (Sadc) : C.R.PAL, SR MGR (PS)Document3 pagesSecondary Air Damper Control (Sadc) : C.R.PAL, SR MGR (PS)Bineet Kumar VarmaNo ratings yet

- Boiler Design and Operation ParametersDocument88 pagesBoiler Design and Operation ParametersNavneet SinghNo ratings yet

- Pressure Parts 500MW BoilerDocument34 pagesPressure Parts 500MW BoilerAbhay Khobragade100% (1)

- HPBPDocument25 pagesHPBPSolaiNo ratings yet

- Mill & Mill Rejects WriteupDocument10 pagesMill & Mill Rejects WriteupEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Why Thermal Power Plant Efficiency is Low & How to Improve ItDocument1 pageWhy Thermal Power Plant Efficiency is Low & How to Improve ItNallathambiNo ratings yet

- L&T-MHI Boilers technical diary for Jaypee Nigrie STPP 2x660 MW SGA packageDocument23 pagesL&T-MHI Boilers technical diary for Jaypee Nigrie STPP 2x660 MW SGA packageShambhu MehtaNo ratings yet

- SADCDocument7 pagesSADCVIJAYPORNo ratings yet

- BHEL SupercriticalDocument87 pagesBHEL SupercriticalHari PrasadNo ratings yet

- Top 50 Boiler Information Booster Question Answers - ASKPOWERPLANTDocument19 pagesTop 50 Boiler Information Booster Question Answers - ASKPOWERPLANTRaju MaityNo ratings yet

- 210 MW Seal Oil SystemDocument6 pages210 MW Seal Oil Systemmag_ktps20021520No ratings yet

- Operation Aspects & Boiler EmergenciesDocument54 pagesOperation Aspects & Boiler EmergenciesPravivVivpraNo ratings yet

- 210 MW Boiler Function System Cycles Main Auxiliaries OperationsDocument30 pages210 MW Boiler Function System Cycles Main Auxiliaries OperationsAhemad100% (2)

- BFP Hyd CouplingDocument21 pagesBFP Hyd CouplingAditya Nandula100% (2)

- Unit Lightup Synchronisation & ShutdownDocument42 pagesUnit Lightup Synchronisation & ShutdownAshvani ShuklaNo ratings yet

- Stg-1 TDBFP Isolation NormalisationDocument4 pagesStg-1 TDBFP Isolation Normalisationnetygen1No ratings yet

- Turbine Rolling and SynchronizationDocument54 pagesTurbine Rolling and Synchronizationsanjeev kushwaha50% (2)

- Boiler Design and Operation ParametersDocument88 pagesBoiler Design and Operation ParametersKrishnan Santhanaraj100% (3)

- Turbine GoverningDocument44 pagesTurbine Governingcoleiro100% (2)

- Cold Srat UpDocument21 pagesCold Srat Upthiagu1989100% (1)

- 500 MW Turbine Cycle DescriptionDocument8 pages500 MW Turbine Cycle DescriptionAhemadNo ratings yet

- Boiler Light UpDocument14 pagesBoiler Light UpSamNo ratings yet

- Kerala BOE-2014 Paper-2 SolutionDocument15 pagesKerala BOE-2014 Paper-2 SolutionAlok DoshiNo ratings yet

- 500MW Boiler NotesDocument360 pages500MW Boiler NotesGanga Prasad100% (1)

- HP Bypass System and Reheater Protection LogicDocument11 pagesHP Bypass System and Reheater Protection LogicPrathamesh Gangal80% (5)

- Report On Unit-5 Clinker FormationDocument18 pagesReport On Unit-5 Clinker Formationsai_mss16No ratings yet

- Secondary Air Damper Control in BoilerDocument10 pagesSecondary Air Damper Control in BoilerSourav DasNo ratings yet

- Bhel - DEVELOPMENT OF ELECTRO-HYDRAULIC CONVERTER WITH PROPORTIONAL VALVE FOR KWU SETS & SITE FEEDBACK ON ITS COMMISSIONINGDocument10 pagesBhel - DEVELOPMENT OF ELECTRO-HYDRAULIC CONVERTER WITH PROPORTIONAL VALVE FOR KWU SETS & SITE FEEDBACK ON ITS COMMISSIONINGckstarun22No ratings yet

- SOP for ACW system operationDocument7 pagesSOP for ACW system operationsambhu100% (1)

- Energy Audit - Turbine CycleDocument27 pagesEnergy Audit - Turbine CycleMadhav Pande100% (1)

- Burner Tilt PDFDocument9 pagesBurner Tilt PDFEE POG-III CSTPSNo ratings yet

- Procedure of Deaerator Charging in Power Plant - ASKPOWERPLANTDocument16 pagesProcedure of Deaerator Charging in Power Plant - ASKPOWERPLANTOtuagaNo ratings yet

- An Overview of CFBC Boiler: By-Mukesh JhaDocument88 pagesAn Overview of CFBC Boiler: By-Mukesh Jhabalaji krishnan100% (2)

- CH 7 Paper 5 Flue Gas Temp Optimisation - Vindhyachal - ActualDocument6 pagesCH 7 Paper 5 Flue Gas Temp Optimisation - Vindhyachal - ActualSamNo ratings yet

- A Presentation On Turbine Rolling Atrs Final 2Document59 pagesA Presentation On Turbine Rolling Atrs Final 2Ramakrishna75% (4)

- Turbine Trip LogicDocument2 pagesTurbine Trip Logicdilbagh_scribd50% (2)

- Boiler Construction and Detail 210 MW: Nashik Generation Training Center, NashikDocument22 pagesBoiler Construction and Detail 210 MW: Nashik Generation Training Center, NashikAhemadNo ratings yet

- Boiler Constr DetailsDocument21 pagesBoiler Constr DetailsAhemadNo ratings yet

- Adtps ReportDocument35 pagesAdtps ReportMANASNo ratings yet

- Steam GeneratorDocument8 pagesSteam GeneratorRaju SubediNo ratings yet

- NTPC Training ReportDocument83 pagesNTPC Training Reportpankajpnd1100% (1)

- Fi NALDocument30 pagesFi NALVipul DabreNo ratings yet

- Cs Mannual FinalDocument18 pagesCs Mannual FinalVipul DabreNo ratings yet

- Indifference Curve AnalysisDocument15 pagesIndifference Curve AnalysisVipul DabreNo ratings yet

- SEI Civil Forum 2010 Reinforcing FoundationsDocument1 pageSEI Civil Forum 2010 Reinforcing FoundationsVipul DabreNo ratings yet

- Earth Moon StatisticsDocument13 pagesEarth Moon StatisticsVipul DabreNo ratings yet

- Invitation: For Sports MeetDocument4 pagesInvitation: For Sports MeetVipul DabreNo ratings yet

- Presentation 7Document1 pagePresentation 7Vipul DabreNo ratings yet

- HRSG SimulationDocument7 pagesHRSG Simulationkaruna346No ratings yet

- Combustion in Si EnginesDocument36 pagesCombustion in Si Enginesrgopi_83No ratings yet

- BurnerDocument8 pagesBurnerbagastcNo ratings yet

- Iwk 119061 VGF p48gldDocument2 pagesIwk 119061 VGF p48gldAwaisMughalNo ratings yet

- General Abbreviations and Piping Symbols GuideDocument1 pageGeneral Abbreviations and Piping Symbols GuideĐỗ Thiện100% (1)

- Hhi Air-Con SystemDocument36 pagesHhi Air-Con SystemBùi Xuân ĐứcNo ratings yet

- Cartercatalog WebDocument933 pagesCartercatalog WebOscar MartinezNo ratings yet

- Well Completion: University of Benghazi Faculty of Engineering Petroleum Engineering DepartmentDocument8 pagesWell Completion: University of Benghazi Faculty of Engineering Petroleum Engineering DepartmentAshrafNo ratings yet

- Energy CourseDocument240 pagesEnergy CourseMosorikNo ratings yet

- R410a 50Hz Air Conditioner Series GuideDocument2 pagesR410a 50Hz Air Conditioner Series GuidealogentleNo ratings yet

- Bill to Code ASC ListingDocument14 pagesBill to Code ASC Listinggalura gizeldaNo ratings yet

- Decree of The Minister of Mines and Energy No-300 K-38-M PE-1997 PDFDocument6 pagesDecree of The Minister of Mines and Energy No-300 K-38-M PE-1997 PDFhamid sobirinNo ratings yet

- DTC P0170 Fuel Trim Malfunction: Circuit DescriptionDocument3 pagesDTC P0170 Fuel Trim Malfunction: Circuit DescriptionWillie AustineNo ratings yet

- Green hydrogen can store 3x more energy than dieselDocument6 pagesGreen hydrogen can store 3x more energy than dieselDilip50% (2)

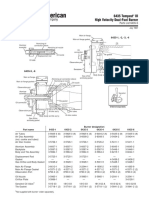

- 6435 Tempest III High Velocity Dual-Fuel Burner: Parts List 6435-5Document2 pages6435 Tempest III High Velocity Dual-Fuel Burner: Parts List 6435-5Jorge Prado DiazNo ratings yet

- Performance Analysis of PVT Module& Array: Deepika Chauhan Sarljay Agarwal Y.S ShishodiaDocument5 pagesPerformance Analysis of PVT Module& Array: Deepika Chauhan Sarljay Agarwal Y.S ShishodiaDeepika ChauhanNo ratings yet

- Axial Flow Fan Test Rig PDFDocument7 pagesAxial Flow Fan Test Rig PDFsunil kumarNo ratings yet

- And Domkundawar, S., A Course in Power Plant Engineering, Dhanpatrai (2002)Document2 pagesAnd Domkundawar, S., A Course in Power Plant Engineering, Dhanpatrai (2002)Dr. Gollapalli NareshNo ratings yet

- Nov152019 PROBLEM SETDocument2 pagesNov152019 PROBLEM SETJerkyArquioDonesaNo ratings yet

- 高压往复泵样本High Pressure Reciprocating Pumps PDFDocument27 pages高压往复泵样本High Pressure Reciprocating Pumps PDFAnonymous Tj3ApePIrNo ratings yet

- Sewage - AU 50-25Document1 pageSewage - AU 50-25Awliya TaqwaNo ratings yet

- MicroGrid and Energy Storage SystemDocument39 pagesMicroGrid and Energy Storage SystemAbin BabyNo ratings yet

- Effect of Number of Buckets On Flow Characteristics in Pelton TurbineDocument4 pagesEffect of Number of Buckets On Flow Characteristics in Pelton TurbineMartromuel RosariaNo ratings yet

- ISGF Report Energy Storage System RoadmapforIndia 2019to2032 11july2019 DraftDocument190 pagesISGF Report Energy Storage System RoadmapforIndia 2019to2032 11july2019 DraftJayanta ChatterjeeNo ratings yet

- Lesson 6 Energy TransformationDocument22 pagesLesson 6 Energy Transformationkriscelle hernandezNo ratings yet

- 1 KW Solar Power Plant Project ReportDocument3 pages1 KW Solar Power Plant Project ReportMohammd EssaNo ratings yet

- Desert - Scientists May Have Found One Answer To The Problem of Water ShortagesDocument3 pagesDesert - Scientists May Have Found One Answer To The Problem of Water ShortagesMam SawNo ratings yet

- R410A Commercial Air Conditioners Engineering Data Medium Static Pressure Duct TVR IDUDocument25 pagesR410A Commercial Air Conditioners Engineering Data Medium Static Pressure Duct TVR IDUHussain Al SanonaNo ratings yet

- ISO 10816-5 GROUP 1 EQUIPMENT VIBRATION DATADocument3 pagesISO 10816-5 GROUP 1 EQUIPMENT VIBRATION DATAazisyuswandiNo ratings yet