Professional Documents

Culture Documents

Robotic End Effector Using 4-Report

Uploaded by

karthikds91Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Robotic End Effector Using 4-Report

Uploaded by

karthikds91Copyright:

Available Formats

DESIGN AND FABRICATION OF ROBOTIC END EFFECTOR USING 4-BAR LINKAGE

A PROJECT REPORT

Submitted by ARUN.S CHARLES GNANAKUMAR.G KARTHIKEYAN.G MADHAN.E 52409114002 52409114007 52409114024 52409114027

in partial fulfillment for the award of the degree of

BACHELOR OF ENGINEERING

in

MECHANICAL ENGINEERING

KINGSTON ENGINEERING COLLEGE, VELLORE

ANNA UNIVERSITY: CHENNAI 600 025

APRIL 2012

www.kingston.ac.in, info@kingston.ac.in

BONAFIDE CERTIFICATE

Certified that this project report DESIGN AND FABRICATION OF ROBOTIC END EFFECTOR USING 4-BAR LINKAGE is the bonafide work of the following students who carried out the project work under my supervision. 1. Arun.S (52409114002) 2. Charles Gnanakumar.G (52409114007) 3. Karthikeyan.G (52409114024) 4. Madhan.E (52409114027)

SIGNATURE

SIGNATURE

Mr. D.SARAVANAN M.E.,

HEAD OF DEPARTMENT

Mr. S.MAHENDIRAN M.E.,

SUPERVISOR

Department of Mechanical Engineering Kingston Engineering College, Chittoor main road, Vellore - 632 059.

Assistant Professor, Department of Mechanical Engineering Kingston Engineering College, Chittoor main road, Vellore - 632 059.

Submitted for the Anna University Practical Examination Held on ___________________ at Kingston Engineering College, Chittoor Main Road, Vellore-632 059.

Signature of Examiners:

______________________ INTERNAL EXAMINER

______________________ EXTERNAL EXAMINER

ACKNOWLEDGEMENT

At this pleasing moment of having successfully completed our project, we wish to convey our sincere thanks and gratitude to the management of our college and our beloved Chairman Thiru.D.M.KATHIR ANAND, M.B.A., (USA) who provided all the facilities to us.

We would like to express our sincere thanks to our principal Dr.G.BASKAR, M.E., Ph.D., FIE for forwarding us to do our project and offering adequate duration in completing our project.

We are also grateful to the Head of the department Mr.D.SARAVANAN, M.E., for his constructive suggestions and encouragement during our project.

With deep sense of gratitude, we extend our earnest and sincere thanks to our guide Assistant Prof. Mr.S.MAHENDIRAN, M.E., Department of Mechanical Engineering for his kind guidance and encouragement during this project.

We also express our in depth thanks to our teaching and non-teaching staffs of Mechanical Engineering Department in KINGSTON ENGINEERING COLLEGE.

TABLE OF CONTENTS

CHAPTER ABSTRACT

TITLE

PAGE iii iv iv vi

LIST OF TABLES LIST OF FIGURES LIST OF SYMBOLS AND ABBREVIATIONS

INTRODUCTION 1.1 1.2 TYPES OF END EFFECTORS TYPES OF GRIPPER MECHANISMS 1 2

GRIPPER FORCE ANALYSIS 2.1 2.2 INTRODUCTION OTHER TYPES OF GRIPPERS 2.2.1 Vacuum Cups 2.2.2 Magnetic Gripper 2.2.3 Adhesive Grippers 2.3 2.4 2.5 TOOLS AS END EFFECTORS POWER AND SIGNAL TRANSMISSION CONSIDERATIONS IN GRIPPER SELECTION 2.6 DESIGN CALCULATION OF WORM GEAR DRIVE 16 7 8 9 10 12 13 13 14

TABLE OF CONTENTS

CHAPTER 3

TITLE MATERIALS AND COST ESTIMATION 3.1 DESIGN OF THE PROJECT 3.1.1 Before Assembly 3.1.2 After Assembly 3.2 COST ESTIMATION 3.2.1 Material Cost 3.2.2 Machining Cost 3.2.3 Miscellaneous cost 3.2.4 Total Cost 3.3 MATERIAL INTRODUCTION 3.3.1 Base Plate 3.3.2 Gripper Plate 3.3.3 Gripper Link 3.3.1 Worm and Worm Gears 3.4 EVALUATION

PAGE

20 20 22 23 23 23 23 23 24 24 24 24 24 25

SUMMARY AND CONCLUSIONS 4.1 4.2 4.3 WHAT HAS BEEN DONE FUTURE DIRECTIONS CONCLUSION 27 27 29

REFERENCES

30

ii

ABSTRACT

In the area of Robotics, the gripper plays a very important role as it is required to hold and place the object at the desired location. The requirements of gripper in terms of load capacity, and flexibility to adapt to the form of the object with tactile sensing capability which suit the strength of the object are necessary. Extensive research work is under way in the design of soft gripper or dexterous hand.

The mechanism is based on the motion characteristic of a parallelogram four-bar linkage and the geometric relationship that chords of concentric circles at a central angle are parallel. The gripper is simple in structure, easy to manufacture, and convenient to use. It has the capability to grip a wide range of part sizes and can achieve high accuracy.

This report presents a design of a new type of robot end-effector with inherent mechanical grasping capabilities. Concentrating on designing an end-effector to grasp a simple class of objects, cylindrical, allowed a design with only one degree of actuation. The key features of this design are high bandwidth response to forces.

Passive grasping capabilities, ease of control and ability to wrap around objects with simple geometries providing form closure. A prototype of this mechanism was built to evaluate these features.

iii

LIST OF TABLES

TABLE

TITLE

PAGE

2.5.1

Checklist of factors in the selection and design of grippers

15

3.2.1

Material Cost

23

3.2.4

Total Cost

23

LIST OF FIGURES

FIGURE

TITLE

PAGE

1.2.1 1.2.2 1.2.3 1.2.4 2.1.1

Some possible linkages for robotic grippers Gear and Rack method of actuating the gripper Cam actuated gripper Screw type gripper actuation Force against part parallel to finger surfaces tending to pull part out of gripper

3 4 5 5 7

2.2.1.1 2.2.2.1

Venturi device used to operate a suction cup. Stripper device operated by air cylinders used with a permanent magnetic gripper.

9 11

2.6.1

Worm iv

16

2.6.2 3.1 3.2 3.4.1 3.4.2 3.4.3 3.4.4 3.4.5 4.2 4.3

Worm Wheel Model of our project Assembled Model of our project Worm Gear Drive Prototype of End Effector Gripper holding Rectangular Plate Gripper holding Square Block Gripper holding Cylindrical Rod Dexterous Hand Robotic arm with 4-bar linkage end effector done by using SOLIDWORKS

16 20 21 26 26 26 26 26 28 28

LIST OF SYMBOLS AND ABBREVATIONS

F nf Fg w P A b c E

-Force, N -Coefficient of friction of the finger contact surface against the part surface -Number of contacting fingers -Gripper force, N -Weight of the part or object being gripped, Kg -Negative pressure, lb/in2 -Total effective area of the suction cup(s) used to create the vacuum, in2 -Bending Stress, N/mm2 -Contact Stress, N/mm2 -Youngs Modulus, N/mm2

-Initial Design Torque, N-mm mx a -Axial Module, mm -Revised Centre distance, mm -Lead angle

vi

1. INTRODUCTION

An end effector is a device that attaches to the wrist of the robot arm and enables the general-purpose robot to perform a specific task. It is sometimes referred to as the robot's "hand." Most production machines require special purpose fixtures and tools designed for a particular operation, and a robot is no. exception. The end effector is pan of that special-purpose tooling for a, robot. Usually, end effectors must be custom engineered for the particular task which is to be performed. This can be accomplished either by designing and fabricating-the device from scratch, or by purchasing a commercially available device and adapting it to the application. The company installing the robot can either do the engineering work itself or it can contract for the services of a firm that does this kind of work.

Most robot manufacturers have special engineering groups whose function is to design end effectors and to provide consultation services to their customers. Also, there are a growing number of robot systems firms which perform some or all of the engineering work to install robot systems. Their services would typically include end effector design.

1.1 TYPES OF END EFFECTORS

There are wide assortments of end effectors required to perform the variety of different work functions. The various types can be divided into two major categories: 1. Grippers 2. Tools Grippers are end effectors used to grasp and hold object. The objects are generally work parts that are to be moved by the robot. These part-handling applications include machine loading and unloading, picking parts from a conveyor, and arranging parts onto a pallet. In addition to work parts, other objects handled by robot grippers include cartons, bottles, raw materials, and tools. We tend to think of grippers as mechanical grasping devices, but there are alternative ways of holding objects involving the use of magnets, suction cups, or other means.

Grippers can be classified as single grippers or double grippers although this classification applies best to mechanical grippers. The single gripper is distinguished by the fact that only one grasping device is mounted on the robot's wrist. A double gripper has two gripping devices attached to the wrist and is used to handle two separate objects. The two gripping devices can be actuated independently.

The double gripper is especially useful in machine loading and unloading applications. With a double gripper, the robot can pick the part from the incoming conveyor with one of the gripping devices and have it ready to exchange for the finished part. When the machine cycle is completed, the robot can reach in for the finished part with the available grasping device, and insert the raw part into the machine with the other grasping device. The amount of time that the machine is open is minimized.

The term multiple gripper is applied in the case where two or more grasping mechanisms are fastened to the wrist. Double grippers are a subset of multiple grippers. The occasions when more than two grippers would be required are somewhat rare. There is also a cost and reliability penalty which accompanies an increasing number of gripper devices on one robot arm.

By definition, the tool-type end effector is attached to the robots wrist. One of the most common applications of industrial robots is spot welding, in which the welding electrodes constitute the end effector of the robot. Other examples of robot applications in which tools are used as end effectors include spray painting and arc welding.

1.2 TYPES OF GRIPPER MECHANISMS

There are various ways of classifying mechanical grippers and their actuating mechanisms. One method is according to the type of finger movement used by the gripper. In this classification the grippers can actuate the opening and closing of the fingers by one of the following motions:

1. Pivoting movement 2. Linear or translational movement

In the pivoting movement the fingers rotate

about fixed pivot points on the gripper to

open and close. The motion is usually accomplished by some kind of linkage mechanism. In the linear movement the fingers open and close by moving in parallel to each other. This is accomplished by means of guide rails so that each finger base slides along a guide rail during actuation. The translational finger movement might also be accomplished by means of a linkage which would maintain the fingers in a parallel orientation to each other during actuation.

Fig.1.2.1: Some possible linkages for robotic grippers

Mechanical grippers can also be classed according to the type of kinematic device used to actuate the finger movement. In this classification we have the following types:

1. Linkage actuation 2. Gear-and-rack actuation 3. Cam actuation 3

4. Screw actuation 5. Rope-and-pulley actuation 6. Miscellaneous

The linkage category covers a wide range of design possibilities to actuate the opening and closing of the gripper. A few examples are illustrated in Fig.1.2.1

The design of the linkage determines how the input force F to the gripper is converted into the gripping force F applied by the fingers. The linkage configuration also determines other operational features such as how wide the gripper fingers will open and how quickly the gripper will actuate.

Fig. 1.2.2: Gear and Rack method of actuating the gripper

Figure 1.2.2 illustrates one method of actuating the gripper fingers using a gear-and-rack configuration. The rack gear would be attached to a piston or some other mechanism that would provide a linear motion. Movement of the rack would drive two partial pinion gears, and these would in turn open and close the fingers.

The cam actuated gripper includes a variety of possible designs, one of which is shown in Fig.1.2.3. A cam and follower arrangement often using a spring-loaded follower can provide the opening and closing action of the gripper.

Fig.1.2.3: Cam actuated gripper

For example, movement of the cam in one direction would force the gripper to open, while movement of the cam in the opposite direction would cause the spring to force the gripper to close. The advantage of this arrangement is that the spring action would accommodate different sized parts. This might be desirable, for example, in a machining operation where a single gripper is used to handle the raw work part and the finished part. The finished part might be significantly smaller after machining.

An example of the screw-type actuation method is shown in Fig.1.2.4. The screw is turned by a motor, usually accompanied by a speed reduction mechanism. When the screw is rotated in one direction, this causes a threaded block to be translated in one direction. The threaded block is, in turn, connected to the gripper fingers to cause the corresponding opening and closing action.

Fig.1.2.4: Screw type gripper actuation 5

Rope-and-pulley mechanisms can be designed to open and close a mechanical gripper. Because of the nature of these mechanisms, some form of tension device must be used to oppose the motion of the rope or cord in the pulley system. For example, the pulley system might operate in one direction to open the gripper, and the tension device would take up the slack in the rope and close the gripper when the pulley system operates in the opposite direction.

The miscellaneous category is included in our list to allow for gripper actuating mechanisms that do not logically fall into one of the above categories. An example might be an expandable bladder or diaphragm that would be inflated and deflated to actuate the gripper fingers.

2. GRIPPER FORCE ANALYSIS 2.1 INTRODUCTION

As indicated previously, the purpose of the gripper mechanism is to convert input power into the required motion and force to grasp and hold an object. Let us illustrate the analysis that might be used to determine the magnitude of the required input power in order to obtain a given gripping force. We will assume that a friction-type grasping action is being used to hold the part. A detailed study of mechanism analysis is beyond the scope of this text, and the reader might refer to other books such as Beer and Johnson and Shigley and Mitchell.

Fig.2.1.1: Force against part parallel to finger surfaces tending to pull part out of gripper

If a force of sufficient magnitude is applied against the part in a direction parallel to the friction surfaces of the fingers as shown in Fig.2.1.1(a), the part might slip out of the gripper. To resist this slippage, the gripper must be designed to exert a force that depends on the weight of the part, the coefficient of friction between the part surface and the finger surface, the acceleration (or deceleration) of the part, and the orientation between the direction of motion during acceleration and the direction of the fingers.

Referring to Fig.2.1.1(b), the following force equations, Equations (a) and (b), can be used to determine the required magnitude of the gripper force as a function of these factors. Equation (a) covers the simpler case in which weight alone is the force tending to cause the part to slip out of the gripper. 7

- - - - - - - - - - - (a)

Where =coefficient of friction of the finger contact surface against the part surface nf= number of contacting fingers Fg =gripper force w = weight of the part or object being gripped

This equation would apply when the force of gravity is directed parallel to the contacting surfaces. If the force tending to pull the part out of the fingers is greater than the weight of the object, then Eq. (a) would have to be altered. For example, the force of acceleration would be a significant factor in fast part-handling cycles. Engelberger suggests that in a high-speed handling operation the acceleration (or deceleration) of the part could exert a force that is twice the weight of the part. He reduces the problem to the use of a g f actor in a revised version of Eq. (a) as follows:

- - - - - - - - - - - - - (b)

Where g =the g factor. The g f actor is supposed to take account of the combined effect of gravity and acceleration. If the acceleration force is applied in the same direction as the gravity force, then the g value = 3.0. If the acceleration is applied in the opposite direction, then the g value = 1.0 (2 x the weight of the part due to acceleration minus 1 x the weight of the part due to gravity). If the acceleration is applied in a horizontal direction, then use g = 2.0.

2.2 OTHER TYPES OF GRIPPERS

In addition to mechanical grippers there are a variety of other devices that can be designed to lift and hold objects. Included among these other types of grippers are the following: 1. Vacuum cups 8

2. Magnetic grippers 3. Adhesive grippers 4. Hooks, scoops, and other miscellaneous devices

2.2.1 Vacuum Cups

Vacuum cups, also called suction cups, can be used as gripper devices for handling certain types of objects. The usual requirements on the objects to be handled are that they be flat, smooth and clean, conditions necessary to form a satisfactory vacuum between the object and the suction cup.

The suction cups used in this type of robot gripper are typically made of elastic material such as rubber or soft plastic. An exception would be when the object to be handled is composed of a soft material. In this case, the suction cup would be made of a hard substance. The shape of the vacuum cup, as shown in the figure (2.2.1.1), is usually round. Some means of removing the air between the cup and the part surface to create the vacuum is required. The vacuum pump and the venturi are two common devices used for this purpose.

Fig.2.2.1.1: Venturi device used to operate a suction cup.

The vacuum pump is a piston-operated or vane-driven device powered by an electric motor. It is capable of creating a relatively high vacuum. The venturi is a simpler device and can be driven by means of "shop air pressure." Its initial cost is less than that of a vacuum pump and

it is relatively reliable because of its simplicity. However, the overall reliability of the vacuum system is dependent on the source of air pressure.

The lift capacity of the suction cup depends on the effective area of the cup and the negative air pressure between the cup and the object. The relationship can be summarized in the following equation

F = PA ------------------ (c) Where F = the force or lift capacity, lb P = the negative pressure, lb/in2 A = the total effective area of the suction cup(s) used to create the vacuum, in2

The effective area of the cup during operation is approximately equal to the unreformed area determined by the diameter of the suction cup. The squashing action of the cup as it presses against the object would tend to make the effective area slightly larger than the unreformed area. On the other hand, if the center portion of the cup makes contact against the object

during deformation, this would reduce the effective area over which the vacuum is applied. These two conditions tend to cancel each other out. The negative air pressure is the pressure differential between the inside and the outside of the vacuum cup.

2.2.2 Magnetic Gripper

Magnetic grippers can be a very feasible means of handling ferrous materials. The stainless steel plate would not be an appropriate application for a magnetic gripper because 18-8 stainless steel is not attracted by a magnet. Other steels, however, including certain types of stainless steel, would be suitable candidates for this means of handling, especially when the materials are handled in sheet or plate form.

In general, magnetic grippers offer the following advantages in robotic handling applications:

10

Pickup times are very fast. Variations in part size can be tolerated. The gripper does not have to be designed for one particular work part. They have the ability to handle metal parts with holes (not possible with vacuum grippers). They require only one surface for gripping.

Disadvantages with magnetic grippers include the residual magnetism remaining in the work piece which may cause a problem in subsequent hand- ling, and the possible side slippage and other errors which limit the precision of this means of potential disadvantage of a magnetic gripper is the problem of handling. Another up only one

picking

sheet from a stack. The magnetic attraction tends to penetrate beyond the top sheet in the stack, resulting in the possibility that more than a single sheet will be lifted by the magnet. This problem can be confronted in several ways.

Magnetic grippers can be divided into two categories, those using electromagnets and those using permanent magnets. Electromagnetic grippers are easier to control, but source of require a

dc power and an appropriate controller unit. As with any other robotic-gripping

device, the part must be released at the end of the handling cycle. This is easier to accomplish with an electromagnet than with a permanent magnet.

Fig.2.2.2.1: Stripper device operated by air cylinders used with a permanent magnetic gripper.

11

When the part is to be released the controller unit reverses the polarity at a reduced power level before switching off the electromagnet. This procedure acts to cancel the residual magnetism in the work piece and ensures a positive release of the part.

Permanent magnets have the advantage of not requiring an external power source operate the magnet. However, there is a loss of control

to

that accompanies this apparent

advantage. For example, when the part is to be released at the end of the handling cycle, some means of separating the part from the magnet must be provided. The device which accomplishes this is called a stripper or stripping device. Its function is to mechanically detach the part from the magnet. One possible stripper design is illustrated in Fig.2.2.2.1.

Permanent magnets are often considered for handling tasks in hazardous environments requiring explosion proof apparatus. The fact that no electrical circuit is needed to operate the magnet reduces the danger of sparks which might cause ignition in such an environment.

2.2.3 Adhesive Grippers

Gripper designs in which an adhesive substance performs the grasping action can be used to handle fabrics and other lightweight materials. The require-ments on the items to be handled are that they must be gripped on one side only and that other forms of grasping such as a vacuum or magnet are not appropriate.

Cine of the potential limitations of an adhesive gripper is that the adhesive substance loses its tackiness on repeated usage.

Consequently, its reliability as a gripping device is diminished with each successive operation cycle. To overcome this limitation, the adhesive material is loaded in the form of a continuous ribbon into a feeding mechanism that is attached to the robot wrist. The feeding mechanism operates in a manner similar to a typewriter ribbon mechanism.

12

2.3 TOOLS AS END EFFECTORS

In many applications, the robot is required to manipulate a tool rather than a work part. In a limited number of these applications, the end effector is a gripper that is designed to grasp and handle the tool. The reason for using a gripper in these applications is that there may be more than one tool to be used by the robot in the work cycle. The use of a gripper permits the tools to be exchanged during the cycle, and thus facilitates this multi tool handling function.

In most of the robot applications in which a tool is manipulated, the tool is attached directly to the robot wrist. In these cases the tool is the end effector. Some examples of tools used as end effectors in robot applications include: Spot-welding tools Arc-welding torch Spray-painting nozzle Rotating spindles for operations such as: Drilling routing Wire brushing Grinding Liquid cement applicators for assembly Heating torches Water jet cutting tool

2.4 POWER AND SIGNAL TRANSMISSION

End effectors require power to operate. They also require control signals to regulate their operation. The principal methods of transmitting power and control signals to the end effector are: I. Pneumatic II. Electric III. Hydraulic IV. Mechanical

13

2.5 CONSIDERATIONS IN GRIPPER SELECTION AND DESIGN

As indicated above, tools are used for spot welding, arc welding, rotating spindle operations, and other processing applications. Certainly one of the considerations deals with determining the grasping requirement for the gripper. Engelberger defines many of the factors that should be considered in assessing gripping requirements. The following list is based on Engelberger's discussion of these factors:

1. The part surface to be grasped must be reachable. For example, it must not be enclosed within a chuck or other holding fixture. 2. The size variation of the part must be accounted for, and how this might influence the accuracy of locating the part. For example, there might be a problem in placing a rough casting or forging into a chuck for machining operations. ,

3. The gripper design must accommodate the change in size that occurs between pan loading and unloading. For example, the part size is reduced in machining and forging operations. 4. Consideration must be given to the potential problem of scratching and distorting the part during gripping, if the part is fragile or has delicate surfaces. 5. If there is a choice between two different dimensions on a part, the larger dimension should be selected for grasping. Holding the part by its larger surface will provide better control and stability of the part in positioning. 6. Gripper fingers can be designed to conform to the part shape by using resilient pads or selfaligning fingers. The reason for using self-aligning fingers is to ensure that each finger makes contact with the part in more than one place. This provides better part control and physical stability. Use of replaceable fingers will allow for wear and also for interchangeability for different part models

14

2.5.1 Checklist of factors in the selection and design of grippers

Factor Consideration Weight and size Shape Changes in shape during processing Tolerances on the part size Surface condition, protection of delicate surfaces Mechanical grasping Vacuum cup Magnet Other methods (adhesives, scoops, etc.) Pneumatic Electrical Hydraulic Mechanical Weight of the object Method of holding (physical constriction or friction) Coefficient of friction between fingers and object Speed and acceleration during motion cycle Length of fingers Inherent accuracy and repeatability of robot Tolerances on the part size Number of actuations during lifetime of gripper Replaceability of wear components (fingers) Maintenance and serviceability

Part to be handled

Actuation method

Power and signal transmission

Gripper force (mechanical gripper)

Positioning problems Service conditions

Operating environment

Heat and temperature Humidity, moisture, dirt, chemicals Heat shields long fingers Forced cooling (compressed air, water cooling, etc.) Use of heat-resistant materials Strength, rigidity, durability Fatigue Strength Cost and ease of fabrication Friction properties f or finger surfaces Compatibility with- operating environment Use of interchangeable fingers Design standards Mounting connections and interfacing with robot Risk of product design changes and their effect on the gripper design Lead time for design and fabrication Spare parts maintenance and service Tryout of the gripper in production

Temperature protection

Fabrication materials

Other considerations

15

The important factors that determine the required grasping force are: The weight of the object. Consideration of whether the part can be grasped consistently about its center of mass. If not, an analysis of the possible moments from off-center grasping should be considered. The speed and acceleration with which the robot arms moves (acceleration and deceleration forces) and the orientational relationship between the direction of movement and the position of the fingers on the object (whether the movement is parallel or perpendicular to the finger surface contacting the part). Whether physical constriction or friction is used to hold the part. Coefficient of friction between the object and the gripper fingers.

2.6 DESIGN CALCULATION OF WORM GEAR DRIVE

Materials used Worm and Worm Wheel - Mild Steel

Fig. 2.6.1: Worm

Fig. 2.6.2: Worm Wheel

Assumed Values Speed of worm (N1) = 100 rpm Number of teeth on worm wheel (Z2) = 65 Number of starts on worm (Z1) = 4 k*kd = 1 Initial Centre Distance (a) = 68mm Standard Values 16

For Mild Steel Bending Stress (b) = 165 N/mm2 Contact Stress (c) = 190 N/mm2 Youngs Modulus (E) = 2.06*105 N/mm2

Transmission Ratio I = Z2/Z1 = 65/4= 16.25 [ ] = *k*kd =

Initial Design Torque = P*60/2N2

65 11

3

Assume k*kd = 1. +

3

68 =

32.08= [ ]

= 33013.98 N-mm = P*60/2N2 = Axial Module mx =

+ 268

+ 1

[ ]

65 11[170]

540

[ ] 2 [ ] 10

P=32W = 0.032Kw

29.26

60

= 33013.98

11+65

= 1.789 ~ 2mm

a= 0.5 mx ( + ) = 0.5*2*(11 + 65)= 76mm Revised Centre distance Pitch Circle Diameters d1=q* mx = 11*2= 22mm 17

d2= * mx = 65*2= 130mm = tan-1( ) = tan-1( ) = 19.98 Lead angle

11 4

Virtual Number of teeth Zv =

3 19.98

65

= 78.3 ~ 79 teeth.

Pitch Line Velocity V1 = V2 =

= =

. .. 60 60

= 0.115m/s

= 0.063m/s

Sliding Velocity Vs =

From PSGDB for Zv =79, form factor, =0.499 = = 0.122m/s Check for Bending b =

.[ ]

19.98

0.115

Since the value of design bending stress [b] is greater than the value of induced bending stress b, (i.e.) [b] = 165 N/mm2 > b = 21.97N/mm2 The design is safe and satisfactory.

23 11650.499

1.933013.98

= 21.97N/mm2

Check for Wear = =

[ ] [.]

18

= 113.83N/mm2 (i.e.)

Since the value of design contact stress [c] is greater than the value of induced contact stress c,

[c] = 190 N/mm2> c = 113.83N/mm2 The design is safe and satisfactory.

19

3. MATERIALS AND COST ESTIMATION

3.1 DESIGN OF THE PROJECT The Worm and Worm Wheel are made according to the dimensions and calculations made in section 2.6. According to that calculation base plate, Gripper plate and various links are designed based on assumptions. The Model of Worm, Worm Wheel, base plate, Gripper plate and various links made by using SOLIDWORKS 2010 are shown below. 3.1.1 BEFORE ASSEMBLY

Gripper Base Plate

20

Worm

Worm Gear

Gripper

Link1

Link 2 Fig. 3.1.1: Model of our project 21

3.1.2 AFTER ASSEMBLY

Isometric View

Top View Fig. 3.1.2: Assembled Model of our project 22

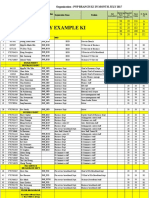

3.2 COST ESTIMATION 3.2.1 S.No MATERIAL COST COMPONENTS NEEDED Base plate Gripper plate Gripper Link Links Worm Gear Worm TYPE OF MATERIAL Mild Steel Mild Steel Mild Steel Mild Steel Mild Steel Mild Steel TOTAL MATERIAL PRICE IN ` (approx.) 400 600 400 800 500 300 `3000

QUANTITY 1 2 2 4 2 1 11

1 2 3 4 5 6

3.2.2

MACHINING COST Machining Cost for all the Components: `3000

3.2.3

MISCELLANEOUS COST Other Miscellaneous Cost: `2000

3.2.4 S.No 1 2 3 4

TOTAL COST STUDENTS NAME Arun.S Charles Gnanakumar.G Karthikeyan.G Madhan.E TOTAL AMOUNT CONTRIBUTION IN ` 2000 2000 2000 2000 `8000

23

3.3 MATERIAL INTRODUCTION 3.3.1 BASE PLATE It is the base of the End Effector. The Base Plate is made of Mild Steel. It gives rigid structure to end effector and it holds all the components of the end effector like worm, worm wheel, various links.

3.3.2 GRIPPER PLATE It is used to hold various types of objects. It is used to pick an object from one place and to place in another place. Generally it is made of lighter materials and the ends of the gripper plate are knurled to provide a grip to hold the object.

3.3.3 GRIPPER LINK It is the major part of the End Effector where it is used to transmit rotary motion of the gear into oscillatory or reciprocating motion of the gripper plate. It is made up of cast iron to form a rigid link between the gear and the gripper plate.

3.3.4 WORM AND WORM GEARS A worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm gear (which is similar in appearance to a spur gear, and is also called a worm wheel). Worm wheels are first gashed to rough out the teeth and then hobbed to the final dimensions The terminology is often confused by imprecise use of the term worm gear to refer to the worm, the worm gear, or the worm drive as a unit. Like other gear arrangements, a worm drive can reduce rotational speed or allow higher torque to be transmitted. Worm and Worm gear is used in this End Effector to transmit power to actuate the links. Worm is meshed with Worm gear to transmit the power to the gripper links. The dimensions and design procedure for worm and worm wheel is already discussed in chapter 2.6.

24

3.4 EVALUATION In this section, important features of the End Effector are discussed in relation to experience in the lab. Figure 3.4.2 shows a photograph of the actuated prototype End Effector. The base link is clamped rigidly to the edge of a table for these tests. The key purpose of this project was to design an end-effector which works well on a simple class of objects. The prototype End Effector is shown in Figure 3.4.5 grasping a cylinder. As you can see, the cylinder can be grasped adequately. The prototype End Effector is shown in Figure 3.4.3 & 3.4.4 grasping a variety of rectangular and square blocks. To improve the workspace in constructing a new version the ratio of link would be changed such that the distal link is proportionally a bit larger. The positive aspects of current lengths are that the mechanism does not typically hit into itself with the tip of the last link. On the other hand the most common mode of failure during grasping is that the distal link doesn't reach the cylinder. A larger distal link increases the primary workspace for small diameter cylinders.

25

Fig.3.4.1: Worm Gear Drive

Fig.3.4.2: Prototype of End Effector

Fig.3.4.3:Gripper Holding Rectangular plate

Fig.3.4.4:Gripper Holding Square Block

Fig.3.4.5:Gripper Holding Cylindrical Rod 26

4. CONCLUSIONS 4.1 WHAT HAS BEEN DONE A Mechanism was designed for grasping a specific class of objects, cylindrical, square and Rectangular blocks. Early in the design process it was decided that compliant characteristics were needed to be able to collide with the environment at high speed. Analysis was performed to determine the relevant kinematics, the workspace, the grasping behavior, and the quality of the grasp. A prototype was constructed to evaluate the design and analysis. This was a first prototype of a new type of gripper which combines passive and active grasping capabilities. The mechanism currently works well as an End Effector which can grab objects rapidly. Natural "grabbiness" and high bandwidth response to forces makes this device a good candidate for a gripper that will come into contact with objects rapidly.

4.2 FUTURE DIRECTIONS An end-effector such as the Worm actuated 4-bar linkage End Effector should be designed to be very strong so it can not only grab but also pick up heavy objects. This project concentrated on a mechanism to improve grasping. The load capacity was analyzed but no attempt was made to increase it. An improvement to the design would be to increase the strength while maintaining the same desirable grasping characteristics. . The possibility to improve the strength is to employ a block and tackle mechanism. This would act similarly to another gear stage, increasing the force while decreasing the speed. Protecting the moving parts of the mechanism would also be a valuable improvement. The advantages of the End Effector design would be maintained and some of the problems resolved. With more gripping surfaces, the device would be able to grasp objects with more 27

complex geometries. . It would also have advantages over current "dexterous" manipulators which are designed to hold objects only with the fingertips as shown in fig 4.2. Another advantage to grabbing an object with two or more fingers is that they would constrain it to a unique configuration, and thus the object would not tend to shift in the grasp.

Fig. 4.2: Dexterous Hand

Fig. 4.3: Robotic arm with 4-bar linkage end effector done by using SOLIDWORKS 28

4.3 CONCLUSION A reasonably brief and inexpensive analysis effort yielded a significant improvement in the performance of the gripping end effector and the mating grip fixture for the end effector and other payloads.

29

REFERENCES

1. F. P. Beer and E. R. Johnson, Jr., Vector Mechanics for Engineers, 3rd edition, McGraw-Hill, New York, 1977. 2. F. Y. Chen. "Gripping Mechanisms for Industrial Robots," Mechanism and Machine Theory 17(5). 299-311 (1982). 3. J. F. Engelberger, Robotics in Practice, AMACOM (American Management Association), NewYork, 1980, chap. 3. 4. M. P.Groover and E.W.Zimmers, Jr.. CAD/CAM : Computuer Aided Design and Manufacturing, Prentice-Hall, Englewood Cliffs, NJ, 1984, chap. 10. 5. G.Lundstrom, B.Glemme, and B. W.Rocks, Industrial Robots-Gripper review, International Fluidics Services Ltd., Bedford, England. 6. J. E. Shigley and L D. Mitchell, Mechanical Engineering Design, McGraw-Hill, New York, 1983. 7. L L. Toepperwein, M.T. Blackman, et al., "ICAM Robotics Application Guide," Technical Report AFWAL-TR-80-4042, vol. II, Materials Laboratory, Air Force Wright Aeronautical Laboratories, Ohio, April 1980. 8. J.M. Vranish, "Quick Change System for Robots," SME paper MS84-418, Conference papers., Robotics Research-The Next Five Years and Beyond, Lehigh University, Bethlehem, Pennsylvania, August 1984. 9. A. J.Wright, "Light Assembly Robots-An End Effector Exchange Mechanism." Mechanical Engineering, July 1983, pp.29-35. 10. Mikell P.Groover, Mitchell Weiss, Roger N. Nagel, Nicholas G. Odrey., INDUSTRIAL ROBOTICS Technology, Programming and Applications, 3rd edition, McGraw-Hill, New York, 1986. 30

You might also like

- Kannada KaliDocument18 pagesKannada Kaliapi-379970091% (11)

- Stonehell Dungeon 1 Down Night Haunted Halls (LL)Document138 pagesStonehell Dungeon 1 Down Night Haunted Halls (LL)some dude100% (9)

- ANSYS Icepak Users GuideDocument1,074 pagesANSYS Icepak Users GuideV CafNo ratings yet

- (Byoung K. Choi, Robert B. Jerard (Auth.) ) Sculptu (B-Ok - Xyz) PDFDocument376 pages(Byoung K. Choi, Robert B. Jerard (Auth.) ) Sculptu (B-Ok - Xyz) PDFgande10No ratings yet

- Smigroup enDocument30 pagesSmigroup enSNNo ratings yet

- Gambit Tutorial GuideDocument485 pagesGambit Tutorial Guidemanjhunathcr8231No ratings yet

- ANSYS ACT API Reference Guide PDFDocument1,964 pagesANSYS ACT API Reference Guide PDFLuis Humberto Martinez PalmethNo ratings yet

- G Code Quick Guide PDFDocument7 pagesG Code Quick Guide PDFTamil Selvan0% (1)

- Exponential Smoothing - The State of The ArtDocument28 pagesExponential Smoothing - The State of The ArtproluvieslacusNo ratings yet

- (Eng) Advanced Training Scia Engineer Integration With Bim Workflows 17Document69 pages(Eng) Advanced Training Scia Engineer Integration With Bim Workflows 17Muscadin MakensonNo ratings yet

- Advent Product CatalogDocument64 pagesAdvent Product CatalogmiculinicNo ratings yet

- Boost 1d3d CouplingDocument42 pagesBoost 1d3d CouplingAdrian FerrerNo ratings yet

- Shanghai - Kaili Yarn Splicer: - Working Manual. - Spares Parts Catalogue.Document27 pagesShanghai - Kaili Yarn Splicer: - Working Manual. - Spares Parts Catalogue.Deepak Kumar0% (1)

- Detailed SyllabusDocument73 pagesDetailed SyllabusRAGHUL MNo ratings yet

- AU5847E AVL Smokemeter415SE PGDocument274 pagesAU5847E AVL Smokemeter415SE PGViktor DilberNo ratings yet

- Gambit PramsDocument561 pagesGambit Pramsapi-3708428100% (2)

- SyllabusDocument81 pagesSyllabusRAJANo ratings yet

- Using Adams/View Command Lang. - MD Adams 2010Document2,578 pagesUsing Adams/View Command Lang. - MD Adams 2010pkokatam100% (1)

- SDNF InterfaceDocument11 pagesSDNF Interfacepopaciprian27No ratings yet

- Qpro 8P ENGLS 121201Document4 pagesQpro 8P ENGLS 121201MdNo ratings yet

- Speed Frame MachineDocument20 pagesSpeed Frame MachineSudheer Singh chauhanNo ratings yet

- Manual Profile Library Editor EnuDocument68 pagesManual Profile Library Editor Enupopaciprian27No ratings yet

- Parametric Solid Modeling ProjectsDocument224 pagesParametric Solid Modeling ProjectsDEEPAK S SEC 2020No ratings yet

- Orthotropy Theory EnuDocument39 pagesOrthotropy Theory Enupopaciprian27No ratings yet

- Configuring MD Adams 2010Document92 pagesConfiguring MD Adams 2010pkokatamNo ratings yet

- Unbrako US Product Guide PDFDocument144 pagesUnbrako US Product Guide PDFVilas m ChinkeNo ratings yet

- Habasit PDFDocument100 pagesHabasit PDFchikoopandaNo ratings yet

- Casting Brochure 1 PDFDocument12 pagesCasting Brochure 1 PDFAkshayNo ratings yet

- Getting Started Using ADAMS/VibrationDocument63 pagesGetting Started Using ADAMS/VibrationvibrosticsNo ratings yet

- ANSYS Mechanical APDL Modeling and Meshing GuideDocument242 pagesANSYS Mechanical APDL Modeling and Meshing GuideFelipe QuevedoNo ratings yet

- Catalog Haydon Kerk 2016 LR-BDocument265 pagesCatalog Haydon Kerk 2016 LR-Bomal06No ratings yet

- Magnetic Bearings - Atsushi Nakajima, Prof. Dr. G. SchweitzerDocument386 pagesMagnetic Bearings - Atsushi Nakajima, Prof. Dr. G. SchweitzerLucas S. CarmoNo ratings yet

- F CA-blowroom Lowres MarzoliDocument28 pagesF CA-blowroom Lowres MarzoliAshiqueNo ratings yet

- ANSYS ACT API Reference Guide PDFDocument2,470 pagesANSYS ACT API Reference Guide PDFJuan David BurgosNo ratings yet

- Formability Simulation DFE (Die Face Engineering) Process GuidanceDocument0 pagesFormability Simulation DFE (Die Face Engineering) Process Guidancejagas123455123No ratings yet

- TC 53 Card Layout DesignDocument1 pageTC 53 Card Layout DesignJ.SathishNo ratings yet

- Delmia Puma Lecture2Document28 pagesDelmia Puma Lecture2manahtewaNo ratings yet

- Step MotorsDocument24 pagesStep MotorsHùng ThanhNo ratings yet

- RELIABILTYDocument237 pagesRELIABILTYtbone412No ratings yet

- GTN Corp BroDocument20 pagesGTN Corp BroShashank ShandilyaNo ratings yet

- Brochure DF TECASINT Compendium enDocument24 pagesBrochure DF TECASINT Compendium enkgrier8966No ratings yet

- Professor Pratyush Sen, Dr. Jian-Bo Yang (Auth.) - Multiple Criteria Decision Support in Engineering Design-Springer-Verlag London (1998)Document275 pagesProfessor Pratyush Sen, Dr. Jian-Bo Yang (Auth.) - Multiple Criteria Decision Support in Engineering Design-Springer-Verlag London (1998)I Wayan Cahya PrabawaNo ratings yet

- ANSYS CFX Reference Guide 18.2Document416 pagesANSYS CFX Reference Guide 18.2Panda HeroNo ratings yet

- Talha Spinning Mills Limited Mulaid, Sreepur, Gazipur.: Carding DrawingDocument1 pageTalha Spinning Mills Limited Mulaid, Sreepur, Gazipur.: Carding DrawingShoreless ShaikatNo ratings yet

- Ansa Meta For CFD PresentationDocument123 pagesAnsa Meta For CFD PresentationRajesh SamalNo ratings yet

- Design Engineering JourneyDocument159 pagesDesign Engineering JourneyKarenNo ratings yet

- Precision Gage Solutions: Thread Check IncDocument51 pagesPrecision Gage Solutions: Thread Check IncAngel Alvarez CarrilloNo ratings yet

- Ansi B107 30 2000 PDFDocument18 pagesAnsi B107 30 2000 PDFpedro100% (1)

- Alum Dosing PumpDocument2 pagesAlum Dosing PumpBassamNo ratings yet

- ANSYS Mechanical APDL Multibody Analysis GuideDocument76 pagesANSYS Mechanical APDL Multibody Analysis Guidesebastian loscriNo ratings yet

- ANSYS, Inc. Known Issues and Limitations 18.2Document30 pagesANSYS, Inc. Known Issues and Limitations 18.2Panda HeroNo ratings yet

- F CA-drawframes Combingsection Lowres MarzoliDocument32 pagesF CA-drawframes Combingsection Lowres MarzoliAshiqueNo ratings yet

- Camco Catalog Web PDFDocument212 pagesCamco Catalog Web PDFCreuza Barbosa100% (1)

- Ansys Polymat Users GuideDocument238 pagesAnsys Polymat Users GuideVicky PolychronidouNo ratings yet

- DF5.8.1 Formability Training ManualDocument107 pagesDF5.8.1 Formability Training ManualkillimakilliNo ratings yet

- 1026 Product CatalogDocument140 pages1026 Product CatalogMahmudNo ratings yet

- Reference Manual PDFDocument796 pagesReference Manual PDFValdemir Pereira100% (1)

- Solidcast ManualDocument67 pagesSolidcast ManualMIGUEL LEYVANo ratings yet

- FENSAP-ICE Beta Features Manual 2021 R2Document72 pagesFENSAP-ICE Beta Features Manual 2021 R2Eric100% (1)

- Using Adams/Solver - MD Adams 2010Document1,810 pagesUsing Adams/Solver - MD Adams 2010pkokatam100% (2)

- 2021 CA Product Guide Price ListDocument388 pages2021 CA Product Guide Price ListDaniel FigueiredoNo ratings yet

- PumpDocument34 pagesPumpkarthikds91No ratings yet

- CSC 443 - Lecture 6 - The Project Procurement ManagementDocument84 pagesCSC 443 - Lecture 6 - The Project Procurement ManagementandoNo ratings yet

- 11 Tirumu 1Document158 pages11 Tirumu 1GeethaRaniNo ratings yet

- 11 Tirumu 1Document158 pages11 Tirumu 1GeethaRaniNo ratings yet

- 11 Tirumu 1Document158 pages11 Tirumu 1GeethaRaniNo ratings yet

- 7aandu Izhakkiya VazharchiDocument90 pages7aandu Izhakkiya Vazharchikarthikds91No ratings yet

- 7aandu Izhakkiya VazharchiDocument90 pages7aandu Izhakkiya Vazharchikarthikds91No ratings yet

- Manase Relax Please by Swami SukhabodhanandaDocument58 pagesManase Relax Please by Swami SukhabodhanandaSampath Mturk100% (1)

- No Mario H.the Mems Applications EngineerDocument8 pagesNo Mario H.the Mems Applications EngineerManoj MuthusamyNo ratings yet

- "Green" Devices: Future Devices On The Frontier of MEMS ResearchDocument1 page"Green" Devices: Future Devices On The Frontier of MEMS Researchkarthikds91No ratings yet

- Taoist Master Zhang 张天师Document9 pagesTaoist Master Zhang 张天师QiLeGeGe 麒樂格格100% (2)

- Tài Liệu Hướng Dẫn Cài Đặt Rơ Le MPS 3000Document55 pagesTài Liệu Hướng Dẫn Cài Đặt Rơ Le MPS 3000nguyenquangtonNo ratings yet

- Positive Psychology in The WorkplaceDocument12 pagesPositive Psychology in The Workplacemlenita264No ratings yet

- Chapter 2.3.3 History of Visual Arts Modernism Post ModernismDocument17 pagesChapter 2.3.3 History of Visual Arts Modernism Post ModernismKim Ashley SarmientoNo ratings yet

- Vocabulary FceDocument17 pagesVocabulary Fceivaan94No ratings yet

- Aribah Ahmed CertificateDocument2 pagesAribah Ahmed CertificateBahadur AliNo ratings yet

- 105 2Document17 pages105 2Diego TobrNo ratings yet

- IQAc 04-05Document10 pagesIQAc 04-05ymcacollegewebsiteNo ratings yet

- Mathematics - Mathematics of Magic - A Study in Probability, Statistics, Strategy and Game Theory XDocument32 pagesMathematics - Mathematics of Magic - A Study in Probability, Statistics, Strategy and Game Theory XHarish HandNo ratings yet

- Data Network Unit 6 - UCDocument15 pagesData Network Unit 6 - UCANISHA DONDENo ratings yet

- Introduction To HDLDocument28 pagesIntroduction To HDLBack UpNo ratings yet

- PNP Ki in July-2017 AdminDocument21 pagesPNP Ki in July-2017 AdminSina NeouNo ratings yet

- Bossypants Autobiography and Womens SelvesDocument26 pagesBossypants Autobiography and Womens SelvesCamila Paz GutiérrezNo ratings yet

- Changed Report 2015 PDFDocument298 pagesChanged Report 2015 PDFAnonymous FKjeRG6AFnNo ratings yet

- Ismb ItpDocument3 pagesIsmb ItpKumar AbhishekNo ratings yet

- Introducing The Thinkcentre M70A. A Desktop You DefineDocument3 pagesIntroducing The Thinkcentre M70A. A Desktop You DefineSiti RohayatiNo ratings yet

- Principles of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions ManualDocument36 pagesPrinciples of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions Manualoutlying.pedantry.85yc100% (28)

- Marketing Micro and Macro EnvironmentDocument8 pagesMarketing Micro and Macro EnvironmentSumit Acharya100% (1)

- Notice: Premerger Notification Waiting Periods Early TerminationsDocument5 pagesNotice: Premerger Notification Waiting Periods Early TerminationsJustia.comNo ratings yet

- Lesson 1: Composition: Parts of An EggDocument22 pagesLesson 1: Composition: Parts of An Eggjohn michael pagalaNo ratings yet

- Newsletter 1-2021 Nordic-Baltic RegionDocument30 pagesNewsletter 1-2021 Nordic-Baltic Regionapi-206643591100% (1)

- SICHEM Brochure 2023Document8 pagesSICHEM Brochure 2023krishnarao badisaNo ratings yet

- 160kW SOFT STARTER - TAP HOLE 1Document20 pages160kW SOFT STARTER - TAP HOLE 1Ankit Uttam0% (1)

- Low Voltage Switchgear Specification: 1. ScopeDocument6 pagesLow Voltage Switchgear Specification: 1. ScopejendrikoNo ratings yet

- 1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Document2 pages1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Mario FloresNo ratings yet

- Spring 2010 - CS604 - 1 - SolutionDocument2 pagesSpring 2010 - CS604 - 1 - SolutionPower GirlsNo ratings yet

- ACCA F2 2012 NotesDocument18 pagesACCA F2 2012 NotesThe ExP GroupNo ratings yet

- What You Need To Know About Your Drive TestDocument12 pagesWhat You Need To Know About Your Drive TestMorley MuseNo ratings yet