Professional Documents

Culture Documents

Surface Roughness

Uploaded by

Rahul BetgeriOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Surface Roughness

Uploaded by

Rahul BetgeriCopyright:

Available Formats

R3

R

V=

1000

DN

T

e

c

h

n

i

c

a

l

I

n

f

o

r

m

a

t

i

o

n

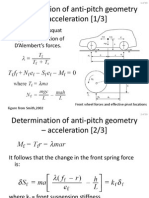

Theoretical (Geometrical) Surface Roughness

How to Obtain Surface Roughness Values

Theoretical Surface Roughness at Turning indicates the minimum

roughness value from the cutting conditions and it is shown by the

formula as follows:

Surface Roughness Symbol Caution

Relationship with Triangle Symbol

Indication in JIS Standard

Arithmetical

Mean Roughness

Ra(m)

0.025

0.05

0.1

0.2

0.4

0.8

1.6

3.2

6.3

12.5

25

Max. Height

Roughness

Rz(m)

0.1

0.2

0.4

0.8

1.6

3.2

6.3

12.5

25

50

100

Ten PointsMean

Roughness

RzJIS(m)

Note:

(Relationship

with Triangle)

3.2

6.3

25

50

100

12.5

0.8

0.4

0.2

1.6

0.1

Note: Finishing symbol (Triangleand wave~) was

abolished from JIS standard from 1994 Revision.

How to Indicate

Example

When Ra is 1.6m1.6mRa

When Rz is 6.3m6.3mRz

When RzJIS is 6.3m6.3mRzJIS

Rz(h)

f

8R(r)

2

10

3

Rz(h)Theoretical Surface Roughnessm

Feed Ratemm/rev

(r)Corner Radius of Insertmm

The above information is based on JIS B 0601-2001.

However, some symbols were revised as shown in the right table in

accordance with ISO Standard from JIS B 0601-2001 version.

Ten Points Mean Roughness (Rz) was eliminated from 2001 version

but it still remains as RzJIS reference, since it was popular in Japan.

Type

Max. Height

Roughness

Ten Points

Mean Roughness

Arithmetical Mean

Roughness

Ry

Rz

Ra

Rz

RzJIS

Ra

Symbol of

JIS B 0601-1994

Symbol of

JIS B 0601-2001

Example of Ra Indication

Note: The indications of Ra and Rz are different.

When indicating upper limit onlyIndicate

surface roughness following the parameter

symbol.

When indicating both lower and upper limit

Indicate surface roughness as (upper limit ~

lower limit) following the parameter symbol.

When indicating the upper limit only

(when upper limit is 6.3mRa)

When indicating both lower and upper limit

(when upper limit is 6.3mRa, lower limit is 1.6mRa)

6.3

1.6

6.3 Rz6.3

Rz6.3~1.6

Example of Ry, (Rz) Indication

Type Symbol

Rz

RzJIS

Ra

How to Obtain Explanation

Ry is obtained from the distance in micron

meter between the highest peak and the

lowest valley in the range of sampled

reference length () to the direction of mean

line of the roughness curve.

Rz is obtained from the total in micron meter

of the mean value of the each distance

between the mean line and 5 peaks (Yp)

from the highest one, and the mean value of

the each distance between the mean line

and the 5 valleys (Yv) from the lowest one,

of the roughness curve in the range of

sampled reference length .

Yp1,Yp2,Yp3,Yp4,Yp5:

Distance from the mean line to highest 5

peaks in the range of sampled reference

length

Yv1,Yv2,Yv3,Yv4,Yv5:

Distance from the mean line to the lowest 5

valleys in the range of sampled reference

length

Ra is obtained from the following formula in

micron meter when the roughness curve is

expressed by y=f(x), taking X-axis to the mean

line direction and Y-axis to the vertical

magnification of the roughness curve in the

range of sampled reference length .

RzRpRv

RzJIS

Yp1Yp2Yp3Yp4Yp5Yv1Yv2Yv3Yv4Yv5

5

Ra

f(x)dx

1

m

R

p

R

y

R

v

m

Y

v

5

Y

v

5

Y

p

1

Y

p

2

Y

p

3

Y

p

4

Y

v

4

Y

v

1

Y

v

3

Y

v

2

X

Y

R

a

m

T

e

n

P

o

i

n

t

s

M

e

a

n

R

o

u

g

h

n

e

s

s

M

a

x

.

H

e

i

g

h

t

R

o

u

g

h

n

e

s

s

A

r

i

t

h

m

e

t

i

c

a

l

M

e

a

n

R

o

u

g

h

n

e

s

s

Surface Roughness (JIS B 0601-2001)

R

r

R

z

(

h

)

f

2839 2840

M

3.2 3.2

6.3

1.6

6.3

1.6

25

6.3 25

25 6.3

25

Milled

FC-24 1

1.PositionsofAuxiliarySymbolsforSurfaceSymbol

A surface roughness value, cut-off value or reference length, machining method, grain direction, surface undulation, etc. are

indicated around the surface symbol as shown in Fig. 1 below.

Fig.1PositionsofAuxiliarySymbols

a : Ra Value

b : Machining Method

c : Cut-Off Value, Evaluation Length

c' : Reference Length, Evaluation Length

d : Grain Direction

f : Parameter other than Ra(tp:Parameter/Cut-Off Level)

g : Surface Undulation(JIS B 0610)

Reference These symbols except a and f are provided when they are needed.

Reference Under ISO 1302, a fnish range should be indicated as e in Fig. 1.

Examples ofGraphicalRepresentation ofSurface Texture

Surface Symbol

Removal of Material by Machining is required

Removal of Material is Prohibited

Upper Limit of Ra

(a) (b) (c)

Grain Direction

Upper and Lower Limits of Ra

(a) (b)

Machining Method

(a) (b)

1.VarietiesofSurfaceRoughnessIndicators

Defnitions and presentations of arithmetic average roughness(Ra), maximum height(Ry), 10 spot average roughness(Rz), average concave to

convex distance(Sm), average distance between local peaks S and load length rate tp are given as parameters indicating the surface roughness

of an industrial product. Surface roughness is the arithmetical average of values at randomly extracted spots on the surface of an object.

[Centerline average roughness(Ra75)is defned in the supplements to JIS B 0031 and JIS B 0601.]

Typicalcalculationsofsurfaceroughness

Reference RelationbetweenArithmeticAverageRoughness(Ra)andConventionalParameters

c a

g d

b

f

c'

d e g e

[TechnicalData]

SurfaceRoughness

JISB0601(1994)

ExcerptsfromJISB0031(1994)

[TechnicalData]

DrawingIndicationsofSurfaceTexture

Excerptsfrom

JISB0031(1994)

Code Meaning Illustration

The trace left by a cutting instrument

is parallel to the projection plane in

the drawing.

Ex. Shaped Surface

The trace left by a cutting instrument

is perpendicular to the projection

plane in the drawing.

Ex. Shaped Surface(Side View)

Circular Cut, Cylindrical Cut

The pattern left by a cutting instrument

diagonally crosses the projection plane

in the drawing.

Ex. Honed Surface

The pattern left by a cutting instrument

crosses in various directions or has no

grain direction.

Ex. Lapped Surface, Superfnished

Surface and Surface Finished

with a Front Mill or End Mill

The pat t er n l ef t by a cut t i ng

instrument is virtually concentric

around the center of the plane in the

drawing.

Ex. Faced Surface

The pattern left by a cutting instrument

is virtually radial around the center of

the plane in the drawing.

ArithmeticAverageRoughnessRa

A portion stretching over a reference length in the direction in which the

average line extends is cut out from the roughness curve. This portion

is presented in a new graph with the X axis extending in the same

direction as the average line and the Y axis representing the magnitude.

Ra is represented by the equation shown at right, in microns(m).

MaximumHeightRy

A portion stretching over a reference length in the direction in which

the average line extends is cut out from the roughness curve. The gap

between the peak line and the trough line is measured in the direction in

which the magnitude axis extends, in microns(m).

Reference A portion without an abnormally high peak or abnormally low trough,

which may be regarded as a faw, is cut out over the reference length.

Ten-spotAverageRoughnessRz

A portion stretching over a reference length in the direction in which

the average line extends is cut out from the roughness curve. The

average of the levels(Yp)of the highest peak to the ffth highest peak as

measured from the average line and the average of the levels(Yp)of the

lowest trough to the ffth lowest trough similarly measured in the said

portion are added together. Rz is this sum, in microns(m).

ArithmeticAverageRoughness

Ra

Maximum Height

Ry

Ten-spot Average

Roughness Rz

Reference Length

ofRy(Rz)

(mm)

Conventional

FinishSymbol

StandardSeries

Cut-offValue

c(mm) GraphicalRepresentation ofSurface Texture StandardSeries

0.012 a

0.025 a

0.05 a

0.1 a

0.2 a

0.08

0.012 ~ 0.2

0.05 s

0.1 s

0.2 s

0.4 s

0.8 s

0.05 z

0.1 z

0.2 z

0.4 z

0.8 z

0.08

0.25

0.25

0.8

0.8

0.4 a

0.8 a

1.6 a

0.4 ~ 1.6

1.6 s

3.2 s

6.3 s

1.6 z

3.2 z

6.3 z

3.2 a

6.3 a

2.5 3.2 ~ 6.3

12.5 s

25 s

12.5 z

25 z 2.5

12.5 a

25 a 8

12.5 ~ 25

50 s

100 s

50 z

100 z

8

50 a

100 a

50 ~ 100

200 s

400 s

200 z

400 z

~

*Interrelations among the three types shown here are not precise, and are presented for convenience only.

*Ra:The evaluation values of Ry and Rz are the cut-off value and the reference length each multiplied by fve, respectively.

Yp1, Yp2, Yp3, Yp4, Yp5 : Levels of the highest peak to the ffth highest peak in the

said portion with the reference length .

Yv1, Yv2, Yv3, Yv4, Yv5 : Levels of the lowest trough to the ffth lowest trough in the

said portion with the reference length .

X 0

R

a

Y

m

R

p

Ry=Rp+Rv

m

R

v

R

y

m

5

Y

p Y

p

4

V

5

Y

3

Y

p Y

p

2

Y

V

4

Y

V

3

Y

V

2

1

V

1

Y

Y

p

Rz=

Yp1 + Yp2 + Yp3 + Yp4 +Yp5 + Yv1 + Yv2 + Yv3 + Yv4 + Yv5

5

Ra =

1

f ( ) dx

0

Trace Left by a Cutting Instrument

Trace Left by a Cutting Instrument

Trace Left by a Cutting Instrument

FC-24-1_E.indd 2839-2840 08.4.7 11:42:03 AM

Technical Data

Surface Roughness by Different Processing Methods

Technical Data

Indications of Geometrical Tolerance on Drawings

Excerpt from

JISB00211984

S! a n d a r d va l u e s

o ! s! a n d a r d l e n g! h

(m m)

0 .1

S S

0 .Z

S

0 .4

S

0 .8

S

1 .6

S

3 .Z

S

6 .3

S

1 Z .6

S

Z 6

S

6 0

S

1 0 0

S

Z 0 0

S

4 0 0

0 .Z 6 0 .8 Z .6 8 Z 6

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_ _

_ _

_

1r ia n gu l a r in d ica ! io n

la x im u m pe a k H y

H m a x .

/ r i! hm e ! ica l m e a n

r o u ghn e ss H a

0 .0 Z 6 0 .0 6 0 .1 0 .Z 0 .4 0 .8 1 .6 3 .Z 6 .3 1 Z .6 Z 6 6 0 1 0 0

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_ _

_

_

_

_

_

_

_

_

_

_ _

_

_

_

_

_

Kin d s a n d Sym b o l s o ! G e o m e ! r ica l 1o l e r a n ce s

For m e r

d e sign a ! ion s

o!

su r !a ce

r o u ghn e ss

W or k in g

m e ! hod

_

_

_

Ex a m pl e s o ! d ia gr a m m a ! ica l in d ica ! io n a n d i! s in ! e r pr e ! a ! io n Kin d o ! ! o l e r a n ce

S! r a igh! n e ss

! o l e r a n ce

Sym b o l

Fl a ! n e ss

! o l e r a n ce

C ir cu l a r i! y

! o l e r a n ce

C yl in d r ici! y

! o l e r a n ce

Pr o !il e ! ol e r a n ce

o ! l in e

L e !in i! io n o ! ! ol e r a n ce zo n e

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Pr o !il e ! ol e r a n ce

o ! su r !a ce

Pa r a l l e l ism

! o l e r a n ce

Pe r pe n d icu l a r i! y

! ol e r a n ce

/ n gu l a r i! y

! o l e r a n ce

_

Po si! io n a l

! o l e r a n ce

C o a x ia l i! y

! o l e r a n ce

o r

co n ce n ! r ici! y

! o l e r a n ce

Sym m e ! r y

! o l e r a n ce

C ir cu l a r r u n -o u !

! o l e r a n ce

_

_

_

_ _

_

_

_

_ _

_

_ _

_

_

_

_

1o ! a l r u n -o u !

! o l e r a n ce

_ _ _

_ _ _

_ _

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

Fo r m

! o l e r a n ce

r ie n ! a ! io n

! o l e r a n ce

Lo ca ! io n

! o l e r a n ce

H u n -o u !

! o l e r a n ce

_ _ _

_ _______ _

_ _ ______ _

_ _ _______

_

_

_

1 1 3 0 1 1 Z 9

You might also like

- 1984 Surf Roughness PGDocument8 pages1984 Surf Roughness PGSajjan SNo ratings yet

- 1984 Surf Roughness PGDocument8 pages1984 Surf Roughness PGMaey AkimNo ratings yet

- Parameters Mahr Roughness PDFDocument19 pagesParameters Mahr Roughness PDFCarlos RamirezNo ratings yet

- Position Measurement On Machine ToolsDocument13 pagesPosition Measurement On Machine ToolsAriel GermainNo ratings yet

- Boring and Jig Boring MachineDocument17 pagesBoring and Jig Boring MachineRohit SahaiNo ratings yet

- Surface RoughnessDocument28 pagesSurface RoughnessNeelesh PatkiNo ratings yet

- Design Specification For Gauges Revision 005Document27 pagesDesign Specification For Gauges Revision 005rubenNo ratings yet

- Wilson Tool Wheel Tool WebinarDocument51 pagesWilson Tool Wheel Tool WebinarAndres Byke SepulvedaNo ratings yet

- Freud Test Table PDFDocument3 pagesFreud Test Table PDFalinupNo ratings yet

- Advance Product Quality Planning Status ReportDocument30 pagesAdvance Product Quality Planning Status ReporttapanNo ratings yet

- Manufacturing TolerancesDocument13 pagesManufacturing TolerancesHarsh100% (1)

- 04 GD&T IntroTutorialDocument73 pages04 GD&T IntroTutorialrust_02No ratings yet

- Optimization of CNC End Milling Process Parameters For Aluminium 6061 Alloy Using Carbide Tool Material by Design of ExperimentsDocument7 pagesOptimization of CNC End Milling Process Parameters For Aluminium 6061 Alloy Using Carbide Tool Material by Design of ExperimentsIJIRSTNo ratings yet

- Leadscrew DesignDocument4 pagesLeadscrew Designmimi_chan_17No ratings yet

- Geometrical Tolerances: Geometrical Tolerances On Drawing Precision Measurement of Geometrical TolerancesDocument30 pagesGeometrical Tolerances: Geometrical Tolerances On Drawing Precision Measurement of Geometrical Tolerancessohkimfai6340100% (3)

- User's Manual For SPC XLDocument104 pagesUser's Manual For SPC XLGlenn PeirisNo ratings yet

- The Accuracy of Angle EncodersDocument9 pagesThe Accuracy of Angle EncodersatulNo ratings yet

- Tool Design TerminologyDocument5 pagesTool Design Terminologyanmol6237No ratings yet

- Process Capability Analysis: Part Number Discription Operation Machine DepartmentDocument3 pagesProcess Capability Analysis: Part Number Discription Operation Machine DepartmentYATHISH BABUNo ratings yet

- Tolerance Stack-up Analysis in Manufacturing Capstone ProjectsDocument10 pagesTolerance Stack-up Analysis in Manufacturing Capstone ProjectsAmirtharaaj VijayanNo ratings yet

- CPK & PPK Calculator V4.1aDocument9 pagesCPK & PPK Calculator V4.1aE-Games E-GamesNo ratings yet

- Fits TolerancesDocument26 pagesFits TolerancesHardeep Singh BaliNo ratings yet

- Passivation Info For Laser Marked PartsDocument8 pagesPassivation Info For Laser Marked Partssaddleman100% (1)

- Tolerancias Pza FundicionDocument3 pagesTolerancias Pza FundicionGuero TeoNo ratings yet

- Determination of True PositionDocument26 pagesDetermination of True Position김병곤No ratings yet

- 1120-Quick Ref PDFDocument2 pages1120-Quick Ref PDFRoman JambrekNo ratings yet

- Casting ToleranceDocument1 pageCasting ToleranceTrushant NakumNo ratings yet

- Control Chart Analysis for Seaming OperationDocument6 pagesControl Chart Analysis for Seaming Operationsudar1477No ratings yet

- 08 - Eng Castingdesign ShrinkagesDocument2 pages08 - Eng Castingdesign ShrinkagesAlex Kiko VillalobosNo ratings yet

- DOE Design & Analysis Using MinitabDocument48 pagesDOE Design & Analysis Using MinitabLibyaFlowerNo ratings yet

- Coating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetDocument6 pagesCoating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetROHITNo ratings yet

- Solidworks CostingDocument4 pagesSolidworks CostingratnakarNo ratings yet

- Basic Components & Elements of Surface TopographyDocument30 pagesBasic Components & Elements of Surface TopographyXin YuNo ratings yet

- Din 76-1Document5 pagesDin 76-1mesa142No ratings yet

- Metrology & Mech. Measurement Ch. 02 System of Limits, Fits, Tolerance and GaugingDocument20 pagesMetrology & Mech. Measurement Ch. 02 System of Limits, Fits, Tolerance and GaugingAjij MujawarNo ratings yet

- Aql Plan Zero DefectDocument2 pagesAql Plan Zero DefectFarrukh JamilNo ratings yet

- Design and Drafting Standards Manual - APS AESDocument64 pagesDesign and Drafting Standards Manual - APS AEShombre.muerto5959No ratings yet

- Fastening &joiningDocument45 pagesFastening &joiningboschir100% (1)

- Surface FinishDocument27 pagesSurface Finishykc38No ratings yet

- SURFACE ROUGHNESS TERMINOLOGY AND PARAMETER DEFINITIONSDocument2 pagesSURFACE ROUGHNESS TERMINOLOGY AND PARAMETER DEFINITIONSfaizan997No ratings yet

- DIN 6930-2 Stamped Steel Parts Part 2 General TolerancesDocument17 pagesDIN 6930-2 Stamped Steel Parts Part 2 General TolerancespopoNo ratings yet

- Sensor Controller Catalog PDFDocument418 pagesSensor Controller Catalog PDFRicardo GonzalezNo ratings yet

- Advance Product Quality Planning-Matrix: LegendDocument1 pageAdvance Product Quality Planning-Matrix: Legendsumit_saraf_5No ratings yet

- Stabilized Camera Platform PatentDocument18 pagesStabilized Camera Platform PatentWilson Walas LlanqmNo ratings yet

- GD&T Symbols, Definitions ASME Y14Document8 pagesGD&T Symbols, Definitions ASME Y14deepak0% (1)

- ISO 5459 IS 10721: - Specified Datums - Datum Systems - Datum TargetsDocument27 pagesISO 5459 IS 10721: - Specified Datums - Datum Systems - Datum TargetsVinoth BalasubramaniyanNo ratings yet

- GDT TutorialDocument76 pagesGDT TutorialSrk ChowdaryNo ratings yet

- Surface Roughness (JIS B 0601-2001)Document3 pagesSurface Roughness (JIS B 0601-2001)Prashantha Raju100% (3)

- Jis B 0601 1994Document1 pageJis B 0601 1994amsubra8874No ratings yet

- 09 Mo1517Document2 pages09 Mo1517TombongNo ratings yet

- Surface FinishDocument38 pagesSurface FinishSunilNo ratings yet

- 1984 Surf Roughness PGDocument8 pages1984 Surf Roughness PGHussn YazdanNo ratings yet

- Surface Roughness - Geometrical Dimensioning & Tolerancing (GD&T)Document24 pagesSurface Roughness - Geometrical Dimensioning & Tolerancing (GD&T)Kishor kumar Bhatia100% (27)

- Explanation of Surface RoughnessDocument8 pagesExplanation of Surface RoughnessN.Palaniappan100% (6)

- 22 - Kyocera Technical Information 2010-2011 (ENG)Document42 pages22 - Kyocera Technical Information 2010-2011 (ENG)HEMANTKHERANo ratings yet

- Metropro Surface Texture ParametersDocument20 pagesMetropro Surface Texture ParametersAnandan NatarajanNo ratings yet

- ZYGO - Surface Texture ParametersDocument20 pagesZYGO - Surface Texture ParametersramadanNo ratings yet

- Motif Parameters of ISO 12085: '96Document2 pagesMotif Parameters of ISO 12085: '96ubllc100% (1)

- MITSUBISHI MATERIALS CORPORATION Surface RoughnessDocument2 pagesMITSUBISHI MATERIALS CORPORATION Surface Roughnessjames.anitNo ratings yet

- A Critical Study of The Work Vaimanika ShastraDocument8 pagesA Critical Study of The Work Vaimanika ShastraMauroBonolloNo ratings yet

- TI Polymer Periodic TableDocument1 pageTI Polymer Periodic TableRahul BetgeriNo ratings yet

- 16 Suspension 3Document37 pages16 Suspension 3Sunilkumar ReddyNo ratings yet

- Fasteners StandardsDocument98 pagesFasteners StandardsRahul Betgeri100% (4)

- Intro To PneumaticsDocument30 pagesIntro To PneumaticskabirbNo ratings yet

- DESIGN OF SPRINGSDocument112 pagesDESIGN OF SPRINGSchshbt80% (5)

- Start End Time Lapse Glucose Mol Glucose Mol: /L /minDocument45 pagesStart End Time Lapse Glucose Mol Glucose Mol: /L /minRahul BetgeriNo ratings yet

- 15-Suspension Systems and Components v2Document42 pages15-Suspension Systems and Components v2Ismail AmlaNo ratings yet

- Fasteners StandardsDocument98 pagesFasteners StandardsRahul Betgeri100% (4)

- Engineering Design I Lecture Part 5Document14 pagesEngineering Design I Lecture Part 5Miguel Cruz IIINo ratings yet

- Screw Size and ToleranceDocument92 pagesScrew Size and Tolerancenick10686100% (1)

- Mead Pneumatic HandbookDocument40 pagesMead Pneumatic Handbookjoydeep100% (5)

- Design GuidelinesDocument15 pagesDesign GuidelinesdolonbgdNo ratings yet

- Material StandardsDocument5 pagesMaterial StandardsamitkumarkarmakarNo ratings yet

- Samenvatting Sterkteleer BASFDocument86 pagesSamenvatting Sterkteleer BASFdroessaert_stijnNo ratings yet

- EbooksDocument12 pagesEbooksRahul BetgeriNo ratings yet

- 2013 Calendar Portrait 1 Page LetterDocument1 page2013 Calendar Portrait 1 Page LetterRahul BetgeriNo ratings yet

- 2013 Calendar Portrait 1 Page LetterDocument1 page2013 Calendar Portrait 1 Page LetterRahul BetgeriNo ratings yet

- Workout SheetDocument8 pagesWorkout SheetRahul BetgeriNo ratings yet

- FOD Prevention GuidelineDocument16 pagesFOD Prevention GuidelinejamilvoraNo ratings yet

- Aeroprobe ScannerDocument7 pagesAeroprobe ScannerRahul BetgeriNo ratings yet

- 2013 Weekly Calendar With Holidays MondayDocument4 pages2013 Weekly Calendar With Holidays MondayRahul BetgeriNo ratings yet

- Fod - NasaDocument23 pagesFod - NasaRahul BetgeriNo ratings yet

- Equivalent MaterialDocument5 pagesEquivalent MaterialRahul Betgeri50% (2)

- Surface RoughnessDocument3 pagesSurface RoughnessRahul BetgeriNo ratings yet

- Fasteners StandardsDocument98 pagesFasteners StandardsRahul Betgeri100% (4)

- FL LinearThrustersDocument49 pagesFL LinearThrustersRahul BetgeriNo ratings yet

- THK Rail CatalogueDocument2 pagesTHK Rail CatalogueRahul BetgeriNo ratings yet

- Pneumatic SymbolsDocument1 pagePneumatic SymbolsRahul BetgeriNo ratings yet

- Failure TheoriesDocument21 pagesFailure TheoriesMadhan Krishnamurthy100% (1)

- E5971 m4n68t-m Series ManualDocument0 pagesE5971 m4n68t-m Series ManualcamiloelosadaNo ratings yet

- Dr. Kumar's Probability and Statistics LectureDocument104 pagesDr. Kumar's Probability and Statistics LectureAnish KumarNo ratings yet

- Rec2009 025 PDFDocument172 pagesRec2009 025 PDFEkaStaVTVNo ratings yet

- Data Sheet 2.07 Issue A: Water Flow Detector Model: WFDENDocument2 pagesData Sheet 2.07 Issue A: Water Flow Detector Model: WFDENOvidiu GavrilasNo ratings yet

- Kodak Film StructureDocument40 pagesKodak Film StructureThu Thu SheinNo ratings yet

- PHYSICS - Quiz Bee ReviewerDocument2 pagesPHYSICS - Quiz Bee ReviewerMikhaela Nazario100% (3)

- MA 102 Tutorial Sheet No. 2 on Limits and ContinuityDocument1 pageMA 102 Tutorial Sheet No. 2 on Limits and ContinuityKanan KumarNo ratings yet

- Price List Grand I10 Nios DT 01.05.2022Document1 pagePrice List Grand I10 Nios DT 01.05.2022VijayNo ratings yet

- Axminster CarpetDocument19 pagesAxminster Carpetrohit sinhaNo ratings yet

- CH 2 Atoms, Ions, and MoleculesDocument64 pagesCH 2 Atoms, Ions, and MoleculesBritney SimmsNo ratings yet

- A Project Report On: "Recreation Club"Document80 pagesA Project Report On: "Recreation Club"Appz100% (2)

- Introduction To The Philosophy of Science First PartDocument138 pagesIntroduction To The Philosophy of Science First PartChandra Sekhar Sahu100% (1)

- GPS Navigator: ModelDocument99 pagesGPS Navigator: ModelMain UddinNo ratings yet

- WozairDocument4 pagesWozairRajakumar Bajji SubburamanNo ratings yet

- Week 2 - Risk AssessmentDocument35 pagesWeek 2 - Risk AssessmentTahir BashirNo ratings yet

- RUDDER PLATING DIAGRAMDocument1 pageRUDDER PLATING DIAGRAMMuhammad Ilham AlfiansyahNo ratings yet

- Fakeaway - Healthy Home-Cooked Takeaway MealsDocument194 pagesFakeaway - Healthy Home-Cooked Takeaway MealsBiên Nguyễn HữuNo ratings yet

- FM200 Clean Agent System Installation GuideDocument6 pagesFM200 Clean Agent System Installation Guidehazro lizwan halimNo ratings yet

- PLOTINUS: On Beauty (Essay On The Beautiful)Document12 pagesPLOTINUS: On Beauty (Essay On The Beautiful)Frederic LecutNo ratings yet

- GMSARN Conf: Design Criteria on Substation ProtectionDocument6 pagesGMSARN Conf: Design Criteria on Substation Protectionbdaminda6701No ratings yet

- Operation Manual: Impedance Audiometer AT235hDocument102 pagesOperation Manual: Impedance Audiometer AT235hmendezoswaldoNo ratings yet

- Yara Crop Nutrition For HorticultureDocument8 pagesYara Crop Nutrition For HorticultureadjieNo ratings yet

- Mtech Geotechnical Engineering 2016Document48 pagesMtech Geotechnical Engineering 2016Venkatesh ThumatiNo ratings yet

- Steam TurbineDocument25 pagesSteam TurbineIshan JunejaNo ratings yet

- Case Presentation On Actue Gangrenous Calculos CholecystitisDocument16 pagesCase Presentation On Actue Gangrenous Calculos CholecystitisNayak DrNareshNo ratings yet

- Self EducationDocument21 pagesSelf EducationSwami VedatitanandaNo ratings yet

- Comp7 - Answer Key - Dec. Exam - 1st SetDocument2 pagesComp7 - Answer Key - Dec. Exam - 1st SetHazel Joy LusellaNo ratings yet

- 06 Scaffold Erection and Dismantling (JHA-JSA)Document4 pages06 Scaffold Erection and Dismantling (JHA-JSA)AmanNo ratings yet

- Eko 75 Spare Part ListDocument23 pagesEko 75 Spare Part ListРустам Хайретдинов100% (1)