Professional Documents

Culture Documents

Project Costing and Economics

Uploaded by

jekos27Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Costing and Economics

Uploaded by

jekos27Copyright:

Available Formats

2/4/2009

Project Costing & Economics

AND... LIFE

Dave Mody

Engineering Design

2/4/2009

Example

Citric Acid Extraction Plant

Citric Acid Extraction Plant

http://www.lemonadegame.com/

2/4/2009

Just A Lemonade Stand

WHO WHEN WHY

2/4/2009

The Time Accuracy of Estimates

% Time vs Estimate Accuracy & % Completion

100 90 80 70 60 50 40 30 20 10 0 0

Capacity Factored

Work Completed Semi Detailed

100 90 80 60 50 40

% Work Completed

32

Estimate Accuracy

70

Equipment Factored

Detailed

Construction Begins

30 20 10 0

20

40

60

80

100

Time (% of total schedule)

Capacity Factor

1000 lb/hr $10 Million

5000 lb/hr $ ? Million = $10 Million 1000 lb/hr

5000 lb/hr ? Million

0.7

2/4/2009

Capacity Factor

The exponent (0.7)

Product Ethylene Acetaldehyde Ammonia Phosphoric Acid Formaldehyde Process Route Refinery Gases Ethylene Steam Reforming Calcium Phosphate/H2SO4 Methanol Exponent 0.85 0.70 0.70 0.60 0.55

Perrrys

TIME!

HEY ! What Changed?

2/4/2009

Capacity Factor - Cost Indices

Chemical Engineering Magazine

33

Lang Factor Estimate

Plant Cost = Lang Factor x Equipment Costs

Plant Type Fluid Processing Plant Solid-Fluid Processing Plant Solid Processing Plant

Lang Factor 4.74, usually rounded to 5.0 3.63 3.10

2/4/2009

Big Box Shopping For Chemical Plants

Equipment Cost

Garage Cost

# Cars

2/4/2009

Equipment Factored Estimates

EQUIPMENT FACTOR

PURCHASE COST

INSTALLED COST

36-37

Equipment Factored Estimates

DIRECT FIELD COSTS (50%)

Equipment (20%) Field Labour & Material to install equip. (30%)

INDIRECT FIELD COSTS (32 %) CONTINGENCY AND FEES (15% + 3%)

35

2/4/2009

Equipment Factored Estimates

Tanks and Vessels Columns and Trays Pumps and Compressors Exchangers Heaters

x Direct Field = Cost Factor

36-37

Equipment Factors

Shop Fab. Vessels Compressors Exchangers Fired Heaters Pumps Material Handling Equipment 2.0 - 2.5 1.5 - 2.5 1.7 - 2.5 1.7 - 2.5 2.5 - 3.5 1.5 - 3.0

37

2/4/2009

Factored Estimate Engineering Requirements

Heat & Material Balance (simulation) Preliminary Equipment Sizing Materials Selection Equipment List 1st Draft P&IDs - recommended Process Hazards Analysis - recommended Preliminary Layout - recommended

Detailed Estimates

10

2/4/2009

Detailed Estimate

% Time vs Estimate Accuracy & % Completion

100 90 80 70 60 50 40 30 20 10 0 0

Capacity Factored

Work Completed Semi Detailed

100 90 80 60 50 40

% Work Completed

32

Estimate Accuracy

70

Equipment Factored

Detailed

Construction Begins

30 20 10 0

20

40

60

80

100

Time (% of total schedule)

Whats Economics?

11

2/4/2009

Angkor Wat Built by a series of kings at huge cost Bankrupt the Khmers

Lucky For Us, No Project Economic Evaluation Was Used

12

2/4/2009

BEFORE YOU BUY!

DECISION MAKING $$

Economics & Project Decision Making

Compound Interest Discounted

$ $

Today The Future

13

2/4/2009

Economics & Project Decision Making

Discounted

PV = FV / (1+i)n

$

Today

$

The Future

PV = FV / (1+i)n

?

Today

$

2 YEARS

$

3YEARS

$

4 YEARS

14

2/4/2009

PV = FV / (1+i)n Time Matters!

Net Present Value

$ $

Today 2 YEARS

$

3YEARS

$

4 YEARS

$ $

Our Initial Cost

$

Revenue

15

2/4/2009

PV = FV / (1+i)n

$ $

Our Initial Cost

$

Revenue

$ $ $

Net Present Value

16

2/4/2009

PV = FV / (1+i)n Discount Rate Matters !

$ $

Our Initial Cost

$

Revenue

PV = FV / (1+i)n

$ $ $

=

Our Initial Cost Net Present Value

With Larger Discount Interest Rate

17

2/4/2009

Discount Rate

Large Discount Rate Values = LOWER NPVS

Typical MARR or Hurdle Rates in Industry

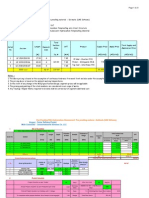

Industry Industrial Chemicals Petroleum Pulp and Paper Pharmaceuticals Metals Paints Fermentation Products

Low-Risk Projects 11 16 18 24 8 21 10

Average Projects 25 25 28 40 15 30 30

High Risk Projects 44 39 40 56 24 44 49

Adapted from Aries and Newton (1995)

PV = FV / (1+i)n

$ $

=

Internal Rate of Return (IRR)

i when NPV = 0

18

2/4/2009

Net Present Value A $ amount exceeding the hurdle interest rate Internal Rate of Return Equivalent Interest Rate of Your Initial Cost

Investment Comparison

You have $200, how do you make the most money in 6 years? A. Put in Bank B. Lemonade C. Soap Box Car

B. Lemonade Stand (i=10%) A. Put Money in Bank (i=10%)

400 300 Dollars ($) 200 100 0 -100 -200 Years 0 Dollars ($) 250 200 150 100 50 0 -50 -100 0 1

354.3122

100 50

2

100 50

3 4

120

130

0 1

0 2

0 3

0 4

0 5

-150 -200

-200

Years

-200

C. Build Soap Box Car (i=10%)

250 200 150 100 50 0 -50 -100 -150 -200

220 120 70 -50

0

250

Dollars ($)

-50

1 2 -100 3 4 5 6

Years

Slide by Dean Latham

19

2/4/2009

Investment Comparison: Net Present Value (NPV)

Risk Analysis

Understand the risk and effects to the project

30

20

2/4/2009

Risk Analysis

Test one value (Tornado Plots)

Develop 3 scenarios

30

Risk Analysis

Monte Carlo

Probability

-50%

-10%

+10%

+50%

30

21

2/4/2009

So This is Engineering Economics Conversion of British Columbia Mountain Pine Beetle Wood to Natural Gas via Syngas Utilize a Turbine to reduce pressure and produce electricity The design of a Water For Injection Utility for a bio/pharma plant

22

You might also like

- F5 Mapit Workbook Questions PDFDocument88 pagesF5 Mapit Workbook Questions PDFBeryl Maliakkal0% (1)

- EconomicsDocument177 pagesEconomicsOscar CamposNo ratings yet

- Aggregate Production Planning - Lecture NotesDocument16 pagesAggregate Production Planning - Lecture NotesJim Mathilakathu100% (1)

- Production and Operational Management: Facility LocationDocument34 pagesProduction and Operational Management: Facility LocationShahnawaz ShaikhNo ratings yet

- 5 - Project Management (S)Document7 pages5 - Project Management (S)Zakiah Abu Kasim100% (2)

- Instructions: Please Complete All 3 Multi-Part Problems For This Week's AssignmentDocument4 pagesInstructions: Please Complete All 3 Multi-Part Problems For This Week's AssignmentMike FasanoNo ratings yet

- Aggregate Production PlanningDocument16 pagesAggregate Production PlanningJitesh.aggarwalNo ratings yet

- Activity-Based Costing and ManagementDocument22 pagesActivity-Based Costing and ManagementDaniel John Cañares LegaspiNo ratings yet

- APADMS 3353 Project Management FinalDocument9 pagesAPADMS 3353 Project Management FinalAt KlaNo ratings yet

- Process Costing OverviewDocument29 pagesProcess Costing OverviewJulrick Cubio EgbusNo ratings yet

- Shipyard Organization 2020-2021 Mid Term ExamDocument2 pagesShipyard Organization 2020-2021 Mid Term ExamvlknbrkkrmnNo ratings yet

- Breakeven and EOQ Exercises (With Answers)Document6 pagesBreakeven and EOQ Exercises (With Answers)Charlene ChorNo ratings yet

- Production Operations Management ExamDocument17 pagesProduction Operations Management ExamBi11y 1eeNo ratings yet

- OM AssignmentDocument15 pagesOM AssignmentShameel AndhoorathodiNo ratings yet

- Semere Tesfaye MBAO-8977-14BDocument8 pagesSemere Tesfaye MBAO-8977-14Bamirhaile71No ratings yet

- MGMT Sample ExamDocument9 pagesMGMT Sample ExamKenny RodriguezNo ratings yet

- Fire Proofing Estimate for Sohar Refinery ProjectDocument21 pagesFire Proofing Estimate for Sohar Refinery ProjectDkPrince100% (5)

- Mechanical PE AM - 001Document20 pagesMechanical PE AM - 001Guru Raja Ragavendran Nagarajan100% (1)

- Tata Toyo Case StudyDocument117 pagesTata Toyo Case StudyGokulraju Rangasamy0% (1)

- AAC Project DetailsDocument7 pagesAAC Project DetailsN Gangadhar Reddy100% (1)

- Estimating The Cost of New ConstructionDocument39 pagesEstimating The Cost of New ConstructionLukman Tarigan Sumatra100% (1)

- Tarek Update ProjDocument18 pagesTarek Update ProjTarek AssafNo ratings yet

- E03 - Capital Cost EstimationDocument39 pagesE03 - Capital Cost EstimationYurie Nurmitasari100% (1)

- Tutorial 09: Questions With Possible SolutionsDocument4 pagesTutorial 09: Questions With Possible SolutionsChand DivneshNo ratings yet

- Final Chydro Gemini Presentation With AnimationsDocument29 pagesFinal Chydro Gemini Presentation With Animationsapi-59751528No ratings yet

- Victoria Chemicals Merseyside Project Boosts EPSDocument24 pagesVictoria Chemicals Merseyside Project Boosts EPSAde AdeNo ratings yet

- Fly Ash BricksDocument8 pagesFly Ash BricksSabhaya ChiragNo ratings yet

- Test 1 F5 QDocument2 pagesTest 1 F5 QMd Enamul BasharNo ratings yet

- Introduction of Project: CementDocument11 pagesIntroduction of Project: CementAli RazaNo ratings yet

- Assignment 2018Document5 pagesAssignment 2018gayneNo ratings yet

- Assignment - 1 - Project Planning and Programming - Chong Wei JunDocument31 pagesAssignment - 1 - Project Planning and Programming - Chong Wei JunWEI JUN CHONGNo ratings yet

- 1.3 ActivityDocument9 pages1.3 ActivityRonald MalicdemNo ratings yet

- LixingcunDocument7 pagesLixingcunmuhammad iman bin kamarudinNo ratings yet

- FII - Assignment 3 y 4Document8 pagesFII - Assignment 3 y 4AdamNo ratings yet

- A Project On:: Launching of A Product: Starline Washing MachineDocument27 pagesA Project On:: Launching of A Product: Starline Washing Machinepankaj dagaNo ratings yet

- Voltage StabilizerDocument11 pagesVoltage StabilizerShreekant KashyapNo ratings yet

- Kemal Inawel - Marini - Pisqa ArisantiDocument15 pagesKemal Inawel - Marini - Pisqa ArisantiBudi Daryanto0% (1)

- Implementation of Dry Wall Module FinalDocument19 pagesImplementation of Dry Wall Module FinalsonuchakdeNo ratings yet

- End Term T&om Spring 2020-Ali RazaDocument6 pagesEnd Term T&om Spring 2020-Ali RazaAhmerNo ratings yet

- BTHM Tourism & Hospitality ExamsDocument6 pagesBTHM Tourism & Hospitality ExamsSanjay VaryaniNo ratings yet

- Estimated Projection of Apparel ProductionDocument9 pagesEstimated Projection of Apparel ProductionDipankar DuttaNo ratings yet

- Planning Production ActivitiesDocument21 pagesPlanning Production ActivitiesBeytullah Gültekin ÇetinerNo ratings yet

- Case Studies For EMBA 615Document3 pagesCase Studies For EMBA 615mzhouryNo ratings yet

- Project Profile on Auto Leaf Spring ManufacturingDocument11 pagesProject Profile on Auto Leaf Spring ManufacturingVijayKrishnaAmaraneniNo ratings yet

- Optimize Plant Capacity with Decision Tree AnalysisDocument5 pagesOptimize Plant Capacity with Decision Tree AnalysisSamarth LahotiNo ratings yet

- Past YearDocument28 pagesPast YearFirdaus LasnangNo ratings yet

- Effect of Quality Management On ProductivityDocument84 pagesEffect of Quality Management On ProductivityvinilkurisingalNo ratings yet

- Final Exam Managerial Accounting Practice ProblemsDocument4 pagesFinal Exam Managerial Accounting Practice ProblemsbilelNo ratings yet

- Eastern Mediterranean University: Faculty of Engineering Department of Industrial EngineeringDocument16 pagesEastern Mediterranean University: Faculty of Engineering Department of Industrial EngineeringBlessing FajemirokunNo ratings yet

- ABC Analysis Reveals True Costs of Wine ProductsDocument11 pagesABC Analysis Reveals True Costs of Wine ProductsShelly ElamNo ratings yet

- End Te EXA Nati: RM MI ONDocument1 pageEnd Te EXA Nati: RM MI ONDhruv GuptaNo ratings yet

- Process Econ S1 2021 Evaluation of Alternatives Wk14Document16 pagesProcess Econ S1 2021 Evaluation of Alternatives Wk14Farhan MuhamadNo ratings yet

- 06 Drilling EconomicsDocument6 pages06 Drilling Economicsswaala4real100% (1)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Managing Successful Projects with PRINCE2 2009 EditionFrom EverandManaging Successful Projects with PRINCE2 2009 EditionRating: 4 out of 5 stars4/5 (3)

- Career Change From Real Estate to Oil and Gas ProjectsFrom EverandCareer Change From Real Estate to Oil and Gas ProjectsRating: 5 out of 5 stars5/5 (1)

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Excel Workbook: 160 Exercises with Solutions and CommentsFrom EverandExcel Workbook: 160 Exercises with Solutions and CommentsAlberto ClericiNo ratings yet

- Muhammad Usama: Internship at Ibrahim Fibres Limited, Polyester PlantDocument20 pagesMuhammad Usama: Internship at Ibrahim Fibres Limited, Polyester PlantUsamaNo ratings yet

- QuestionsDocument10 pagesQuestionsmfoNo ratings yet

- Subscriber Loop Design LectureDocument36 pagesSubscriber Loop Design LectureAlas Mallari DonatoNo ratings yet

- Engine Coolant Temperature Sensor PM3516 3516B Power Module NBR00001-UPDocument2 pagesEngine Coolant Temperature Sensor PM3516 3516B Power Module NBR00001-UPFaresNo ratings yet

- KFC District HeatingDocument15 pagesKFC District HeatingAdrianUnteaNo ratings yet

- CPDocument29 pagesCPsandugandhiNo ratings yet

- Critical Path Method: A Guide to CPM Project SchedulingDocument6 pagesCritical Path Method: A Guide to CPM Project SchedulingFaizan AhmadNo ratings yet

- This Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsDocument135 pagesThis Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic Schematicsrvalverde50gmailcomNo ratings yet

- Klem Et Al 2022 - Part 5 Rigor in Qualitative ResearchDocument3 pagesKlem Et Al 2022 - Part 5 Rigor in Qualitative ResearchNora ElaNo ratings yet

- George Novack's - Understanding HistoryDocument272 pagesGeorge Novack's - Understanding HistoryagustibravoNo ratings yet

- Arduino The Ultimate Beginners Guide To Arduino Learn How To Get Started With Arduino Programming Projects and More PDFDocument33 pagesArduino The Ultimate Beginners Guide To Arduino Learn How To Get Started With Arduino Programming Projects and More PDFefrain100% (1)

- Convention of Film Blocking Day 2Document6 pagesConvention of Film Blocking Day 2GENELYN GAWARANNo ratings yet

- Calculating Ampacity in Small-Gauge, Electrical Cables: Greig S. Latham, Member, IEEEDocument4 pagesCalculating Ampacity in Small-Gauge, Electrical Cables: Greig S. Latham, Member, IEEEAlaa RamadanNo ratings yet

- Classroom Management PlanDocument6 pagesClassroom Management Planapi-607580556No ratings yet

- Milgrams Experiment On Obedience To AuthorityDocument2 pagesMilgrams Experiment On Obedience To Authorityapi-233605868No ratings yet

- Iron and Steel ReviewDocument2 pagesIron and Steel ReviewSajal SinghNo ratings yet

- Lexmark™ X950de, X952dte and X954dhe (7558-xxx) - Service ManualDocument1,178 pagesLexmark™ X950de, X952dte and X954dhe (7558-xxx) - Service ManualNikkiSpencerNo ratings yet

- G5 - CLC 30Document5 pagesG5 - CLC 30Phuong AnhNo ratings yet

- 2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONDocument5 pages2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONkkumar_717405No ratings yet

- CH 1 Limits & ContinuityDocument35 pagesCH 1 Limits & ContinuityDzulFadhly100% (3)

- Lion Dam Gate Seals - INTLDocument3 pagesLion Dam Gate Seals - INTLIoannis SanoudosNo ratings yet

- Chapter 1 PPT (Compressibility and Consolidation)Document65 pagesChapter 1 PPT (Compressibility and Consolidation)Eba GetachewNo ratings yet

- Musical Instruments Speech The Chinese Philosopher Confucius Said Long Ago ThatDocument2 pagesMusical Instruments Speech The Chinese Philosopher Confucius Said Long Ago ThatKhánh Linh NguyễnNo ratings yet

- Contanuity Case StudyDocument14 pagesContanuity Case StudyUsama TariqNo ratings yet

- SUZ BusaDocument165 pagesSUZ BusaPraveen kumar RNo ratings yet

- Bus Order SummaryDocument3 pagesBus Order SummaryKhairul IdhamNo ratings yet

- Forever Living ContractDocument2 pagesForever Living ContractRishi SehgalNo ratings yet

- Horse Meets Dog, by Elliot Kalan and Tim Miller, Is A Book About A Horse That Meets A Dog ForDocument14 pagesHorse Meets Dog, by Elliot Kalan and Tim Miller, Is A Book About A Horse That Meets A Dog Forapi-559432931No ratings yet

- Rt380T 230/400 PCB Rohs: Analog Three-Phase Thyristor Trigger ModuleDocument3 pagesRt380T 230/400 PCB Rohs: Analog Three-Phase Thyristor Trigger ModuleFelipe CasasNo ratings yet

- Computers & Industrial Engineering: Guohui Zhang, Xinyu Shao, Peigen Li, Liang GaoDocument10 pagesComputers & Industrial Engineering: Guohui Zhang, Xinyu Shao, Peigen Li, Liang Gaocloud69windNo ratings yet