Professional Documents

Culture Documents

Siwes Project

Uploaded by

Zana Godsgift UmukoroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Siwes Project

Uploaded by

Zana Godsgift UmukoroCopyright:

Available Formats

CHAPTER 1 INTRODUCTION 1.1 Introduction to Employer I undertook my Industrial Training for the 2009 SIWES at S. B.

ADEWALE MECHANICAL WORKS, Idi-iroko. Bodija, Ibadan. S. B Adewale Mechanical Works is an establishment that specializes in the repair, service and maintenance of Mercedes Benz cars. It is a Sole-Proprietorship established in 1995. Aside from other On- The- Job trainees, there are three (3) key members of staff with specialize technical skills. 1.2 General Experience Acquired During the Duration of the training I was introduced to Mechanical tools and equipments and also the different systems and Automobile components. There are up to nine (9) major systems in Automobile generally. These systems are associated with different faults unique maintenance procedures. Some of these systems I was opportune to be trained on during the SIWES are listed below. Engine system Transmission system Suspension system Steering system Braking system Cooling system Ignition system Electrical system Starting system Lubrication system Fuel supply system

1.2.1

Summary of Skills Acquired During the eight weeks of training I acquired practical, technical skills and experience in the following areas and systems in the Automobile (Mercedes Benz) i. ii. Tools and Equipment handling skills Engine system In this section I acquired the skill in: Checking and fitting Piston rings Assembly and disassembly of Engine Unit and components Correcting and adjusting Carburetor faults Correcting Cold starting and slow running problems Misfiring, fuel consumption, smoky exhaust Set inlet and exhaust valves using Feeler gauge iii. Transmission System: under this section I gained experience in correcting the following faults in Benz cars: Noisy Gear-box, Oil leakage from gear box, Difficulty in engaging gears Replace worn out clutch plate, release bearings etc Adjust and correct clutch faults such as Clutch slip and clutch drag Drain and refill transmission fluids iv. Suspension system Replacing shock Absorber Replacing suspension ball joints Correct faults such as Noisy Front end, Car wanders, Tight steering etc v. Braking System Adjust spongy and springy brake pedals Correct faults such as Noisy brakes, brakes fails to release, brake pedal feels hard Replace brake pads and brake lining vi. Ignition system Ignition timing Check distributor and high tension cable etc vii Cooling system

1.3

Correct problem such as Overheating, external leakages, water loss, corrosion and over cooling.

Broader Classification of systems in Benz car as experienced in Industrial Training For the purpose of this work report I further classify the afore-mentioned system in 1.2 to two sections/parts, the Engine section and Other sections. The Engine section will include the primary engine unit, its ignition and fuel and air supplies while the Other section will cover secondary systems like the Transmission, suspension, Braking etc. which are not directly connected to the engine unit The Engine Section: Systems classified under this section include; Engine system Fuel supply system Ignition system Other sections; Transmission system Suspension, Steering and Braking system Cooling system These broad sections, their component parts, principle of operation and their common problems encountered during industrial training will be explained in the chapters to follow.

1.4

Principle of Operation of Benz car.

CHAPTER 2 ENGINE SECTION AND SYSTEMS The Engine section will include the primary engine unit, its ignition and fuel and air supplies systems close to the engine. 2.1

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- BraginskiiDocument97 pagesBraginskiicordella_francescoNo ratings yet

- Hoarding Guide 2020Document46 pagesHoarding Guide 2020Mohammed HafizNo ratings yet

- DiGas 4000 Light E 08.02Document2 pagesDiGas 4000 Light E 08.02manit1963No ratings yet

- Corrosion in Oil and Gas Industry A Perspective On Corrosion InhibitorsDocument1 pageCorrosion in Oil and Gas Industry A Perspective On Corrosion InhibitorsAsma Sed100% (1)

- Husky Air Assignment 5 and 6Document15 pagesHusky Air Assignment 5 and 6varunkalra6No ratings yet

- Partitioned Data Set Extended Usage Guide Guide: Front CoverDocument364 pagesPartitioned Data Set Extended Usage Guide Guide: Front CoverCsutka PocsNo ratings yet

- Peanut Brittle LabDocument2 pagesPeanut Brittle LabMary Bacon HillebrandNo ratings yet

- Nuclear Radioactivity WorksheetDocument3 pagesNuclear Radioactivity Worksheet14569874No ratings yet

- PactFocus Report - Sample - LPGDocument27 pagesPactFocus Report - Sample - LPGIqbal HussainNo ratings yet

- DTH Equipment - Product - Catalogue - tcm45-3560033 PDFDocument48 pagesDTH Equipment - Product - Catalogue - tcm45-3560033 PDFJALFARORONo ratings yet

- The B-GON Solution: To Mist EliminationDocument20 pagesThe B-GON Solution: To Mist EliminationDimitris Sardis LNo ratings yet

- PalindromeDocument7 pagesPalindromeZy AdrianneNo ratings yet

- Development and Evaluation - KocabaDocument263 pagesDevelopment and Evaluation - KocabaWRLSNo ratings yet

- Deterministic Inventory Control FormulasDocument6 pagesDeterministic Inventory Control FormulasvivekNo ratings yet

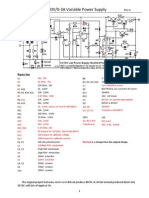

- Modified 0-30V - 0-3A Variable Power Supply - Rev.2Document2 pagesModified 0-30V - 0-3A Variable Power Supply - Rev.2Manuel Cereijo NeiraNo ratings yet

- Vacuum Chill BlockDocument2 pagesVacuum Chill BlockAditheya Varthan MNo ratings yet

- GDCF 2 240 - 2nd - 01 10Document2 pagesGDCF 2 240 - 2nd - 01 10edgardomichligNo ratings yet

- International Log Building StandardsDocument19 pagesInternational Log Building Standardsursind100% (1)

- Price Quotation: Quote/Project Description Ref. Details: Project DetailDocument3 pagesPrice Quotation: Quote/Project Description Ref. Details: Project DetailAhmad AyyoubNo ratings yet

- Adobe Photoshop: The EditingDocument10 pagesAdobe Photoshop: The EditingMer Cjielo BalloonsNo ratings yet

- Physical and Rheological Properties of Modified Sulfur Asphalt BinderDocument8 pagesPhysical and Rheological Properties of Modified Sulfur Asphalt Binderramesh naikNo ratings yet

- (Mamoru Hosaka (Auth.) ) Modeling of Curves and SuDocument363 pages(Mamoru Hosaka (Auth.) ) Modeling of Curves and Suamalendu_biswas_1No ratings yet

- R5310105-Structural Analysis - IIDocument4 pagesR5310105-Structural Analysis - IIsivabharathamurthyNo ratings yet

- High Voltage Grease Reduces Wear and ArcingDocument2 pagesHigh Voltage Grease Reduces Wear and ArcingtlnferreiraNo ratings yet

- Metronidazole AnalysisDocument5 pagesMetronidazole AnalysisHendri WasitoNo ratings yet

- Reliance Jio Industry AnalysisDocument45 pagesReliance Jio Industry AnalysisBhavya BhartiNo ratings yet

- BTSDocument75 pagesBTSgyanesh198450% (2)

- Iso Dis 20283-4 2011Document27 pagesIso Dis 20283-4 2011Ricardo RamirezNo ratings yet

- Physicaltestingofrubberrogerbrown2006 Book 150514103634 Lva1 App6892Document389 pagesPhysicaltestingofrubberrogerbrown2006 Book 150514103634 Lva1 App6892AbdelhamidHarratNo ratings yet

- Online Quiz System DocumentationDocument92 pagesOnline Quiz System DocumentationSultan Aiman100% (1)