Professional Documents

Culture Documents

Piping Fabrication ITP

Uploaded by

NatrajiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping Fabrication ITP

Uploaded by

NatrajiCopyright:

Available Formats

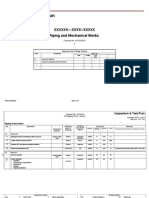

Inspection and Test Plan

Piping Fabrication

Document Number: XXXX XXXX XXXXX

XXXXXXXXXX--XXXXX Piping and Mechanical Works

Contract No. XXXXXXXXX

X

Approval and Change History

Issue Description Date 0 1 Issued for Approval Revised to Incorporate Client Comments Quality Approval Proj. Man.

Piping Fabrication

Page 1 of 5

Contract No. XXXXXXX ITP Number XXXX XXXXX

Inspection & Test Plan

Authorised: XXXXX XXXXX Date: XXX XXX XXX

Piping Fabrication

No. Operation Document Number

1.0 1.1 1.2 1.3 1.4 Approvals Welding Procedure Specification (WPS) approval Qualify welders to approved WPS Prepare WPS and Approved Welder Registers Review Subcontractors ITPs Project Quality Plan B31.3 B31.3 B31.3 XXXXXXXX Approved WPS/PQR WQR Registers ITP PE/QC PE/QC PE/QC PE/QC H H H H H/R H/R H/R H/R R M/R R R Not required if this pre-approved ITP is used

Standard, Spec or Drawing

Verifying Document/ Report

Inspection

Response .

Workshop Fabricator

Remarks

Client (May be used as a sign off column by xxxxxxxxxxx or the Client to indicate that the activity has been satisfactorily completed)

Fabricato r

2.0 2.1 2.1

Materials Receive materials Inspect materials: quantities conformance to requirements dimensional damage material certification Project Quality Plan B31.3 D/Dkt/PO D/Dkt/PO XXXXXX WF/ST WF/ST M V/D M M M M

Inspection Codes Key H W M Hold Point Witness Monitor V D R Visual Inspection Dimension Inspection Review & Approve Documentation

Page 2 of 5

PE WF TR QC

Project Engineer Workshop Foreman Tradesman Quality Inspector

Responsibility ST EX SC

Storeman Inspection/Expeditor Sub-Contractor

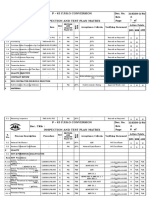

Piping Fabrication

Contract No. XXXXXXX ITP Number XXXX XXXXX

Inspection & Test Plan

Authorised: XXXXX XXXXX Date: XXX XXX XXX

Piping Fabrication

No. Operation Document Number

3.0 3.1 3.2 3.3 3.4 Shop Fabrication Approved WPS available at work station Check material for item, type, material, size, rating & unique number Check weld preparations Calculate NDT % Requirements on Piping Confirm Piping Class Project Quality Plan B31.3 B31.3 B31.3 WPS B31.3 Current Revision Documents AFC Dwg AFC Dwg EC-F-054 WF/QC WF/EX WF/QC WF/QC M V/M V/M V/D M M M M M M M R Nominate on Subcontractors NDT% Form amount and type of NDT required. i.e PT/MT or UT/RT - Construction code acceptance criteria shall be as ANSI B31.3 on all NDT testin g reports

Standard, Spec or Drawing

Verifying Document/ Report

Inspection

Response .

Workshop Fabricator

Remarks

Client (May be used as a sign off column by xxxxxxxxxxx or the Client to indicate that the activity has been satisfactorily completed)

Fabricato r

3.5 3.6 3.7 3.8

Check welding consumables Check fit up, configuration, dimension and orientation Check for spool and sub spool identification Check welder qualification

WPS WPS

WPS AFC Dwg AFC Dwg

WF/QC WF/QC WF/QC WF/QC

V/M V/M V/M R

M M M M

M M M M

Drawings Welder Register WPS

Register/WQR

3.9 3.10 3.11 3.12 3.13

Check welding parameters Check weld marking (welders ID, date and consumable) Check weld root and hot pass Check removal of slag, spatter, scale and flux Check completed weld

WPS Weld Maps WPS ITP

WF/QC WF/QC WF/QC WF/QC WF/QC

M V/M V/M V/M V/M

M M M M M

M M M M M Verify & accept by signing section 4.6 of this ITP Verify & accept by signing section 4.6 of this ITP

B31.3

ITP

Inspection Codes Key H W M Hold Point Witness Monitor V D R Visual Inspection Dimension Inspection Review & Approve Documentation

Page 3 of 5

PE WF TR QC

Project Engineer Workshop Foreman Tradesman Quality Inspector

Responsibility ST EX SC

Storeman Inspection/Expeditor Sub-Contractor

Piping Fabrication

Contract No. XXXXXXX ITP Number XXXX XXXXX

Inspection & Test Plan

Authorised: XXXXX XXXXX Date: XXX XXX XXX

Piping Fabrication

No. Operation Document Number

3.14 3.15 4.0 4.1 4.2 Record welding traceability information Final dimensional check Inspection and Testing All Welds 100% Visual NDE as per AS4041 5% RT and MPI for Class 2A Piping Exempt for Class 3 Piping Pipework marking and identification correct Mark up drawings as built as necessary Engineering Drawings Project Quality Plan B31.3 This ITP WF/QC V H NATA Report Punch list Engineering Drawing marked in red pen NDT Reports M R M R M M R M W Verify & Accept by signing section 4.1 of this ITP

Standard, Spec or Drawing

B31.3 B31.3

Verifying Document/ Report

Not Report AFC Dwg

Inspection

Response .

Workshop Fabricator

Remarks

Client (May be used as a sign off column by xxxxxxxxxxx or the Client to indicate that the activity has been satisfactorily completed)

Fabricato r

WF/QC WF/Ex

R V/D/M

M M

M M

4.3 4.4

4.5

Veryify NDT% has been completed Final Inspection Inspect delivery dockets to ensure that they record every item Final inspection and release Project Quality Plan

31.3

5.0 5.1 5.2

31.3 This ITP

Ex/PE Ex/PE

M H

M H/W

M M

Verify & Accept by signing section 5.2 of this ITP

6.0 6.1

Delivery Ensure that all inspections and tests are completed, all reports and documentation are available and all results comply with requirements Check tagging/marking is in place, correct and secure Check Delivery Docket completed and forwarded to projects office Project Management Plan 31.3 Drwgs P. O./ Scope 31.3 Delivery Docket Reports/ Checklists PE/Ex H/R H/R R

6.2 6.3

Ex Ex

M H/R

M M

M M/R

Every item shall be marked and listed on the Delivery Docket

Inspection Codes Key H W M Hold Point Witness Monitor V D R Visual Inspection Dimension Inspection Review & Approve Documentation

Page 4 of 5

PE WF TR QC

Project Engineer Workshop Foreman Tradesman Quality Inspector

Responsibility ST EX SC

Storeman Inspection/Expeditor Sub-Contractor

Piping Fabrication

Contract No. XXXXXXX ITP Number XXXX XXXXX

Inspection & Test Plan

Authorised: XXXXX XXXXX Date: XXX XXX XXX

Piping Fabrication

No. Operation Document Number

6.4 Ensure that all items are loaded with sufficient dunnaging to allow safe transport and unloading and prevent damage to material and surface coatings Weights and dimensions of the load shall comply with statutory requirements. Compliance is the responsibility of the approved transport contractor Deliver product and documentation to nominated location

Standard, Spec or Drawing

Verifying Document/ Report

Inspection

Response .

Workshop Fabricator

Remarks

Client (May be used as a sign off column by xxxxxxxxxxx or the Client to indicate that the activity has been satisfactorily completed)

Fabricato r

Ex

6.5

Ex

6.6

Contract/ Purchase Order

D/Dkt

Ex/PE

7.0 7.1

Records Check MDR complete and available. Project Quality Plan MDR Records PE/QC R R R/H MPDJV Rep to review completed MDR at source (MEA or Subcontractor facility) covering SOW

Inspection Codes Key H W M Hold Point Witness Monitor V D R Visual Inspection Dimension Inspection Review & Approve Documentation

Page 5 of 5

PE WF TR QC

Project Engineer Workshop Foreman Tradesman Quality Inspector

Responsibility ST EX SC

Storeman Inspection/Expeditor Sub-Contractor

Piping Fabrication

You might also like

- Pressure Safety Valve Inspection PlanDocument3 pagesPressure Safety Valve Inspection PlanLim Dongseop100% (1)

- ITP-001 Steelwork Fabrication Rev ADocument5 pagesITP-001 Steelwork Fabrication Rev AMarcus Cox100% (2)

- Radiography - Film Quality ChecklistDocument4 pagesRadiography - Film Quality ChecklistNatraji100% (1)

- Alchemical Psychology Uniform Edition o - HillmanDocument207 pagesAlchemical Psychology Uniform Edition o - HillmanElsy Arana95% (22)

- Construction Instrument Tubing Pressure & Leak Test ProcedureDocument9 pagesConstruction Instrument Tubing Pressure & Leak Test Procedurezack zeeartNo ratings yet

- Inspection Test Plan - Piping FabricationDocument5 pagesInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- Release For GroutingDocument1 pageRelease For GroutingUmair AwanNo ratings yet

- Baroque MusicDocument15 pagesBaroque Musicthot777100% (2)

- NDT BrochureDocument96 pagesNDT Brochureendri2000No ratings yet

- NDT BrochureDocument96 pagesNDT Brochureendri2000No ratings yet

- Iso 27001 Auditor TrainingDocument19 pagesIso 27001 Auditor TrainingITOPS TeamNo ratings yet

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- ITP Heat ExchangerDocument1 pageITP Heat Exchangersarmad009No ratings yet

- ITP For PipingDocument3 pagesITP For PipingAbdullah Al Jubayer100% (1)

- Piping Inspect & Testing ProcedureDocument11 pagesPiping Inspect & Testing ProcedureErlanggaBonaparteNo ratings yet

- PSV Test FrequencyDocument130 pagesPSV Test FrequencysamysmcNo ratings yet

- Operations and Maintenance GuideDocument321 pagesOperations and Maintenance GuideNatrajiNo ratings yet

- Industrial Radiography Image Forming TechniquesDocument99 pagesIndustrial Radiography Image Forming TechniquesAnonymous gFcnQ4goNo ratings yet

- Inspection and Test Plan For Line Pipe PDFDocument4 pagesInspection and Test Plan For Line Pipe PDFsherviny100% (1)

- Hindustan Petroleum Standard Piping Inspection Test PlanDocument6 pagesHindustan Petroleum Standard Piping Inspection Test Planمحمد أزها نو الدينNo ratings yet

- Piping System Hydraulic Test Procedure R0Document6 pagesPiping System Hydraulic Test Procedure R0cmc261185No ratings yet

- Process Piping Inspection and Test PlanDocument6 pagesProcess Piping Inspection and Test Planmanoj thakkarNo ratings yet

- Factory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: DDocument6 pagesFactory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: Dbayu dewantoNo ratings yet

- Komatsu HD785-7 Shop Manual PDFDocument1,491 pagesKomatsu HD785-7 Shop Manual PDFIB EldinNo ratings yet

- ITP-000 Piping Fabrication (Exemple)Document5 pagesITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- QW 406 Asme CodeDocument3 pagesQW 406 Asme CodeMardeOpamenNo ratings yet

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- Itp PipingDocument4 pagesItp PipingkennethNo ratings yet

- APV STD Insp & Test Plan API6D ValvesDocument4 pagesAPV STD Insp & Test Plan API6D ValvesdbmingoNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- WE1884 - ITP For Shop Fab. of Header Coils-120813Document4 pagesWE1884 - ITP For Shop Fab. of Header Coils-120813imran100% (1)

- GX Audit Internal Audit Risk and Opportunities For 2022Document26 pagesGX Audit Internal Audit Risk and Opportunities For 2022Muhammad SamiNo ratings yet

- Quality Control Plan For Ducting: Project Name: TokushimaDocument4 pagesQuality Control Plan For Ducting: Project Name: TokushimaNguyen Anh TuanNo ratings yet

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198No ratings yet

- Viewing and Interpretation of RadiographsDocument30 pagesViewing and Interpretation of RadiographsNatrajiNo ratings yet

- To Commissioning Manual: Appendix No. 1Document7 pagesTo Commissioning Manual: Appendix No. 1Bassem BalghouthiNo ratings yet

- Hot Tap ReportDocument2 pagesHot Tap ReportCak NhassNo ratings yet

- ITP SampleDocument2 pagesITP Sampleeiman_zerep50% (2)

- BSEE Test ProcedureDocument35 pagesBSEE Test ProcedureNatraji100% (2)

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- Itp Line PipeDocument8 pagesItp Line Pipekaml100% (1)

- ITP For Piping WorksDocument44 pagesITP For Piping WorksSyafril Akbar100% (3)

- Welding InspectionDocument7 pagesWelding Inspectionzahid_497100% (1)

- Ionising Radiation Safety ProcedureDocument43 pagesIonising Radiation Safety ProcedureNatraji100% (1)

- World Nondestructive Test Inspection Services MarketDocument88 pagesWorld Nondestructive Test Inspection Services MarketNatrajiNo ratings yet

- Hydrogen Induced CrackingDocument2 pagesHydrogen Induced CrackingNatrajiNo ratings yet

- Marine Facilities Work Egyptian LNG Project-Idku Work Instruction FOR Handling of Consuamable MaterialsDocument6 pagesMarine Facilities Work Egyptian LNG Project-Idku Work Instruction FOR Handling of Consuamable Materialszaki fadlNo ratings yet

- Cp-117-Project EngineeringDocument67 pagesCp-117-Project Engineeringkattabomman100% (1)

- Piping Overview 01Document18 pagesPiping Overview 01Rajkumar ANo ratings yet

- Pressure Test in Piping Systems - Hydro and Pneumatic TestsDocument3 pagesPressure Test in Piping Systems - Hydro and Pneumatic Testssj22No ratings yet

- TANK 06 Test PackDocument12 pagesTANK 06 Test PackGomathyselvi100% (2)

- ITP For Pipe Materials (Stock)Document7 pagesITP For Pipe Materials (Stock)Hamid Taghipour ArmakiNo ratings yet

- Material Inspection Report: Project Name Date InspDocument22 pagesMaterial Inspection Report: Project Name Date InspRafiqKuNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Inspection and Test Plan for Piping Fabrication and InstallationDocument16 pagesInspection and Test Plan for Piping Fabrication and InstallationEyoh EffiongNo ratings yet

- Welding ProceduresDocument29 pagesWelding ProceduresLaith Salman100% (1)

- ASME Section I Code Preheat and PWHT GuidanceDocument4 pagesASME Section I Code Preheat and PWHT GuidanceArul Edwin Vijay VincentNo ratings yet

- Financial Modeling Interview Questions AnsweredDocument6 pagesFinancial Modeling Interview Questions AnsweredBHAVEN ASHOK SINGHNo ratings yet

- Lesson Plan For DemoDocument7 pagesLesson Plan For DemoShiela Tecson GamayonNo ratings yet

- Thickness Qualification Range For PQR and WPQDocument5 pagesThickness Qualification Range For PQR and WPQOuled BladiNo ratings yet

- Lahore ResolutionDocument6 pagesLahore ResolutionMZCHOHAN100% (1)

- Punch Points For Piping EngineersDocument8 pagesPunch Points For Piping EngineersVignesh MohanNo ratings yet

- Oscam SkyDocument2 pagesOscam SkyColetor de OfertasNo ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- Work Method Statement FOR HSS PQTDocument6 pagesWork Method Statement FOR HSS PQTenels77No ratings yet

- Inspection Report - ValvesDocument2 pagesInspection Report - ValvesJaspal KaurNo ratings yet

- PMS-V32-Ball Valves - FlangedDocument2 pagesPMS-V32-Ball Valves - FlangedMB Azharudeen100% (1)

- Interactive Form QW-485 PDFDocument1 pageInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNo ratings yet

- PENETRANT OIL TEST TANKS PROCEDUREDocument4 pagesPENETRANT OIL TEST TANKS PROCEDUREhasan_676489616No ratings yet

- Hydraulic crash barriers ITPDocument4 pagesHydraulic crash barriers ITPmoytabura96No ratings yet

- Field Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectDocument12 pagesField Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectbasukiNo ratings yet

- 1.13 Inspection & Test PlansDocument1 page1.13 Inspection & Test Plansabimanyubawono100% (2)

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- Hydro test report for 750mm dismantling jointDocument2 pagesHydro test report for 750mm dismantling jointAnonymous a8oga83No ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- Finished Goods Packing & Dispatch ProcedureDocument2 pagesFinished Goods Packing & Dispatch ProcedurePratik KarekarNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFRadhakrishna VachaNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- Final Inspection Release NoteDocument2 pagesFinal Inspection Release NoteMark ThrelfallNo ratings yet

- Eil Spec For PmiDocument8 pagesEil Spec For Pmisachinchavan1981No ratings yet

- Floating Head Heat Exchanger Hydrotest ProcedureDocument15 pagesFloating Head Heat Exchanger Hydrotest ProcedureDoğuhan DenizgezNo ratings yet

- Shades of GreyDocument1 pageShades of GreyNatraji0% (1)

- INS - Phased Array Pipework Inspection PDFDocument2 pagesINS - Phased Array Pipework Inspection PDFEngr Arfan Ali DhamrahoNo ratings yet

- Technical Note 35Document13 pagesTechnical Note 35NatrajiNo ratings yet

- Cfluo - Ta !LL - : !+ - J :QF SLDocument1 pageCfluo - Ta !LL - : !+ - J :QF SLNatrajiNo ratings yet

- MS 5800 Tube EN 201204Document8 pagesMS 5800 Tube EN 201204NatrajiNo ratings yet

- Corrosion HSEDocument5 pagesCorrosion HSENatrajiNo ratings yet

- Industrial Colour ScheduleDocument4 pagesIndustrial Colour ScheduleMadhan KumarNo ratings yet

- 19336Document8 pages19336gopidhanNo ratings yet

- Manufacturing of Welded DefectsDocument8 pagesManufacturing of Welded DefectsNatrajiNo ratings yet

- Innerspec TechnologiesDocument17 pagesInnerspec TechnologiesNatrajiNo ratings yet

- IQI RadiographyDocument3 pagesIQI RadiographyNatrajiNo ratings yet

- CB - Corroion Under Support InspectionDocument2 pagesCB - Corroion Under Support InspectionNatrajiNo ratings yet

- CUI - PreventionDocument7 pagesCUI - PreventionNatrajiNo ratings yet

- Combining CR and SCAR Technology Paper July 2010Document0 pagesCombining CR and SCAR Technology Paper July 2010NatrajiNo ratings yet

- Ceramic RepairDocument1 pageCeramic RepairNatrajiNo ratings yet

- Catalogueiendt PDFDocument43 pagesCatalogueiendt PDFNatrajiNo ratings yet

- (Module Study Area 2011 - 2012) ENM305 - Online Distance - Quiz For Topic 10 (Graded by First Attempt and Limited To 40 Minutes)Document5 pages(Module Study Area 2011 - 2012) ENM305 - Online Distance - Quiz For Topic 10 (Graded by First Attempt and Limited To 40 Minutes)NatrajiNo ratings yet

- Cathodic ProtectionDocument68 pagesCathodic ProtectionNatrajiNo ratings yet

- Heat Exchanger Installtion Operation MaintenanceDocument8 pagesHeat Exchanger Installtion Operation MaintenanceNatrajiNo ratings yet

- Future TenseDocument6 pagesFuture TenseMuhammad Ibnu LaksonoNo ratings yet

- Tie Technology DK SKDocument32 pagesTie Technology DK SKVladimir PleșcaNo ratings yet

- 1) How Are Lakes Classified in Regards To Trophic Status? 2) What Is Cultural Eutrophication?Document31 pages1) How Are Lakes Classified in Regards To Trophic Status? 2) What Is Cultural Eutrophication?Enzo TapingNo ratings yet

- Sexual ExtacyDocument18 pagesSexual ExtacyChal JhonnyNo ratings yet

- Role and Function of Government As PlanningDocument6 pagesRole and Function of Government As PlanningakashniranjaneNo ratings yet

- VR 2200 CatalogueDocument4 pagesVR 2200 Catalogueh.torabyNo ratings yet

- Pamantasan NG Lungsod NG Maynila - Freshmen AdmissionDocument6 pagesPamantasan NG Lungsod NG Maynila - Freshmen AdmissionPoppy HowellNo ratings yet

- MR - Abhishek JiDocument4 pagesMR - Abhishek Jimalikgaurav01No ratings yet

- SDH PDFDocument370 pagesSDH PDFClaudia GafencuNo ratings yet

- Pressure Vessel Components and MaterialsDocument30 pagesPressure Vessel Components and MaterialsFirst UserNo ratings yet

- Metaswitch Datasheet Network Transformation OverviewDocument5 pagesMetaswitch Datasheet Network Transformation OverviewblitoNo ratings yet

- CHAPTER 8 SULLIVAN MyReviewerDocument7 pagesCHAPTER 8 SULLIVAN MyReviewerFrances LouiseNo ratings yet

- Accenture Security RansomwareDocument8 pagesAccenture Security RansomwareAbubakar Saddiq MusaNo ratings yet

- Sidney W A Dekker From Threat and Error Management To ResilienceDocument11 pagesSidney W A Dekker From Threat and Error Management To ResilienceDaniel fabian Sánchez henaoNo ratings yet

- The Message Development Tool - A Case For Effective Operationalization of Messaging in Social Marketing PracticeDocument17 pagesThe Message Development Tool - A Case For Effective Operationalization of Messaging in Social Marketing PracticesanjayamalakasenevirathneNo ratings yet

- OE & HS Subjects 2018-19Document94 pagesOE & HS Subjects 2018-19bharath hsNo ratings yet

- Chartered Accountants and Accountans in AmbalaDocument3 pagesChartered Accountants and Accountans in AmbalaGurmeet kaurNo ratings yet

- Past Paper 1 Ibsl: Phone: 7514251,0816930718Document4 pagesPast Paper 1 Ibsl: Phone: 7514251,0816930718santhiNo ratings yet

- Tauros TBM Guidance SystemDocument3 pagesTauros TBM Guidance SystemMiloš StanimirovićNo ratings yet

- ICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseDocument8 pagesICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseZayd Iskandar Dzolkarnain Al-Hadrami100% (1)