Professional Documents

Culture Documents

AISC - Lecture 16

Uploaded by

Manoj JaiswalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISC - Lecture 16

Uploaded by

Manoj JaiswalCopyright:

Available Formats

Lecture 16 AISC Code of Standard Practice

Design, fabrication, and erection of steel-framed buildings should incorporate provisions of the AISC Code of Standard Practice for Steel Buildings and Bridges and is found in AISC Spec. Section 16.3 and also online at www.AISC.org. It was first published in 1924 and is now in its 6th edition, dated March 7, 2005. It provides a useful framework for the understanding of the acceptable standards for the construction of structural steel structures. It is useful for owners, architects, engineers, contractors, fabricators, construction managers and anyone else involved with construction using structural steel. The Code also serves as a basis for technical project specifications, typically CSI Specification Section 05100 Structural Steel (see Lecture 17). A summary of the Code of Standard Practice is given below. GLOSSARY Definitions and abbreviations of relevant terms used throughout the Code. Some important, (but often vague) definitions include: AESS Architecturally Exposed Structural Steel Contract Documents Design Drawings EOR Engineer-of-Record Erection Drawings Erector Fabricator Inspector Owner Owners Designated Representative for Construction Owners Designated Representative for Design RCSC Research Council on Structural Connections RFI written Request for Information SER Structural Engineer-of-Record Shop Drawings Specifications SSPC Society for Protective Coatings (formerly Steel Structures Painting Council) Steel Detailer Structural Steel

Lecture 16 - Page 1 of 13

Section 1 GENERAL PROVISIONS 1.1 Scope The Code shall govern the fabrication and erection of structural steel (unless otherwise noted in Contract Documents). 1.2 Referenced Specifications, Codes and Standards AISC Manual of Steel Construction AISC Seismic Provisions AISC Specification ASTM (lots of referenced standards) AWS D1.1 Structural Welding Code RCSC Specification Specification for Structural Joints using ASTM A325 or A490 Bolts SSPC Steel Structures Painting Council

1.3 Units Either U.S. customary or metric units will be used. Each system shall be independent of the other. 1.4 Design Criteria The AISC Specification shall be used in the absence of other design criteria. 1.5 Responsibility for Design If the Owners Designated Representative for Design provides the design, the Fabricator and Erector are NOT responsible for building code conformance of the design. If the Owner enters a contract with the Fabricator for design/build, then the Fabricator IS responsible for building code conformance of the design.

1.6 Patents and Copyrights The EOR is responsible for obtaining patents and copyrights of design.

Lecture 16 - Page 2 of 13

1.7 Existing Structures Demolition, protection, field dimensions and/or abatement or removal of hazardous are NOT the responsibility of the Fabricator or Erector. 1.8 Means, Methods and Safety of Erection Erector is responsible for erection of frame. SER is responsible for structural adequacy of completed project.

Section 2 CLASSIFICATION OF MATERIALS Structural Steel shall consist of the following typical elements:

Anchor Rods that will receive structural steel Base Plates & bearing plates Beams Bracing (permanent) Columns Connections Fasteners for connecting structural steel Girders Hangers Lintels Shear stud connectors Trusses

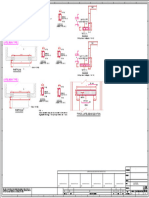

Section 3 DESIGN DRAWINGS AND SPECIFICATIONS 3.1 Structural Design Drawings and Specifications Structural design drawings shall consider design loads and forces in the completed project. Drawings must show: Size, section, location and material grade of all members Geometry and working points necessary for layout Floor elevations Column centers and offsets Camber requirements for beams (if required) Permanent bracing, stiffeners, reinforcement Connection details or data that can be used by fabricator for design including ASD or LRFD methodology Data relating to non-Structural steel elements that interact with frame Painting requirements of Structural steel

Lecture 16 - Page 3 of 13

3.2 Architectural, Electrical and Mechanical Design Drawings Other trades design drawings may be used to show structural steel elements for purposes of defining detail configurations and other construction information, however, ALL STRUCTURAL INFO. MUST BE SHOWN ON STRUCTURAL DRAWINGS. 3.3 Discrepancies Discrepancies discovered in the Contract Documents shall be resolved by the EOR in a timely manner so as not to delay the Fabricators work. Which Governs: Design Drawings Written info in drawings Structural Drawings

Discrepancies between: Design Drawings Specifications Scaled graphic drawings Written info in drawing Arch., Elect., Mech. Structural Drawings Drawings 3.4 Legibility of Design Drawings

Design Drawings must be legible and drawn to a scale of not smaller than 1/8 = 1-0 (unless clarity of the drawing is carefully considered), larger as necessary to convey detailed information. 3.5 Revisions to Design Drawings and Specifications All revisions must be communicated either by issuing new Design Drawings and Specifications or by re-issuing existing Design Drawings and Specifications. Revisions must be clearly and individually indicated, dated and identified by a revision number. These revised sketches become amendments to the Contract Drawings. 3.6 Fast-Track Project Delivery Release of structural Design Drawings and Specifications shall constitute a release for construction, regardless of the status of the architectural, electrical, mechanical, or any other trades documents.

Lecture 16 - Page 4 of 13

Section 4 SHOP AND ERECTION DRAWINGS 4.1 Owner Responsibility The Owner shall furnish the complete structural Design Drawings and Specifications to the Fabricator in a TIMELY MANNER. 4.2 Fabricator Responsibility Fabricator shall produce Shop Drawings and Erection Drawings. Fabricators are permitted to use the services of independent detailers. 4.3 Use of CAD and/or Copies of Design Drawings Fabricator shall NOT reproduce any part of the Design Drawings as part of the Shop or Erection Drawings without the express written permission of Owners Designated Representative for Design. 4.4 Approval Shop and Erection Drawings must be submitted to Owners Representative for Design for review and approval and returned to Fabricator within 14 calendar days.

Lecture 16 - Page 5 of 13

Section 5 MATERIALS 5.1 Mill Materials Fabricator is permitted to order materials upon receipt of Contract Documents that have been issued for construction. If mill materials do not meet ASTM A6 tolerances, Fabricator is permitted to make corrective procedures. 5.2 Stock Materials Fabricator may use stock materials if they meet with required ASTM specifications. Certified mill test reports are used as evidence of record of quality of material. Section 6 SHOP FABRICATION AND DELIVERY 6.1 Identification of Material Materials used for special requirements shall be marked by the supplier as specified by ASTM A6 prior to delivery to Fabricators shop or point of use. 6.2 Preparation of Material Thermal cutting of material is permitted. Surfaced specified as finished shall have a roughness in accordance with ANSI/ASME B46.1 that is less than or equal to 500. 6.3 Fitting and Fastening Projecting elements of connection materials need not be straightened in the connecting plane. Backing bars and runoff tabs shall be used to produce as required to produce sound welds, and do not need be removed unless specifically designated in the Contract Documents.

Lecture 16 - Page 6 of 13

6.4 Fabrication Tolerances The following tolerances are to be used: Member Type: Both ends finished for contact bearing Members < 30-0 Members > 30-0 All members Beam length < 50-0 Beam length > 50-0 Tolerance Variation: Length = 1/32 Length = 1/16 Length = 1/8 Straightness < 1/1000 axial length Camber variation = 0 Camber variation = 0 + 1/8 per 10-0 additional length beyond 50-0

6.5 Shop Cleaning and Painting Structural steel that does not require shop paint shall be cleaned of oil, grease, dirt and any foreign material. Structural steel requiring shop painting shall be free of oil, grease, dirt and any foreign material; as well as meeting the requirements of SSPC-SP2. 6.6 Marking and Shipping of Materials Erection marks shall be painted to all structural steel members. Connection members shall be shipped in separate closed containers according to grade, length and diameter. 6.7 Delivery of Materials Steel shall be delivered in a sequence that will permit efficient and economical fabrication and erection. Section 7 ERECTION 7.1 Method of Erection Structural steel shall be erected using methods and a sequence that will permit efficiency and economy.

Lecture 16 - Page 7 of 13

7.2 Job-Site Conditions Owners Representative for Construction shall provide the following: Access road for deliveries and movement of materials Adequate obstruction-free space for operation of Erectors equipment Adequate storage space

7.3 Foundations, Piers and Abutments Owners Representative for Construction shall be responsible for accurate location, suitability and access to all foundations, piers and abutments. 7.4 Building Lines and Bench Marks Owners Representative for Construction shall be responsible for accurate location of building lines and benchmarks and shall furnish the Fabricator with a plan containing such information. 7.5 Installation of Anchor Rods and Other Embedded Items Owners Representative for Construction shall be responsible for setting in accordance with Embedment Drawings. The variation in location shall be as follows: Item: Centers of any 2 anchor rods within an anchor rod group Centers of adjacent anchor rod groups Elevation of tops of anchor rods Accumulated variation between centers of anchor rod groups 7.6 Installation of Bearing Devices All leveling plates, nuts, washers and bearing plates that can be handled without crane are set to line and grade by the Owners Representative for Construction (otherwise set by Erector). 7.7 Grouting Grouting shall be the responsibility of the Owners Representative for Construction. The usual method for supporting columns during erection is by use of leveling nuts and washers or shims. Variation in Dimension: < 1/8 < < per 100-0 not to exceed a total of 1

Lecture 16 - Page 8 of 13

7.8 Field Connection Material Fabricator shall provide field connection details consistent with Contract Documents. 7.9 Loose Material Unless otherwise noted, loose structural steel items that are not connected to the steel frame by the Owners Representative for Construction without assistance from Fabricator. 7.10 Temporary Support of Structural Steel Frames The Owners Designated Representative for Design shall identify the following: Lateral load resisting system and connecting diaphragm elements providing stability in the completed structure Any special erection conditions that are required by the design concept, such as use of jacks, shores, etc.

7.11 Safety Protection The Erector shall provide floor coverings, handrails, walkways and other protection for the Erectors personnel in accordance with all applicable safety regulations. Unless otherwise specified, the Erector is permitted to remove such safety protection form areas where the erection operations are completed. Safety protection for other trades that are not under the direct employment of the Erector shall be the responsibility of the Owners Representative for Construction. 7.12 Structural Steel Frame Tolerances The accumulation of the mill tolerances (Section 6.4) and fabrication tolerances shall not cause the erection tolerances (Section 7-13) to be exceeded.

Lecture 16 - Page 9 of 13

7.13 Erection Tolerances Erection tolerances are referenced from Work Points and Work Lines defined as: Members other than horizontal members, the member work point is the actual center of the member at each end of the shipping piece. Horizontal members work point shall be the actual centerline of the top flange or top surface at each end. Work line is defined a s a straight line that connects the member work points. Erection Tolerance: 1/500 distance between work points not to exceed 1 total for first 20 stories + 3/16 - 5/16 3/8

Member: Column tolerance deviation from plumb Individual straight piece (other than column) connecting to column Adjustable members 7.14 Correction of Errors

Correction of minor misfits by means of reaming, grinding, drawing of elements into line by drift pins, welding or cutting shall be considered normal erection operations. Errors that cannot be corrected by these means must be promptly reported to the Owners Designated Representative for Design and Construction. 7.15 Cuts, Alterations and Holes for Other Trades The Fabricator or the Erector may NOT cut, drill or otherwise alter their work to accommodate other trades unless work is specified in the Contract Documents. 7.16 Handling and Storage The Erector shall take reasonable care in the proper handling and storage of structural steel during erection to avoid excess dirt and foreign matter. However, it is not the Erectors responsibility to remove dirt or other foreign material that may accumulate during normal erection procedures.

Lecture 16 - Page 10 of 13

7.17 Field Painting The Fabricator or the Erector is NOT responsible to paint field bolts, or to touch-up abrasions of the shop coat, or to perform any field painting. 7.18 Final Cleaning Up Upon completion and acceptance, the Erector shall remove any of the Erectors falsework, scaffolding, rubbish and temporary structures. Section 8 QUALITY ASSURANCE 8.1 General The Fabricator shall maintain a quality assurance program to assure that the work is performed in accordance with this Code. 8.2 Inspection of Mill Material Certified mill test reports shall constitute sufficient evidence that the mill product satisfies material order requirements. 8.3 Non-Destructive Testing As per Contract Documents. 8.4 Surface Preparation and Shop Painting Inspection As per Contract Documents. 8.5 Independent Inspection Fabricator and Erector shall provide the Inspector with access to all places where work is being performed, and a minimum of 24 hours notice must be given prior to commencement of work. Inspector shall inspect work at shop as much as possible. Field inspections should be performed as promptly as possible. Deficiencies discovered by Inspector shall be reported to Fabricator and Erector as soon as possible. The Inspector shall NOT approve of any deviations from the Contract Documents without written approval from the Owners Designated Representative for Design and Construction.

Lecture 16 - Page 11 of 13

Section 9 CONTRACTS 9.1 Types of Contracts Lump sum price Price per pound Price per item Unit price

9.2 Calculation of Weights Weight is determined by calculation of gross weight of materials as shown on the Shop Drawings. This does NOT include shop and field weld metal or protective coatings. Deductions shall not be made for holes, copes, drilling or other removals for connections. Steel unit weight = 490 lb/ft3. 9.3 Revisions to Contract Documents Revisions to Contract Drawings shall be confirmed by change order or extra work order, and shall constitute authorization by the Owner that the revision is released for construction. 9.4 Contract Price Adjustment When the scope of work and responsibilities of the Fabricator and the Erector are changed, an appropriate modification to the contract price shall be made. Requests for contract price adjustments shall be presented to the Owner and approved/disapproved in a timely manner. 9.5 Scheduling The contract schedule shall state when the Design Drawings will be released for construction so that erection can start at the designated time and continue without interference or delay. 9.6 Terms of Payment Terms of payment shall be outlined in the Contract Documents.

Lecture 16 - Page 12 of 13

Section 10 ARCHITECTURALLY EXPOSED STRUCTURAL STEEL The rapidly increasing use of exposed structural steel as an aesthetic design medium has prompted the use of additional requirements that apply to these members. Typically they call for closer dimensional tolerances and smoother finished surfaces than for ordinary structural steel. 10.1 General Requirements When members are specifically designated in the Design Drawings as Architecturally Exposed Structural Steel, the requirements in Sections 1 through 9 shall apply as modified in Section 10. 10.2 Fabrication Permissible tolerances shall conform to ASTM A6. All copes, miters and cuts in surfaces exposed to view shall be made with uniform gaps of 1/8. All welds exposed to view shall not project more than 1/16 above the surface. Seams of hollow structural sections (HSS) shall be oriented away from view.

10.3 Delivery of Materials Fabricator shall take extra care and precautions to avoid bending, twisting or otherwise damaging the structural steel. 10.4 Erection Erector shall take extra care and precautions to minimize damage during handling and erection procedures. Unless otherwise noted, AESS members shall be plumbed, leveled and aligned to a tolerance that is that of non-AESS members.

Lecture 16 - Page 13 of 13

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Corporation and Partnership Law NotesDocument13 pagesCorporation and Partnership Law NotesKristine Joy TumbagaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Foundation Analysis and Design: Michael Valley, S.EDocument52 pagesFoundation Analysis and Design: Michael Valley, S.Esalahaddinsharif100% (3)

- Equivalent Frame Analysis For Slab Design Corley W.G., Jirsa J.O.Document10 pagesEquivalent Frame Analysis For Slab Design Corley W.G., Jirsa J.O.fukuroxyz100% (1)

- Pile Foundation DesignDocument82 pagesPile Foundation Designcuongnguyen89% (28)

- Transnational Organized CrimeDocument5 pagesTransnational Organized CrimeSalvador Dagoon JrNo ratings yet

- FLorida Code Flood Resistant ConstructionDocument9 pagesFLorida Code Flood Resistant ConstructionManoj JaiswalNo ratings yet

- Deed of Agreement On Investment and Financial Co-Operation: Otrust Global Company, Holder PassportDocument8 pagesDeed of Agreement On Investment and Financial Co-Operation: Otrust Global Company, Holder PassportVăn Thành TrầnNo ratings yet

- Offer LetterDocument2 pagesOffer LetterIpe ClosaNo ratings yet

- Republic v. FNCBDocument2 pagesRepublic v. FNCBBibi JumpolNo ratings yet

- RemediallawDocument25 pagesRemediallawGuya BanoNo ratings yet

- Abdulla v. PeopleDocument1 pageAbdulla v. PeopleMarc VirtucioNo ratings yet

- Roque Vs LapuzDocument2 pagesRoque Vs LapuzJames Evan I. ObnamiaNo ratings yet

- ASCE 7-22 NotesDocument4 pagesASCE 7-22 NotesManoj JaiswalNo ratings yet

- Conc Footing DesignDocument1 pageConc Footing DesignManoj JaiswalNo ratings yet

- Stair Connection - Metal Detail 5Document1 pageStair Connection - Metal Detail 5Manoj JaiswalNo ratings yet

- Conc Grade DesignDocument1 pageConc Grade DesignManoj JaiswalNo ratings yet

- Stair Connection - Metal Detail 2Document1 pageStair Connection - Metal Detail 2Manoj JaiswalNo ratings yet

- Stair Connection - Metal Detail 1Document1 pageStair Connection - Metal Detail 1Manoj JaiswalNo ratings yet

- Stair Connection - Metal Detail 2Document1 pageStair Connection - Metal Detail 2Manoj JaiswalNo ratings yet

- Stair Connection - Metal Detail 3Document1 pageStair Connection - Metal Detail 3Manoj JaiswalNo ratings yet

- Detail 4-Lintel 4Document1 pageDetail 4-Lintel 4Manoj JaiswalNo ratings yet

- Notches Shapes and DetailsDocument1 pageNotches Shapes and DetailsManoj JaiswalNo ratings yet

- Stair Connection - Metal Detail 3Document1 pageStair Connection - Metal Detail 3Manoj JaiswalNo ratings yet

- Stair Connection - Metal Detail 5Document1 pageStair Connection - Metal Detail 5Manoj JaiswalNo ratings yet

- Detail 2 - Concrete Beam DetailsDocument1 pageDetail 2 - Concrete Beam DetailsManoj JaiswalNo ratings yet

- Pile DesignDocument65 pagesPile DesignManoj JaiswalNo ratings yet

- Duct Anchorage SupportDocument8 pagesDuct Anchorage SupportManoj JaiswalNo ratings yet

- Duct Anchorage SupportDocument8 pagesDuct Anchorage SupportManoj JaiswalNo ratings yet

- AAI invites bids for Snack Bar facility at Kullu Manali AirportDocument22 pagesAAI invites bids for Snack Bar facility at Kullu Manali AirportManoj JaiswalNo ratings yet

- General Sheet NotesDocument1 pageGeneral Sheet NotesManoj JaiswalNo ratings yet

- P-752 Unit5Document94 pagesP-752 Unit5Josh JoshuaNo ratings yet

- SandyRA5DesignAboveBFE 508 FINAL2Document12 pagesSandyRA5DesignAboveBFE 508 FINAL2Manoj JaiswalNo ratings yet

- Bond Development Lengths and Hook-7-2-2016v1 PDFDocument11 pagesBond Development Lengths and Hook-7-2-2016v1 PDFManoj JaiswalNo ratings yet

- Design Consideration in FLood PRoofing PDFDocument52 pagesDesign Consideration in FLood PRoofing PDFManoj JaiswalNo ratings yet

- Flood Map - 12086C0612L Florida AreaDocument1 pageFlood Map - 12086C0612L Florida AreaManoj JaiswalNo ratings yet

- ASCE 7 - 10 Page Component & Cladding ForcesDocument1 pageASCE 7 - 10 Page Component & Cladding ForcesManoj JaiswalNo ratings yet

- ACI APP D Supplemental Reinf PDFDocument2 pagesACI APP D Supplemental Reinf PDFManoj JaiswalNo ratings yet

- Linterp 101 Rev1.1Document32 pagesLinterp 101 Rev1.1Manoj JaiswalNo ratings yet

- (Refugees and Stateless Persons) Submitted byDocument17 pages(Refugees and Stateless Persons) Submitted byMacoyPalNo ratings yet

- 10k Direct Payments Pro 1Document5 pages10k Direct Payments Pro 1ofallsstoresNo ratings yet

- Ateneo de Naga vs. ManaloDocument7 pagesAteneo de Naga vs. ManaloArianne BagosNo ratings yet

- Product Manual For ACCORDING To IS 1363 (Part 2) :2018: Annex - ADocument7 pagesProduct Manual For ACCORDING To IS 1363 (Part 2) :2018: Annex - Avelu.gNo ratings yet

- Condillac, Essay On The Origin of Human KnowledgeDocument409 pagesCondillac, Essay On The Origin of Human Knowledgedartgunn3445No ratings yet

- TK8A50D Field Effect Transistor SpecificationsDocument6 pagesTK8A50D Field Effect Transistor Specifications劉毛毛No ratings yet

- Coercion in Contract LawDocument17 pagesCoercion in Contract LawBba ANo ratings yet

- Contract Closeout FormDocument5 pagesContract Closeout FormMarvin Pavo0% (1)

- Service Letter: BeechcraftDocument17 pagesService Letter: Beechcraftahmed.19.77.4.5No ratings yet

- HYBRIFLEX 540 Sealant Technical Data SheetDocument3 pagesHYBRIFLEX 540 Sealant Technical Data SheetVirah Sammy ChandraNo ratings yet

- RPD Daily Incident Report 4/20/21Document6 pagesRPD Daily Incident Report 4/20/21inforumdocsNo ratings yet

- Dwelly Cauley v. United States, 11th Cir. (2010)Document5 pagesDwelly Cauley v. United States, 11th Cir. (2010)Scribd Government DocsNo ratings yet

- Know Your Rights Brochure 0110Document21 pagesKnow Your Rights Brochure 0110api-28723550No ratings yet

- HR Practices in Uco BankDocument7 pagesHR Practices in Uco BankShubhadeep SinghaNo ratings yet

- HORIZON Manpower ContractDocument3 pagesHORIZON Manpower ContractAngeilyn RodaNo ratings yet

- UP Land Reforms Act SummaryDocument101 pagesUP Land Reforms Act SummaryLalit SharmaNo ratings yet

- Report of Chapter 3 - Redfern and HunterDocument9 pagesReport of Chapter 3 - Redfern and HunterLucas Vasconcelos de LimaNo ratings yet

- Puteh Aman Power v Bittersweet Estates Mareva Injunction VariationDocument12 pagesPuteh Aman Power v Bittersweet Estates Mareva Injunction VariationsyamilteeNo ratings yet

- Yllana Bay View College: "The Builder of Future Leaders"Document4 pagesYllana Bay View College: "The Builder of Future Leaders"Criseljosa LacapagNo ratings yet

- BA5104 LEGAL ASPECTS OF BUSINESS Reg 2017 MBA Question BankDocument7 pagesBA5104 LEGAL ASPECTS OF BUSINESS Reg 2017 MBA Question BankAngemin AfexenaNo ratings yet

- License and Affiliation Agreement: B. LA Licensing AgreementDocument19 pagesLicense and Affiliation Agreement: B. LA Licensing AgreementWilliamsburg GreenpointNo ratings yet

- Barbados road safety overviewDocument1 pageBarbados road safety overviewBarbi PoppéNo ratings yet