Professional Documents

Culture Documents

15680

Uploaded by

Ratna TryOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15680

Uploaded by

Ratna TryCopyright:

Available Formats

15680

CHILLED WATER SYSTEMS

General The designer shall consult with the U-M Mechanical Design Coordinator and Plant Operations before making decisions on chilled water system type and configuration. Related Sections Special Instructions to Designers: SID-J University Provided Utilities SID-D Energy Conservation U-M Design Guideline Technical Sections: 15680 Water Chillers U-M Master Specification: 15680 Centrifugal Chillers 15681 Absorption Chillers 15515 Refrigerant leak detection 15516 Water Treatment 15975 Mechanical Systems Controls 15710 Cooling Towers Chiller Plant Sizing, Redundancy, Diversity, Future Growth, Emergency Power Calculate systems loads based on connected load (total of scheduled load at design condition) and peak diversified load (anticipated or measured actual peak load within a building or system that reflects diversity between loads). Base system sizing on peak diversified load (PDL). Consider potential need for future growth when calculating PDL. Consider need for system and equipment redundancy. For critical laboratory and animal facilities and for multiple building chiller plants provide plant with multiple chillers to provide N-1 redundancy (capacity that can meet PDL with largest chiller, pump or cooling tower out of service). For single building chiller plants, the design shall provide at least, sufficient redundancy for the critical portion of the facility. For building areas such as vivaria or certain hospital areas, requiring cooling operation during power outage, consider providing a smaller chiller connected to emergency power. Redundant pumping shall be considered normal for all installations. For multiple chillers, design systems to provide a single redundant condenser water pump and a single redundant chilled water pump that can be manually valved into service for the other pumps of the same service. Chilled Water Configuration

CHILLED WATER SYSTEMS 15680 PAGE 1 OF 4

OCTOBER, 2005

15680

In general, design systems with constant volume primary chilled water (through evaporator), with a decoupled variable flow secondary, with distribution based on two-way valve control of cooling coils. The decoupler pipe shall be sized to handle the full flow of the largest chiller. Chiller staging shall be via decoupler flow volume. For chiller plants of less than 1000 tons aggregate, serving a single building, variable volume primary systems may be considered with the approval of the U-M Project Coordinator, given a proper volumecontrolled bypass arrangement is provided to maintain minimum chilled water flow at the evaporator. For multiple building chilled water plants, design should normally indicate primary pumping, secondary distribution variable pumping and tertiary building pumping. The tertiary design should indicate a decoupled pumping arrangement with a modulating valve in the secondary return leg, which will maintain the tertiary at +1F above the distribution temperature. For plants that serve newer buildings, design for a minimum distribution temperature differential (delta T) of 15 F (eg. 44F CHWS/ 59F CHWR). For plants serving existing buildings, the existing coil performance must be considered when defining system temperatures. Design for Maintenance Design piping and machine placement so that complete machine overhaul, including motor replacement, may be performed without the removal of permanent piping. Provide permanent steel rail hoistways or other approved measures for this purpose. Where possible, locate chiller plant to minimize future work that will be required to replace the chiller. Design for Cleaning/Flushing Design system (include appropriate connections, etc.) such that, during construction, pipe cleaning and flushing can be conducted without contamination of the chiller. Design shall require provision of conical startup strainers at the chiller inlets and fine mesh pump startup strainers. Design shall incorporate temporary bypasses of cooling coils to avoid fouling coils during flushing and cleaning. Water Treatment Refer to U-M master specifications and guidelines. For systems over 400 tons, the design shall include chemical bulk storage adequate for a two month supply of chemical treatment and shall indicate a piping system for filling from a convenient grade-level loading area. Bulk systems shall be provided with double- wall storage vessels or other approved packaged base containment method. For smaller systems using 55 gallon chemical barrels, design shall include containment via a low, beveled curb that will allow wheeled hand truck passage along its length for barrel movement. Strainers and Filtration

OCTOBER, 2005

CHILLED WATER SYSTEMS 15680 PAGE 2 OF 4

15680

Basket strainers shall be provided for all cooling tower systems. In addition, provide coalescing type solids separators. Provide combination coalescing solids separator/air separators on the chilled water system. Sidestream separators shall be sized for at least one third of the full system flow. Free Cooling and Winter Cooling Where there is a significant winter chilled water load, consider free cooling (making winter chilled water utilizing a cooling tower and a plate-frame heat exchanger). Provide life cycle calculations in accordance with the Special Instructions to Designers (SID-J) Energy Conservation section. In addition to energy savings, free cooling can minimize low load short cycling. Filtration and wet-bulb approach controls shall be part of such a system. Winter-operated cooling towers and outdoor piping shall be winterized in accordance with the Design Guildeline section 15710 - Cooling Towers. Heat-trace systems shall be DDC controlled and monitored; separate programmable controllers are not permitted. Where winter chilled water demand is less than that practical for free cooling, provide a smaller indoor air cooled chiller with remote condenser connected in parallel with the larger chillers. Drained Condenser Water Piping If condenser water piping is intended to be drained down during off-season, consider the use of non-ferrous piping (stainless steel schedule 10 or other) for that section of piping to be drained to eliminate off-season corrosion of empty piping. Make provisions in the design (sight glasses and testing ports) so that risers within the building may be tested to insure treated water is present year-around. Chiller Room Noise and Vibration Consider noise and vibration criteria in mechanical room and adjacent area. Specify machine noise and vibration limits, and specify testing procedures. Evaluate the need for noise and vibration abatement to achieve acceptable noise levels. Controls Use of U-M standard control diagrams and sequences is preferred. Chillers enable, start/stop functions, sequencing, cooling tower operation and secondary pumps shall be controlled by the Building Automation System (BAS). Use of proprietary chiller or pump control packages is not permitted. Generally, primary chilled water pumps and condenser water pumps are started and stopped by the associated chiller, but where redundant pumps are provided, using BAS to start pumps can be considered. The design shall indicate manual selector switches, providing digital inputs to BAS, located at an auxiliary panel near the chillers for the following functions: o Select lead/lag chillers sequence.

CHILLED WATER SYSTEMS 15680 PAGE 3 OF 4

OCTOBER, 2005

15680

o Where BAS starts the pumps, to functionally connect the backup pump with the applicable chiller. Cooling tower filter or separator blow down valves shall be controlled as the first stage of tower blowdown via the water treatment panel. Generally, absorption chillers system design shall provide fixed constant condenser water temperature per design setpoint. Centrifugal systems design shall provide condenser water temperature reset; the chiller control panel shall generate a standard 4-20ma linear reset signal output to the BAS. BAS will reset condenser water setpoint, indexed against outside air wet bulb temperature. Water cooled chillers or chiller groups shall have full-sized condenser water three-way valve bypasses of the cooling tower. Two way valves may only be utilized where specifically approved. The valve shall be controlled by the BAS with pneumatic controlled back up. For combination absorption and centrifugal chiller plants, separate three way bypasses shall be designed to provide higher fixed temperature to absorption and resetable lower temperature to centrifugals. Control of water treatment shall be by the specified water treatment controller, which will report conductivity to the BAS. Metering Metering required: o Cooling tower make-up water metering and cooling tower blow-down metering shall be in accordance with the City of Ann Arbor requirements and these standards. Meter cooling tower makeup water separately from the building service. o For a chilled water plant serving multiple buildings, all utilities and services serving the generation of chilled water shall be metered separately from the building in which it resides. o Each separate building using central plant chilled water shall have chilled water BTU load metering via a magnetic flow meter in conjunction with a BTU meter and sensors with matched calibration in accordance with the U-M Master Specification section 15975 - Mechanical Systems Controls.

10/5/2005 1:54 PM

OCTOBER, 2005

CHILLED WATER SYSTEMS 15680 PAGE 4 OF 4

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Introduction To Music Theory: Inversions of ChordsDocument3 pagesIntroduction To Music Theory: Inversions of Chordsnaveenmanuel8879No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Scania DC09, DC13, DC16 Industrial Engines - Electrical System - CompressedDocument40 pagesScania DC09, DC13, DC16 Industrial Engines - Electrical System - CompressedMaurice ConnorNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Finite Element Project Abaqus TutorialDocument46 pagesFinite Element Project Abaqus TutorialhasibNo ratings yet

- 08PR167C - Loading and Unloading ProcedureDocument14 pages08PR167C - Loading and Unloading ProcedureRatna Try100% (1)

- Danfoss PVE - Series - 7 - Technical - Information PDFDocument56 pagesDanfoss PVE - Series - 7 - Technical - Information PDFJuan Felipe Garza GNo ratings yet

- ACL Injuries in The Female Athlete: Causes, Impacts, and Conditioning Programs Frank R. Noyes Sue Barber-WestinDocument658 pagesACL Injuries in The Female Athlete: Causes, Impacts, and Conditioning Programs Frank R. Noyes Sue Barber-WestinluizamgoNo ratings yet

- ECI Symposium Proceedings Optimizes Fouling Mitigation DesignDocument6 pagesECI Symposium Proceedings Optimizes Fouling Mitigation DesignJoseAndresCarreñoNo ratings yet

- Bus Network Topology GuideDocument8 pagesBus Network Topology GuideMjjames Manalo100% (1)

- Ships and Ship Terms ExplainedDocument12 pagesShips and Ship Terms ExplainedgamronNo ratings yet

- MVAC Testing & Commissioning Procedure - 2007Document245 pagesMVAC Testing & Commissioning Procedure - 2007spencersiu100% (6)

- 9th-Implementing Lockout Function With IEC61850 PDFDocument11 pages9th-Implementing Lockout Function With IEC61850 PDFBharath SaiNo ratings yet

- FB-04-A - Preventive Maintenance Check List (2020)Document1 pageFB-04-A - Preventive Maintenance Check List (2020)Ratna TryNo ratings yet

- Chemical Purchase ChecklistDocument2 pagesChemical Purchase ChecklistRatna TryNo ratings yet

- Business Plan OutlineDocument2 pagesBusiness Plan OutlineRatna TryNo ratings yet

- Magnetic BaseDocument2 pagesMagnetic BaseRatna TryNo ratings yet

- JHA Lifting-Moving Heavy Objects - ROMODocument5 pagesJHA Lifting-Moving Heavy Objects - ROMOsyafiqhashim1703No ratings yet

- Table of Factors and Terms For Bending FormulasDocument2 pagesTable of Factors and Terms For Bending FormulasRatna TryNo ratings yet

- Hazard IdentificationDocument5 pagesHazard IdentificationRatna TryNo ratings yet

- Office risk assessmentDocument8 pagesOffice risk assessmentGokul pNo ratings yet

- Hazard IdentificationDocument5 pagesHazard IdentificationRatna TryNo ratings yet

- Business Plan OutlineDocument2 pagesBusiness Plan OutlineRatna TryNo ratings yet

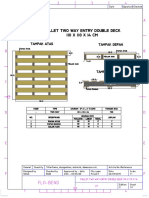

- Pallet 110x110x14 (4 Balok)Document1 pagePallet 110x110x14 (4 Balok)Ratna TryNo ratings yet

- Table of Factors and Terms For Bending FormulasDocument2 pagesTable of Factors and Terms For Bending FormulasRatna TryNo ratings yet

- Work Measurement Approach To Determine Standard Time in Assembly LineDocument4 pagesWork Measurement Approach To Determine Standard Time in Assembly Lineyogesh prajapatiNo ratings yet

- Evaluasi Penjadwalan Perawatan Mesin Hanger Shot Blast Kazo Dengan RCM Ii (Studi Kasus: Foundry Plant Perusahaan Manufaktur)Document6 pagesEvaluasi Penjadwalan Perawatan Mesin Hanger Shot Blast Kazo Dengan RCM Ii (Studi Kasus: Foundry Plant Perusahaan Manufaktur)Ratna TryNo ratings yet

- C Fe Exam Prep CourseDocument66 pagesC Fe Exam Prep CourseKunal Goldmedalist0% (1)

- MWM G 05Document118 pagesMWM G 05Ratna TryNo ratings yet

- Designing Either Chilled Beam or VAV Systems For High PerformanceDocument22 pagesDesigning Either Chilled Beam or VAV Systems For High PerformanceEdward SiuNo ratings yet

- 23 64 11 Packaged Water ChillersDocument10 pages23 64 11 Packaged Water ChillersRatna TryNo ratings yet

- DHC HandbookDocument86 pagesDHC HandbookLeto LimeurNo ratings yet

- 1956 - Colinese - Boiler Efficiencies in SugarDocument7 pages1956 - Colinese - Boiler Efficiencies in SugarPaul DurkinNo ratings yet

- Rational Expectation TheoryDocument7 pagesRational Expectation TheoryIsmith PokhrelNo ratings yet

- Welding robot aviation plug terminal definitionDocument4 pagesWelding robot aviation plug terminal definitionPhươngNguyễnNo ratings yet

- Transaction MR22-Cost Component Split in A Single Cost Component.Document4 pagesTransaction MR22-Cost Component Split in A Single Cost Component.vyigitNo ratings yet

- Maths Class VIII: Chapter As Per NCERT LessonsDocument1 pageMaths Class VIII: Chapter As Per NCERT Lessonsabhijeet_sangwanNo ratings yet

- Laminar Flow Reactor ProblemDocument6 pagesLaminar Flow Reactor ProblemAileen Banua Añonuevo100% (1)

- Basic Chromatography Notes 1Document27 pagesBasic Chromatography Notes 1Aufa InsyirahNo ratings yet

- Battery ModelingDocument6 pagesBattery ModelingmusabnajeebNo ratings yet

- Assignment2AI - 2023 Moderated2Document11 pagesAssignment2AI - 2023 Moderated2minajadritNo ratings yet

- Class - 8 PT3 - Portion 2023 24 - 1Document5 pagesClass - 8 PT3 - Portion 2023 24 - 1gurdeepbeniwal97No ratings yet

- IgE Level Effect of Phyllanthus Acidus Leaf ExtractDocument5 pagesIgE Level Effect of Phyllanthus Acidus Leaf Extractkhatami muhammadNo ratings yet

- Johannes KeplerDocument25 pagesJohannes KeplersigitNo ratings yet

- TheAndTecOfRocExcForCivEng Páginas 283 285,294 302,319 329,449 485Document60 pagesTheAndTecOfRocExcForCivEng Páginas 283 285,294 302,319 329,449 485Omar George Cayllahua SaicoNo ratings yet

- 4 UIUm 8 JHNDQ 8 Suj H4 NsoDocument8 pages4 UIUm 8 JHNDQ 8 Suj H4 NsoAkash SadoriyaNo ratings yet

- PLC Introduction: Programmable Logic Controller BasicsDocument3 pagesPLC Introduction: Programmable Logic Controller Basicssreekanthtg007No ratings yet

- Installation and Setup Guide For The Cisco Active Directory Agent, Release 1.0Document62 pagesInstallation and Setup Guide For The Cisco Active Directory Agent, Release 1.0Madelaine Velasquez Blacutt100% (1)

- Aqa MM1B W QP Jun07Document8 pagesAqa MM1B W QP Jun07Annan_Faridi_517No ratings yet

- Total Quality Management (TQM) ToolsDocument7 pagesTotal Quality Management (TQM) ToolsLaks_AsgNo ratings yet

- Project PPTDocument47 pagesProject PPTIshant KumawatNo ratings yet

- CSEC® Chemistry Past Papers January 2015Document20 pagesCSEC® Chemistry Past Papers January 2015Jonathan RamsundarNo ratings yet

- Structural Design of Penstock - Criteria: Indian StandardDocument21 pagesStructural Design of Penstock - Criteria: Indian StandardAlok KumarNo ratings yet

- DBMS Queries OverviewDocument98 pagesDBMS Queries OverviewAbhinay YadavNo ratings yet

- 3dsmax2013 PU06 Readme0Document6 pages3dsmax2013 PU06 Readme0Divad Zoñum CostaNo ratings yet