Professional Documents

Culture Documents

Copper LX SX EW

Uploaded by

Ricardo SandovalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Copper LX SX EW

Uploaded by

Ricardo SandovalCopyright:

Available Formats

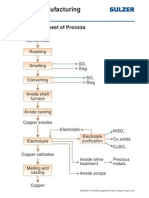

Copper Lx-Sx-Ew Manufacturing Process

General Flowsheet of Process

Ores Sulphuric acid Water Leaching Raffinate solution Pregnant leach solution Solvent extraction extraction stage Loaded organic Unloaded organic Solvent extraction washing stage Washed loaded organic Solvent extraction stripping stage Spent electrolyte Advance electrolyte Electrowinning Copper cathodes

V00672/01 (10.2000) Copyright Sulzer Pumps Finland Oy

Copper Lx-Sx-Ew Manufacturing Process

Pumps in Leaching Process (Lx)

Broken ores Ores low grade and semi-waste Low and medium grade H2SO4 H2SO4 H2O 6.APP/T 5.APP/T Autoclave Dump leaching Heap leaching H2O 6.APP/T Loading Crushing Agglomeration

Truck

5.APP/T

PLS Tank

PLS Tank

PLS Tank

ILS Tank

1.APP/T 1.APP/T

ILS Tank

ILS Tank

2.APP/T

RF Tank

2.APP/T

RF Tank

2.APP/T

RF Tank

1.APP/T

SX

3.APP/T 6.APP/T H2O

SX

6.APP/T

3.APP/T H2O

3.APP/T 6.APP/T H2O H2SO4 5.APP/T SX 4.APP/T Pregnant solution to solvent extraction SX

H2SO4 5.APP/T

5.APP/T RF-tanks

H2SO4

V00672/02 (10.2000) Copyright Sulzer Pumps Finland Oy

Copper Lx-Sx-Ew Manufacturing Process

Pumps in Leaching Process (Lx)

Liquid pH Copper 1 content g/l Temp. (oC, oF) Density (kg/m3, lb/ft3) 1150/ 72 1150/ 72 1100/ 69 1100/ 69 1830/ 114 1000/ 63 Typical head m, ft 5 - 20/ 16 - 66 5 - 20/ 16 - 66 5 - 20/ 16 - 66 1 - 20/ 3 - 66 1 - 10 3 - 33 1 - 10/ 3 - 33 Pump type Impeller type Seal type Material 2 Duty

Pregnant leach solution, H2SO4 1-5 g/l Intermediate leach solution, H2SO4 7-12 g/l Raffinate solution, H2SO4 10-15 g/l Raffinate solution, H2SO4 10-15 g/l Sulfuric acid, H2SO4 93-95% Process water

1-2

3.0 - 7.0

10 - 20/ 50 - 68 10 - 20/ 50 - 68 10 - 20/ 50 - 68 10 - 20/ 50 - 68 15 - 20/ 59 - 68 10 - 20/ 50 - 68

APP/T

Closed

Dyn. (DS01) /Double mech. (MR22) Dyn. (DS01) /Double mech. (MR22) Dyn. (DS01) /Double mech. (MR22) Dyn. (DS01) /Double mech. (MR22) Single mech. (MR02) Dynamic (DS01)

A890 3A

PLS to SX, from PLS pond ILS to leach, from ILS pond RF to leach, from RF pond RF to RF pond, from SX Process and make-up sulfuric acid Process and make-up water

1.0 - 2.0

APP/T

Closed

A890 3A

<1

0.2 - 0.8

APP/T

Closed

A890 3A

<1

0.5 - 1.0

APP/T

Closed

A890 3A

<1

APP/T

Closed

A890 3A

~7

APP/T

Closed

A890 3A

1) Dissolved 2) Material recommendation is only for specified application

V00672/03 (10.2000) Copyright Sulzer Pumps Finland Oy 28

Copper Lx-Sx-Ew Manufacturing Process

Pumps in Solvent Extraction Process (Sx)

Pregnant leach solution from leaching 2.APP/T Leaching RF After Settler 1.APP/T 3.APP/T RF Tank Water to RF tanks Leaching

Extraction

Washing 5.APP/T

Fresh Kerosene

4.APP/T Wash water tank Washed loaded organic tank Crud tank RF 8.APP/T

6.APP/T

Make-up 7.APP/T 10.APP/T

10.APP/T

Stripping 9.APP/T

RF 11.APP/T RF Spent electrolyte Advance electrolyte to electrowinning

V00672/04 (10.2000) Copyright Sulzer Pumps Finland Oy

Copper Lx-Sx-Ew Manufacturing Process

Pumps in Solvent Extraction Process (Sx)

Liquid pH Copper 1 Temp. Density g/l (oC, oF) (kg/m3, lb/ft3) 3.0 - 7.0 10 - 20/ 50 - 68 1.0 - 2.0 15 - 20/ 59 - 68 0.5 - 1.0 10 - 20/ 50 - 68 15 - 20/ 59 - 68 15 - 20/ 59 - 68 15 - 20/ 59 - 68 15 - 20/ 59 - 68 1150/ 72 900/ 56 1100/ 69 1000/ 62 1000/ 62 1830/ 114 1200/ 75 850/ 53 1200/ 75 850/ 53 1200/ 75 Typical head m, ft 5 - 20/ 16 - 66 1 - 5/ 3 - 16 1 - 20/ 3 - 66 1 - 5/ 3 - 16 1 - 5/ 3 - 16 1 - 5/ 3 - 16 1 - 10/ 3 - 33 1 - 5/ 3 - 16 1 - 10/ 3 - 33 1 - 5/ 3 - 16 1 - 10/ 3 - 33 Pump type APP/T Impeller type Closed Seal type Material 2 Duty

Pregnant leach solution, H2SO4 1-5 g/l Kerosene Raffinate solution, H2SO4 10-15 g/l Wash water, H2SO4 <45 g/l Demineralizated water Sulfuric acid, H2SO4 93-95% g/l Electrolyte bleed, H2SO4 165-175 g/l Kerosene Advance electrolyte, H2SO4 140-150 g/l

1-2

Dyn. (Ds01)/ Double mech. (MR22) Double mech. (MR20) Dyn. (DS01) /Double mech. (MR22) Dynamic seal (DS01) Dynamic seal (DS01) Dyn. (DS01) /Double mech. (MR22) Dyn. (DS01) /Double mech. (MR22) Double mech. (Mr20) Dyn. (DS01) /Double mech. (MR22) Dyn. (DS01) /Double mech. (MR22) Dyn. (DS01) /Double mech. (MR22)

A890 3A

PLS to SX, from PLS pond Organic removal RF to RF pond , from SX Wash water to washing stage Deminer. water to wash water tank Process sulfuric acid Electrolyte bleed to wash water tank Loaded organic to stripping stage Advance electrolyte to EW, from SX Crud to crud treatment system Spent electrolyte to SX, from EW

2 3

7 <1

APP/T APP/T

Open Closed

A890 3A A890 3A

4 5 6

<1 7 <1

APP/T APP/T APP/T

Closed Closed Closed

A890 3A A890 3A A890 3A

<1

30 - 35

APP/T

Closed

A890 3A

8 9

7 <1

5.0 - 8.0 15 - 20/ 59 - 68 45 - 55 40 - 50/ 104 122 15 - 20/ 59 - 68 40 - 50/ 104 122

APP/T APP/T

Open Closed

A890 3A A890 1B

10 Crud 11 Spent electrolyte, H2SO4 165-175 g/l

7 <1

30 - 40

APP/T APP/T

Closed Closed

A890 3A A890 1B

1) Dissolved 2) Material recommendation is only for specified application

V00672/05 (10.2000) Copyright Sulzer Pumps Finland Oy 30

Copper Lx-Sx-Ew Manufacturing Process

Pumps in Electrowinning Process (Ew)

Advance electrolyte from extraction

1.APP/T

Electrolyte tank

Cathodes Extraction 2.APP/T

2.APP/T Extraction Flotation 3.APP/T Extraction Leaching Extraction Condensate Heat exchanging Steam

Electrowinning

4.APP/T

5.APP/T Cathodes

Electrowinning

V00672/06 (10.2000) Copyright Sulzer Pumps Finland Oy

Copper Lx-Sx-Ew Manufacturing Process

Pumps in Electrowinning Process (Ew)

Liquid pH Copper 1 content g/l 45 - 55 Temp. (oC, oF) 40 - 50/ 104-122 15 - 20/ 59-68 15 - 20/ 59-68 40 - 50/ 104-122 40 - 50/ 104-122 Density Typical (kg/m3, head lb/ft3) m, ft 1200/ 75 850/ 53 1200/ 75 1200/ 75 1200/ 75 1 -10/ 3 - 33 1 - 5/ 3 - 16 1 -10/ 3 - 33 1 - 10/ 3 - 33 1 - 5/ 3 - 16 Pump type APP/T Impeller type Closed Seal type Material 2 Duty

Advance electrolyte, H2SO4 140-150 g/l Kerosene

<1

Dyn (DS01) /Double mech. (MR22) Double mechanical (MR20) Dyn (DS01) /Double mech. (MR22) Dyn. (DS01) /Double mech. (MR22) Dyn. (DS01) /Double mech. (MR22)

A890 1B

Advance electrolyte to EW, from SX Organic removal to SX Electrolyte bleed to wash water tank Spent electrolyte to SX, from EW Electrolyte to commercial cells

5.0 - 8.0

APP/T

Closed

A890 3A

Electrolyte bleed, H2SO4 165-175 g/l Spent electrolyte, H2SO4 165-175 g/l electrolyte, H2SO4 160-170 g/l

<1

30 - 35

APP/T

Closed

A890 3A

<1

30 - 40

APP/T

Closed

A890 1B

<1

35 - 40

APP/T

Closed

A890 1B

1) Dissolved 2) Material recommendation is only for specified application 3) The floating installation of the pumps in Electrowinning process

V00672/07 (10.2000) Copyright Sulzer Pumps Finland Oy 32

You might also like

- Pre-Feasibility Studies of Copper Hydrometallurgical PlantsDocument29 pagesPre-Feasibility Studies of Copper Hydrometallurgical Plantsjoseph kafumbila100% (10)

- Modelling of Heap Leaching (Full Thesis Text)Document116 pagesModelling of Heap Leaching (Full Thesis Text)Alexey Cherkaev100% (2)

- Design of Wash Stage in Copper Solvent ExtractionDocument36 pagesDesign of Wash Stage in Copper Solvent Extractionjoseph kafumbila100% (2)

- Design of Copper Electrowinning Circuit Using Conventional CellsDocument59 pagesDesign of Copper Electrowinning Circuit Using Conventional Cellsjoseph kafumbila95% (20)

- SX Mixer-Settler DesignDocument10 pagesSX Mixer-Settler Designmario_acevedoNo ratings yet

- Stage Efficiency in Copper Solvent Extraction PlantsDocument9 pagesStage Efficiency in Copper Solvent Extraction PlantsPatricio AcuñaNo ratings yet

- AAA - Beneficiation of Iron Ore by Flotation - Review of Industrial and Potential ApplicationsDocument22 pagesAAA - Beneficiation of Iron Ore by Flotation - Review of Industrial and Potential Applicationsmehra222No ratings yet

- Electrowinning and Electrorefining of Copper (Murdoch University)Document76 pagesElectrowinning and Electrorefining of Copper (Murdoch University)Victor100% (8)

- Prediction Method For Equilibrium Values in Copper Solvent Extraction in Sulfate System - Effect of Ionic StrengthDocument29 pagesPrediction Method For Equilibrium Values in Copper Solvent Extraction in Sulfate System - Effect of Ionic Strengthjoseph kafumbilaNo ratings yet

- SimSXCu Full Version 2.0Document345 pagesSimSXCu Full Version 2.0joseph kafumbila50% (4)

- Advances in Gold ProcessingDocument9 pagesAdvances in Gold Processingjavicol70No ratings yet

- Cytec Solutions 7Document16 pagesCytec Solutions 7Баттөр Уртнасан100% (1)

- Gold Electrowinning From Diluted Cyanide Liquors PDFDocument12 pagesGold Electrowinning From Diluted Cyanide Liquors PDFAlguienNo ratings yet

- Copper Hydrometallurgy ProcessDocument80 pagesCopper Hydrometallurgy ProcessPedro Camero Hermoza100% (1)

- Recovery of Nickel From PAL Disc LiquorsDocument15 pagesRecovery of Nickel From PAL Disc LiquorsKtishna100% (1)

- Metallurgical Accounting: AMIRA's P754 Code of Practice in ItsDocument2 pagesMetallurgical Accounting: AMIRA's P754 Code of Practice in ItsEngineering Office Shahrak100% (1)

- Cytec Solutions 14 FinalDocument24 pagesCytec Solutions 14 FinalAnonymous KDM8wArgNo ratings yet

- Developments Hydrometallurgical Treatment of Copper ConcentratesDocument27 pagesDevelopments Hydrometallurgical Treatment of Copper Concentratesjose amezquita100% (1)

- Electrowinning Course Notes HydrometallurgyDocument68 pagesElectrowinning Course Notes HydrometallurgyGhassen Rojbi100% (7)

- Investments Summary of Plant Equipment CostsDocument13 pagesInvestments Summary of Plant Equipment CostsRandhu AronNo ratings yet

- Copper Production Technology: A Brief History and OverviewDocument47 pagesCopper Production Technology: A Brief History and OverviewHolgerBrand100% (1)

- Progress On Geoenvironmental Models For Selected Mineral DepositDocument217 pagesProgress On Geoenvironmental Models For Selected Mineral DepositJHOEL_GEONo ratings yet

- David Dreisinger Presentation On ZincDocument55 pagesDavid Dreisinger Presentation On ZincRoger Rumbu100% (2)

- Jiangsu Lithium Carbonate PlantDocument4 pagesJiangsu Lithium Carbonate PlantpetroloritoNo ratings yet

- Interpretation of Flotation Data For The Design of Process PlantsDocument28 pagesInterpretation of Flotation Data For The Design of Process PlantshNo ratings yet

- High Pressure Acid Leach & Pressure Oxidation TestingDocument4 pagesHigh Pressure Acid Leach & Pressure Oxidation TestingReece100% (1)

- The Direct Electrowinning of Gold From Dilute Cyanide Leach LiquorsDocument15 pagesThe Direct Electrowinning of Gold From Dilute Cyanide Leach LiquorsLennonNo ratings yet

- OTE Copper SX-EW Technology Eng WebDocument12 pagesOTE Copper SX-EW Technology Eng WebRavian LhrNo ratings yet

- CIP/CIL/CIC Adsorption Circuit Process Selection GuideDocument8 pagesCIP/CIL/CIC Adsorption Circuit Process Selection GuideSheila Mae GardonNo ratings yet

- Galaxy Resources ReportDocument28 pagesGalaxy Resources Reportokeydokey01No ratings yet

- Copper SX-EW Technology: Our Solution For Leaching, Solvent Extraction and ElectrowinningDocument12 pagesCopper SX-EW Technology: Our Solution For Leaching, Solvent Extraction and Electrowinningjose alejandro venegas sucllaNo ratings yet

- Hydro Metallurgy of Complex Sulfide Ores by P. Dharma RaoDocument172 pagesHydro Metallurgy of Complex Sulfide Ores by P. Dharma RaoFerudun Akyol100% (1)

- 03 - Heap Leaching Technique in Mining Within The Context of Best Available Techniques PDFDocument33 pages03 - Heap Leaching Technique in Mining Within The Context of Best Available Techniques PDFUlfa RianiNo ratings yet

- Electrowinning of Cobalt From Acidic Sulphate Solutions-Effect of Chloride IonDocument9 pagesElectrowinning of Cobalt From Acidic Sulphate Solutions-Effect of Chloride IontabatabayiNo ratings yet

- Mineral ProcessingDocument2 pagesMineral Processingbhati_mukesh8933% (3)

- Hidrometallurgy of CobaltDocument11 pagesHidrometallurgy of CobaltJorge Alexander Rocha Alvarez100% (4)

- Recent operation and environmental control in the Kennecott SmelterDocument17 pagesRecent operation and environmental control in the Kennecott SmelterHat CopterNo ratings yet

- 01 1500 David DreisingerDocument74 pages01 1500 David DreisingerJaime MercadoNo ratings yet

- IM World Lithium Map 2015 PDFDocument1 pageIM World Lithium Map 2015 PDFKiran JojiNo ratings yet

- Metallurgical Performance Analysis of Froth Flotation Plant From Material BalaneDocument18 pagesMetallurgical Performance Analysis of Froth Flotation Plant From Material Balanejoseph kafumbilaNo ratings yet

- Material Balance in Froth Flotation (Excel File Additional Document)Document4 pagesMaterial Balance in Froth Flotation (Excel File Additional Document)joseph kafumbila100% (1)

- Cy Tec Solutions 8Document12 pagesCy Tec Solutions 8Edwin AnccoNo ratings yet

- Metsim Print 2018 PDFDocument1 pageMetsim Print 2018 PDFWalter Andrés OrqueraNo ratings yet

- CIP-Carbon in Pulp gold recoveryDocument1 pageCIP-Carbon in Pulp gold recoverySammy OmbiroNo ratings yet

- GoldDocument6 pagesGoldPaul CaballeroNo ratings yet

- Design of Agitated Leach CircuitDocument80 pagesDesign of Agitated Leach Circuitjoseph kafumbilaNo ratings yet

- A New Approach To Metallurgical Accounting: October 2012Document8 pagesA New Approach To Metallurgical Accounting: October 2012Cesar Francisco Quispe RomeroNo ratings yet

- IsaMill Carbon Presentation BHPB Nov 07Document56 pagesIsaMill Carbon Presentation BHPB Nov 07Manuel Leiva CerdaNo ratings yet

- Appendix 20 - Cyanide Facility Decommissioning Plan (ICM Code Principle 5) For Kalgoorlie Consolidated Gold MinesDocument38 pagesAppendix 20 - Cyanide Facility Decommissioning Plan (ICM Code Principle 5) For Kalgoorlie Consolidated Gold MinesPaipinpokoNo ratings yet

- Emerging Technology Contact CellDocument10 pagesEmerging Technology Contact Cellsnarf273No ratings yet

- Industrial Use of Nitrogen in Flotation of MolybdeniteDocument4 pagesIndustrial Use of Nitrogen in Flotation of MolybdenitedanisaNo ratings yet

- Copper Production ProcessDocument28 pagesCopper Production ProcessTolstoy LeoNo ratings yet

- Copper Manufacturing Process: General Flowsheet of ProcessDocument28 pagesCopper Manufacturing Process: General Flowsheet of ProcessflaviosazevedoNo ratings yet

- Singhania-CO2 INERTISATION SYSTEM DataDocument12 pagesSinghania-CO2 INERTISATION SYSTEM DataAnandharaj .KNo ratings yet

- W.T.P Alarm List: Tabdil Energy PayaDocument3 pagesW.T.P Alarm List: Tabdil Energy PayaepbamdadNo ratings yet

- Tac PDFDocument3 pagesTac PDFfonsecaglNo ratings yet

- Qautet, 100 and 150 LPH Ro SystemDocument3 pagesQautet, 100 and 150 LPH Ro SystemSrinivas SriNo ratings yet

- NHT OperationsDocument61 pagesNHT OperationsIrfan Shahzad75% (4)

- Dissolved O2 AnalyzersDocument3 pagesDissolved O2 AnalyzerssolbahiaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Albaniapresentation PDFDocument23 pagesAlbaniapresentation PDFRicardo SandovalNo ratings yet

- Albania PresentationDocument23 pagesAlbania PresentationRicardo SandovalNo ratings yet

- Guibal 2001 - Variography A Tool For The Resource GeologistDocument6 pagesGuibal 2001 - Variography A Tool For The Resource GeologistRicardo SandovalNo ratings yet

- Gringarten Deutsch 2001 - Variogram Interpretation and ModelingDocument28 pagesGringarten Deutsch 2001 - Variogram Interpretation and ModelingFabián CárdenasNo ratings yet

- Quick Reference Guide To Heat TreatingDocument1 pageQuick Reference Guide To Heat TreatingArtisan IdeasNo ratings yet

- MaklumatDocument1 pageMaklumatمحمد رحيميNo ratings yet

- 2014 MR - Metal-Layer Capacitors in The 65 NM CMOS Process and The Application For Low-Leakage Power-Rail ESD Clamp CircuitDocument7 pages2014 MR - Metal-Layer Capacitors in The 65 NM CMOS Process and The Application For Low-Leakage Power-Rail ESD Clamp CircuitspaulsNo ratings yet

- GEPCO Phones TelenorDocument5 pagesGEPCO Phones TelenorAwais Farrukh ButtNo ratings yet

- CEEMIS AgenciesDocument33 pagesCEEMIS AgenciesAnon0o0100% (2)

- Designing Memory Array Subsystems CH 12 PDFDocument87 pagesDesigning Memory Array Subsystems CH 12 PDFrao rehNo ratings yet

- ACBr Boleto FCFortes FRDocument96 pagesACBr Boleto FCFortes FRAldy SalvinoNo ratings yet

- Mitsubishi 1Document36 pagesMitsubishi 1Юрий СавчукNo ratings yet

- MOSFET Seminar: An Introduction to the Metal-Oxide-Semiconductor Field-Effect TransistorDocument23 pagesMOSFET Seminar: An Introduction to the Metal-Oxide-Semiconductor Field-Effect TransistorRahulKushwahaNo ratings yet

- VvlsiDocument7 pagesVvlsiBhaskar KNo ratings yet

- Graphics Timeline 1Document5 pagesGraphics Timeline 1api-358369971No ratings yet

- Short Stories RC - Juanita Does The LaundryDocument1 pageShort Stories RC - Juanita Does The LaundryandreidmannnNo ratings yet

- Social Icons: C-80 GradeDocument3 pagesSocial Icons: C-80 GradeEdward OropezaNo ratings yet

- Semiconductors DiscretesDocument96 pagesSemiconductors Discretespacho2117100% (4)

- Smithy Workshop ManualDocument11 pagesSmithy Workshop ManualshahzaibNo ratings yet

- Comparison of Metalizing Vs Hot Dip GalvanizingDocument2 pagesComparison of Metalizing Vs Hot Dip GalvanizingKanishk100% (1)

- BOOST THE POWER OF WATERDocument8 pagesBOOST THE POWER OF WATERNAVEEN JATNo ratings yet

- 1 Staff Salary & House Rent 1,165,833.00 2 Imprest 640,764.00 3 Transportion & Taxi 887,549.00 4 Other Expenses 155,088.00Document89 pages1 Staff Salary & House Rent 1,165,833.00 2 Imprest 640,764.00 3 Transportion & Taxi 887,549.00 4 Other Expenses 155,088.00KA25 ConsultantNo ratings yet

- B.tech Welding LAb QuestionsDocument2 pagesB.tech Welding LAb QuestionsArg SreekarNo ratings yet

- Unit 2 Welding III HazDocument9 pagesUnit 2 Welding III HazHada NanuNo ratings yet

- Rolling Process Explained: Hot vs Cold Rolling and UsesDocument3 pagesRolling Process Explained: Hot vs Cold Rolling and UsesMuhammad YasirNo ratings yet

- Mumetal Permimphy Supermimphy EngDocument10 pagesMumetal Permimphy Supermimphy Englemco7777No ratings yet

- Hilti Anchor Specification GuidelineDocument3 pagesHilti Anchor Specification GuidelineenggmohanNo ratings yet

- Mineral Processing MillingDocument6 pagesMineral Processing MillingMohsin KhanNo ratings yet

- Machining: Machining Is Any of Various Processes in Which A Piece of RawDocument7 pagesMachining: Machining Is Any of Various Processes in Which A Piece of RawAshwin KumarNo ratings yet

- Bus Bar Ampacity Table Ampacities of Copper Bus Bars Alloy Uns C11000Document6 pagesBus Bar Ampacity Table Ampacities of Copper Bus Bars Alloy Uns C11000edalzurcNo ratings yet

- Specification of Steel BarDocument1 pageSpecification of Steel BarsutrisnoNo ratings yet

- Fabrication of MosfetDocument19 pagesFabrication of Mosfetnarayana89% (9)

- Cadence Virtuoso layout of minimum size CMOS inverterDocument11 pagesCadence Virtuoso layout of minimum size CMOS inverterNavid Anjum AaditNo ratings yet

- CH-24-Stainless Steel Notes PDFDocument7 pagesCH-24-Stainless Steel Notes PDFArvind RaguNo ratings yet