Professional Documents

Culture Documents

TT Bearing Insp Proc v3

Uploaded by

Rino AdityaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TT Bearing Insp Proc v3

Uploaded by

Rino AdityaCopyright:

Available Formats

Manitowoc Cranes 1565 Buchanan Trail East PO Box 21 Shady Grove, PA 17256-0021 T 717 597 8121 F 717 593

5999 www.manitowoc.com

Service Bulletin G08-043

Information Only Product Update - Warranty Product Update - Non Warranty Action Required

Date

December 15, 2008

To

All Mobile Hydraulic Distributor Service Managers

Subject

Measuring and Recording of Turntable Bearing Vertical Movement

Model(s) Affected

All

Please remind Grove Crane owners/users of the importance of performing routine inspections and maintenance of turntable bearings. The required inspection protocol for turntable bearing vertical movement is described in this Service Bulletin. This Service Bulletin replaces Service Bulletin G04-013. A. INSPECTION AND ADJUSTMENT OF TURNTABLE BEARING ATTACHMENT BOLTS

It is imperative to ensure the turntable bearing attachment bolts are properly torqued. Therefore, all bearing attaching bolts must be inspected for lack of torque and retorqued, as required, in accordance with the following schedule as the bolts may loosen in service due to vibration, shock-loads and temperature changes: 1. Grove Designed AT/RT/TMS (except TMS900E & TMS9000E) and Industrial Cranes

All bearing attaching bolts must be inspected after the first 300 hours of crane operation and every 500 hours of crane operation thereafter. 2. KMK/GMK Designed AT Cranes and Grove Designed TMS900E & TMS9000E Cranes

All bearing attaching bolts must be inspected every 300 hours of crane operation or every three months.

Page 2

WARNING: Failure to maintain proper torque of the turntable bearing attaching bolts may result in serious injury or death as well as damage to the crane and other property. Maintaining proper torque value for bolts is extremely important for structural strength, performance and reliability of the crane. Variations in torque can cause distortion, binding, or complete separation of the superstructure from the carrier. CAUTION: Repeated re-torquing may cause bolts to stretch. If bolts keep working loose, they must be replaced with new bolts of the proper grade and size. Proper identification of bolt grade is important. When marked as a high strength bolt (grade 8), the serviceman must be aware of bolt classifications and that he is installing a high strength heat-treated tempered component and the bolt must be installed according to specifications. Special attention should be given to the existence of lubricant and plating that will cause variation from dry torque values. When a high strength bolt is removed, or un-torqued, the bolt must be replaced with a new bolt of the same classification. B. INSPECTION AND LUBRICATION OF TURNTABLE BEARINGS

For the continued satisfactory operation of cranes, turntable bearings must be routinely lubricated and inspected for wear. Please see the Service Manual for complete inspection and lubrication instructions. C. PROCEDURE BEARINGS FOR MEASURING VERTICAL MOVEMENT IN TURNTABLE

If you suspect that there is too much vertical movement in the turntable bearing on an affected crane, measure the vertical movement in accordance with the procedure attached to this Service Bulletin. The procedure describes the proper method for measuring the vertical movement in turntable bearing and includes a list of equipment required, step by step instructions, and a form to record the required information. Please note that the dial indicator must be placed as close to the outer perimeter of the turntable bearing as possible and must be adjusted to zero when performing this procedure. The procedure includes a list of bearing part numbers and the maximum acceptable axial movement for each part number. If your readings exceed the maximum acceptable limit or the bearing is rough or binding when swinging, the bearing must be replaced. For any bearings not listed, the information must be sent to Crane Care for evaluation. Record the dimensions on the attached form and forward it to crane care where it will become a permanent part of the unit file. Manitowoc Crane Care

Page 3

TURNTABLE BEARING VERTICAL MOVEMENT MEASURING PROCEDURE Equipment required: 1. Dial indicator with a magnetic base (calibration to have been checked within the last 90 days.) 2. Carpenters level. 3. "Erick Miracle Point or equivalent calibrated electronic boom angle indicator for boom elevation (not required if the unit is equipped with a calibrated electronic boom angle indicator.) Procedure: NOTE: During this procedure, the crane shall be set up with the minimum amount of counterweight and the boom extension shall be either in the stowed position or removed. 1. Position the unit on a firm level surface. 2. If the unit is equipped with outriggers, fully extend the outriggers and raise the unit until all wheels are clear of the ground. 3. Using the procedure in the applicable manual, check to assure the torque on all the turntable bearing bolts is correct. 4. If applicable, fully extend the counterweight to the working position. 5. Thoroughly clean the upper (superstructure) and the lower (carrier) bearing mounting plates. 6. Place a carpenters level on the lower bearing mounting plate. If the unit is equipped with outriggers, raise and lower the outriggers as required to level the unit front to rear and side to side. If the unit is not equipped with outriggers, it may be necessary to crib under the wheels to level the unit. NOTE: If the unit is not equipped with a calibrated electronic boom angle indicator, an "Erick Miracle Point" or an equivalent indicator must be attached to the boom. 7. With boom fully retracted, elevate the boom to the maximum elevation. 8. Swing the boom over the right front outrigger. 9. Position the dial indicator as shown in Figure 1 with the magnetic base on the lower bearing mounting plate at a point directly under the centerline of the boom, and as close to the outer

Page 4

perimeter of the turntable bearing as possible. Adjust the dial indicator so it is against the upper bearing mounting plate and zero the indicator. 10. Lower the boom to horizontal (0) degrees for Grove Designed AT/RT/TMS (except TMS900E & TMS9000E) and Industrial Cranes. Lower the boom to ten (10) degrees KMK/GMK Designed AT Cranes and Grove Designed TMS900E & TMS9000E Cranes 11. Record the reading on the dial indicator in the appropriate space on the form. 12. Remove the dial indicator and its magnetic base. 13. Repeat steps (7 through 13) at each of the other three outrigger locations (i.e. right rear, left rear, left front.) 14. If your turntable bearing is not on the attached list, please forward this information to Crane CARE for evaluation and reply. Please forward all evaluation forms to Crane Care for inclusion in the unit history

file.

Page 5

Page 6

Page 7

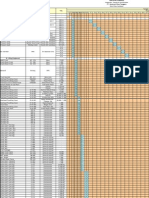

Grove P/N 7069000048 7069000118 7069000120 7069000121 7069000122 7069000125 7069000169 7069000188 7069000225 7069000230 7069000243 7069000247 7069000249 7069000253 7069000256 7069000261 7069000264 7069000272 7069000283 7069000284 7069000290 7069000294 7069000295 7069000311 7069000312 7069000323 7069000324 7069000329 7069000342 7069000343 7069000352 7069000353 7069000365 7069000366 7069000369 7069000376 7069000377 7069000391 European P/N 6069990064

(in.) 0.063 0.084 0.112 0.108 0.112 0.108 0.141 0.125 0.037 0.090 0.100 0.112 0.084 0.108 0.090 0.112 0.125 0.140 0.108 0.108 0.108 0.132 0.121 0.141 0.100 0.132 0.132 0.108 0.065 0.060 0.065 0.065 0.088 0.088 0.055 0.100 0.112 0.065 (in.) 0.121

Grove P/N 7069000392 7069000406 7069000410 7069000416 7069000420 7069000448 7069000458 7069000459 7069001048 7069001063 7069001085 7069001095 7069001122 7069001126 7069001127 7069001133 7069001158 7069001159 7069001162 7069001165 7069001166 7069001177 7069001191 7069001192 7069001230 7069100038 7069100068 7069100072 7069100081 7069100090 7069102041 7069102055 7069102067 7069102074 7069102076 7069102079 7069800000

(in.) 0.065 0.125 0.084 0.100 0.075 0.115 0.060 0.060 0.055 0.065 0.085 0.085 0.055 0.115 0.075 0.065 0.125 0.084 0.132 0.100 0.141 0.121 0.060 0.060 0.105 0.075 N/A 0.102 0.085 0.085 0.090 0.090 0.090 0.090 0.070 0.090 0.140

You might also like

- SB G13-005 TT Bearing Movement PDFDocument7 pagesSB G13-005 TT Bearing Movement PDFDeepak MishraNo ratings yet

- SB G20 011 Measuring and Recording of Turntable BearingDocument8 pagesSB G20 011 Measuring and Recording of Turntable BearingCristyan GabrielNo ratings yet

- Sebf 8054 Обмеры и Правка КвDocument33 pagesSebf 8054 Обмеры и Правка КванджелаNo ratings yet

- SET UP AND USE OPTICAL ALIGNMENT GAUGEDocument3 pagesSET UP AND USE OPTICAL ALIGNMENT GAUGEUchenna AkintayoNo ratings yet

- SPANCO PFseries Gantry Instparts Manual 103 0003Document12 pagesSPANCO PFseries Gantry Instparts Manual 103 0003raulcont786No ratings yet

- Combitiller Instruction Manual Spare Parts GuideDocument62 pagesCombitiller Instruction Manual Spare Parts GuideMessi EmetievNo ratings yet

- Erection & Installation ProcedureDocument3 pagesErection & Installation ProcedureForos IscNo ratings yet

- SB1208 - ZF As Tronic - Clutch Component LubricationDocument12 pagesSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNo ratings yet

- Engine Alignment DetailsDocument13 pagesEngine Alignment DetailsNaufal HilmiNo ratings yet

- 8013 Instruction Manual For Camflex and VarimaxDocument10 pages8013 Instruction Manual For Camflex and Varimaxtoche33No ratings yet

- Manual OTC Jack TransmisionDocument3 pagesManual OTC Jack Transmisionlucass1No ratings yet

- Manual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)Document15 pagesManual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)victoranticonajicaro100% (1)

- Install, operate and maintain VCP pumpsDocument21 pagesInstall, operate and maintain VCP pumpsKaushik ChakrabortyNo ratings yet

- Erection Procedure SCRDocument23 pagesErection Procedure SCRvskreddy90% (10)

- 722.9, 7G-Tronic NAG2 Uncomfortable Shift QualityDocument3 pages722.9, 7G-Tronic NAG2 Uncomfortable Shift QualityИгорь НаумовNo ratings yet

- Warning: Complete Gearbox With MotorDocument35 pagesWarning: Complete Gearbox With MotorSinaNo ratings yet

- Operation & Maintenance Manual for End Suction PumpsDocument25 pagesOperation & Maintenance Manual for End Suction PumpsNorizah OnieNo ratings yet

- Helical Inline Geared Motors Manual PDFDocument24 pagesHelical Inline Geared Motors Manual PDFHEMANTKHERA0% (2)

- Chip Conveyor Manual (Direct Drive)Document10 pagesChip Conveyor Manual (Direct Drive)Roberto RamírezNo ratings yet

- Chip Conveyor Manual (Direct Drive)Document10 pagesChip Conveyor Manual (Direct Drive)Roberto RamírezNo ratings yet

- TMS9000 2 SM CTRL649 01 SPANISH With Alignment Supp Light PDFDocument414 pagesTMS9000 2 SM CTRL649 01 SPANISH With Alignment Supp Light PDFJhonnatan Alexis roaNo ratings yet

- Acoplamiento Sure-Flex Couplings PDFDocument4 pagesAcoplamiento Sure-Flex Couplings PDFFederico Pérez de LeónNo ratings yet

- IOM Actuator AutomaxSupernovaDocument4 pagesIOM Actuator AutomaxSupernovaNaser JahangiriNo ratings yet

- Tms700e13 SM Ctrl512 01 Spanish With Alignment SuppDocument390 pagesTms700e13 SM Ctrl512 01 Spanish With Alignment SuppVictor VegaNo ratings yet

- AUMA Valve ActuatorDocument14 pagesAUMA Valve ActuatorSellappan MuthusamyNo ratings yet

- Operatiion & Maintenance Instructions Sharpe Mixers - Side Entry With SealDocument16 pagesOperatiion & Maintenance Instructions Sharpe Mixers - Side Entry With Sealrongweius100% (1)

- General inspection and leveling of a Reed-Prentice latheDocument25 pagesGeneral inspection and leveling of a Reed-Prentice latheMikelyn Anderson100% (2)

- c20547 PDFDocument34 pagesc20547 PDFGuillermo Andrés CoupeNo ratings yet

- Torque Screwdriver ManualDocument16 pagesTorque Screwdriver ManualFrancisco Ros AlvaradoNo ratings yet

- SDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Document15 pagesSDS28-6-5 - 380V-3-50Hz - IOM Rev 1.0 201509Ali YükselNo ratings yet

- 7HB (A, B, C, D, E, X) Assembly-Disassembly ManualDocument33 pages7HB (A, B, C, D, E, X) Assembly-Disassembly ManualYavuz Ercanli100% (1)

- 6 SteeringDocument63 pages6 SteeringAdrian MotocNo ratings yet

- Valve Lash G3408Document9 pagesValve Lash G3408Djebali MouradNo ratings yet

- ML-1600 Manual Die Cutting Creasing Machine Operating InstructionsDocument11 pagesML-1600 Manual Die Cutting Creasing Machine Operating InstructionsTaposhNo ratings yet

- 126e PTP Shale Shaker Operations ManualDocument13 pages126e PTP Shale Shaker Operations ManualAndrew GoadNo ratings yet

- Multigraphics 1450/1650 Heavy-Duty Drive Motor Conversion KitDocument8 pagesMultigraphics 1450/1650 Heavy-Duty Drive Motor Conversion KitporqNo ratings yet

- Mitsubishi Transfer Case Recall BulletinDocument20 pagesMitsubishi Transfer Case Recall BulletinSteven LewisNo ratings yet

- Manual Stinger Mts FTDocument16 pagesManual Stinger Mts FTFabian Andres CelyNo ratings yet

- Installation, Operation, & Maintenance Manual: Wall Mounted Articulating Jib CraneDocument12 pagesInstallation, Operation, & Maintenance Manual: Wall Mounted Articulating Jib CraneFernando Gonzales HNo ratings yet

- Cook INSTALLATION, OPERATION, AND MAINTENANCE MANUALDocument12 pagesCook INSTALLATION, OPERATION, AND MAINTENANCE MANUALtylerdurdaneNo ratings yet

- Alignment of Diesel Generator Sets With The Two-Bearing GeneratorDocument10 pagesAlignment of Diesel Generator Sets With The Two-Bearing Generatorwillian100% (3)

- C107C1 - CAT TH580B Chain Shackles - Dist PDFDocument15 pagesC107C1 - CAT TH580B Chain Shackles - Dist PDFBart JohnNo ratings yet

- Tms700e13 SM Ctrl512-01 SpanishDocument390 pagesTms700e13 SM Ctrl512-01 Spanishjose veraNo ratings yet

- Dodge DGF Gear Couplings: Instruction ManualDocument2 pagesDodge DGF Gear Couplings: Instruction ManualTony_Black99No ratings yet

- Sensenich Ground Adjustable Propeller Log BookDocument12 pagesSensenich Ground Adjustable Propeller Log BookFaisNo ratings yet

- Installation and Service Instructions For 180-210 C-Face MotorsDocument4 pagesInstallation and Service Instructions For 180-210 C-Face MotorsAnonymous gMMbTAQlNo ratings yet

- SB388CDocument13 pagesSB388CBenjamin LeedsNo ratings yet

- Grove LOADDocument20 pagesGrove LOADburak cikirkanNo ratings yet

- Axis & Ball Screw Inspection GuideDocument15 pagesAxis & Ball Screw Inspection GuidePham LongNo ratings yet

- 3 To 16 MV Series Turbine SDocument8 pages3 To 16 MV Series Turbine SealsolanoNo ratings yet

- Ar 40Document6 pagesAr 40jose maria machin sanchezNo ratings yet

- VM TYPE Undercarriages CIPI2001Document30 pagesVM TYPE Undercarriages CIPI2001Edgar Revok VelazquezNo ratings yet

- Click Wrench RepairDocument31 pagesClick Wrench RepairTu PhamNo ratings yet

- 3116 Cat Valvuklas Calibre PDFDocument4 pages3116 Cat Valvuklas Calibre PDFsergio blandon lNo ratings yet

- Subject AreaDocument30 pagesSubject Areauri.cruz.zamoraNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Termodinamika Vol 1Document138 pagesTermodinamika Vol 1Moh Rusli BahtiarNo ratings yet

- Sull Air 750Document2 pagesSull Air 750Rino AdityaNo ratings yet

- Spec 185Document2 pagesSpec 185Rino AdityaNo ratings yet

- S020sga enDocument64 pagesS020sga enRino AdityaNo ratings yet

- PV - NNT - R1Document6 pagesPV - NNT - R1Rino AdityaNo ratings yet

- 0073 enDocument44 pages0073 enRino AdityaNo ratings yet

- Bms enDocument32 pagesBms enRino Aditya100% (1)

- Cleasby Conveyors MaintenanceDocument2 pagesCleasby Conveyors MaintenanceRino AdityaNo ratings yet

- 23 Conveyor 208Document2 pages23 Conveyor 208Rino AdityaNo ratings yet

- Chem Lab (Interpretation)Document2 pagesChem Lab (Interpretation)CyberR.DomingoNo ratings yet

- A Hundred Years of Consciousness IsaiahDocument25 pagesA Hundred Years of Consciousness IsaiahingmarvazquezNo ratings yet

- GRE2023六月机经02Document42 pagesGRE2023六月机经02Xiwen WeiNo ratings yet

- East West University: Department of Computer Science and EngineeringDocument8 pagesEast West University: Department of Computer Science and EngineeringPartho Kumar DuttaNo ratings yet

- Design of Penstock Pipe For A HydroelectDocument21 pagesDesign of Penstock Pipe For A HydroelectWanderson WadjôNo ratings yet

- Octavia Manual Running Gear Part4Document136 pagesOctavia Manual Running Gear Part4Mihai IordacheNo ratings yet

- Dar Es Salaam Institute Technology Power Electronics Design Tutorial QuestionsDocument4 pagesDar Es Salaam Institute Technology Power Electronics Design Tutorial Questionsgeofrey fungoNo ratings yet

- Alarm System ReportDocument29 pagesAlarm System Reportsyafikahl100% (2)

- Vertical Turbine PumpDocument30 pagesVertical Turbine PumpAkie MontepiaNo ratings yet

- On-Line Mid Term Examination Semester Ii SESSION 2019/2020: LecturerDocument4 pagesOn-Line Mid Term Examination Semester Ii SESSION 2019/2020: Lecturernor asyiqinNo ratings yet

- VIVA Institute of Technology: Department of Mechanical EngineeringDocument3 pagesVIVA Institute of Technology: Department of Mechanical EngineeringJayesh JainNo ratings yet

- PADHMASREE.P XII-A Physics Project 2023-24Document14 pagesPADHMASREE.P XII-A Physics Project 2023-24punni1978No ratings yet

- Documenting Process Calibrator: Getting StartedDocument16 pagesDocumenting Process Calibrator: Getting Startedelperrote3No ratings yet

- Checklist For Installation of Pressurization UnitDocument1 pageChecklist For Installation of Pressurization Unitvictor100% (3)

- Multiple Disc Brakes: Posi-Torque Winch Brakes, Pressure Override Brakes, Wheel Mount Brakes, and Driveline BrakesDocument52 pagesMultiple Disc Brakes: Posi-Torque Winch Brakes, Pressure Override Brakes, Wheel Mount Brakes, and Driveline BrakesLucas BritoNo ratings yet

- Q1 TLE Shielded Metal Arc Welding (SMAW) NC I Module 1Document64 pagesQ1 TLE Shielded Metal Arc Welding (SMAW) NC I Module 1Pladie Salomon100% (5)

- CM2500 DTDocument64 pagesCM2500 DTcaferNo ratings yet

- IntelligAIRE II Diagnostic Procedures Using Drivers Display ModuleDocument2 pagesIntelligAIRE II Diagnostic Procedures Using Drivers Display ModuleNino PamindoNo ratings yet

- z2gbm ZokDocument57 pagesz2gbm ZokcarlsNo ratings yet

- Supercritical Fluid Extraction: by Nicole Adams and Morgan CampbellDocument27 pagesSupercritical Fluid Extraction: by Nicole Adams and Morgan CampbellAni KushwahaNo ratings yet

- DB 60zlg Mono Premium MiA ENDocument2 pagesDB 60zlg Mono Premium MiA ENelreydereyesNo ratings yet

- Energetics and Kinetics of Protein FoldingDocument28 pagesEnergetics and Kinetics of Protein FoldingSasikala RajendranNo ratings yet

- 1565 - Intermediate Grammar Test 04Document5 pages1565 - Intermediate Grammar Test 04Naber MüdürNo ratings yet

- 1.1 Testing of PPE For Eye and Face Protection FPDocument6 pages1.1 Testing of PPE For Eye and Face Protection FPWalter PossoNo ratings yet

- Experiment 6: Kirchhoff's Law Rachel Perry Lab Partners: N/A Date Performed: 14 July 2018 1635 Hours PHY 112 C11Document19 pagesExperiment 6: Kirchhoff's Law Rachel Perry Lab Partners: N/A Date Performed: 14 July 2018 1635 Hours PHY 112 C11Samira Viloria OchoaNo ratings yet

- 1 Which Intermolecular Force Is The Weakest?Document4 pages1 Which Intermolecular Force Is The Weakest?Loh Jun Xian100% (1)

- Cairo University Faculty Numerical Analysis Curve FittingDocument4 pagesCairo University Faculty Numerical Analysis Curve FittingGhaida mohamedNo ratings yet

- Conversion Chart for Length, Volume, Area, Temperature and MoreDocument2 pagesConversion Chart for Length, Volume, Area, Temperature and MoreJoshua VelascoNo ratings yet

- Technical Data - Modbus Communication For Electric Fire Pump ControllerDocument2 pagesTechnical Data - Modbus Communication For Electric Fire Pump ControllerJust RysdanNo ratings yet

- Manual Pitot TubeDocument10 pagesManual Pitot TubeMinh Nguyễn Phúc NhậtNo ratings yet