Professional Documents

Culture Documents

Exe-sum-eurobond-Eng Madhye Pradesh Pillet Plant

Uploaded by

patrik710Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exe-sum-eurobond-Eng Madhye Pradesh Pillet Plant

Uploaded by

patrik710Copyright:

Available Formats

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt.

- Jabalpur (Madhya Pradesh)

Executive Summary of EIA

EXECUTIVE SUMMARY

1.0 1.1 PROJECT DESCRIPTION INTRODUCTION

Eurobond Industries Pvt. Ltd (EIPL) is promoted by Euro group. EIPL is proposing to install Iron Ore Beneficiation & Pelletisation plant of 1.0 MTPA capacity, at village Dharmpura, district Jabalpur (MP). The land measuring 12.10 hectares (ha) is available for setting up of the Plant. The supply of Iron ore will be met from near by mines. As per the New EIA Notification issued from MoEF, New Delhi, dated 14.09.2006, this project falls in category A, Project Activity 3 (a).

1.2

S.No. A

DETAILS OF THE PROJECT

Particulars Name of the Project Iron Ore Details Beneficiation and

Pelletization B Location of the Project Area i. ii. Village Tehsil Dharampura Sihora Jabalpur Madhya Pradesh

iii. District iv. State C 1 2 Area Specific Details Proposed project area Proposed Green Belt

12.10 Hectares Approx.4 ha (approx. 33% of the total land area)

3 4 5

Toposheet No. Latitude Longitude

64 A/3 2323 56.17 North 800145.13 East

M/s Eurobond Industries Pvt. Limited

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

S.No. D 1 2 3 4 5 E 1 2 3 4

Particulars Requirements Total Fresh Water requirement Total Power requirement Total Manpower requirement Total cost of the project Environmental Protection Cost Details of Project Area Nearest National Highway Nearest Railway Station Nearest Airport National Parks, Sanctuaries, Biosphere Reserves, Wildlife Corridors, Tiger/Elephant reserves within 10 km radius NH 7; 3.5 km 1040 m3/day 13 MW 244

Details

Rs. 200.09 crores Rs. 800 Lacs

Gosalpur; 4 km Jabalpur; 50 km No National Parks, Sanctuaries, Biosphere Reserves, Wildlife Corridors, Tiger/Elephant reserves within 10 km radius Bohra Reserved forest (8.5 Km SE)

5 6

Nearest major city Nearest River

Jabalpur Hirren river (2 km in N direction)

1.3

S.No.

RAW MATERIAL REQUIREMENTS

Raw material Quantity (in MTPA)

17,40,000 42000 15,000 10,000 10,000

Source

Adjacent Mining Imported Local Mining Jharkhand & Orissa Kutch, Gujarat

1. Iron Ore 2. Bituminous Coal (Imported) 3. Limestone 4. Coke Breeze 5. Bentonite 6. Furnace Oil

As and when needed From Local petroleum Supplier

M/s Eurobond Industries Pvt. Limited

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

1.3.1

Process:

(i) Beneficiation Process:

Grinding to liberate Iron Ore from gangue material Spiral classifying to separate lighter particles High intensity Magnetic Separation Reverse Flotation Dewatering by Thickener Dewatering by Ceramic Disc Filter Dewatering by Press Filter

(ii)

Pelletisation Process:

Grate Kiln technology is proposed for pelletization & the process is as below: Additives (Limestone & Coke Breeze) grinding. Coal Pulverisation. Proportioning & Mixing of additives, binder & Iron Ore fines concentrate. Green Balling & Screening. Drying & Preheating in travel grate. Roasting/ Induration in pulverised coal fired rotary kiln. Cooling & Heat recovery in circular cooler. Exhaust gas cleaning through ESP for emission control.

M/s Eurobond Industries Pvt. Limited

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

1.3.2

S.No. 1. 2. 3. 4. 5. 6. 7.

Equipment Details

Equipment JAW CRUSHER GRANULATOR PRIMARY BALL MILL DOUBLE-SPIRAL CLASSIFIER ROTARY SCREEN SPIRAL LAUNDER VERTICAL PULSATING HIGH Size: 1500mm dia., , 2 Nos 1500MM Dia, 8 Sets GRADE SLon 1750, 2 Nos Details Capacity: 50 TPH Capacity: 50 TPH Size: 2.4 m dia.x 5.8m long

MAGNETIC SEPERATOR 8. FLOTATION CELLS 6 chamber, 2.8 m3, impeller dia-600mm, 4 Sets 9. 10. 11. 12. 13. 14. SECONDARY BALL MILL AUTOMATIC FILTER PRESS THICHKENER TANK/POND AGITATION TANKS WATER & SLURRY PUMPS PRESS FILTER FOR DEAWATERING OF SLURY Size: 2.1m dia. x 3 m long 2 Sets Dia- 24m, 3 Nos 3 sets 16 sets

M/s Eurobond Industries Pvt. Limited

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

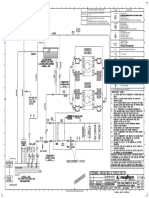

1.5

PROCESS FLOW CHART

CRUSH ER

B ELT CO NVEYO R

S P IR A L C L A S SIF IE R

B A L L M IL L

S P IR A L L A U N D E R

WR

T H IC K E N E R

M A G N E T IC SEPARATO RS

F L O T A T IO N S E P A R A T O R S

H YDRO CYCLONE

BALL M IL L

T H IC K E N E R

WR T A IL IN G S /S O L ID R E JE C T B E L T C O N V E Y O R F e< 25 %

F IL T E R P R E S S T H IC K E N E R F IL T E R W ATER R E C IR C U L A T IO N WR

STO CK Y ARD

B A C K F IL L SIT E (W O R K E D M IN E ) STO RA GE Y ARD P E L L E T IZ A T IO N P L A N T IR O N O R E CONCENTRATE 9 % M O IS T U R E + 66% F e

Here WR stands for Water Recovery being re-circulating.

M/s Eurobond Industries Pvt. Limited

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

2.0

DESCRIPTION OF THE ENVIRONMENT (During Study Period- December 2007 to February 2008)

2.1

CLIMATIC CONDITION

Climate of the area is generally dry. Temperature ranges from Minimum 5.3oC to Maximum 23.7oC. Relative Humidity ranges from Minimum 21-52% to Maximum 9196%. Average Annual Rainfall is 793 mm.

2.2

AMBIENT AIR QUALITY MONITORING

Ambient air quality monitoring has been carried out at 10 stations in the study area on 24 hourly basis. The average concentration for all the 10 AAQM stations of SPM ranges between 74 to 173 g/m3 , RSPM ranges between 31 to 63 g/m3 , SO2 range between 6 to 11 g/m3 and NOx range between 9 to 18 g/m3.

2.3

NOISE LEVEL

Noise monitoring in the study area at 10 stations shows that the noise level varies in Leq value ranges from 45dB (A) to 66 dB (A) in day time. The noise level recorded at night time 40 to 49 dB (A).

2.5

WATER QUALITY

Water samples were collected from 6 stations and the analysis of the samples shows that the concentration of Total Dissolved Solids (TDS) ranges between 201 mg/l to 403 mg/l, pH value varies from 7.05 to 7.68, Total Hardness varies from 216.14 mg/l to 662.56 mg/l and fluoride concentration varies from 0.14 to 0.59 mg/l in all ground water samples.

M/s Eurobond Industries Pvt. Limited

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

2.6

SOIL QUALITY MONITORING

The soil samples collected from 5 different stations and analyzed. The analysis report shows that the pH value ranges from 6.6 to 7.9, organic carbon ranges from 0.62 to 2.31%, soil texture is varies from Clay loamy to Sandy loamy and conductivity of the soil samples ranges from 0.13 to 0.48 mS/cm.

2.7

BIOLOGICAL ENVIRONMENT

Flora : Commonly found flora of the region includes Tectona grandis (Common Teak), Shorea robusta (Sal), Terminallia tomentosa (Saja), Pterocarpus marsupium (Bija), Lagerstroemia parviflora (Lendia), Adina cardifolia (Haldu), Angogeissus pendula (Dhokra), Boswellia serrata (Salai), Emblica officinalis (Aonla), Cassia fistula (Amaltas), Dendrocalamus strictus (Babul), Pongamia Pinnata (Karanj), Acacia Catechu (Khair), Emblica officinalis (Amla) etc. Fauna : The fauna found in the study area are mostly Boselaphus tragocamelus (Neel gai), Velpes bengalensis (Fox), Cervus axis (Hare), Gaxella dennchi (Jackal), Funambulus pennati (Squirrel), Herpestes edwardsi (Common Mongoose), Lepus nigricollis (Rabbit), Acridotheres tristis (Myna), Columba livia (Blue Rock Pigeon), Eudyanamus spp (Koel), Psittacula krameri (Parrot), Corvus splendens (House crow), Calotes vesicolor (Common garden lizard), etc.

2.8

SOCIO-ECONOMIC STATUS OF THE STUDY AREA

The population of the district Jabalpur as per census records 2001 is 2,151,203. Scheduled Caste & Scheduled Tribe fraction of the population of the study area is 12.73% and 15.01% respectively. Percentage of literacy is 75.69%.

M/s Eurobond Industries Pvt. Limited

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

3.0

ANTICIPATED MITIGATION

ENVIRONMENTAL MEASURES

IMPACTS

AND

3.1.1

Impact on Soil

The anticipated pollution impacts to soil environment due to plant activities are as follows. i) Changes in soil texture & chemistry due to settling of air borne dust or due to wash off of solid particulates by storm water. This will lead to change in porosity, permeability & other such physical characteristics of soil of the area. ii) Soil erosion due to waste water discharge.

But in this project proper mitigation steps for the plant like proper pollution control equipments, suitable stack height; will result in no significant impact on the ground level concentration of the pollutants in the soil of the study area located beyond the working area of the proposed integrated project. Also the process is a zero discharge, hence waste water will not be affecting the quality of the soil. The disposal of tailings in the abandoned mines will help in reclamation of the near by areas, as they serve a purpose for a good plantation.

3.1.2

Impact on Land Use

The total land area required for the project is about 12.10 hectares. Out of which 33% of the total area i.e. about 4 ha will be used for green belt development. Preparatory activities like the use of access roads and construction of storage sheds, etc. being spread over an area would have no significant impact on land use pattern. Reclamation of abandoned mine pits by disposal of solid waste consisting of impurities of naturally available iron ore in the vicinity will have a positive impact on the land use of the area.

M/s Eurobond Industries Pvt. Limited

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

There is likely to be some impact on the cropping pattern in the close vicinity of the plant, due to air & water, which will be minimized by adequate mitigative measures.

3.1.3

Air Quality

The emissions during construction phase are expected to have adverse impact on ambient air quality of surroundings of the construction site which will be temporary and reversible in nature and will be localized. The key emissions from the Iron Ore Beneficiation & Pelletisation manufacturing process are emissions of particulate matter, oxides of nitrogen (NOx) and Sulphur dioxide (SO2). Automobile emissions from transportation have not been

considered as continuous source of any significant air pollution. But proper mitigative measures like pollution control equipments such as use of ESP, Bag houses Bag filters and Spot Bag filters will maintain the dust concentration at its outlet well within the prescribed CPCB Norms.

3.1.4

Water Quality

During the construction phase the small amount of water will be drawn through the bore well and from nearby villages, which will not affect the ground water availability in the area. No wastewater will be discharged from the plant operation. Slurry generated from beneficiation plant will be fed to a specially designed press filter, which would recover the water from slurry. All the water collected from this filter will be re-circulated to plant for reuse. Therefore there will be no significant impact on either the hydraulic gradient or the flow rates in the wells as well as on the surface water due to the plant operations.

M/s Eurobond Industries Pvt. Limited

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

3.1.5

Solid Waste

During construction phase, solid waste such as excavated soil, debris, some metal waste and very small amount of oil & grease from construction machines will be generated. This waste may contaminate soil at plant site temporarily and would be restricted to a small area. The Process would not be generating any Hazardous Waste, as there is no Hazardous Chemical involved in the process. Disposable solid waste consisting of impurities of naturally available iron ore would be used for filling of the abandoned mines in the vicinity. Solid disposable waste is also ideally suitable for brick making and would be delivered to local brick makers. Thus solid waste generated will not be having any negative impact on the environment.

3.1.6

Noise Level

The Iron Ore Crusher & Ball Mil wet Grinding unit will be the major equipment where maximum noise generation will be taking place. Acoustic wall will be used to control noise pollution in these units. General noise level generated from equipment in the proposed project would usually be kept below 85 Leq dB (A) in the working area and below 70 Leq dB (A) around periphery. These noise levels are temporary in nature and its transient insignificant due to the large distances.

M/s Eurobond Industries Pvt. Limited

10

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

4.0

Sr.No. 1. 2. 3. 4. 5. 6. 7.

POST PROJECT MONITORING PROGRAMME

Description Ambient Air Quality at project site. Stack Emissions Meteorological Data Noise Level Monitoring Health Check-up Water Quality Soil Quality Frequency of Monitoring Once in a quarter. Once in a week Daily Once in a quarter Once in a year for plant employees. Once in a quarter. Once in a quarter.

5.0

ADDITIONAL STUDIES

A comprehensive hydro-geological study of the area has been under taken with the objective of making full use of groundwater potential and also through rainwater harvesting for collecting the precipitation of water & runoff through nearby hill slopes. The Total precipitation received by Plant Area & outside Plant Area (run-off) & directly in tank has been calculated to be approx. 20,000 m3/day. Suitable Rainwater Harvesting structures have been proposed for the project. And in this way a proper planning for the drainage of rainwater, its harvesting and recharge into the groundwater has been done.

6.0

PROJECT BENEFITS

The area around the project site is economically backward. This will be first major project in the area. The proposed unit, apart from generating direct and indirect employment and various business opportunities will contribute toward the infrastructural development of the project area. Euro Foundation has been actively involved in various socio economic development programmes as Euro Global Academy having its head office in Kutch & branch office at Mumbai. Similarly here in this project area Euro Foundation in coordination with the local panchayat will be contributing towards a sustainable development of the area. In

M/s Eurobond Industries Pvt. Limited

11

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

the recruitment process of the organization, local people will be given preference. Also green belt development in the plant area as well as the nearby abandoned mines will improve the land cover of the area.

7.0 7.1

ENVIRONMENT MANAGEMENT PLAN AIR POLLUTION CONTROL

Bag Filters in the crushing plant, coal mill & additive mill system; Spot Filters at crusher transfer point & raw coal storage filter; and ESP at the traveling grate kiln each with an efficiency of about 99.95% have been proposed to minimize air pollution due to the plant operation. Proper measures will be used to keep emissions as per CPCB guidelines. Also guidelines to control fugitive emissions as per CPCB will be followed. All roads will be concreted. Thick green belt will be developed around the plant to arrest the fugitive emissions.

7.2

NOISE MANAGEMENT

To mitigate the high noise level, following steps should be adopted: Crushing and Grinding activity will be done in a closed environment, which helps in minimizing generation of noise. Silencers will be provided in the areas generating high noise. Proper care is taken by incorporating sound-proof enclosures for equipments and providing earmuffs and earplugs for operators. Acoustic enclosure for D.G. set will be used. Green belt will be developed in an area, which will greatly help in reducing noise levels in plant and colony area. Walls and ceilings of the concerned buildings would be lined with sound absorbing materials. Regular monitoring of noise level will be carried out and corrective measures in concerned machinery will be adopted accordingly.

M/s Eurobond Industries Pvt. Limited

12

IRON ORE BENEFICIATION AND PELLETIZATION PLANT Capacity : 1.0 MTPA At Tehsil Sihora, Distt. - Jabalpur (Madhya Pradesh)

Executive Summary of EIA

7.3

WATER MANAGEMENT

Water requirement of the plant will be around 1040 KLD, which is proposed to be met from bore wells and River Herran. The process will be zero discharge. Special arrangements to

dewater and recycle the water from tailings have been proposed. Filter Press technology will be used to recover water from tailings which will be recirculated in the system. Efforts would be made to conserve as much water as possible by recycling and reuse. Rainwater Harvesting will be done with suitable structures.

7.4

SOLID WASTE MANAGEMENT

The Process would not be generating any Hazardous Waste. Dust collected through ESP & Bag house etc. will be recycled in the respective processes. Disposable solid waste (tailings) would be used for filling of the abandoned mines in the vicinity. It is also ideally suitable for bricks, tiles & blocks making and would be marketed to local brick makers.

7.5

GREENBELT PROGRAMME

DEVELOPMENT

AND

PLANTATION

The Company proposes to develop green belt in about 4 ha. (33%) of the total 12.10 ha project area.

Green belt development is planned to be completed within 3 years by planting about 10,000 plants each year.

It is also proposed to build a green belt at the solid waste disposal sites.

Plantation along the road will attenuate noise level, arrest dust and improve the environment in surrounding.

The plant species will be selected as per CPCB guidelines.

M/s Eurobond Industries Pvt. Limited

13

You might also like

- Dungeness and Romney Marsh: Barrier Dynamics and Marshland EvolutionFrom EverandDungeness and Romney Marsh: Barrier Dynamics and Marshland EvolutionNo ratings yet

- Microstructural Geochronology: Planetary Records Down to Atom ScaleFrom EverandMicrostructural Geochronology: Planetary Records Down to Atom ScaleDesmond E. MoserNo ratings yet

- Sharda Iron Ore Benefication Prefeasibility ReportDocument8 pagesSharda Iron Ore Benefication Prefeasibility ReportKalpesh GotiNo ratings yet

- EnglishDocument18 pagesEnglishlks.tembosteelsNo ratings yet

- PUBLIC HEARING EXECUTIVE SUMMARY FOR PROPOSED IRON AND ALLOY PLANTSDocument11 pagesPUBLIC HEARING EXECUTIVE SUMMARY FOR PROPOSED IRON AND ALLOY PLANTSGiri DeepakNo ratings yet

- JKLakshmi Cement LTD EnglishDocument12 pagesJKLakshmi Cement LTD EnglishSanket SatpathyNo ratings yet

- Exe Sum Arkay EngDocument11 pagesExe Sum Arkay EngBijuNo ratings yet

- Ind Bharat Energy (Utkal) LTD (English)Document11 pagesInd Bharat Energy (Utkal) LTD (English)Prateek DubeyNo ratings yet

- Grasim Industry Information in KANNADADocument28 pagesGrasim Industry Information in KANNADApnaronaNo ratings yet

- Executive SummaryDocument13 pagesExecutive SummaryakaashishNo ratings yet

- MDSW TamilNadu06Document14 pagesMDSW TamilNadu06miningnova1No ratings yet

- BIL Exe Sum EngDocument12 pagesBIL Exe Sum EngpdiconpNo ratings yet

- Final Ambuja Cements Pali Ex Summary English 31 05Document12 pagesFinal Ambuja Cements Pali Ex Summary English 31 05Anuj PatelNo ratings yet

- Kasia Iron Dolomite Mines (English)Document13 pagesKasia Iron Dolomite Mines (English)Neeraj KishoreNo ratings yet

- Sludge Characterization of Khartoum Petroleum Refining Wastewater Treatment Plant - Khartoum-SudanDocument10 pagesSludge Characterization of Khartoum Petroleum Refining Wastewater Treatment Plant - Khartoum-SudanIJAR JOURNALNo ratings yet

- Green Tech Industries (India) Pvt. LTD., EXE SUM-EnGDocument7 pagesGreen Tech Industries (India) Pvt. LTD., EXE SUM-EnGkalyanm203515No ratings yet

- Training Report RajharaDocument31 pagesTraining Report RajharaJay PrakashNo ratings yet

- Ex Sumry-Eng HirdyanagarDocument13 pagesEx Sumry-Eng HirdyanagarnarendrasinghsjsNo ratings yet

- RODM PresentationDocument67 pagesRODM PresentationSekharNo ratings yet

- EIA Tps RaghunathpurDocument18 pagesEIA Tps RaghunathpurthiyagarajankNo ratings yet

- UltraTech Cement's 28 MW captive power plant expansion projectDocument3 pagesUltraTech Cement's 28 MW captive power plant expansion projectModi NiharNo ratings yet

- The India Cements LimitedDocument14 pagesThe India Cements Limitedminingnova1No ratings yet

- Exe Sum EnglishDocument13 pagesExe Sum EnglishGyan Alok GiriNo ratings yet

- Selection of Mercury Accumulator Plants For Gold MDocument6 pagesSelection of Mercury Accumulator Plants For Gold MstametNo ratings yet

- Eia ReportDocument192 pagesEia ReportbarathiNo ratings yet

- Dareh Alou Thickened Tailings Management Scheme: Design ConsiderationsDocument12 pagesDareh Alou Thickened Tailings Management Scheme: Design ConsiderationsrgjphilippeNo ratings yet

- Environmental Impacts of Drilling Mud and Cutting WastesDocument7 pagesEnvironmental Impacts of Drilling Mud and Cutting Wastesasma sedNo ratings yet

- Eia Report of Expansion of Thermal Power Plant: Tamnar, Tehsil Gharghoda, Dist Raigarh (Chhattisgarh)Document16 pagesEia Report of Expansion of Thermal Power Plant: Tamnar, Tehsil Gharghoda, Dist Raigarh (Chhattisgarh)Agila R RamamoorthyNo ratings yet

- Bunder Diamond Mine Executive Summary 1.1 Project Location and Project DescriptionDocument7 pagesBunder Diamond Mine Executive Summary 1.1 Project Location and Project Descriptiondevendrasahu45No ratings yet

- v112n04p295 Cyanidation of ReefDocument6 pagesv112n04p295 Cyanidation of ReefergfaradNo ratings yet

- High Chromium Tolerant Bacterial Strains From Palar River Basin: Impact of Tannery PollutionDocument6 pagesHigh Chromium Tolerant Bacterial Strains From Palar River Basin: Impact of Tannery PollutionRamakrishna NatarajanNo ratings yet

- Magnetic Separation in South AfricaDocument28 pagesMagnetic Separation in South AfricaDaniel TangkauNo ratings yet

- Impact of Artisanal Perma Gold Mining On Groundwater QualityDocument10 pagesImpact of Artisanal Perma Gold Mining On Groundwater QualityIJAR JOURNALNo ratings yet

- Tramiento de Escorias 3Document5 pagesTramiento de Escorias 3Diego Ignacio ALvarez AlvarezNo ratings yet

- EIA Baseline Report-1Document26 pagesEIA Baseline Report-1Abhinav AbhiNo ratings yet

- CHJV04I03P0118Document7 pagesCHJV04I03P0118chemistryjournalNo ratings yet

- Indian Land Research PDFDocument5 pagesIndian Land Research PDFIRADUKUNDA jean BoscoNo ratings yet

- Presence of Heavy Metals in Slaughterhouse Wastewater, A Study at Al Sahafa Abattoir Khartoum, North SudanDocument4 pagesPresence of Heavy Metals in Slaughterhouse Wastewater, A Study at Al Sahafa Abattoir Khartoum, North SudanInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 10 1 1 436 8744 PDFDocument9 pages10 1 1 436 8744 PDFJosé Luis Nava RebollarNo ratings yet

- 10 1 1 436 8744 PDFDocument9 pages10 1 1 436 8744 PDFJosé Luis Nava RebollarNo ratings yet

- Recovery of iron values from iron ore slimes using VPHGMSDocument6 pagesRecovery of iron values from iron ore slimes using VPHGMSravibelavadiNo ratings yet

- Eco-Restoration of A High-Sulphur Coal Mine Overburden Dumping Site in Northeast India: A Case StudyDocument12 pagesEco-Restoration of A High-Sulphur Coal Mine Overburden Dumping Site in Northeast India: A Case StudyPawan KumarNo ratings yet

- Summary of the CAK Limestone BlockDocument4 pagesSummary of the CAK Limestone BlockadNo ratings yet

- Executive SummaryDocument15 pagesExecutive Summaryniharika SinhaNo ratings yet

- EBS 322 (Malay To Eng) 2010Document264 pagesEBS 322 (Malay To Eng) 2010Nur Ain Zainol AbidinNo ratings yet

- Heavy Metal Levels in Edible Crabs from Lower Gangetic DeltaDocument7 pagesHeavy Metal Levels in Edible Crabs from Lower Gangetic DeltaAndrew FincoNo ratings yet

- Executive Summary: Type of Vessel Existing/Proposed Nos. Capacity Total CapacityDocument6 pagesExecutive Summary: Type of Vessel Existing/Proposed Nos. Capacity Total Capacityvivek1280No ratings yet

- Suresh Khatri-Pimpalvihir Stone QuarryDocument40 pagesSuresh Khatri-Pimpalvihir Stone QuarryVIKAS PANDEYNo ratings yet

- Jsir 67 (1) (2008) 11-18Document8 pagesJsir 67 (1) (2008) 11-18oumy.ab.gcNo ratings yet

- Effect of Gravel-Sand Substrate On Sub-Surface Flow Constructed Wetland For Palm Oil Mill Effluent TreatmentDocument7 pagesEffect of Gravel-Sand Substrate On Sub-Surface Flow Constructed Wetland For Palm Oil Mill Effluent TreatmentCt Kamariah Md SaatNo ratings yet

- Comparative study of contaminated sites in Ranipet, IndiaDocument10 pagesComparative study of contaminated sites in Ranipet, IndiaArun MithunNo ratings yet

- Assessment of Drinking Water Quality ParametersDocument40 pagesAssessment of Drinking Water Quality Parametersshadab ansariNo ratings yet

- Exe Summ RajatCement Eng PDFDocument12 pagesExe Summ RajatCement Eng PDFflytorahulNo ratings yet

- Concentration of Itakpe Iron OreDocument9 pagesConcentration of Itakpe Iron OreChima C. UgwuegbuNo ratings yet

- Optimisation of The Proeminent Hill Flotation CircuitDocument14 pagesOptimisation of The Proeminent Hill Flotation CircuitThiago JatobáNo ratings yet

- Eia Pulau Tioman Group PresentationDocument81 pagesEia Pulau Tioman Group Presentationaja_zai0% (1)

- Aluminum Waste Cans Recycling in Lagos State, Nigeria: Analysis of Soil and Water BenefitsDocument11 pagesAluminum Waste Cans Recycling in Lagos State, Nigeria: Analysis of Soil and Water BenefitsIJAR JOURNALNo ratings yet

- EIA - Sumathi - Eng - Environmental Impect Analysis Steel Rolling MillDocument13 pagesEIA - Sumathi - Eng - Environmental Impect Analysis Steel Rolling MillsarashviNo ratings yet

- M/S. Sri Kanakadurga Tribal Labour Contract Mutually Aided Co-Op Society.Document11 pagesM/S. Sri Kanakadurga Tribal Labour Contract Mutually Aided Co-Op Society.Daneshwer VermaNo ratings yet

- Environmental Impact Assessment: Final Report After Public HearingDocument554 pagesEnvironmental Impact Assessment: Final Report After Public HearingRishabh100% (3)

- Water Treatment Plant Specs and EquipmentDocument1 pageWater Treatment Plant Specs and Equipmentpatrik710No ratings yet

- Ring FormationDocument5 pagesRing Formationpatrik710No ratings yet

- Observation ChartDocument5 pagesObservation Chartpatrik710No ratings yet

- PO Box 1010, Liverpool L70 1NL, United KingdomDocument2 pagesPO Box 1010, Liverpool L70 1NL, United Kingdompatrik710No ratings yet

- Bearing 6202 and 6203 ConsumptionDocument2 pagesBearing 6202 and 6203 Consumptionpatrik710No ratings yet

- BookletDocument1 pageBookletpatrik710No ratings yet

- Hardness Shore C C MN MN Si P S Ni CRDocument2 pagesHardness Shore C C MN MN Si P S Ni CRpatrik710No ratings yet

- Leadership Quotes to Inspire and MotivateDocument3 pagesLeadership Quotes to Inspire and Motivatepatrik710No ratings yet

- List of ContractorDocument1 pageList of Contractorpatrik710No ratings yet

- Shut DownDocument1 pageShut Downpatrik710No ratings yet

- Po Sel PIPEDocument2 pagesPo Sel PIPEpatrik710No ratings yet

- Organgram of Shyam MetalicDocument1 pageOrgangram of Shyam Metalicpatrik710No ratings yet

- Electrical MotorsDocument6 pagesElectrical Motorspatrik710No ratings yet

- Po Sel PIPEDocument2 pagesPo Sel PIPEpatrik710No ratings yet

- Shyam Metallic Pipe Plant FacilitiesDocument3 pagesShyam Metallic Pipe Plant Facilitiespatrik710No ratings yet

- Rolling Mill Gear Teeth Chemical Composition ComparisonDocument1 pageRolling Mill Gear Teeth Chemical Composition Comparisonpatrik710No ratings yet

- Sti 2062Document6 pagesSti 2062patrik710No ratings yet

- SafetyDocument1 pageSafetypatrik710No ratings yet

- Based On Liquids Not Exceeding 200 CST Viscosity and 70Document1 pageBased On Liquids Not Exceeding 200 CST Viscosity and 70patrik710No ratings yet

- Crompton Greaves LetterDocument1 pageCrompton Greaves Letterpatrik710No ratings yet

- VMHDocument6 pagesVMHpatrik710No ratings yet

- Crompton Greaves LetterDocument1 pageCrompton Greaves Letterpatrik710No ratings yet

- Efficient Furnace Operation1Document7 pagesEfficient Furnace Operation1patrik710No ratings yet

- Crompton Greaves LetterDocument1 pageCrompton Greaves Letterpatrik710No ratings yet

- Tata SteelDocument32 pagesTata Steelpatrik710No ratings yet

- V Pully DimensionDocument1 pageV Pully Dimensionpatrik710No ratings yet

- Based On Liquids Not Exceeding 200 CST Viscosity and 71Document2 pagesBased On Liquids Not Exceeding 200 CST Viscosity and 71patrik710No ratings yet

- Misc Pipe and Grade For Iph & OphDocument1 pageMisc Pipe and Grade For Iph & Ophpatrik710No ratings yet

- Hydrolic Cylinder Dspec DetaDocument1 pageHydrolic Cylinder Dspec Detapatrik710No ratings yet

- The Steel Pipe Data Chart Below Can Be Used To Find Pipe SizesDocument6 pagesThe Steel Pipe Data Chart Below Can Be Used To Find Pipe Sizespatrik710100% (1)

- Topic: References: Materials: Value Focus: Lesson Plan in Health 6Document7 pagesTopic: References: Materials: Value Focus: Lesson Plan in Health 6Kathleen Rose ReyesNo ratings yet

- Admmodule Stem Gp12eu Ia 1Document26 pagesAdmmodule Stem Gp12eu Ia 1Garry GuralNo ratings yet

- A Course of Theoretical Physics Volume 1 Fundamental Laws Mechanics Electrodynamics Quantum Mechanics-A.S. Kompaneyets PDFDocument574 pagesA Course of Theoretical Physics Volume 1 Fundamental Laws Mechanics Electrodynamics Quantum Mechanics-A.S. Kompaneyets PDFRoberto Pomares100% (1)

- Nominal vs. Actual SizesDocument2 pagesNominal vs. Actual SizesaminNo ratings yet

- Bac Sample 1Document2 pagesBac Sample 1Kouam AbdelkaderNo ratings yet

- Astrophysics Project Reaction PaperDocument2 pagesAstrophysics Project Reaction PaperEdson DavidNo ratings yet

- Chapter QuestionDocument5 pagesChapter Questionsn nNo ratings yet

- Application of Geomechanics in Longwall Operation: 201&transacl1ons Vol. 280 Society of M N N G Eng Neers of AimeDocument5 pagesApplication of Geomechanics in Longwall Operation: 201&transacl1ons Vol. 280 Society of M N N G Eng Neers of AimeKevRiosNo ratings yet

- 04 ET EXCERPTS Field Guide To Human Centered DesignDocument49 pages04 ET EXCERPTS Field Guide To Human Centered DesignMahesh ReddyNo ratings yet

- Project Management Phases and ObjectivesDocument60 pagesProject Management Phases and ObjectivesShanju ShanjuNo ratings yet

- 9 Fracture CharacterizationDocument17 pages9 Fracture Characterizationpepito perezNo ratings yet

- Lesson Plan on Colors of LightDocument3 pagesLesson Plan on Colors of LightKristel Joy ManceraNo ratings yet

- Topic 2 ResourcesDocument144 pagesTopic 2 ResourcesTia WardNo ratings yet

- Mothly Supervisory PlanDocument6 pagesMothly Supervisory Planclaire alcantaraNo ratings yet

- Marimekko's Approach to Sustainability and Global OperationsDocument3 pagesMarimekko's Approach to Sustainability and Global OperationsHannah Van GeeresteinNo ratings yet

- Tle10 Afa Poultry q4 Mod8 Collectingeggs v4Document27 pagesTle10 Afa Poultry q4 Mod8 Collectingeggs v4Claes TrinioNo ratings yet

- Lec-19 Ethical Framework For Helath ResearchDocument17 pagesLec-19 Ethical Framework For Helath ResearchNishant KumarNo ratings yet

- 2d Circular Convolution 2 PDFDocument6 pages2d Circular Convolution 2 PDFVincent HanNo ratings yet

- Statement of PurposeDocument3 pagesStatement of PurposeenecheumiNo ratings yet

- Synthesis PowerpointDocument31 pagesSynthesis PowerpointKara DNo ratings yet

- Grain Oriented Electrical Steels: M-2, M-3, M-3X Lite Carlite Goes M-2, M-3, M-4, M-5, M-6 Mill-Anneal GoesDocument47 pagesGrain Oriented Electrical Steels: M-2, M-3, M-3X Lite Carlite Goes M-2, M-3, M-4, M-5, M-6 Mill-Anneal GoesLucio PereiraNo ratings yet

- ProjectDocument13 pagesProjectFE3056 NAGARAJ.SNo ratings yet

- Why NAM remains relevant todayDocument2 pagesWhy NAM remains relevant todaySourabh PawarNo ratings yet

- Syllabus Sibos CLTDocument5 pagesSyllabus Sibos CLTgopimicroNo ratings yet

- ITM Unit 2 - Tutorial Sheet - StudentsDocument4 pagesITM Unit 2 - Tutorial Sheet - StudentsalexNo ratings yet

- Matlab HW PDFDocument3 pagesMatlab HW PDFMohammed AbdulnaserNo ratings yet

- Marriage Builders Emotional Needs Questionnaire PDFDocument12 pagesMarriage Builders Emotional Needs Questionnaire PDFPrarthanaRavikumarNo ratings yet

- Yulo, Brittany L. August 15, 2021 FS - 301 WEEK 4: Incised WoundsDocument2 pagesYulo, Brittany L. August 15, 2021 FS - 301 WEEK 4: Incised WoundsBrittany YuloNo ratings yet

- Cover Letter For Drilling Engineering PDFDocument1 pageCover Letter For Drilling Engineering PDFHein Htet ZawNo ratings yet

- 9 Ws of ActingDocument7 pages9 Ws of ActingNihar KambleNo ratings yet