Professional Documents

Culture Documents

Anchorage To Concrete

Uploaded by

makakkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anchorage To Concrete

Uploaded by

makakkCopyright:

Available Formats

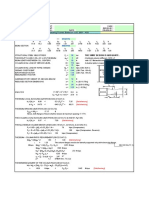

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

INPUT DATA & DESIGN SUMMARY

CONCRETE STRENGTH f

c

' = 4 ksi

SPECIFIED STRENGTH OF ANCHOR f

uta

= 58 ksi

BASE PLATE YIELD STRESS f

y

= 36 ksi

CRITICAL BASE PLATE CANTILEVER m = 3.3 in

FACTORED AXIAL LOAD AT WORK POINT P

u

= 150 kips

FACTORED SHEAR LOAD AT WORK POINT V

u

= 16 kips, ( 0 if shear lug used.)

FACTORED MOMENT AT WORK POINT M

u

= 260 ft-kips

ANCHOR LOCATION TO WORK POINT

EFFECTIVE EMBEDMENT DEPTH h

ef

= 22 in Anchor

X (in) Y (in)

ANCHOR DIAMETER d = 1 in 1 -8 8 1

ANCHOR HEAD TYPE 4 Heavy Hex 2 -8 -8 1

( 1=Square, 2=Heavy Square, 3=Hex, 4=Heavy Hex, 5=Hardened Washers ) 3 8 8

BASE PLATE THICKNESS t = 1.75 in 4 8 -8

SEISMIC LOAD ? (ACI 318 D3.3) == > Yes 5 24 8 1

6 24 -8 1

7 -8 0 1

8 24 0 1

BASE PLATE SIZE - 36 in x 20 in x 1.75 in (thk.)

Corner X (in) Y (in)

1 -9.75 -9.75 Edge = 1.75 in

2 -9.75 9.75 (AISC 360-05, Tab J3.4 & J3.5)

3 25.75 9.75

4 25.75 -9.75

-9.75 -9.75 3 3

THE BASE PLATE & GROUP ANCHORS DESIGN IS ADEQUATE.

ANALYSIS

CHECK FLEXURAL & AXIAL COMPRESSION CAPACITY OF ANCHORED CONCRETE (ACI 318-08 Sec 9 & Sec 10)

| P

n

(k)

| M

n

(ft-k)

Base Plate and Group Anchors Design Based on ACI 318-08 & AISC 360-05

Work Point

0

500

1000

1500

2000

2500

3000

0 500 1000 1500

c

c

(cont'd)

| M

n

= 451 ft-kips @ P

u

= 150 kips

> M

u, c

= 363 ft-kips to center of base plate

[Satisfactory]

| P

max

= 2643 kips

> P

u

= 150 ft-kips [Satisfactory]

N

ua,1

= 3.13 kips

(The 1/0.4 times max tension, ACI 318 D3.3.6)

f

p

= 4.42 ksi, the max possible concrete compression stress.

(ACI 318-08, 10.17.1 & 9.3.2.4, or AISC Guide - 1)

DETERMINE EACH ANCHOR FORCES WITHOUT CONCTERE COMPRESSION CAPCAITY CONSIDERED

Anchor

X (in) Y (in) X

CG

2

Y

CG

2

N

ua, 2

V

ua

1 -8 8 256 64 1.25 2.00

2 -8 -8 256 64 1.25 2.00 X

CG

= 8 in

3 8 8 0 64 -18.75 2.00 Y

CG

= 0 in

4 8 -8 0 64 -18.75 2.00

5 24 8 256 64 -38.75 2.00 P

u,CG

= 150.0 kips

6 24 -8 256 64 -38.75 2.00 V

u,CG

= 16.0 kips

7 -8 0 256 0 1.25 2.00 M

u,CG, X

= 160.0 ft-kips

8 24 0 256 0 -38.75 2.00 M

u,CG, Y

= 0.0 ft-kips

E 1536 384 -150 16

CHECK GOVERNING ANCHOR TENSILE STRENGTH (ACI 318, D.5.1.2)

= 19.77 kips > N

ua

= Max( N

ua,1

, N

ua,2

) = 3.13 kips [Satisfactory]

where : | = 0.75 x 0.75 = 0.5625 , (ACI 318-08 D.4.4 & D.3.3.3)

A

se

= 0.606

in

2

CHECK CONCRETE BREAKOUT STRENGTH OF GOVERNING ANCHOR (ACI 318, D.5.2.1)

= 22.026 k > N

ua

= 3.13 kips [Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

ec,N

= 1.0, for no eccentricity in the connection.

c,N

= 1.0, for location where concrete cracking is likely to occur.

A

N

= 1089 in

2

, (conservative value)

CHECK CONCRETE BREAKOUT STRENGTH OF ALL ANCHORS (ACI 318, D.5.2.1)

= 136.134 k >

- P

u

=

-150 kips [Satisfactory]

( ) se s uta

f N A

| | =

( )

( )

'

1.5

, , , , ,

2

1.0 24

9

N N

cb b ef

ec N ed N c N ec N c N c

No ef

A A

f

N N h

A h

| | | = =

( )

( )

'

1.5

, , , , ,

2

1.0 24

9

N N

cbg b ef ec N ed N c N ec N c N c

No ef

A A

f

N N h

A h

| | | = =

'

'

2

'

'

2

1

2

1

2

1

2

0.85 , 2 , 57 , 29000

0.85 , 2 2 , 0

0.85 , 2 ,

,

,

C

C

C

C

C

S

f

A

Min ksi f E E

c s o

E A

c

A c c

Min for f

c o

A

o o

f

A

Min for f

c o

A

for

E

s s s y

f

for f

s y y

c

c c

c c

c c

c c

c c c

c c

| |

= = =

|

|

\ .

(

| | | | | |

( < <

| | |

|

(

\ . \ . \ .

=

| |

>

|

|

\ .

s

=

>

where : | = 0.75 x 0.75 = 0.5625 (cont'd)

ec,N

= 0.84 , (ACI 318-08 Fig. RD.5.2.4)

A

N

= 98 x 82 = 8036 in

2

CHECK PULLOUT STRENGTH OF GOVERNING ANCHOR (ACI 318, D.5.3.1)

= 27.018 k > N

ua

= 3.13 kips [Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

A

b

= 1.501

in

2

, ( or determined from manufacture's catalogs.)

cp,N

= 1.0, for location where concrete cracking is likely to occur.

CHECK SIDE-FACE BLOWOUT STRENGTH (ACI 318, D.5.4.1)

cmin > 0.4 hef [Satisfactory]

Since this fastener is located far from a free edge of concrete (c > 0.4 hef ) this type of failure mode is not applicable.

DETERMINE DESIGN TENSILE STRENGTH OF GOVERNING ANCHOR

= 19.771 K

CHECK GOVERNING ANCHOR SHEAR STRENGTH (ACI 318, D.6.1.2b & D.3.3.6)

= 10.28 k > V

ua

= 5.00 kips [Satisfactory]

where : | = 0.65 x 0.75 = 0.4875

(for built-up grout pads, first factor shall be multiplied by 0.8, ACI 318 D.6.1.3)

CHECK CONCRETE BREAKOUT STRENGTH OF GOVERNING ANCHOR FOR SHEAR LOAD (ACI 318, D.6.2.1b)

= 71.555 k > V

ua

= 5.00 kips [Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

ec,V

= 1.0, for no eccentricity in the connection.

c,V

= 1.0, for location where concrete cracking is likely to occur.

l term is load bearing length of the anchor for shear, not to exceed 8d.

CHECK CONCRETE BREAKOUT STRENGTH OF ALL ANCHORS FOR SHEAR LOAD : (ACI 318, D.6.2.1b)

= 77.826 k > V

u

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

CHECK PRYOUT STRENGTH FOR SHEAR LOAD ON GOVERNING ANCHOR (ACI 318, D.6.3.1)

= 44.052 k > V

ua

= 5.00 kips [Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

k

cp

= 2.0

for h

ef

> 2.5 in.

CHECK PRYOUT STRENGTH FOR SHEAR LOAD ON ALL ANCHOR (ACI 318, D.6.3.1)

= 325.072 k > V

u

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

DETERMINE DESIGN SHEAR STRENGTH OF GOVERNING ANCHOR

= 10.281 K

REQUIRED EDGE DISTANCES AND SPACING TO PRECLUDE SPLITTING FAILURE :

Since headed cast-in-place anchors are not like to be highly torqued, the minimum cover requirements of ACI 318 Sec. 7.7 apply.

Cover

Provd

> Cover

Reqd

[Satisfactory]

( )

'

,

8

b pn

cp N c

f

N A

| | =

( ) min , ,

n s cb pn N N N N

| | | | =

0.6

se s ut

f V A

| | =

( )

0.2

1.5

'

, , , , ,

1.0 1.0 7 1.5

V

cb b ec N cd V c V ec V c V c

Vo

l

A

d f

V V h

ef

d

A

| | |

| |

| |

= =

|

|

|

\ .

\ .

( )

( )

'

1.5

, , ,

2

1.0 24

9

N N

cp cp b cp ef

ed N c N c N c

No ef

A A

f

V k N k h

A h

| | | = =

( ) min , ,

n s cb cp V V V V

| | | | =

( )

( )

0.2

1.5

'

, , , , , 2

1.0 7 1.5

4.5 1.5

V V

cbg b ec N cd V c V ec V c V c

Vo

l

A A

d f V V h

ef

d

A

h

ef

| | |

| |

| |

= = |

|

|

\ .

\ .

( )

( )

' 1.5

, , ,

2

1.0 24

9

N N

cpg cp b cp ef ed N c N c N c

No ef

A A

f

V k N k h

A h

| | | = =

(cont'd)

CHECK TENSION AND SHEAR INTERACTION OF GOVERNING ANCHORS : (ACI 318, D.7)

Since N

ua,2

< 0.2 | N

n

and

V

ua,2

< 0.2 | V

n

the full tension design strength is permitted.

The interaction equation may be used

0.26 < 1.2 [Satisfactory]

Summary of Dimensional Properties of Anchors

Effective

Gross Area of

Area of Threaded

Anchor Anchor Heavy Heavy Hardened

( in

2

) ( in

2

) Square Hex Washers

0.250 1/4 0.049 0.032 0.142 0.201 0.117 0.167 0.258

0.375 3/8 0.110 0.078 0.280 0.362 0.164 0.299 0.408

0.500 1/2 0.196 0.142 0.464 0.569 0.291 0.467 0.690

0.625 5/8 0.307 0.226 0.693 0.822 0.454 0.671 1.046

0.750 3/4 0.442 0.334 0.824 1.121 0.654 0.911 1.252

0.875 7/8 0.601 0.462 1.121 1.465 0.891 1.188 1.804

1.000 1 0.785 0.606 1.465 1.855 1.163 1.501 2.356

1.125 1 1/8 0.994 0.763 1.854 2.291 1.472 1.851 2.982

1.250 1 1/4 1.227 0.969 2.288 2.773 1.817 2.237 3.682

1.375 1 3/8 1.485 1.160 2.769 3.300 2.199 2.659 4.455

1.500 1 1/2 1.767 1.410 3.295 3.873 2.617 3.118 5.301

1.750 1 3/4 2.405 1.900 - - - 4.144 6.541

2.000 2 3.142 2.500 - - - 5.316 7.903

CHECK BASE PLATE THICKNESS (AISC Guide - 1, Eq. 3.3.14a)

1.73 in < t = 1.75 in

[Satisfactory]

Hex Square

( in )

Anchor

Diameter

Bearing Area of Heads, Nuts, and Washers

( A

b

) ( in

2

)

,2 ,2 ua ua

n n

N V

N V

| |

+ =

1.5

p

reqD

y

f

m t

F

= =

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

INPUT DATA & DESIGN SUMMARY

CONCRETE STRENGTH f

c

' = 4 ksi

SPECIFIED STRENGTH OF FASTENER f

uta

= 60 ksi

(The strength of most fastenings is likely to be controlled by the embedment strength rather

than the steel strength, so it is usually economical to use ASTM A307 Grade A fastener.)

FACTORED DESIGN LOAD N

ua,1

= 11.7 k

EFFECTIVE EMBEDMENT DEPTH h

ef

= 4.5 in

FASTENER DIAMETER d = 0.5 in

FASTENER HEAD TYPE 2 Heavy Square

( 1=Square, 2=Heavy Square, 3=Hex, 4=Heavy Hex, 5=Hardened Washers )

ECCENTRICITY e = 2 in

FASTENER CENTER-TO-CENTER SPACING s = 6 in

DIST. FR. THE OUTER FASTENERS TO EDGE c = 3 in

SEISMIC LOAD ? (ACI 318 D3.3) No

ANALYSIS

TOTAL NUMBER OF FASTENERS n = 4

EFFECTIVE AREA OF FASTENER A

se

= 0.142

in

2

[THE FASTENER DESIGN IS ADEQUATE.]

BEARING AREA OF HEAD A

b

= 0.569

in

2

, ( or determined from manufacture's catalogs.)

CHECK HIGHTEST TENSILE STRENGTH : (ACI 318, D.5.1.2)

= 6.390 k > = 4.875 k

[Satisfactory]

where : | = 0.75 x 1 = 0.75 , (ACI 318-08 D.4.4 & D.3.3.3)

CHECK CONCRETE BREAKOUT STRENGTH : (ACI 318, D.5.2.1)

= 11.773 k > N

ua

[Satisfactory]

where : | = 0.75 x 1 = 0.75

c,N

term is 1.0 for location where concrete cracking is likely to occur.

CHECK PULLOUT STRENGTH OF SINGLE STUD : (ACI 318, D.5.3.1)

= 13.656 k > N

ua

= 4.875 k, (ACI 318, D.3.3.6)

[Satisfactory]

where : | = 0.75 x 1 = 0.75

cp,N

term is 1.0 for location where concrete cracking is likely to occur.

EVALUATE SIDE-FACE BLOWOUT : (ACI 318, D.5.4.1)

c > 0.4 h

ef

[Satisfactory]

Since this fastener is located far from a free edge of concrete (c > 0.4 hef ) this type of failure mode is not applicable.

REQUIRED EDGE DISTANCES AND SPACING TO PRECLUDE SPLITTING FAILURE :

Since a welded, headed fastener is not torqued, the minimum cover requirements of ACI 318 Sec. 7.7 apply.

Cover

Provd

> Cover

Reqd

[Satisfactory]

Summary of Dimensional Properties of Fasteners

Effective

Gross Area of

Area of Threaded

Fastener Fastener Heavy Heavy Hardened

( in

2

) ( in

2

) Square Hex Washers

0.250 1/4 0.049 0.032 0.142 0.201 0.117 0.167 0.258

0.375 3/8 0.110 0.078 0.280 0.362 0.164 0.299 0.408

0.500 1/2 0.196 0.142 0.464 0.569 0.291 0.467 0.690

0.625 5/8 0.307 0.226 0.693 0.822 0.454 0.671 1.046

0.750 3/4 0.442 0.334 0.824 1.121 0.654 0.911 1.252 Technical Reference:

0.875 7/8 0.601 0.462 1.121 1.465 0.891 1.188 1.804 1. Ronald Cook, "Strength Design

1.000 1 0.785 0.606 1.465 1.855 1.163 1.501 2.356 of Anchorage to Concrete," PCA,

1.125 1 1/8 0.994 0.763 1.854 2.291 1.472 1.851 2.982 1999.

1.250 1 1/4 1.227 0.969 2.288 2.773 1.817 2.237 3.682

1.375 1 3/8 1.485 1.160 2.769 3.300 2.199 2.659 4.455

1.500 1 1/2 1.767 1.410 3.295 3.873 2.617 3.118 5.301

1.750 1 3/4 2.405 1.900 - - - 4.144 6.541

2.000 2 3.142 2.500 - - - 5.316 7.903

Group of Tension Fasteners Near an Edge with Eccentricity Based on ACI 318-08

Hex Square

( in )

Fastener

Diameter

Bearing Area of Heads, Nuts, and Washers

( Ab ) ( in

2

)

( )

,1 se s stud

uta

f

N A

| | =

( )

( )

'

1.5

, , , ,

2

1 0.3

0.7 24

2

1.5 9

1

3

N N

cbg b ef ec N ed N c N c N c

No ef ef

ef

c

A A

f

N N h

e

h A h

h

| | |

| |

|

| |

|

= = +

|

|

\ .

+

|

\ .

( )

'

,

8

b pn

cp N c

f

N A

| | =

( )

,max,1

2

u

ua stud

s e

N

N

ns

+

=

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

INPUT DATA & DESIGN SUMMARY

CONCRETE STRENGTH f

c

' = 4 ksi

SPECIFIED STRENGTH OF FASTENER f

uta

= 60 ksi

(The strength of most fastenings is likely to be controlled by the embedment strength rather

than the steel strength, so it is usually economical to use ASTM A307 Grade A fastener.)

FACTORED DESIGN TENSION LOAD N

ua,1

= 2.47 k

FACTORED DESIGN SHEAR LOAD V

ua,1

= 1 k

EFFECTIVE EMBEDMENT DEPTH h

ef

= 7 in

FASTENER DIAMETER d = 0.5 in

FASTENER HEAD TYPE 3 Hex

( 1=Square, 2=Heavy Square, 3=Hex, 4=Heavy Hex, 5=Hardened Washers ) [THE FASTENER DESIGN IS ADEQUATE.]

DIST. BETWEEN THE FASTENER AND EDGE c = 6 in

SEISMIC LOAD ? (ACI 318 D3.3) Yes

ANALYSIS

EFFECTIVE AREA OF FASTENER A

se

= 0.142

in

2

BEARING AREA OF HEAD A

b

= 0.291

in

2

, ( or determined from manufacture's catalogs.)

CHECK FASTENER TENSILE STRENGTH (ACI 318, D.3.3.6):

= 4.793 k = N

ua

= 4.793 k [Satisfactory]

where : | = 0.75 x 0.75 = 0.5625 , (ACI 318-08 D.4.4 & D.3.3.3)

CHECK CONCRETE BREAKOUT STRENGTH : (ACI 318, D.5.1.2)

= 10.827 k > N

ua

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

c,N

term is 1.0 for location where concrete cracking is likely to occur.

CHECK PULLOUT STRENGTH : (ACI 318, D.5.3.1)

= 5.238 k > N

ua

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

cp,N

term is 1.0 for location where concrete cracking is likely to occur.

CHECK SIDE-FACE BLOWOUT STRENGTH : (ACI 318, D.5.4.1)

= 18.423 k > N

ua

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

DETERMINE DESIGN TENSILE STRENGTH :

= 4.793 K

CHECK FASTENER SHEAR STRENGTH : (ACI 318, D.6.1.2b & D.3.3.6)

= 2.492 k = V

ua

= 2.492 k [Satisfactory]

where : | = 0.65 x 0.75 = 0.4875

(for built-up grout pads, first factor shall be multiplied by 0.8, ACI 318 D6.1.3)

CHECK CONCRETE BREAKOUT STRENGTH FOR SHEAR LOAD : (ACI 318, D.6.2.1a)

= 3.923 k > V

ua

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

c,V

term is 1.0 for location where concrete cracking is likely to occur.

A

V

/ A

Vo

and

cd,V

terms are 1.0 for single shear fastener not influenced by more than one free edge.

l term is load bearing length of the anchor for shear, not to exceed 8d.

Single Fastener in Tension and Shear Near an Edge Based on ACI 318-08

( )

se s

uta

n f

N A

| | =

( )

( )

'

1.5

, , ,

2

0.3

0.7 24

1.5 9

N N

cb b ef

ed N c N c N c

No ef ef

c

A A

f

N N h

h A h

| | |

| |

= = +

|

\ .

( )

'

,

8

b pn

cp N c

f

N A

| | =

( )

'

160

b sb

c

c f

N A

|| =

( )

min , , ,

n s cb pn sb N N N N N

||||| =

0.6

se s

ut

n f

V A

|| =

0.2

'

1.5

, , , ,

7

V V

cb b

cd V c V cd V c V c

Vo Vo

l

A A

d f

V V c

d

A A

| | |

| |

| |

= =

|

|

|

\ .

\ .

(Cont'd)

CHECK PRYOUT STRENGTH FOR SHEAR LOAD : (ACI 318, D.6.3.1)

= 21.654 k > V

ua

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

c,N

term is 1.0 for location where concrete cracking is likely to occur.

k

cp

= 2.0 for h

ef

> 2.5 in.

DETERMINE DESIGN SHEAR STRENGTH :

= 2.492 K

CHECK TENSION AND SHEAR INTERACTION : (ACI 318, D.7)

Since N

ua,1

> 0.2 | N

n

and

V

ua,1

> 0.2 | V

n

the full design strength is not permitted.

The interaction equation must be used

0.92 < 1.2 [Satisfactory]

Summary of Dimensional Properties of Fasteners

Effective

Gross Area of

Area of Threaded

Fastener Fastener Heavy Heavy Hardened

( in

2

) ( in

2

) Square Hex Washers

0.250 1/4 0.049 0.032 0.142 0.201 0.117 0.167 0.258

0.375 3/8 0.110 0.078 0.280 0.362 0.164 0.299 0.408

0.500 1/2 0.196 0.142 0.464 0.569 0.291 0.467 0.690

0.625 5/8 0.307 0.226 0.693 0.822 0.454 0.671 1.046

0.750 3/4 0.442 0.334 0.824 1.121 0.654 0.911 1.252 Technical Reference:

0.875 7/8 0.601 0.462 1.121 1.465 0.891 1.188 1.804 1. Ronald Cook, "Strength Design

1.000 1 0.785 0.606 1.465 1.855 1.163 1.501 2.356 of Anchorage to Concrete," PCA,

1.125 1 1/8 0.994 0.763 1.854 2.291 1.472 1.851 2.982 1999.

1.250 1 1/4 1.227 0.969 2.288 2.773 1.817 2.237 3.682

1.375 1 3/8 1.485 1.160 2.769 3.300 2.199 2.659 4.455

1.500 1 1/2 1.767 1.410 3.295 3.873 2.617 3.118 5.301

1.750 1 3/4 2.405 1.900 - - - 4.144 6.541

2.000 2 3.142 2.500 - - - 5.316 7.903

Hex Square

( in )

Fastener

Diameter

Bearing Area of Heads, Nuts, and Washers

( A

b

) ( in

2

)

( )

( )

'

1.5

, , ,

2

0.3

0.7 24

1.5 9

N N

cp cp b cp ef

ed N c N c N c

No ef ef

c

A A

f

V k N k h

h A h

| | |

| |

= = +

|

\ .

( )

min , ,

n s cb cp V V V V

||||=

,1 ,1 ua ua

n n

N V

N V

| |

+ =

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

INPUT DATA & DESIGN SUMMARY

CONCRETE STRENGTH f

c

' = 4 ksi

SPECIFIED STRENGTH OF FASTENER f

uta

= 58 ksi

(The strength of most fastenings is likely to be controlled by the embedment strength rather

than the steel strength, so it is usually economical to use ASTM A307 Grade A fastener.)

FACTORED DESIGN TENSION LOAD N

ua,1

= 10 k

FACTORED DESIGN SHEAR LOAD V

ua,1

= 3 k

EFFECTIVE EMBEDMENT DEPTH h

ef

= 20 in

FASTENER DIAMETER d = 1 in

FASTENER HEAD TYPE 4 Heavy Hex

( 1=Square, 2=Heavy Square, 3=Hex, 4=Heavy Hex, 5=Hardened Washers )

FASTENER CENTER-TO-CENTER SPACING s = 7 in

DIST. BETWEEN THE FASTENER AND EDGE c1 = 14 in

DIST. BETWEEN THE FASTENER AND EDGE c2 = 9 in

SEISMIC LOAD ? (ACI 318 D3.3) Yes

[THE FASTENER DESIGN IS ADEQUATE.]

ANALYSIS

NUMBER OF FASTENERS n = 2

EFFECTIVE AREA OF FASTENER A

se

= 0.606

in

2

BEARING AREA OF HEAD A

b

= 1.501

in

2

, ( or determined from manufacture's catalogs.)

CHECK THE FASTENERS TENSILE STRENGTH : (ACI 318, D.5.1.2 & D.3.3.6)

= 39.542 k > N

ua

= 25.000 k [Satisfactory]

where : | = 0.75 x 0.75 = 0.5625 , (ACI 318-08 D.4.4 & D.3.3.3)

CHECK CONCRETE BREAKOUT STRENGTH : (ACI 318, D.5.2.1)

= 33.919 k > N

ua

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

ec,N

term is 1.0 for no eccentricity in the connection.

c,N

term is 1.0 for location where concrete cracking is likely to occur.

CHECK PULLOUT STRENGTH : (ACI 318, D.5.3.1)

= 54.036 k > N

ua

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

cp,N

term is 1.0 for location where concrete cracking is likely to occur.

CHECK SIDE-FACE BLOWOUT STRENGTH : (ACI 318, D.5.4.1)

c

min

> 0.4 h

ef

[Satisfactory]

Since this fastener is located far from a free edge of concrete (c > 0.4 hef ) this type of failure mode is not applicable.

DETERMINE DESIGN TENSILE STRENGTH :

= 33.919 K

CHECK Fasteners SHEAR STRENGTH : (ACI 318, D.6.1.2b & D.3.3.6)

= 20.562 k > V

ua

= 7.500 k [Satisfactory]

where : | = 0.65 x 0.75 = 0.4875

(for built-up grout pads, first factor shall be multiplied by 0.8, ACI 318 D6.1.3)

Group of Tension and Shear Fasteners Near Two Edges Based on ACI 318-08

( )

se s

uta

n f

N A

| | =

( )

( )

' min 1.5

, , , , ,

2

0.3

0.7 24

1.5 9

N N

cbg b ef

ec N ed N c N ec N c N c

No ef ef

c A A

f

N N h

h A h

| | |

| |

= = +

|

\ .

( )

'

,

8

b pn

cp N c

f n

N A

| | =

( )

min , ,

n s cb pn N N N N

||||=

0.6

se s

ut

n f

V A

|| =

CHECK CONCRETE BREAKOUT STRENGTH FOR SHEAR LOAD : (ACI 318, D.6.2.1b) (Cont'd)

= 14.433 k > V

ua

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

cp,N

term is 1.0 for no eccentricity in the connection.

c,V

term is 1.0 for location where concrete cracking is likely to occur.

l term is load bearing length of the anchor for shear, not to exceed 8d.

CHECK PRYOUT STRENGTH FOR SHEAR LOAD : (ACI 318, D.6.3.1)

= 67.838 k > V

ua

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

c,N

term is 1.0 for location where concrete cracking is likely to occur.

k

cp

= 2.0 for h

ef

> 2.5 in.

DETERMINE DESIGN SHEAR STRENGTH :

= 14.433 K

REQUIRED EDGE DISTANCES AND SPACING TO PRECLUDE SPLITTING FAILURE :

Since headed cast-in-place fasteners are not like to be highly torqued, the minimum cover requirements of ACI 318 Sec. 7.7 apply.

Cover

Provd

> Cover

Reqd

[Satisfactory]

CHECK TENSION AND SHEAR INTERACTION : (ACI 318, D.7)

Since N

ua,1

> 0.2 | N

n

and

V

ua,1

> 0.2 | V

n

the full design strength is not permitted.

The interaction equation must be used

0.50 < 1.2 [Satisfactory]

Summary of Dimensional Properties of Fasteners

Effective

Gross Area of

Area of Threaded

Fastener Fastener Heavy Heavy Hardened

( in

2

) ( in

2

) Square Hex Washers

0.250 1/4 0.049 0.032 0.142 0.201 0.117 0.167 0.258

0.375 3/8 0.110 0.078 0.280 0.362 0.164 0.299 0.408

0.500 1/2 0.196 0.142 0.464 0.569 0.291 0.467 0.690

0.625 5/8 0.307 0.226 0.693 0.822 0.454 0.671 1.046

0.750 3/4 0.442 0.334 0.824 1.121 0.654 0.911 1.252 Technical Reference:

0.875 7/8 0.601 0.462 1.121 1.465 0.891 1.188 1.804 1. Ronald Cook, "Strength Design

1.000 1 0.785 0.606 1.465 1.855 1.163 1.501 2.356 of Anchorage to Concrete," PCA,

1.125 1 1/8 0.994 0.763 1.854 2.291 1.472 1.851 2.982 1999.

1.250 1 1/4 1.227 0.969 2.288 2.773 1.817 2.237 3.682

1.375 1 3/8 1.485 1.160 2.769 3.300 2.199 2.659 4.455

1.500 1 1/2 1.767 1.410 3.295 3.873 2.617 3.118 5.301

1.750 1 3/4 2.405 1.900 - - - 4.144 6.541

2.000 2 3.142 2.500 - - - 5.316 7.903

Hex Square

( in )

Fastener

Diameter

Bearing Area of Heads, Nuts, and Washers

( A

b

) ( in

2

)

( )( )

0.2

'

1.5

, , , , ,

2

1.5 1 1.5 1 2 2

0.7 0.3 7

1

4.5 1.5 1

1

V

cbg b

ec V cd V c V ec V c V c

Vo

c c s c c l

A

d f

V V c

d c

c A

| | |

| |

+ +

| | | |

= = +

|

| |

|

\ . \ .

\ .

( )

( )

' min 1.5

, , ,

2

0.3

0.7 24

1.5 9

N N

cpg cp b cp ef

ed N c N c N c

No ef ef

c A A

f

V k N k h

h A h

| | |

| |

= = +

|

\ .

( )

min , ,

n s cb cp V V V V

||||=

,1 ,1 ua ua

n n

N V

N V

| |

+ =

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

INPUT DATA & DESIGN SUMMARY

CONCRETE STRENGTH f

c

' = 4 ksi

SPECIFIED STRENGTH OF FASTENER f

uta

= 60 ksi

(The strength of most fastenings is likely to be controlled by the embedment strength rather

than the steel strength, so it is usually economical to use ASTM A307 Grade A fastener.)

FACTORED DESIGN LOAD N

ua,1

= 4 k

EFFECTIVE EMBEDMENT DEPTH h

ef

= 5 in

FASTENER DIAMETER d = 0.5 in

FASTENER HEAD TYPE 2 Heavy Square

( 1=Square, 2=Heavy Square, 3=Hex, 4=Heavy Hex, 5=Hardened Washers ) [THE FASTENER DESIGN IS ADEQUATE.]

SEISMIC LOAD ? (ACI 318 D3.3) Yes

ANALYSIS

EFFECTIVE AREA OF FASTENER A

se

= 0.142

in

2

BEARING AREA OF HEAD A

b

= 0.569

in

2

CHECK FASTENER TENSILE STRENGTH : (ACI 318, D.5.1.2 & D.3.3.6)

= 4.793 k = N

ua

= 4.793 k [Satisfactory]

where : | = 0.75 x 0.75 = 0.5625 , (ACI 318-08 D.4.4 & D.3.3.3)

CHECK CONCRETE BREAKOUT STRENGTH : (ACI 318, D.5.2.1)

= 9.546 k > N

ua

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

A

N

/A

no

and

ed,N

terms are 1.0 for single fasteners away form edges.

c,N

term is 1.0 for location where concrete cracking is likely to occur (i.e., bottom of the slab)

CHECK PULLOUT STRENGTH : (ACI 318, D.5.3.1)

= 10.242 k > N

ua

[Satisfactory]

where : | = 0.75 x 0.75 = 0.5625

cp,N

term is 1.0 for location where concrete cracking is likely to occur.

EVALUATE SIDE-FACE BLOWOUT :

Since this fastener is located far from a free edge of concrete (c > 0.4 h

ef

) this type of failure mode is not applicable.

REQUIRED EDGE DISTANCES AND SPACING TO PRECLUDE SPLITTING FAILURE :

Since this fastener is located far from a free edge of concrete (c>0.4h

ef

) this type of failure mode is not applicable.

Summary of Dimensional Properties of Fasteners

Effective

Gross Area of

Area of Threaded

Fastener Fastener Heavy Heavy Hardened

( in

2

) ( in

2

) Square Hex Washers

0.250 1/4 0.049 0.032 0.142 0.201 0.117 0.167 0.258

0.375 3/8 0.110 0.078 0.280 0.362 0.164 0.299 0.408 Technical Reference:

0.500 1/2 0.196 0.142 0.464 0.569 0.291 0.467 0.690 1. Ronald Cook, "Strength Design

0.625 5/8 0.307 0.226 0.693 0.822 0.454 0.671 1.046 of Anchorage to Concrete," PCA,

0.750 3/4 0.442 0.334 0.824 1.121 0.654 0.911 1.252 1999.

0.875 7/8 0.601 0.462 1.121 1.465 0.891 1.188 1.804

1.000 1 0.785 0.606 1.465 1.855 1.163 1.501 2.356

1.125 1 1/8 0.994 0.763 1.854 2.291 1.472 1.851 2.982

1.250 1 1/4 1.227 0.969 2.288 2.773 1.817 2.237 3.682

1.375 1 3/8 1.485 1.160 2.769 3.300 2.199 2.659 4.455

1.500 1 1/2 1.767 1.410 3.295 3.873 2.617 3.118 5.301

1.750 1 3/4 2.405 1.900 - - - 4.144 6.541

2.000 2 3.142 2.500 - - - 5.316 7.903

Hex Square

( in )

Fastener

Diameter

Bearing Area of Heads, Nuts, and Washers

( A

b

) ( in

2

)

Single Tension Fastener Away from Edges Based on ACI 318-08

( )

se s

uta

n f

N A

| | =

( )

'

1.5

, , , ,

24

N N

cb b ef

ed N c N ed N c N c

No No

A A

f

N N h

A A

| | | = =

( )

'

,

8

b pn

cp N c

f

N A

| | =

You might also like

- Pipe Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryDocument1 pagePipe Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryYatsen Jepthe Maldonado SotoNo ratings yet

- Anchorage To ConcreteDocument18 pagesAnchorage To ConcreteNEONo ratings yet

- EMBEDMENT CALCULATIONDocument5 pagesEMBEDMENT CALCULATIONMWKELIOLANo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Anchoring To Concrete VerificationDocument16 pagesAnchoring To Concrete VerificationZeinab100% (1)

- N F N A: Input Data & Design SummaryDocument9 pagesN F N A: Input Data & Design SummaryOswaldo SuárezNo ratings yet

- Tension Anchor Reinforcement: Design SatisfactoryDocument1 pageTension Anchor Reinforcement: Design SatisfactoryAnonymous xcFcOgMiNo ratings yet

- Beam Web Opening AnalysisDocument3 pagesBeam Web Opening AnalysisgetweiNo ratings yet

- PurlinDocument1 pagePurlinCe WinNo ratings yet

- Combined Axial Force and Biaxial Bending Interaction Diagram for Reinforced Concrete ColumnDocument29 pagesCombined Axial Force and Biaxial Bending Interaction Diagram for Reinforced Concrete ColumnEng-bashir Said AbshirNo ratings yet

- ACI 209R-92 - Effects of creep, shrinkage, and temperature in concreteDocument15 pagesACI 209R-92 - Effects of creep, shrinkage, and temperature in concreteHussein BeqaiNo ratings yet

- CompositeDocument11 pagesCompositeluuvandong48xf396100% (1)

- Seismic Design For Special MomentDocument2 pagesSeismic Design For Special MomentreynoldNo ratings yet

- Effective LengthDocument17 pagesEffective LengthJob NantawatNo ratings yet

- Software Verification: AISC-360-10 Example 001Document9 pagesSoftware Verification: AISC-360-10 Example 001Davico HernandezNo ratings yet

- Beam DesignDocument7 pagesBeam DesignKasi ViswanathanNo ratings yet

- Coupling BeamDocument2 pagesCoupling Beamwilliam6703100% (1)

- Anchorbolt (318 08) ShearDocument1 pageAnchorbolt (318 08) ShearAnonymous xcFcOgMiNo ratings yet

- Concrete PierDocument3 pagesConcrete PierAbdullah Al MamunNo ratings yet

- RC Slab Crack Width CalculationDocument6 pagesRC Slab Crack Width CalculationDonny. B TampubolonNo ratings yet

- Bsep SMFDocument6 pagesBsep SMFamirgholami1100% (1)

- ACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017!04!10Document11 pagesACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017!04!10Muhammad Imran ZafarNo ratings yet

- Anchorbolt R1Document12 pagesAnchorbolt R1Matheus HenrichNo ratings yet

- Moment Connection Using Mathcad PDFDocument11 pagesMoment Connection Using Mathcad PDFbong2rmNo ratings yet

- A) Shear Capacity of BoltsDocument30 pagesA) Shear Capacity of BoltsAjit JiNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example According To ACI 318 Appendix D - Breakout Strength in ShearDocument5 pagesConcrete Anchor Foundation Bolt Design Calculations With Example According To ACI 318 Appendix D - Breakout Strength in ShearMohammad AasimuddinNo ratings yet

- Connections I V2.0.6b FinalDocument71 pagesConnections I V2.0.6b FinalNick Andrews50% (2)

- Enhanced Composite Beam Design Project SummaryDocument5 pagesEnhanced Composite Beam Design Project SummarygalatiansNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionDocument6 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionVenu GopalNo ratings yet

- ACI 350 - ACI224R-01 Rectangular Section Flexural Crack Width ControlDocument1 pageACI 350 - ACI224R-01 Rectangular Section Flexural Crack Width ControlAie Bantugan0% (1)

- 1 Input Data: Hilti PROFIS Engineering 3.1.1Document10 pages1 Input Data: Hilti PROFIS Engineering 3.1.1Zaido Al HalabiNo ratings yet

- Column W10x49 2L6x4x1/2 BraceDocument4 pagesColumn W10x49 2L6x4x1/2 BraceDario Federico Noguez GonzalézNo ratings yet

- Splice ConnectionDocument18 pagesSplice ConnectionAhmad Pooladi0% (1)

- Steel Building Brace Connection DesignDocument4 pagesSteel Building Brace Connection Designmoganna73No ratings yet

- Steel ConnectionsDocument83 pagesSteel ConnectionsMEPNo ratings yet

- Corner Cast in Place AnchorDocument7 pagesCorner Cast in Place Anchorwaweng22No ratings yet

- 275 THK Slab Design 1 .Document4 pages275 THK Slab Design 1 .bittuchintuNo ratings yet

- Anchor Reinf. AnalysisDocument5 pagesAnchor Reinf. AnalysisRusdha MaulanaNo ratings yet

- Composite Floor Deck Design PDFDocument4 pagesComposite Floor Deck Design PDFsaipodinNo ratings yet

- Rectangular Concrete Beam Analysis in ExcelDocument16 pagesRectangular Concrete Beam Analysis in ExcelAli Syaputra100% (1)

- G EOTECHNICAL CAPACITY OF R. C. C PILEDocument1 pageG EOTECHNICAL CAPACITY OF R. C. C PILEChowdhury PriodeepNo ratings yet

- Prestressed Beam Design for Conventional HallDocument12 pagesPrestressed Beam Design for Conventional HallHaymanAHMEDNo ratings yet

- Steel Beams With Web Openings-V2Document369 pagesSteel Beams With Web Openings-V2Brian Krug100% (1)

- ACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017!04!10Document2 pagesACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017!04!10Diana RamosNo ratings yet

- SWD-CSA-A23.3-04 Shear Wall Design ManualDocument82 pagesSWD-CSA-A23.3-04 Shear Wall Design ManualYohan LimNo ratings yet

- Design of Bracket BR-1 & BR-2 for Concrete Grade and Steel GradeDocument4 pagesDesign of Bracket BR-1 & BR-2 for Concrete Grade and Steel Gradekushaljp8989No ratings yet

- Direct Analysis and Its Implentation in Staad - Pro: Applies ToDocument15 pagesDirect Analysis and Its Implentation in Staad - Pro: Applies ToZULFIKAR AZANNo ratings yet

- Compare BS and ACI CodeDocument12 pagesCompare BS and ACI CodeMiski45100% (1)

- Bolt capacity and plate designDocument2 pagesBolt capacity and plate designvtalexNo ratings yet

- Design of Composite Beams for Building ProjectDocument6 pagesDesign of Composite Beams for Building Projectdovi01No ratings yet

- U-BORA Tower DesignDocument5 pagesU-BORA Tower DesignAnbalaganVNo ratings yet

- DE010 of-053123-1.0-P-Vulcraft Joist and Deck Plans - Datum ReviewedDocument9 pagesDE010 of-053123-1.0-P-Vulcraft Joist and Deck Plans - Datum ReviewedAzeemuddin Gulam MohammedNo ratings yet

- Pdelta & Repeat LoadDocument5 pagesPdelta & Repeat LoadGautam PaulNo ratings yet

- Shear Lug Verification Example 2Document1 pageShear Lug Verification Example 2Nasrul AdliNo ratings yet

- Footing Design As Per BS 8110 PDFDocument1 pageFooting Design As Per BS 8110 PDFBobby A MathewNo ratings yet

- Concrete Design SummaryDocument3 pagesConcrete Design Summaryyanu13No ratings yet

- Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryDocument3 pagesConcrete Column Design Based On ACI 318-11: Input Data & Design Summaryjaimeleoxxx0% (1)

- 25 R04 - CofrajeDocument3 pages25 R04 - CofrajemakakkNo ratings yet

- 8 Multi Storey Car ParkingDocument34 pages8 Multi Storey Car Parkingfaezah adnan97% (31)

- Flexion Déviéeelsdans Unesection Deformequelconque Calculs en Section FissuréeDocument1 pageFlexion Déviéeelsdans Unesection Deformequelconque Calculs en Section FissuréemakakkNo ratings yet

- Load From Computer Analysis : Design of Isolated FootingDocument4 pagesLoad From Computer Analysis : Design of Isolated FootingChanakya SharmaNo ratings yet

- 1Document75 pages1rig2003No ratings yet

- Agrement PlanseeDocument1 pageAgrement PlanseemakakkNo ratings yet

- Agrement Tehnic BST500SDocument23 pagesAgrement Tehnic BST500SPopescu Ana MariaNo ratings yet

- ETABS Composite Floor Frame Design ManualDocument420 pagesETABS Composite Floor Frame Design Manualleovorig100% (5)

- Profile ArcelorDocument58 pagesProfile ArcelormarrianescuNo ratings yet

- MaterialsDocument3 pagesMaterialsmakakkNo ratings yet

- Wood PreservationsDocument239 pagesWood Preservationsdora_grebeNo ratings yet

- 2 WayslabDocument8 pages2 WayslabAnonymous 9ltPgg1e6No ratings yet

- Opt FootDocument3 pagesOpt FootAnupama BharathNo ratings yet

- Design of RC Pad With Single Column Footing: Dead Imposed WindDocument22 pagesDesign of RC Pad With Single Column Footing: Dead Imposed Windsvrao4u100% (2)

- Agricole 3Document27 pagesAgricole 3rig2003No ratings yet

- Counter Fort Reatining WAll With HORZONTAL Bach FillDocument52 pagesCounter Fort Reatining WAll With HORZONTAL Bach FillHilary Watson100% (1)

- Autocad Structural Detailing 2012Document18 pagesAutocad Structural Detailing 2012Siva Senthil50% (2)

- RC WorkbookDocument28 pagesRC WorkbookmakakkNo ratings yet

- SarpantaDocument7 pagesSarpantadadadianaNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)thusiNo ratings yet

- One Way Two Way Slab S6Document1 pageOne Way Two Way Slab S6manishnparmarNo ratings yet

- Excel Program For Timber StructuresDocument36 pagesExcel Program For Timber StructuresCarmel Buniel Sabado100% (9)

- One Way Slab1Document4 pagesOne Way Slab1api-19754583No ratings yet

- Base Plate - FixedDocument4 pagesBase Plate - Fixedbhaskardharani80% (5)

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Miguel Angel GalindoNo ratings yet

- Calcul SarpantaDocument3 pagesCalcul Sarpantacrmn_matNo ratings yet

- Spread Footing DesignDocument3 pagesSpread Footing Designjkem_fontanilla542580% (10)

- JEC Prog T BeamsDocument6 pagesJEC Prog T BeamsmakakkNo ratings yet

- Astm D2041-11 GMMDocument4 pagesAstm D2041-11 GMMAbbasi HussainNo ratings yet

- Light Fastness of Blue PigmentDocument7 pagesLight Fastness of Blue PigmentShaik DawoodNo ratings yet

- Asma Zaghbani Publications ScientifiquesDocument2 pagesAsma Zaghbani Publications Scientifiquesapi-227010260No ratings yet

- Kalibrasi Mesin DialDocument78 pagesKalibrasi Mesin DialMrQmonkNo ratings yet

- ITT American Electric Power-Pad Horizontal Cutoff Series 213 & 214 Spec Sheet 9-81Document8 pagesITT American Electric Power-Pad Horizontal Cutoff Series 213 & 214 Spec Sheet 9-81Alan MastersNo ratings yet

- Kingdom of Saudi Arabia: Aggregate Loss Correction by Bituminometer MethodDocument1 pageKingdom of Saudi Arabia: Aggregate Loss Correction by Bituminometer MethodHamza AldaeefNo ratings yet

- International GCSE Chemistry Teacher Resource Pack SampleDocument25 pagesInternational GCSE Chemistry Teacher Resource Pack SampleRaneem HaddadinNo ratings yet

- Karkim Kar Ben enDocument1 pageKarkim Kar Ben enIqbal batchaNo ratings yet

- Paper 2 June 2007 PhysicsDocument16 pagesPaper 2 June 2007 PhysicssolarixeNo ratings yet

- BS en Iso 12944-1-2017Document41 pagesBS en Iso 12944-1-2017Dwarakanathan Makkada YuvarajNo ratings yet

- Tolerances of A Polystyrene Film: 2.2.25. ABSORPTION Spectrophotometry, Ultraviolet and VisibleDocument3 pagesTolerances of A Polystyrene Film: 2.2.25. ABSORPTION Spectrophotometry, Ultraviolet and Visibleivan cuadradoNo ratings yet

- Industrial Crops & ProductsDocument11 pagesIndustrial Crops & ProductsAleksandrs ArnautovsNo ratings yet

- DSSC PresentationDocument50 pagesDSSC PresentationWisaruth MaethasithNo ratings yet

- Mid-Term Test 2012Document9 pagesMid-Term Test 2012Muhammad FauzanNo ratings yet

- 4-2 Rha 2Document1 page4-2 Rha 2Dragan LazicNo ratings yet

- HMTDocument3 pagesHMTRuby SmithNo ratings yet

- Gmaw STTDocument4 pagesGmaw STTAnonymous 0rt9KWmNNo ratings yet

- Revision Test 1-KPT and Separation TechniquesDocument18 pagesRevision Test 1-KPT and Separation TechniquesFangru CaoNo ratings yet

- RetroSled OverviewDocument1 pageRetroSled OverviewdigdreamNo ratings yet

- Formation of The Heavy ElementsDocument17 pagesFormation of The Heavy ElementsSheiloiNo ratings yet

- Sellos T-5610 T-5610QDocument8 pagesSellos T-5610 T-5610QBenicio Joaquín Ferrero BrebesNo ratings yet

- The Report ofDocument8 pagesThe Report ofAhyana RehaniNo ratings yet

- Astm A 1084 2013 PDFDocument17 pagesAstm A 1084 2013 PDFjoao carlos protzNo ratings yet

- Disintegration TestDocument19 pagesDisintegration TestUsman Najeeb Cheema100% (1)

- Microencapsulation of Cinnamon and Garlic Oils in Beta-CyclodextrinDocument10 pagesMicroencapsulation of Cinnamon and Garlic Oils in Beta-CyclodextrinErman ÇutukNo ratings yet

- Presentacion CECABASE Rosario en InglésDocument23 pagesPresentacion CECABASE Rosario en InglésLa FoliakNo ratings yet

- Air Quality Guidelines For EuropeDocument288 pagesAir Quality Guidelines For EuropeAlex OliveiraNo ratings yet

- Capacitor PosterDocument1 pageCapacitor PosterMajorNo ratings yet

- Pressure Relief ValvesDocument6 pagesPressure Relief ValvesShashank Sudhakar PathakNo ratings yet

- Advances in Modern Refractory CastableDocument12 pagesAdvances in Modern Refractory CastableBagas Prasetyawan Adi Nugroho100% (1)