Professional Documents

Culture Documents

Cadweld Multi: An Evolution in Exothermic Welding

Uploaded by

akshaf10Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cadweld Multi: An Evolution in Exothermic Welding

Uploaded by

akshaf10Copyright:

Available Formats

CADWELD MULTI Connection Capabilities

Copper Cable/Solid to Copper Cable/Solid

An Evolution In Exothermic Welding

SS SC PA TA XA GG GJ TD TE TF

Copper concentric conductor sizes up to 25 mm2 (6.6 mm dia.) or #3 AWG (0.26 dia.)

CADWELD MULTI

GF

GW

XB

PP

PK

GE

PG

Copper concentric conductor sizes up to 50 mm2 (9.3 mm dia.) or 1/0 AWG (0.37 dia.)

Copper Cable/Solid Strip to Rebar

Copper Strip to Copper Strip

RG

RH

RK

RF

RD

BB

CG

BG

EB

Copper concentric conductor sizes up to 50 mm2 (9.3 mm dia.) or 1/0 AWG (0.37 dia.) Copper or steel strip sizes up to 30 x 3,5 mm (1.2 x 0.14) Rebar sizes up to 10 mm (#3)

BB and CG: Copper strip sizes up to 30 x 3,5 mm (1.2 x 0.14) BG and EB: Copper strip sizes up to 30 x 3,0 mm (1.2 x 0.12)

Copper Cable/Solid to Copper or Steel Strip/Lug

Galvanized Steel Strip to Galvanized Steel Strip

HA

HC

HS

HT

GL

LA

LJ

LE

BB

CG

Copper concentric conductor sizes up to 50 mm2 (9.3 mm dia.) or 1/0 AWG (0.37 dia.) Copper or steel lug / strip sizes up to 30 x 3,5 mm (1.2 x 0.14)

Galvanized steel strip sizes up to 30 x 3,5 mm (1.2 x 0.14)

Ground Rod Connections

TG

GT

CN

CP

GR

GT

CN

CP

GR

Copper concentric conductor sizes up to 10 mm2 (4.2 mm dia.) or #6 AWG (0.18 dia.) Copper strip sizes up to 30 x 2,0 mm (1.2 x 0.08)

Copper concentric conductor sizes greater than 10 mm2 (4.2 mm dia.) or #6 AWG (0.18 dia.) Copper strip sizes 30 x (2,5 - 3,0 mm) or 1.2 x (0.10 0.12) Steel strip sizes 30 x (0,5 - 3,5 mm) or 1.2 x (0.02 0.14)

CADWELD MULTI Available Items

Part Nr Article Nr Description Weight (kg)

KITCDMV01 167782 CADWELD MULTI Kit 1 25.000 The CADWELD MULTI kit (KITCDMV01) contains the following list of items: FMCDMV01 120883 Handle Clamp 1 1.800 CDMV01H 240399 Mold for H welds 1 1.200 CDMV0112 240398 Mold for welds on 1/2 rods 1 1.200 CDMV0158 240397 Mold for welds on 5/8 rods 1 1.200 CDMV0134 240396 Mold for welds on 3/4 rods* 1 1.200 SCDM01 120886 Set of 33 batting/gaskets 2 0.200 B399P 162070 SKK1 clamp 1 0.500 NOTES: TSCSTP 197295 Toolset 1 2.000 * For connections using a 3/4 ground rod, it is necessary B136B 182030 Slag Removal Spade 1 0.144 to use #115 / 115PLUSF20 weld material (sold separately). Language free instruction sheet 1 The following items can be used with the CADWELD MULTI Kit (KITCDMV01). They are sold separately. For all other connection types, use #90 or 90PLUSF20. T320 165000 Flint Ignitor T320 1 0.090 For connections using galvanized material, remove 90 163040 CADWELD Traditional welding material 10 0.090 galvanizing before welding, for a better connection. 115 163050 CADWELD Traditional welding material 10 0.115 PLUSCU 165745 Control Unit 1 1.088 PLUS#90F20 165705 CADWELD PLUS welding material 10 0.158 PLUS#115F20 165706 CADWELD PLUS welding material 10 0.185

Due to ERICOs continuous product improvement policy, products shown in this catalog are subject to change without notice. If you would like to know more about the benefits of CADWELD MULTI contact ERICO or visit: www.erico.com

IEEE is a registered trademark of the Institute of Electrical and Electronics Engineers, Incorporated.

Symbol denotes number of batting (gaskets) required for each connection.

Requires 2 batting layers for weld Requires 3 batting layers for weld

WELD CAD LTI MU orms er f now pections conn ound to gr s r od

WARNING ERICO products shall be installed and used only as indicated in ERICOs product instruction sheets and training materials. Instruction sheets are available at www.erico.com and from your ERICO customer service representative. Improper installation, misuse, misapplication or other failure to completely follow ERICOs instructions and warnings may cause product malfunction, property damage, serious bodily injury and death. WARRANTY ERICO products are warranted to be free from defects in material and workmanship at the time of shipment. NO OTHER WARRANTY, WHETHER EXPRESS OR IMPLIED (INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), SHALL EXIST IN CONNECTION WITH THE SALE OR USE OF ANY ERICO PRODUCTS. Claims for errors, shortages, defects or nonconformities ascertainable upon inspection must be made in writing within 5 days after Buyers receipt of products. All other claims must be made in writing to ERICO within 6 months from the date of shipment or transport. Products claimed to be nonconforming or defective must, upon ERICOs prior written approval in accordance with its standard terms and procedures governing returns, promptly be returned to ERICO for inspection. Claims not made as provided above and within the applicable time period will be barred. ERICO shall in no event be responsible if the products have not been stored or used in accordance with its specifications and recommended procedures. ERICO will, at its option, either repair or replace nonconforming or defective products for which it is responsible or return the purchase price to the Buyer. THE FOREGOING STATES BUYERS EXCLUSIVE REMEDY FOR ANY BREACH OF ERICO WARRANTY AND FOR ANY CLAIM, WHETHER SOUNDING IN CONTRACT, TORT OR NEGLIGENCE, FOR LOSS OR INJURY CAUSED BY THE SALE OR USE OF ANY PRODUCT. LIMITATION OF LIABILITY ERICO excludes all liability except such liability that is directly attributable to the willful or gross negligence of ERICOs employees. Should ERICO be held liable its liability shall in no event exceed the total purchase price under the contract. ERICO SHALL IN NO EVENT BE RESPONSIBLE FOR ANY LOSS OF BUSINESS OR PROFITS, DOWNTIME OR DELAY, LABOR, REPAIR OR MATERIAL COSTS OR ANY SIMILAR OR DISSIMILAR CONSEQUENTIAL LOSS OR DAMAGE INCURRED BY BUYER.

Copyright 2003, 2004, 2008, 2012 ERICO International Corporation. All rights reserved. CADDY, CADWELD, CRITEC, ERICO, ERITECH, ERIFLEX, and LENTON are registered trademarks of ERICO International Corporation.

www.erico.com

E399B-WWEN E1494LT12WWEN WB1112

CADWELD MULTI

CADWELD MULTI offers all of the benefits of CADWELD connections:

Current-carrying capacity equal to that of the conductor Permanent molecular bond that will not loosen or corrode Works with CADWELD traditional welding material Works with CADWELD PLUS welding material Will withstand repeated fault currents No external power or heat required Ground rod capabilities Visual inspection possible Welding Requires minimal training

material sold separately.

Exothermic Welded Connections

Exothermic welded connections are immune to thermal conditions which can cause mechanical and compression joints to become loose or corrode. They are recognized for their durability and longevity.

Welding material sold separately.

The complete welding system for improving grounding system performance, reliability, and installation convenience.

CADWELD MULTI simplifies the exothermic welding process. Make over 30 separate connection types with a single, universal mold, which now enables you to make connections to a ground rod.

How Does It Work?

CADWELD MULTI combines a versatile mold block and a range of gaskets (batting) to allow numerous different welded connections to be produced without the need to change the mold for each connection type.

Easy steps for multiple, permanently welded, electrical connections

GT

PK

CADWELD Connection

The CADWELD exothermic welding process fuses conductors together to form a molecular bond with a currentcarrying capacity equal to that of the conductor. Grounding systems incorporating this type of connection therefore operate as a continuous conductor with lower resistivity.

CP

SS

CADWELD MULTI

CADWELD MULTI offers enhanced user benefits: Performs welds to ground rods Versatile mold produces an unlimited variety of connections Compact compression structure enables easy alignment of conductors Language-free instruction guide Lightweight kit for easy transportation Easy-to-use system completes weld in seconds Video available on www.erico.com

The process is similar to the classic CADWELD with one distinct difference... there is no need to change the mold for different connection types. The whole process is complete in about one minute. The back page table details the gasket quantities required for each weld.

CN

STEP

RF

Layer batting and variable conductor sizes to be welded into dry mold.

STEP

Add CADWELD PLUS welding material.

TG

XA

Standard Compliance

CADWELD MULTI satisfies the requirements of: BS 6651 BS 7430 NFC 15-100 IEEE 837-1987 IEEE 80-2000 IEC 1025-1 (ENV 61024-1)

TA

STEP

PG

Close cover and connect CADWELD PLUS control unit.

STEP

Press and hold operate button. Open mold after 10 seconds.

CADWELD MULTI also works with CADWELD Traditional Welding Material.

You might also like

- DSR Electrical 2012Document60 pagesDSR Electrical 2012vijay_raina31140% (1)

- SYBLINGs B.O.QDocument2 pagesSYBLINGs B.O.Qmichael_reedxyzNo ratings yet

- Furse Exothermic Welding Method StatementDocument18 pagesFurse Exothermic Welding Method StatementOğuz Üçer100% (1)

- Appendix 11, Electrical Inspection and Test PlanDocument1 pageAppendix 11, Electrical Inspection and Test PlanNidhin MohanNo ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Item Checklist Description Result RemarksDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Item Checklist Description Result RemarksmeeNo ratings yet

- 004 Material Inspection Request MepDocument1 page004 Material Inspection Request MepAbdalrhman KararNo ratings yet

- MOS For T&C Data & Telecommunication NetworkDocument11 pagesMOS For T&C Data & Telecommunication NetworkTarek Mahmoud GhazyNo ratings yet

- Qatar Petroleum Construction Co. Ltd Inspection & Test PlanDocument1 pageQatar Petroleum Construction Co. Ltd Inspection & Test PlanmeeNo ratings yet

- Earthing and Bonding Method StatementDocument4 pagesEarthing and Bonding Method StatementMusthafa Shaik100% (1)

- Method Statement - Elect. Jerry ShellDocument5 pagesMethod Statement - Elect. Jerry ShellnayumNo ratings yet

- Fiber Optic Cable Splicing and Termination Test ReportDocument2 pagesFiber Optic Cable Splicing and Termination Test ReportBharathiNo ratings yet

- Method Statement FOR Laying of LV Cables: M & E ContractorDocument4 pagesMethod Statement FOR Laying of LV Cables: M & E ContractorJoe_AverageNo ratings yet

- Engineering Design Reports & Equipment SelectionDocument1 pageEngineering Design Reports & Equipment SelectionmitasyahuNo ratings yet

- MS Earthing of Bonding Lighting ArrestorsDocument25 pagesMS Earthing of Bonding Lighting ArrestorsJaafar LagayanNo ratings yet

- New Senate Building Project: Method StatementDocument2 pagesNew Senate Building Project: Method Statementjerrick raulNo ratings yet

- 16320Document9 pages16320uddinnadeemNo ratings yet

- Acknowledgement I List of Figures II List of Tables IV List of Abbreviations V VIDocument8 pagesAcknowledgement I List of Figures II List of Tables IV List of Abbreviations V VIPoorna DeviNo ratings yet

- Cgk063 Rfa Mos M XXX - Cooling Tower InstallationDocument24 pagesCgk063 Rfa Mos M XXX - Cooling Tower Installationdiki anggriawanNo ratings yet

- Video Intercom Solution and Cabling SpecificationsDocument20 pagesVideo Intercom Solution and Cabling SpecificationsSaid GedeonNo ratings yet

- Blackall Aerodrome Lighting QuotationDocument53 pagesBlackall Aerodrome Lighting Quotationgraceenggint8799No ratings yet

- Final Distribution Boards SpecificationsDocument18 pagesFinal Distribution Boards SpecificationsDolyNo ratings yet

- Fire Flow CalculationDocument2 pagesFire Flow Calculationcoolsummer1112143No ratings yet

- CSC 03Document5 pagesCSC 03Azmi NordinNo ratings yet

- Technical Specification For Communication EquipmentDocument79 pagesTechnical Specification For Communication EquipmentumamaheshwarraoNo ratings yet

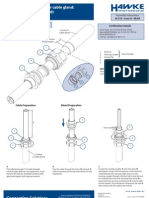

- Assembly Instructions for 501/414 Exd IIC/Exe II ExtD Cable GlandDocument2 pagesAssembly Instructions for 501/414 Exd IIC/Exe II ExtD Cable GlandFoe AungNo ratings yet

- IP - Ingress Protection RatingsDocument1 pageIP - Ingress Protection Ratingsanon_904868564No ratings yet

- Gupsum Board PDFDocument2 pagesGupsum Board PDFMuhammadYehiaNo ratings yet

- Transformers, Dry Type, Air-Cooled, Low Voltage, SmallDocument2 pagesTransformers, Dry Type, Air-Cooled, Low Voltage, SmallHoneylyn IgnacioNo ratings yet

- Elect M&eDocument277 pagesElect M&eSOEYUAUNGNo ratings yet

- Installationguide T484 120510 UkDocument44 pagesInstallationguide T484 120510 UkBesugoNo ratings yet

- PAL - Construction GuidelinesDocument28 pagesPAL - Construction GuidelinesCarew Mohammed AbayomiNo ratings yet

- Electrical Power Distribution Specification-IIDocument6 pagesElectrical Power Distribution Specification-IIssb100% (1)

- CP5 Amendment 1 27 Feb 2009 Fact SheetDocument4 pagesCP5 Amendment 1 27 Feb 2009 Fact Sheetkyawswarpm100% (1)

- Twm-z1 & Z-2 - PH & FF SpecsDocument175 pagesTwm-z1 & Z-2 - PH & FF SpecsmimrusfanNo ratings yet

- DIV 16 Electrical Labor1Document43 pagesDIV 16 Electrical Labor1Anila SadasivanNo ratings yet

- Certificate of Compliance Under The Electricity (Electrical Installations) Regulations 2002Document2 pagesCertificate of Compliance Under The Electricity (Electrical Installations) Regulations 2002Zhu Qi WangNo ratings yet

- Lightning Strike and Surge CounterDocument2 pagesLightning Strike and Surge Countersampath muthunayakeNo ratings yet

- Method Statement FOR Testing and Commissioning: Grounding SystemDocument3 pagesMethod Statement FOR Testing and Commissioning: Grounding SystemNon Etabas Gadnatam100% (1)

- Blue Eyed Muse InspectionDocument2 pagesBlue Eyed Muse InspectionBen SchachtmanNo ratings yet

- 04 - ElectricalDocument220 pages04 - ElectricalwegNo ratings yet

- BeldenDocument156 pagesBeldenRonald H SantosNo ratings yet

- Ooredoo: Method Statement For Fiber Optic Cable WorkDocument5 pagesOoredoo: Method Statement For Fiber Optic Cable WorkYousaf RichuNo ratings yet

- 50-year-old Singaporean resume for construction rolesDocument6 pages50-year-old Singaporean resume for construction rolesengrkafilNo ratings yet

- Electrical Works Terms and ConditionsDocument4 pagesElectrical Works Terms and Conditionsdefiantoro91No ratings yet

- ChecklistDocument35 pagesChecklistShashi Kant Singh100% (1)

- SG Cable Colour Code ChangesDocument4 pagesSG Cable Colour Code ChangesOA AooNo ratings yet

- Bs 76712018 Model Forms Minor Electrical Installation Works CertificateDocument4 pagesBs 76712018 Model Forms Minor Electrical Installation Works Certificatehany mohamedNo ratings yet

- Section 16200 Electrical, GeneralDocument6 pagesSection 16200 Electrical, GeneralctoujagueNo ratings yet

- Underfloor Trunking CatalogueDocument60 pagesUnderfloor Trunking CatalogueARUNDAS572No ratings yet

- Camlock Electrical Maintenance ServicesDocument3 pagesCamlock Electrical Maintenance ServicesCamlock0% (1)

- Form 4 Test Results SummaryDocument1 pageForm 4 Test Results SummaryKarim AmerNo ratings yet

- Requirements For Streetlight Design PDFDocument33 pagesRequirements For Streetlight Design PDFBADRI VENKATESHNo ratings yet

- Sl. No. Description Page No.: List of FiguresDocument1 pageSl. No. Description Page No.: List of FiguresARSHEEYA BONo ratings yet

- E524c AsenDocument56 pagesE524c AsenmaungmaunglattNo ratings yet

- Installers and Inspectors Guide For Cadweld Electrical ConnectionsDocument24 pagesInstallers and Inspectors Guide For Cadweld Electrical ConnectionsHumberto SagárnagaNo ratings yet

- CIR CatalogDocument12 pagesCIR Catalogchaupha1No ratings yet

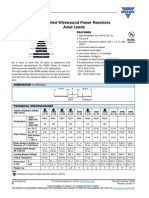

- Vishay Sfernice: FeaturesDocument4 pagesVishay Sfernice: FeaturesAnonymous onIfGeuU0No ratings yet

- E 2209 AcdcDocument2 pagesE 2209 AcdcLuis Alejandro Gonzalez SantanaNo ratings yet

- PKC DixieWire CatalogDocument16 pagesPKC DixieWire CatalogSlobodan VeljovicNo ratings yet

- FRLS building wiresDocument2 pagesFRLS building wiresAmit PaulNo ratings yet

- DFDF PDFDocument1 pageDFDF PDFakshaf10No ratings yet

- Handbook on Water Supply and Drainage with Emphasis on PlumbingDocument181 pagesHandbook on Water Supply and Drainage with Emphasis on PlumbingHolly Hart91% (11)

- Calculate available fault currentDocument11 pagesCalculate available fault currentrdelgranadoNo ratings yet

- Document 2Document1 pageDocument 2akshaf10No ratings yet

- Calculate available fault currentDocument11 pagesCalculate available fault currentrdelgranadoNo ratings yet

- To Do ListDocument1 pageTo Do Listakshaf10No ratings yet

- Document 2Document1 pageDocument 2akshaf10No ratings yet

- C.B Tripping Setting-Motor Data (28!5!11)Document31 pagesC.B Tripping Setting-Motor Data (28!5!11)KIS610No ratings yet

- CP Salary Guide HK 2010Document26 pagesCP Salary Guide HK 2010suitamNo ratings yet

- Books Id 0UkhIkR 9IMC&Pg PA192&Lpg PADocument1 pageBooks Id 0UkhIkR 9IMC&Pg PA192&Lpg PAakshaf10No ratings yet

- Metro AlighDocument1 pageMetro Alighakshaf10No ratings yet

- Exothermic welding types and applicationsDocument1 pageExothermic welding types and applicationsakshaf10No ratings yet

- Codes StandardsDocument3 pagesCodes Standardsakshaf10No ratings yet

- AnixtureDocument2 pagesAnixturemanojj65No ratings yet

- AnixtureDocument2 pagesAnixturemanojj65No ratings yet

- Earth Mat Risk AssessmentDocument1 pageEarth Mat Risk Assessmentakshaf10No ratings yet

- CENT BA E (Caln) - 09 ASS2Document1 pageCENT BA E (Caln) - 09 ASS2akshaf10No ratings yet

- Draka ftp120Document2 pagesDraka ftp120akshaf10100% (1)

- CML PROJECT - EARTHING CALCULATIONS FOR STATION REV BDocument1 pageCML PROJECT - EARTHING CALCULATIONS FOR STATION REV Bakshaf10No ratings yet

- Quick CalculatorDocument20 pagesQuick Calculatorakshaf10No ratings yet

- Mergermarket Deals Export 20230403 Ca931cadDocument57 pagesMergermarket Deals Export 20230403 Ca931cadEmanuele TattaNo ratings yet

- Employee Relations and Labour LawDocument3 pagesEmployee Relations and Labour LawMonika ShindeyNo ratings yet

- Shikha Sharma Report WritingDocument5 pagesShikha Sharma Report WritingAniruddh Singh ThakurNo ratings yet

- Critique of Consignment Sales AccountingDocument6 pagesCritique of Consignment Sales Accounting123r12f1No ratings yet

- Case 1Document7 pagesCase 1Vatsala ChaudhryNo ratings yet

- Kadapa 1Document12 pagesKadapa 1Turumella VasuNo ratings yet

- Investment Appraisal TechniquesDocument2 pagesInvestment Appraisal TechniquesKANAK KOKARENo ratings yet

- Local Media3905203087700177579 PDFDocument8 pagesLocal Media3905203087700177579 PDFJhen May AydallaNo ratings yet

- Developments Affecting Future Changes in Treasury Auction SizesDocument33 pagesDevelopments Affecting Future Changes in Treasury Auction SizesZerohedgeNo ratings yet

- Books of Original EntryDocument14 pagesBooks of Original EntryDiana BellNo ratings yet

- Economic OptimizationDocument11 pagesEconomic OptimizationCasillar, Irish Joy100% (1)

- Corporate Finance Ross 10th Edition Test BankDocument24 pagesCorporate Finance Ross 10th Edition Test BankJonathanThomasobgc100% (25)

- Principles of Financial Accounting 1Document6 pagesPrinciples of Financial Accounting 1Amonie ReidNo ratings yet

- Physical Inventory by Inventory DimensionDocument301 pagesPhysical Inventory by Inventory Dimensionadnanrehan620No ratings yet

- Right To Strike 5000.docxHHDocument13 pagesRight To Strike 5000.docxHHAKRITI SINHANo ratings yet

- Hannes Meyer's biographical essay explores the architect's workDocument52 pagesHannes Meyer's biographical essay explores the architect's worknisivocciaNo ratings yet

- BASICS OF INSURANCE - Question & AnswersDocument14 pagesBASICS OF INSURANCE - Question & Answersjeganrajraj100% (2)

- Bank BranchesDocument23 pagesBank BranchesMuhammad Faraz CheemaNo ratings yet

- Analysis of Balancesheet ItlDocument78 pagesAnalysis of Balancesheet Itlnational coursesNo ratings yet

- An Analysis of The Impact of Imports of Steel From China On Indian Steel Industry 2167 0234 1000340Document7 pagesAn Analysis of The Impact of Imports of Steel From China On Indian Steel Industry 2167 0234 1000340SANTOSH KUMARNo ratings yet

- Mas 1Document1 pageMas 1Tk KimNo ratings yet

- School of Architecture, Building & Design: Highpark Suites, Kelana JayaDocument42 pagesSchool of Architecture, Building & Design: Highpark Suites, Kelana JayaZue Rai Fah100% (1)

- Wallfort - 29 April 2022Document24 pagesWallfort - 29 April 2022Utsav LapsiwalaNo ratings yet

- Islamic Marketing: Strategy For Marketing Islamic Agro Products in Islamic Banking Institutions in MalaysiaDocument25 pagesIslamic Marketing: Strategy For Marketing Islamic Agro Products in Islamic Banking Institutions in MalaysiaMuhammad Ridhwan Ab. Aziz50% (2)

- Swot Analysis: Presented by Piyush Aggarwal Bba - Vi EDocument9 pagesSwot Analysis: Presented by Piyush Aggarwal Bba - Vi Epiyush aggarwalNo ratings yet

- Productivity Improvement in Construction Industry: Sneha Jamadagni, Prof.B.V.BirajdarDocument5 pagesProductivity Improvement in Construction Industry: Sneha Jamadagni, Prof.B.V.BirajdarShaklain NarmawalaNo ratings yet

- Marketing Australia July-August 2019 PDFDocument89 pagesMarketing Australia July-August 2019 PDFppusky11No ratings yet

- More RRLDocument45 pagesMore RRLMyrna PeronaNo ratings yet

- Leadership Changes and Strategic Focus at Hyundai MotorDocument6 pagesLeadership Changes and Strategic Focus at Hyundai MotorALEN AUGUSTINENo ratings yet

- Acm PDFDocument29 pagesAcm PDFJoule974No ratings yet