Professional Documents

Culture Documents

Boiler Design Step

Uploaded by

thiruvilanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boiler Design Step

Uploaded by

thiruvilanCopyright:

Available Formats

Thiruvilan A M Boiler Design Step

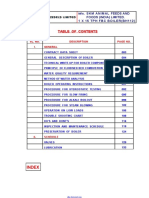

STEP-1 Received data from customer Steam output, feedwater inlet Fuel analysis, boiler type Power plant heat balance STEP-2 Boiler Thermal Sizing: Combustion, efficiency, steam output calculation, Furnace, Back pass & Cyclone sizing, Metal temperature calculation, Emission calculation, Air Heater Calculation, etc. Iteration with customer/steam turbine back to STEP-1 STEP-3 Pressure part material selection and ASME calculation & Pipe Stress Analysis: Tubing, pipe manifold, drum and internal piping & external piping Furnace Sizing, Boiler Circulation STEP-4 Non Pressure Part selection and calculation/Simulation Structural steel Design calculation Pressure part hanger calculation, etc. Iteration to STEP-3 for pressure part weight and arrangement STEP-5 From step-2, perform external piping selection: Material selection, ASME calculation, Pipe Stress Analysis Pressure Drop Calculation STEP-6 Create Pressure Part Arrangement Iteration with Step-3/4/5 STEP-7 Create General Arrangement & Layout Iteration with Step-3/4/5/6 STEP-8 Create P&ID Drawing Steam/Water Diagran, Flue Gas Diagram, Fuel Diagram, Limestone Diagram, Inert Injection Diagram STEP-9 Create Bill of Material of Structural & Support (Non Pressure Part) STEP-10 Create Bill of Material of Tubing, Piping (Pressure Part)

STEP-11 Create Drum Arrangement Drawing, Drum Internal Drawing, Welding Detail STEP-12 Create Pressure Part Drawing & Welding Detail: Evaporator, Furnace wall, superheater section STEP-13 Create Non Pressure Part Drawing & Welding Detail: Structural Steel, Casing, Ducting, Cyclone, Stack, Air Heater STEP-14 Sizing & Create Coal Silo, Inert, Limestone Create drawing, specification of silo system STEP-15 Create Specification & Sizing of Coal Crusher & System Create emission equipment, baghouse, dust collector (if required) STEP-16 Create Equipment List & Data Sheet: Primary Air Fans, Secondary Air Fans, Blower, Feed Pump, Start-up burner, Damper, Ash Screw Cooler, Soot blower, Chemical Injection System, etc. STEP-17 Create Valve List & Valve Data Sheet: Manual valve, pneumatic block valve, MOV, Control Valve, Blowdown valve, desuperheater system, etc. STEP-18 Create Instrument List & Instrument Data Sheet: Flow/pressure/temperature transmitter/gauge Flue gas analyzer & sampling system Water/steam sampling and analyzer Create Bill of material of instrument tube & fitting Create drawing & bill of material cabling system STEP-19 Boiler Operation and Control Concept Create functional control diagram Create logic diagram Verify/Iterate with P&ID and Selected Equipment STEP-20 Electrical System Create bill of material of electrical Create drawing & bill of material electrical cabling system STEP-21 Pipe routing for external piping & 3-D Drawing, Pipe Stress Analysis Feedwater piping system, steam piping system, fuel/inert/limestone piping system, ducting for flue gas Iteration with selected equipment

STEP-22 External piping: Pipe Stress Analysis & Pipe Support Drawing Pipe Insulation System, Ducting & Casing Insulation System STEP-23 Refractory Lining System Anchoring System, Material Selection, Testing and Installation Procedures STEP-24 Iteration to previous STEP, to verify selected equipment with design data. Note: In general, as one system of boiler, each of process and step need to be verified and iteration with other process or system. Drawing output, data sheet, etc. will be submitted to sub-vendor for fabrication, manufacturing or equipment supply. Selected equipment shall be verified with the design data, iteration process is required to verify the design data compare to manufacturer data.

You might also like

- Steam Boilers Guide - Types, Parts & MountingsDocument26 pagesSteam Boilers Guide - Types, Parts & MountingsAnkit bohra0% (1)

- 100 Questions On BoilersDocument5 pages100 Questions On Boilerskalpanaadhi100% (5)

- SCHROEDAHL Automatic Recirculation ValveDocument12 pagesSCHROEDAHL Automatic Recirculation ValveJaebeom YiNo ratings yet

- Proceedings of The South African Sugar Technologists' Association boiler selectionDocument35 pagesProceedings of The South African Sugar Technologists' Association boiler selectionAlsmoual AbdallaNo ratings yet

- BoilerDocument57 pagesBoilerjonofs100% (1)

- Boiler CalculationsDocument16 pagesBoiler CalculationshuliplayNo ratings yet

- Essential boiler system functions and safety questionsDocument4 pagesEssential boiler system functions and safety questionsanhhung8080% (5)

- Understanding natural circulation in boilersDocument5 pagesUnderstanding natural circulation in boilerssugumar100% (1)

- The Boiler DesignDocument154 pagesThe Boiler DesignAyman Esa100% (2)

- Boiler CalculationDocument24 pagesBoiler Calculationmordidomi96% (27)

- Boiler Theoretical QuestionDocument14 pagesBoiler Theoretical QuestionEzora Mushera0% (1)

- The Implementation of A Steam Transformer PDFDocument9 pagesThe Implementation of A Steam Transformer PDFASHIL PRABHAKARNo ratings yet

- Water Circulation SystemDocument31 pagesWater Circulation SystemSaurav Kumar0% (1)

- Boe (Boiler Operation Engineer) Short Type Question Answer-3 For Examination - AskpowerplantDocument14 pagesBoe (Boiler Operation Engineer) Short Type Question Answer-3 For Examination - AskpowerplantRaju MaityNo ratings yet

- Tray-Type Deaerator: A. Parallel DownflowDocument4 pagesTray-Type Deaerator: A. Parallel DownflowMuhammad Fakhriy IndallahNo ratings yet

- 15 TPH FBC Boiler Technical DetailsDocument348 pages15 TPH FBC Boiler Technical DetailsMuttappa T JainapurNo ratings yet

- Spec BoilerDocument9 pagesSpec BoilerAchmad MakmuriNo ratings yet

- Boiler Circulation SystemDocument32 pagesBoiler Circulation SystemRitik Dewangan100% (1)

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDocument224 pagesBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadNo ratings yet

- Basic Concept of BoilerDocument108 pagesBasic Concept of BoilerBrijraj PandeyNo ratings yet

- 7.steam Headers and OfftakesDocument6 pages7.steam Headers and Offtakessandeep kumarNo ratings yet

- Boilers of Thermal Power PlantsDocument150 pagesBoilers of Thermal Power PlantsanasawaisNo ratings yet

- Boiler Related QuestionDocument7 pagesBoiler Related QuestionBrijraj PandeyNo ratings yet

- 600MW Training Manual of Boiler 20110326Document94 pages600MW Training Manual of Boiler 20110326chandhramohan100% (5)

- Boiler Code Study GuideDocument104 pagesBoiler Code Study Guidearmstrong323590% (10)

- DESIGN CALCULATION FOR THE CONSTRUCTION OF A STEAM BOILER - Main PDFDocument20 pagesDESIGN CALCULATION FOR THE CONSTRUCTION OF A STEAM BOILER - Main PDFKehinde Amoo92% (26)

- Top 50 Boiler Information Booster Question Answers - ASKPOWERPLANTDocument19 pagesTop 50 Boiler Information Booster Question Answers - ASKPOWERPLANTRaju MaityNo ratings yet

- Once-through supercritical pressure boiler technologyDocument0 pagesOnce-through supercritical pressure boiler technologySreenivas100% (1)

- Boiler DesignDocument10 pagesBoiler DesignbobNo ratings yet

- Efficient Industrial Heat Exchangers - Seminar ReportDocument67 pagesEfficient Industrial Heat Exchangers - Seminar ReportdaemonohNo ratings yet

- h (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8Document9 pagesh (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8RajashekarBheemaNo ratings yet

- Boiler and Steam SystemDocument33 pagesBoiler and Steam SystemDr. Akepati Sivarami Reddy100% (4)

- Boiler Feed Water Design CalculationsDocument4 pagesBoiler Feed Water Design Calculationsmohan100% (1)

- Vapour Absorption Machine - Basics - UploadDocument20 pagesVapour Absorption Machine - Basics - UploadNallasivam Be A BizzaroNo ratings yet

- Design of Boiler Forced Draft FanDocument5 pagesDesign of Boiler Forced Draft FanAu TagolimotNo ratings yet

- Design Calculation of An Electric Steam Boiler - Google SearchDocument2 pagesDesign Calculation of An Electric Steam Boiler - Google SearchzoksiNo ratings yet

- Boiler Economizer CalculationDocument1 pageBoiler Economizer CalculationSuyog12312350% (2)

- Boiler Feed Water Pumps & Water Analysis (PB QBook)Document8 pagesBoiler Feed Water Pumps & Water Analysis (PB QBook)Ehsan Pappu100% (1)

- Boiler SystemDocument22 pagesBoiler SystemMuhammad AfifuddinNo ratings yet

- DEAERATORDocument32 pagesDEAERATORJagadeesan Sai100% (2)

- Boiler Operator Exam Preparation Guide pdf-1 PDFDocument27 pagesBoiler Operator Exam Preparation Guide pdf-1 PDFEmmanuel Jesus Marquez Rea100% (1)

- Steam Boiler - DesignDocument44 pagesSteam Boiler - DesigntelldivyaNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AFrom EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ARating: 5 out of 5 stars5/5 (1)

- Master HVAC Course DetailsDocument2 pagesMaster HVAC Course Detailsನವೀನ್ಕುಮಾರ್No ratings yet

- P&ID Levels ExplainedDocument2 pagesP&ID Levels ExplainedsmithworkNo ratings yet

- MATHEMATICAL MODELLING OF TUBULAR AIR HEATERSDocument50 pagesMATHEMATICAL MODELLING OF TUBULAR AIR HEATERSBalaji NatarajanNo ratings yet

- 01b. - Design Phases & InformationDocument9 pages01b. - Design Phases & InformationAna Carrasco MartínezNo ratings yet

- SCOPE of Plant AuditDocument2 pagesSCOPE of Plant AuditaroontpeNo ratings yet

- HVAC Design Manual CalculationDocument114 pagesHVAC Design Manual CalculationPhyu Mar Thein Kyaw0% (1)

- AES Pipes - Engineering Basis.12890711Document84 pagesAES Pipes - Engineering Basis.12890711Wuttichai PoontanodNo ratings yet

- Steam Tables & Engineering DataDocument187 pagesSteam Tables & Engineering DataAnonymous W79EljRNo ratings yet

- Complete HVAC Course OutlineDocument2 pagesComplete HVAC Course OutlineMohammed Abdul MoiedNo ratings yet

- Energy Audit of Cooling Water SystemDocument39 pagesEnergy Audit of Cooling Water Systemmadan karkiNo ratings yet

- Individual ResponsibilityDocument3 pagesIndividual Responsibilityalex24arulNo ratings yet

- Mep JD PDFDocument6 pagesMep JD PDFAnbalagan PrabhuNo ratings yet

- List of ASME PTC Codes and Their Respective TitlesDocument2 pagesList of ASME PTC Codes and Their Respective TitlesNagLakshmananNo ratings yet

- Comfort Design - HVAC BrochureDocument8 pagesComfort Design - HVAC Brochureshivam134019No ratings yet

- Heat Exchanger Ball Cleaning Package Data SheetDocument2 pagesHeat Exchanger Ball Cleaning Package Data SheetEDUARDONo ratings yet

- JD - Health, Safety and Security Officer - B6Document12 pagesJD - Health, Safety and Security Officer - B6thiruvilanNo ratings yet

- Waste Compliance Manager Job DescriptionDocument9 pagesWaste Compliance Manager Job DescriptionthiruvilanNo ratings yet

- Basic Option Strategies: Ron Shonkwiler (Shonkwiler@math - Gatech.edu) WWW - Math.gatech - Edu/ ShenkDocument67 pagesBasic Option Strategies: Ron Shonkwiler (Shonkwiler@math - Gatech.edu) WWW - Math.gatech - Edu/ ShenkthiruvilanNo ratings yet

- 7 - 1 Simplifying Radicals PDFDocument8 pages7 - 1 Simplifying Radicals PDFthiruvilanNo ratings yet

- Example Risk Assessment For An Office-Based BusinessDocument5 pagesExample Risk Assessment For An Office-Based Businessphelo1No ratings yet

- 4-A2 Unit 4 PacketMPLG PDFDocument47 pages4-A2 Unit 4 PacketMPLG PDFthiruvilanNo ratings yet

- Example Risk Assessment For An Office-Based BusinessDocument5 pagesExample Risk Assessment For An Office-Based Businessphelo1No ratings yet

- Year 8 Basics of Algebra Assessment PRACTICE TEST - Elycollege.119890673Document8 pagesYear 8 Basics of Algebra Assessment PRACTICE TEST - Elycollege.119890673thiruvilanNo ratings yet

- Forex Trading Guide for BeginnersDocument8 pagesForex Trading Guide for BeginnersthiruvilanNo ratings yet

- Working Safely During COVID-19 in Labs and Research FacilitiesDocument42 pagesWorking Safely During COVID-19 in Labs and Research FacilitiesthiruvilanNo ratings yet

- Accident Report FormDocument6 pagesAccident Report FormthiruvilanNo ratings yet

- Melchert Duijve - MSC Thesis - LCA Insulation Materials - 2012 PDFDocument139 pagesMelchert Duijve - MSC Thesis - LCA Insulation Materials - 2012 PDFthiruvilanNo ratings yet

- Physics Formula Sheet PDFDocument4 pagesPhysics Formula Sheet PDFthiruvilanNo ratings yet

- Synapsis Trading ThesisDocument187 pagesSynapsis Trading ThesisthiruvilanNo ratings yet

- Introduction To Options - The BasicsDocument27 pagesIntroduction To Options - The BasicsAlexNo ratings yet

- Basic Option Strategies: Ron Shonkwiler (Shonkwiler@math - Gatech.edu) WWW - Math.gatech - Edu/ ShenkDocument67 pagesBasic Option Strategies: Ron Shonkwiler (Shonkwiler@math - Gatech.edu) WWW - Math.gatech - Edu/ ShenkthiruvilanNo ratings yet

- Option Trading StrategiesDocument0 pagesOption Trading StrategiesGarvit Garg100% (1)

- Understanding OptionsDocument44 pagesUnderstanding OptionsSunil Kk0% (1)

- Short Story Telling Options TradingDocument62 pagesShort Story Telling Options TradingthiruvilanNo ratings yet

- Short Story Telling Options TradingDocument62 pagesShort Story Telling Options TradingthiruvilanNo ratings yet

- US7111950-Method For Forming A Metallic Mirror Surface On A Receiving SurfaceDocument11 pagesUS7111950-Method For Forming A Metallic Mirror Surface On A Receiving SurfacethiruvilanNo ratings yet

- Devon County Council Job DescriptionDocument7 pagesDevon County Council Job DescriptionthiruvilanNo ratings yet

- Dep Manufacture Chinese PatentDocument19 pagesDep Manufacture Chinese PatentthiruvilanNo ratings yet

- Google Be Internet Legends Activities 1Document2 pagesGoogle Be Internet Legends Activities 1thiruvilanNo ratings yet

- Beginner'S Guide To Forex Trading: October 2018Document8 pagesBeginner'S Guide To Forex Trading: October 2018HeyJob TaskNo ratings yet

- Life Cycle Assessment To Di-2-Ethylhexyl Phthalate (Dehp), Applications and Potential AlternativesDocument109 pagesLife Cycle Assessment To Di-2-Ethylhexyl Phthalate (Dehp), Applications and Potential AlternativesthiruvilanNo ratings yet

- Counting Atoms Concept ReviewDocument2 pagesCounting Atoms Concept ReviewthiruvilanNo ratings yet

- Standard Tube Map PDFDocument2 pagesStandard Tube Map PDFDiego Ricardo CarriazoNo ratings yet

- Phthalates: On The Issue of Sources, Human Uptake, Time Trends and Health EffectsDocument67 pagesPhthalates: On The Issue of Sources, Human Uptake, Time Trends and Health EffectsthiruvilanNo ratings yet

- Nebosh IGC Element 5. Rish Assessment (Notes)Document6 pagesNebosh IGC Element 5. Rish Assessment (Notes)kkalvi96% (25)

- 1204-Barge 2 Tech SpecsDocument13 pages1204-Barge 2 Tech SpecsmardiradNo ratings yet

- CH3010 - Power Plant Engineering Notes .Document75 pagesCH3010 - Power Plant Engineering Notes .VijayNo ratings yet

- Venkat RamanDocument5 pagesVenkat Ramanvenkatraman JNo ratings yet

- Heating and Cooling Design for EfficiencyDocument16 pagesHeating and Cooling Design for EfficiencyAmer GaladNo ratings yet

- Tanjung Jati B Boiler Design and Performance OverviewDocument73 pagesTanjung Jati B Boiler Design and Performance OverviewFahrul FauziNo ratings yet

- TPS Internship ReportDocument34 pagesTPS Internship Reportmkhalil1148No ratings yet

- A Handbook On Piping - Carl L SvensenDocument442 pagesA Handbook On Piping - Carl L SvensenAndresNo ratings yet

- DB EKHVX EN tcm135-186767 PDFDocument21 pagesDB EKHVX EN tcm135-186767 PDFdino_pNo ratings yet

- ASHRAE Journal - The Fundamentals of Expansion TanksDocument7 pagesASHRAE Journal - The Fundamentals of Expansion TanksJavier VespaNo ratings yet

- Consensus Tube SamplingDocument33 pagesConsensus Tube SamplingjycortesNo ratings yet

- Making Carbon Black: Presented by Sid Richardson Carbon CoDocument37 pagesMaking Carbon Black: Presented by Sid Richardson Carbon ColatshareNo ratings yet

- Pipe Support Program at PickeringDocument9 pagesPipe Support Program at PickeringMohammedBujairNo ratings yet

- Engine Room Arrangement PlanDocument128 pagesEngine Room Arrangement PlanIsmael Redoña Conde100% (2)

- Manual Service Vitodens 200Document77 pagesManual Service Vitodens 200MariusMNo ratings yet

- ASHUGANJ Power Station Company Limited Transmission, ProtectionDocument88 pagesASHUGANJ Power Station Company Limited Transmission, Protectionmaruf048No ratings yet

- Introduction to 500 MW Once Through Boiler DesignDocument18 pagesIntroduction to 500 MW Once Through Boiler DesignAlok Ranjan TripathiNo ratings yet

- PPChem RepeatsDocument11 pagesPPChem RepeatsAnonymous lHiaDxlpkxNo ratings yet

- Naini Tissues FDSDocument20 pagesNaini Tissues FDSHarshit SharmaNo ratings yet

- Statement of PurposeDocument6 pagesStatement of PurposeMichelleMich Mangubat Descartin50% (2)

- Sesi PotteryDocument20 pagesSesi PotteryTefera Adugna100% (1)

- EX Firetube Boiler Changed by Advances in Design TechnologyDocument7 pagesEX Firetube Boiler Changed by Advances in Design TechnologyXamir Suarez AlejandroNo ratings yet

- Kobelco Low Alloy SteelDocument5 pagesKobelco Low Alloy Steeltiffanyyy00No ratings yet

- Boilers 23Document2 pagesBoilers 23Israel SanchezNo ratings yet

- SRU Operating ManualDocument517 pagesSRU Operating Manualsathya perumal100% (4)

- Dit 4th Yr SyllabusDocument54 pagesDit 4th Yr SyllabusErPriyeRanjanNo ratings yet

- Control Box For Boiler & BurnerDocument10 pagesControl Box For Boiler & BurnerSergeyNo ratings yet

- Power Utility Course CatalogDocument27 pagesPower Utility Course CatalogFikre HailuNo ratings yet

- Literature Review: Forced Draft and Induced Draft FansDocument6 pagesLiterature Review: Forced Draft and Induced Draft FansAlif Nur FirdausNo ratings yet

- Marine Boilers: Rajan BhandariDocument34 pagesMarine Boilers: Rajan BhandariJomar TorrechillaNo ratings yet

- Material and Energy BalanceThis document provides a concise title for the given document within 40 characters:TITLE 4. MATERIAL AND ENERGY BALANCE SYLLABUSDocument51 pagesMaterial and Energy BalanceThis document provides a concise title for the given document within 40 characters:TITLE 4. MATERIAL AND ENERGY BALANCE SYLLABUSsmith100% (1)