Professional Documents

Culture Documents

An Algorithm On Optimal Placement Decision of Automatic Switches

Uploaded by

ostojic007Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Algorithm On Optimal Placement Decision of Automatic Switches

Uploaded by

ostojic007Copyright:

Available Formats

328 Journal of Electrical Engineering & Technology Vol. 6, No. 3, pp. 328~333, 2011 DOI: 10.5370/JEET.2011.6.3.

328

An Algorithm on Optimal Placement Decision of Automatic Switches for 6 Sections/3 Links Configuration in DAS

Il-Hyung Lim, Wen-Hao Zhang*, HamsyahTrirohadi**, Myeon-Song Choi***, Seung Jae Lee*** and Bok-Nam Ha

Abstract A Distribution Automation System (DAS) is operated by monitoring and control of the

field statesusing Feeder Remote Terminal Units (FRTUs) installed together withautomatic switches.An optimal placement of automatic switchescan enhance efficiencyof the operation and restoration, and improve the power supply reliability ofa DAS.This paper proposes an algorithm to decide the optimal placement of automatic switches ina DAS.The proposed algorithm was developed ona DAS witha six sections and three links configuration. The proposed algorithm was provided inaneight-feeder power distribution system. Keywords: Distribution automation system, Automatic switch, FRTU, Power distribution system

1. Introduction

A Distribution Automation System (DAS) operatesremotelyby monitoring and control of power distribution system through Feeder Remote Terminal Units (FRTUs). FRTU measuressystem information from the field andreports them to a DAS server. The DAS can control and changethe power distribution system configuration for optimal operation through the FRTUs installed together with automatic switches [1]. The placement of automatic switches with FRTUs (A/S) is the most important element in increasing the operation efficiency of a DAS. When fault occurs on the power distribution line of a DAS, a restorationmakesa minimized blackout areadepends on controls of the A/S switches. The minimized blackout area means power is supplied to the customers to except customers of fault section; hence, the placement of the A/S switches should be considered a vital factor in the operation of a DAS. To date, automatic switches in a DAShave beeneither installed when a DASis initiallyconstructed or addedlater. Although a distribution of the automatic switches in a DASis required to be constructed with six sections and three links configuration, the automatic switches have been installed a position to be required by operation and as a

Corresponding author: Department of Electricaland Computer Engineering, The University of Western Ontario, Canada. (sojoo2jan@gmail.com) * Department of Electrical Engineering, Tongji University, China (xiwen.ren@gmail.com) ** PT.PLN (Persero)National Electricity Company, Indonesia (hamsyah_t@hotmail.com) *** Department of Electrical Engineering, Myongji University, Korea.(mschoi@mju.ac.kr, sjlee@mju.ac.kr) Department of Transmission and Distribution Research, KEPRI, Korea.(bnha@kepri.re.kr) Received: November 26, 2009; Accepted: March 7, 2011

result, six sections and three links configuration werent kept in the field. To increase the operation efficiency of a DAS,many papers have been published for deciding the optimal placement of automatic switches. Several studies have sought to address this problem from various aspects. Reference [1] studied the placement of power facilities from a geographical perspective. In [2-6], the placements of switches were located using the intelligence algorithms. The switch location,which takes the operating reliability into account, was introduced in [79]. Moreover, methods considering various economic viewswere explored in [10]. The mostefficient function of a DAS is restoration through remote monitoring and control. However, previous researches have studied placements of automatic switches from initial system planning, butdid not consider restoration efficiency. In this paper, an algorithm is proposed to decide the optimal placement of automatic switches considering the outage load equalization forthe restoration of the DAS. The proposed algorithm is applied tothe six sections and three links system configuration. Section 2 explains the relationship between the placements of automatic switches and restoration under the configuration of six sections and three links. Section 3 illustrates the optimal placement of automatic switches algorithm through three steps. In Section 4, the effectiveness of the proposed algorithm is proven by case studies.

2. Relation of the placement of automatic switches and restoration in DAS

In a distribution feeder, asection is defined by a group of line segments between adjacent switches or circuit breakers.

Il-Hyung Lim, Wen-Hao Zhang, HamsyahTrirohadi, Myeon-Song Choi, Seung Jae Lee and Bok-Nam Ha

329

Each section has manycustomers and a section loadis decided fromthe summation of a contract load or the maximum load of customers within a section[10]. A link is defined as the connection with an automatic tie switch thatis opened normally and closed for restoration. In the current study, a voltage level is 22.9 kV, a normal permit capacity(Cn) is 10 MVA, and an emergency capacity(Ce) is 14 MVA on a power distribution line. The optimal number of links to different feeders can be obtained as follows:

Ln Cn ( Ce Cn )

(1)

where Ln : number of links Cn : normal capacity Ce : emergency capacity. Eq. (1) indicates a number of necessary links considering a margin for restoration. If feeders are being operated with full loads (10MW) and a fault occurs at a feeder, the faulted feeder may need 10 MW loads for restoration in the worst case. Then, a number of necessary links will be 3 because a result by Eq. (1) is 2.5.

Fig. 2. Structures of four, five, and six sections with three links Structures with different sections are shown in Fig. 2. As seen from the load distribution in each section, we can infer that more section switches canreduce outage load capacity, but the cost of facilities and management will increase correspondingly. Thus, in this paper, an algorithm on optimal placement decision of automatic switches wasdevelopedby considering a structure of six sections and three links on the power distribution line in DAS following KEPCOs technical report [11].

3. An algorithm for optimal placement of automatic switches

Fig. 1. Three links on a power distribution line From(1), the optimal number of links can be ascertained as three, and the feederneeds to be divided intoat least four sections. Thus, each link connects a section to the other feeder, except for the first section which only connects to the source, as shown in Fig. 1. According to an effect by number of section switches, three links based on each case of four sections, five sections, and six sections are shown in Fig. 2. In a four sections case, the section load is 2.5 MVA on a standard that the maximum load on a power distribution line is 10 MVA at a normal state. In a five sections case, the section load is 2 MVA, and in a sixsections case, the section load is 1.6 MVA. In all of the four, five, and six sections cases, a DAS can secure the restoration capacity from other feeders in any fault location. Thus, the outage load is 2.5 MVA when a fault occurs in a structure of four sections. A structure with six sections is better than that with four sections from the standpoint of restoration because DAS can reduce an outage load when a fault occurs. The optimal placement of the automatic switches algorithm is composed of three steps.The first step is to find the normal open switches in the radial distribution lines. The next step is to choosean automatic tie switch among the normal open switches. Finally, the automatic switches to divide sections aredecidedby section load equalization, a position of link line, and the configuration of the six sections.

3.1 Tie Switch Allocation

To determinethe optimal placement of automatic switches, the first step is torearrange the distribution system with eight feeders (Fig. 3) as radial structure. The optimal placement of the tie switch should enable all feeders to have evenly distributedloads, which also ensure the largest marginconsidering restorationunder the sixsections andthreelinks configuration. Fig. 4 shows a method to find the location of the tie switch using the following steps:

330

An Algorithm on Optimal Placement Decision of Automatic Switches for 6 Sections/3 Links Configuration in DAS

3.2 Decision of Three Links

The tie switches selected through the procedure in 3.1 are manual tie switches, among which the automatic switches are selected to decide the three links. When a fault occurs in the system, the three links among the feeders are supposed to provide reserved capacity to the faulty feeder. If the links are not properly decided, there would be failure of fault restoration.

Fig. 3. Eight feeders on the power distribution system Fig. 5. A process for finding the link with the automatic tie switch line In the current study, the proposed method which decides the three links location divides a power distribution line as shown in Fig. 5. Assuming that the normal open point is decided, the feeder is divided into sixsections with evenly distributed loads. Then, all sections are grouped into threegroups as shown in Fig. 5. Three groups should be made byevenly distribution of the loads in all the feeders and a possible that a fault can be in all the feeders. So there would be only one link in each group. According to the six sectionsthree links configuration, the three links can be connectedto sections givenby the rules below: Fig. 4. A method to findthe manual tie switch between feeders (1) Assume each feeder has a virtual tie switch at the beginning of the feeder; (2) Move the assumed tie switch along the feeder with evenly distributed loads; (3) If there are multi-branches along the feeder during the switch movement, add a number of virtual tie switches corresponding to the branch number; (4) Decide the point where the tie switches meet one another as the normal open point. If location of the tie switches with the above method is decided, the loads of all feeders would not always be evenly distributed so the tie switch should move from the feeder with larger loads to a feeder with smaller loads. To ensureevenly distributed loads, we can calculate the minimum sum of the squares of all the feeders. For example, if there are two feeders with loads as 3 and 5 respectively, the sum of the squares would be 9+25=34. If these two loads become evenly distributed, which means that each feeder has a load as 4, the sum of the squareswould be16+16=32.According to this rule, we can obtain the optimal location of the tie switch. Rule 1. Section 2, section 4, section 6 Rule 2. Section 3, section 4, section 6 Rule 3. Section 3, section 5, section 6 The tie switches which satisfythe above rules will be selected as the automatic tie switch. Consequently, the restoration can be successfully processed no matter where the fault occurs.

3.3 Decision of Section Automatic Switch Placement

The distribution system would operate efficientlyif all feeders are well configured. However, there arevariouscases that do not satisfy the presented rules in the field.

Fig. 6. Decision of the automatic tie switch by moving section A/S (Case I)

Il-Hyung Lim, Wen-Hao Zhang, HamsyahTrirohadi, Myeon-Song Choi, Seung Jae Lee and Bok-Nam Ha

331

Fig. 6 shows a case where there is no linkin Section 2. In this case, if there is a fault occurring in Section 1, with reserved capacity, Sections 4 and 6 cannot conduct the restoration successfully.Thus, S1 moves to the source side and the link is connected to Section 2 to satisfy Rule 1.

Fig. 7. Decision of the automatic tie switch by moving section A/S (Case II) In Fig. 7, all sections do not satisfy any rule except the last section. Similarly, we need to move the switches in order to enable all the sections to satisfy the rules of the link connection and the requirement of the load distribution. In Fig. 8, there are two successful results based on the method to find the three links, and the optimal configuration should guarantee that the loads are evenly distributed.

Fig. 9. Distributed parameters of two configurations

4. Case Study

In order to test the validity of the proposed algorithm, the model system shown in Fig. 10 is adopted for the case study.

(a) Success 1

(b) Success 2

Fig. 8. Two results by the proposed algorithm The distributed parameter to judge the load distribution is calculated by

Fig. 10. Initial configuration of the model system The proposed algorithm is conducted through three steps.The distributed loads of all sections, which are shown in Fig. 11, finally achieved the optimized six sections andthree linksconfiguration.

( x x)

i i =1

(3)

where x : Average section load of a power distribution line n : Total section : Distributed load factor xi : Load at section i The two results shown in Fig. 9 correspond to the load distribution of the two systems in Fig. 8. Evidently, Success 2 has a smaller distributed parameter which means that the loads are better dispatched in all the sections.

Fig. 11. Load dispersion after optimal placement of the automatic switches

332

An Algorithm on Optimal Placement Decision of Automatic Switches for 6 Sections/3 Links Configuration in DAS

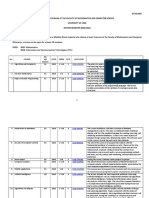

In Table 1, the total load of each feeder is given and the load dispersion is calculated with the loading level 1.67. Table 1. Load dispersion final results

Feeder number 1 2 3 4 5 6 7 8 Total load 10.02 10.04 10.02 10.02 10.02 10.05 10.03 10.02 Load dispersion 0 0.02 0 0 0 0.03 0.01 0

[2] [3]

[4]

Through the case study, this paper proves the effectiveness of the algorithm in establishing the optimal placement of automatic switches in the six sections andthree linksconfiguration.

[5]

[6]

5. Conclusion

The optimal placement of the automatic switches plays an important role in the restoration of the DAS. To date, the system configuration differs with the variation of the operating condition so that most of them do notcomply with the criterion of the six-section three-link configuration. In this paper, an algorithm is proposed for the optimal placement of automatic switches to meet the requirement of the six-section three-link configuration. The proposed optimal A/S placement algorithm is composed of three steps: The first step is to find the normal open point of the switches to make the distribution system a radial system. Second, decide the link as the position of the automatic tie switch. Finally,distribute the load evenly to ensure its restoration capacity. The proposed algorithm is applied to a system with eight feeders to test its effectiveness; it is also loaded to the Intelligent Distribution Management System of KEPCO and will be applied in the field soon. [7] [8] [9]

[10]

[11]

Politehnica University of Bucharest. M.-R. Haghifam, "Optimal Allocation of Tie Points Distribution Systems Using a Genetic Algorithm," Euro. Trans.Elect.Power 2004. C.-S. Chen, C.-H. Lin, H.-J. Chuang, M.-Y. Huang, and C.-W. Hung, "Optimal Placement of Line Switches for Distribution Automation Systems Using Immune Algorithm," IEEE Trans. Power Delivery, vol. 21, no. 3, pp. 1209-1217, August 2006. D. B. Kulkarni, G. R. Udupi, ANN-Based SVC Switching at DistributionLevel for Minimal-Injected Harmonics, IEEE Trans.on Power Delivery, vol. 25, no. 4, pp. 1978-1985,Jul. 2010. Ahmed E. B. Abu-Elanien, M. M. A. Salama, A Wavelet-ANN Technique for Locating SwitchedCapacitors in Distribution Systems, IEEE Trans.on Power Delivery, vol. 24, no. 1, pp. 400-409,Jan. 2009. C. Chen, C. Lin, H. Chuang, C. Li, M. Huang, C. Huang, Optimal Placement of Line Switches for DistributionAutomation Systems Using Immune Algorithm, IEEE Trans.on PowerSystems, vol. 21, no. 3, pp. 1209-1217, Aug. 2006 Willis H., Power distribution planning reference book, New York, Marcel Dekker, pp 29-30, 1997. TuranGonen, "Electric Power Distribution System Engineering," McGraw-Hill International Edition, pp. 226-229. H. Khani, M.Moallem, S. Sadri, M.Dolatshahi, A New Method for Online Determination ofthe Location of Switched Capacitor Banks inDistribution Systems, IEEE Trans.on Power Delivery, vol. 26, no. 1, pp. 341-351, Jan. 2011. A. Moradi, and M. Fotuhi-Firuzabad, "A Reliability cost/worth approach to determine optimum switching placement in distribution systems," IEEE/Power Eng. Soc. Transmission and Distribution Conf. Exhibit: Asia and Pacific, Dalian, China, 2005. KEPCO, A study on the configuration and the operation standard for distribution network, 2002.

Acknowledgments

This work was supported by the National Research Foundation of Korea Grant funded by the Korean Government (NRF-2010-013-D00025)and Intelligent Distribution Management System developmentprogram of Ministry of Commerce, Industry and Energy.

References

[1] A.M. Morega, J.C. Ordonez and M. Morega, "A Constructal Approach to Power Distribution Networks Design," Department of Electrical Engineering

Ilhyung Lim He received his B.E., M.S., and Ph.D. degrees in Electrical Engineering at Myongji University, Korea in 2005, 2007, and 2010, respectively. Currently, he is working as aPost-doctoral Fellow inthe Department of Electrical and Computer Engineering, The University of Western Ontario, Canada. His research interests are power system protection and control, power automation system, multiagent application, smart grid, and IEC 61850/61968/61970.

Il-Hyung Lim, Wen-Hao Zhang, HamsyahTrirohadi, Myeon-Song Choi, Seung Jae Lee and Bok-Nam Ha

333

Wen-Hao Zhang He received his B.E. degree in Electrical Engineering from the Harbin Institute of Technology, Harbin, China in 2003. He received his M.S. degree in Electrical Engineering from Xian Jiao Tong University, Xian, China in 2006. He received his Ph.D. at MyongjiUniversity, Yongin, Korea in 2010. Currently, he is working in the Department of Electrical Engineering at Tongji University, China. His research interests are power system protection and control, and power system automation. HamsyahTrirohadi He received his B.S inElectrical Engineering from GadjahMadaUniversity, Yogyakarta, Indonesia, in 2002.Currently, he is a M.S student at MyongjiUniversity and an employ of PT.PLN (Persero)National Electricity Company in Indonesia. Hisresearch interest is Distribution Automation System. Myeon-Song Choi He received his B.E., M.S., and Ph.D. degrees in Electrical Engineering from Seoul National University, Korea in 1989, 1991, and 1996, respectively. He was a Visiting Scholar at the University of Pennsylvania State in 1995. Currently, he is a Professor at MyongjiUniversity. His major research fields include power system control and protection, including multi-agent applications.

Seung-Jae Lee He received his B.E.and M.S. degrees in Electrical Engineering from Seoul National University, Korea in 1979 and 1981, respectively. He received his Ph.D. in Electrical Engineering from the University of Washington, Seattle, USA in 1988. Currently, he is a Professor at MyongjiUniversity and a Director at the Next-Generation Power Technology Center (NPTC). His major research fieldsincludeprotective relaying, distribution automation, and multi-agent applications to power systems. Bok-Nam Ha He received M.S.E.E degree and Ph.D. from the Chungnam National University, Korea. He is currently working in Korea Electric Power Research Institute of Korea Electric Power Corporation since he joined in 1978. He is a deputy researcher and the leader of distribution automation group to develop intelligent distribution automation system since 1990. His research interests are the application programs of distribution automation, Smart Grid and field application.

You might also like

- Mirror Descent and Nonlinear Projected Subgradient Methods For Convex OptimizationDocument9 pagesMirror Descent and Nonlinear Projected Subgradient Methods For Convex OptimizationfurbyhaterNo ratings yet

- Psat Ref Paper 1Document8 pagesPsat Ref Paper 1Iam SriNo ratings yet

- InTech-Optimal Feeder Reconfiguration With Distributed Generation in Three Phase Distribution System by Fuzzy Multiobjective and Tabu SearchDocument21 pagesInTech-Optimal Feeder Reconfiguration With Distributed Generation in Three Phase Distribution System by Fuzzy Multiobjective and Tabu SearchbajricaNo ratings yet

- Capacitor Placement in Unbalanced Power SystemsDocument6 pagesCapacitor Placement in Unbalanced Power SystemsFabio NobNo ratings yet

- Transient StabilityDocument4 pagesTransient StabilitySantoshkumar KandagalNo ratings yet

- Shan Zhong, Student Member, IEEE, and Ali Abur, Senior Member, IEEEDocument5 pagesShan Zhong, Student Member, IEEE, and Ali Abur, Senior Member, IEEEAhmadinijadNo ratings yet

- 10 1049@iet-Gtd 2015 0303Document8 pages10 1049@iet-Gtd 2015 0303sanjeevNo ratings yet

- Critical NodesDocument6 pagesCritical Nodesfarhan beighNo ratings yet

- Applied Sciences: Decision Optimization For Power Grid Operating Conditions With High-And Low-Voltage Parallel LoopsDocument18 pagesApplied Sciences: Decision Optimization For Power Grid Operating Conditions With High-And Low-Voltage Parallel Loopsyesar laftaNo ratings yet

- Optimal Branch Exchange For Feeder Reconfiguration in Distribution NetworksDocument6 pagesOptimal Branch Exchange For Feeder Reconfiguration in Distribution NetworksAli RazaNo ratings yet

- Optimal Allocation of TCSC Devices Using Genetic AlgorithmsDocument5 pagesOptimal Allocation of TCSC Devices Using Genetic AlgorithmsMas Hud ANo ratings yet

- Branch Current Based State EstimationDocument5 pagesBranch Current Based State EstimationhockpinNo ratings yet

- Slack Bus SelectionDocument9 pagesSlack Bus SelectionTirthankar DattaNo ratings yet

- Service Restoration in Distribution Networks Via Network ReconfigurationDocument7 pagesService Restoration in Distribution Networks Via Network Reconfigurationbluemoon1172No ratings yet

- Design of Unified Power Quality Conditioner (UPQC)Document7 pagesDesign of Unified Power Quality Conditioner (UPQC)Hari PrasadNo ratings yet

- Loss ReductionDocument35 pagesLoss Reductionsolomon nchor akansakeNo ratings yet

- Paper 13Document5 pagesPaper 13Reena PalNo ratings yet

- A New Fault Locator For Three-Terminal Transmission Lines-Using Two-Terminal Synchronized Voltage and Current PhasorsDocument8 pagesA New Fault Locator For Three-Terminal Transmission Lines-Using Two-Terminal Synchronized Voltage and Current Phasorsveljss007No ratings yet

- Zeina L Zadeh 2019Document4 pagesZeina L Zadeh 2019Gustavo FloresNo ratings yet

- CORPOELECDocument33 pagesCORPOELECjoelNo ratings yet

- Particle Swarm Optimization Based Capacitor Placement On Radial Distribution SystemsDocument37 pagesParticle Swarm Optimization Based Capacitor Placement On Radial Distribution SystemsMudavath ChandramNo ratings yet

- Steady State Analysis of Induction Generator Infinite Bus SystemsDocument21 pagesSteady State Analysis of Induction Generator Infinite Bus SystemsHarieesh VjraNo ratings yet

- Multi-Phase Power System SimulationDocument18 pagesMulti-Phase Power System SimulationIJRASETPublicationsNo ratings yet

- Problem On Overloaded Phases Can HaveDocument13 pagesProblem On Overloaded Phases Can HaveJean-nette BarlisanNo ratings yet

- Energies 15 03460 v2Document16 pagesEnergies 15 03460 v2Haneen GamalNo ratings yet

- Quasi-Coupled Three-Phase Radial Load Flow: Esther Romero Ramos, Antonio Gómez Expósito, and Gabriel Álvarez CorderoDocument6 pagesQuasi-Coupled Three-Phase Radial Load Flow: Esther Romero Ramos, Antonio Gómez Expósito, and Gabriel Álvarez Corderojaach78No ratings yet

- 28 FTp01Document6 pages28 FTp01Squishi JilbertNo ratings yet

- 261 Medina LiQi ButlerDocument7 pages261 Medina LiQi Butlerazulhilmi_89No ratings yet

- Newton-Raphson Algorithm For 3-Phase Load Flow: R. G. Wasley, B.Sc. Tech., M.SC, PH.D., and M. A. Shlash, M.SCDocument9 pagesNewton-Raphson Algorithm For 3-Phase Load Flow: R. G. Wasley, B.Sc. Tech., M.SC, PH.D., and M. A. Shlash, M.SCKeri WoodsNo ratings yet

- Model For Three-Phase Contactless Power Transfer SystemDocument17 pagesModel For Three-Phase Contactless Power Transfer SystemNisanth PaNo ratings yet

- Multi-Objective Unbalanced Distribution Network Reconfiguration Through Hybrid Heuristic AlgorithmDocument8 pagesMulti-Objective Unbalanced Distribution Network Reconfiguration Through Hybrid Heuristic AlgorithmbaalaajeeNo ratings yet

- A Procedure To Specify The Weighting Matrices For An Optimal Load-Frequency ControllerDocument13 pagesA Procedure To Specify The Weighting Matrices For An Optimal Load-Frequency ControllerSai SivaNo ratings yet

- Fast Unbalanced Three-Phase Adjustment Base On SinDocument8 pagesFast Unbalanced Three-Phase Adjustment Base On SinMuhamad Hasan HafifiNo ratings yet

- Multi-Objective Optimal Placement of Recloser and Sectionalizer in Electricity Distribution FeedersDocument4 pagesMulti-Objective Optimal Placement of Recloser and Sectionalizer in Electricity Distribution Feedersabera alemayehuNo ratings yet

- Format - MSC Course ProjectDocument12 pagesFormat - MSC Course ProjectQasim KhanNo ratings yet

- Reconfiguration and Capacitor Placement For Loss Reduction of Distribution Systems by Ant Colony Search AlgorithmDocument9 pagesReconfiguration and Capacitor Placement For Loss Reduction of Distribution Systems by Ant Colony Search AlgorithmthanatitosNo ratings yet

- Improved Three-Phase Power-Flow Methods Using Sequence Components - MA Akher - KM Nor - AHA RashidDocument13 pagesImproved Three-Phase Power-Flow Methods Using Sequence Components - MA Akher - KM Nor - AHA RashidIndra AditamaNo ratings yet

- Coordination Design PSS and TCSC Controller For Power System Stability Improvement Using CLA-PSO AlgorithmDocument10 pagesCoordination Design PSS and TCSC Controller For Power System Stability Improvement Using CLA-PSO Algorithmvinodkumar57No ratings yet

- Transient Stability Analysis of Power SystemsDocument17 pagesTransient Stability Analysis of Power Systemsrasim_m1146No ratings yet

- Power System Modeling-Mo-Shing ChenDocument15 pagesPower System Modeling-Mo-Shing ChenOscar ßg0% (1)

- Smart Electrical Infrastructure For AC-fed Railways With Neutral ZonesDocument10 pagesSmart Electrical Infrastructure For AC-fed Railways With Neutral ZonesnpfhNo ratings yet

- Application of Fuzzy Logic For Loss Reduction in A Transmission NetworkDocument22 pagesApplication of Fuzzy Logic For Loss Reduction in A Transmission NetworkOhanyelu Okeoma DanielNo ratings yet

- Power System Stabilizer Placement and TuningDocument6 pagesPower System Stabilizer Placement and TuningrnmukerjeeNo ratings yet

- Ieee 30 BusDocument6 pagesIeee 30 BusDARPAN100% (1)

- Fundamentals of Modern Electrical Substations - Part 3Document21 pagesFundamentals of Modern Electrical Substations - Part 3Ajay DasNo ratings yet

- Mohiti Et Al. - 2013 - Optimal Placement and Tuning of TCSC For Damping OscillationsDocument5 pagesMohiti Et Al. - 2013 - Optimal Placement and Tuning of TCSC For Damping OscillationsHarish KumarNo ratings yet

- 04311828matlab 2Document1 page04311828matlab 2AbdulrahmanNo ratings yet

- Parametros de Cables SubterraneosDocument8 pagesParametros de Cables SubterraneosMarcos EmmanuelNo ratings yet

- A Carrier-Based PWM Techniques Applied To A Three-Level Four-Leg Inverter For Use As A Shunt Active Power FilterDocument6 pagesA Carrier-Based PWM Techniques Applied To A Three-Level Four-Leg Inverter For Use As A Shunt Active Power FilterZellagui EnergyNo ratings yet

- 22.a Single Stage Three Phase PV System With Enhanced MPPTDocument13 pages22.a Single Stage Three Phase PV System With Enhanced MPPTkunusenseiNo ratings yet

- Two-Stage Power Network Reconfiguration Strategy Considering Node Importance and Restored Generation CapacityDocument13 pagesTwo-Stage Power Network Reconfiguration Strategy Considering Node Importance and Restored Generation CapacityFlorin NastasaNo ratings yet

- Optimal Placement of SVC and Statcom For Voltage Stability Enhancement Under Contingency Using Cat Swarm OptimizationDocument16 pagesOptimal Placement of SVC and Statcom For Voltage Stability Enhancement Under Contingency Using Cat Swarm Optimizationsabarullah haliNo ratings yet

- A 3-kW Unity-Power-Factor Rectifier Based PDFDocument9 pagesA 3-kW Unity-Power-Factor Rectifier Based PDFRacielMCNo ratings yet

- Review of Power Flow Studies On Distribution Network With Distributed GenerationDocument7 pagesReview of Power Flow Studies On Distribution Network With Distributed GenerationAbdulrahmanNo ratings yet

- A Power Distribution Network Restoration Via Feeder Reconfiguration by Using Epso For Losses ReductionDocument5 pagesA Power Distribution Network Restoration Via Feeder Reconfiguration by Using Epso For Losses ReductionMohammed ShifulNo ratings yet

- 1 s2.0 S0378779612000405 Main - 2Document10 pages1 s2.0 S0378779612000405 Main - 2BodoShowNo ratings yet

- Load Flow in Power SystemDocument60 pagesLoad Flow in Power SystemShantasree RoyNo ratings yet

- Optimized Restoration of Unbalanced Distribution SystemsDocument7 pagesOptimized Restoration of Unbalanced Distribution SystemsMihir HembramNo ratings yet

- DOW11Document5 pagesDOW11Rama KrishnaNo ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Evaluation of Power System Transient Stability and Definition of The Basic Criterion PDFDocument8 pagesEvaluation of Power System Transient Stability and Definition of The Basic Criterion PDFostojic007No ratings yet

- What Influences Length of CCT?: Zaneta - Eleschova@stuba - SKDocument6 pagesWhat Influences Length of CCT?: Zaneta - Eleschova@stuba - SKostojic007No ratings yet

- Electric Field Analysis of High Voltage InsulatorsDocument5 pagesElectric Field Analysis of High Voltage Insulatorsostojic007No ratings yet

- Finite Element Analysis On Post Type Silicon Rubber Insulator Using MATLABDocument6 pagesFinite Element Analysis On Post Type Silicon Rubber Insulator Using MATLABostojic007No ratings yet

- Finite Element Modeling For Electric Field and Voltage Distribution Along The Polluted Polymeric InsulatorDocument11 pagesFinite Element Modeling For Electric Field and Voltage Distribution Along The Polluted Polymeric Insulatorostojic007No ratings yet

- CIGRE 2008: 21, Rue D'artois, F-75008 PARISDocument8 pagesCIGRE 2008: 21, Rue D'artois, F-75008 PARISostojic007No ratings yet

- Reliability of Electrical Insulating Systems - Statistical Approach To Empirical Endurance ModelsDocument5 pagesReliability of Electrical Insulating Systems - Statistical Approach To Empirical Endurance Modelsostojic007No ratings yet

- Electric Field and Voltage Distribution Along Non-Ceramic Insulators PDFDocument16 pagesElectric Field and Voltage Distribution Along Non-Ceramic Insulators PDFostojic007No ratings yet

- Loss-Of-Excitation Protection and Underexcitation Controls Correlation For Synchronous Generators in A Real-Time Digital SimulatorDocument12 pagesLoss-Of-Excitation Protection and Underexcitation Controls Correlation For Synchronous Generators in A Real-Time Digital Simulatorostojic007100% (1)

- Electric Field and Potential Distributions Along Surface of Silicone Rubber Polymer Insulators Using Finite Element MethodDocument6 pagesElectric Field and Potential Distributions Along Surface of Silicone Rubber Polymer Insulators Using Finite Element Methodostojic007No ratings yet

- Calculation of The Electric Field On An Insulator String Using The Finite Elements MethodDocument4 pagesCalculation of The Electric Field On An Insulator String Using The Finite Elements Methodostojic007No ratings yet

- Noise: How To Overcome The High, Hidden Cost of Inconsistent Decision MakingDocument12 pagesNoise: How To Overcome The High, Hidden Cost of Inconsistent Decision MakingDr. Anila FaisalNo ratings yet

- Design and VLSI Implementation of High-Performance Face-Detection Engine For Mobile ApplicationsDocument2 pagesDesign and VLSI Implementation of High-Performance Face-Detection Engine For Mobile ApplicationsArjun0607No ratings yet

- Design and Analysis of Algorithms: Text BookDocument76 pagesDesign and Analysis of Algorithms: Text Bookdhana210No ratings yet

- Analysing Privacy Policies and Terms of Use To Understand Algorithmic Recommendations - The Case Studies of Tinder and SpotifyDocument15 pagesAnalysing Privacy Policies and Terms of Use To Understand Algorithmic Recommendations - The Case Studies of Tinder and Spotifyweixia792No ratings yet

- CC102 Lesson Proper For Week 1 To 5Document28 pagesCC102 Lesson Proper For Week 1 To 5Alejandro Francisco Jr.No ratings yet

- Detecting Fake Accounts in Media Application Using Machine LearningDocument4 pagesDetecting Fake Accounts in Media Application Using Machine LearningAbhishek AgrawalNo ratings yet

- Applying Case-Based Reasoning To Code Understanding and GenerationDocument14 pagesApplying Case-Based Reasoning To Code Understanding and GenerationGoverto Eko CahyonoNo ratings yet

- Elementary Programming With C - Theory PDFDocument249 pagesElementary Programming With C - Theory PDFVu DinhNo ratings yet

- 868B Computer SC-2-QPDocument5 pages868B Computer SC-2-QPAtanuBhandaryNo ratings yet

- NDTV WorkshopDocument70 pagesNDTV Workshopslash020No ratings yet

- C ProgrammingDocument615 pagesC ProgrammingSardonicw100% (2)

- Week 3 Flowchats, AlgorithmsDocument20 pagesWeek 3 Flowchats, AlgorithmsSahir AliNo ratings yet

- 1974 Fast One-Dimensional Digital Convolution by Multidimensional TechniquesDocument10 pages1974 Fast One-Dimensional Digital Convolution by Multidimensional TechniquesRajesh BathijaNo ratings yet

- Isc Computer Science Project: The Assembly of God Church SchoolDocument48 pagesIsc Computer Science Project: The Assembly of God Church SchoolMajama BhaiNo ratings yet

- Evolutionary Programming Using A Mixed Mutation Strategy and An Online DemoDocument65 pagesEvolutionary Programming Using A Mixed Mutation Strategy and An Online Demojaved765No ratings yet

- Computational Thinking, Computer Science, and CodingDocument40 pagesComputational Thinking, Computer Science, and CodingMai Hồ An ThúyNo ratings yet

- Jump and Sentinel SearchDocument3 pagesJump and Sentinel SearchxivalanoNo ratings yet

- Application of Data Mining in AgricultureDocument10 pagesApplication of Data Mining in AgricultureBoris MilovicNo ratings yet

- A Tour of Machine Learning AlgorithmsDocument68 pagesA Tour of Machine Learning AlgorithmsbrianccummingsNo ratings yet

- Unit Ii: 2.1 Problem Solving TechniquesDocument31 pagesUnit Ii: 2.1 Problem Solving TechniquesseravanakumarNo ratings yet

- CSC 201 Assignment - Odeniyi VictorDocument2 pagesCSC 201 Assignment - Odeniyi VictorvictorNo ratings yet

- BE First Year Scheme & Syllabi 2018-19 PDFDocument42 pagesBE First Year Scheme & Syllabi 2018-19 PDFSampanna UmredkarNo ratings yet

- UL Mobility Courses Mathematics Computer Science 2023 2024 WinterDocument5 pagesUL Mobility Courses Mathematics Computer Science 2023 2024 WinterDOG FRIENDNo ratings yet

- 10.3 As File HandlingDocument43 pages10.3 As File Handlingemadkareem.ktNo ratings yet

- A Deep Learning Based Framework For Physical Assets Health Prognostics Under Uncertainty For Big Machinery DataDocument74 pagesA Deep Learning Based Framework For Physical Assets Health Prognostics Under Uncertainty For Big Machinery DatajudarangocaNo ratings yet

- Conductivity-Depth Imaging of Helicopter-Borne TEM Data Based On Pseudo-Layer Half Space ModelDocument7 pagesConductivity-Depth Imaging of Helicopter-Borne TEM Data Based On Pseudo-Layer Half Space ModelFachmy Muhammad ZulfikarNo ratings yet

- On Track Scheme of Work Unit 4293 - Programming For A Purpose - For Assessment From January 2019Document28 pagesOn Track Scheme of Work Unit 4293 - Programming For A Purpose - For Assessment From January 2019anuveenaNo ratings yet

- Sequential Decoding of Polar CodesDocument4 pagesSequential Decoding of Polar CodesBui Van ThanhNo ratings yet

- 3-2 Human Machine - Minimum CardDocument2 pages3-2 Human Machine - Minimum Cardapi-372568750No ratings yet