Professional Documents

Culture Documents

Wheatland Electrical Metallic Tubing Catalog

Uploaded by

Yousif_AbdalhalimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wheatland Electrical Metallic Tubing Catalog

Uploaded by

Yousif_AbdalhalimCopyright:

Available Formats

Wheatland Tube Company Wheatland Galvanized Electrical Metallic Tubing (EMT) -Steel

General

Steel Electrical Metallic Tubing is manufactured from mild steel tube. It has an accurate circular cross section, a uniform wall thickness, a defect free interior surface, and continuously welded seams. The exterior surface is thoroughly and evenly coated with zinc using an inline galvanizing process, so that metal-tometal contact and galvanic protection against corrosion are provided. Additionally, the exterior is protected by a clear zinc chromate coating. The interior surface is coated with organic lubricating coating to reduce friction during wire insertion and retard corrosion. Wheatlands EMT and its associated tubular fittings are produced in nominal trade sizes from 1/2 to 4. EMT is produced in standard lengths of 10 feet (3.05 m). Bundles of finished EMT are wrapped with color coded special light weight filament tape. Black tape identifies trade sizes 1/2 and 1 1/2, Red tape identifies 3/4 and 1 1/4, and Blue tape 1. Trade sizes 2 and larger are not bundled. Wheatland EMT is a UL Listed product. Each length of tubing has a label affixed containing UL Listing information and a bar code. Each length is identified with Wheatlands name, Logo, the letters EMT clearly and durably marked once per 10 foot (3.05 m) length, a U.L. listing number and the words, Consult manufacturer for installation instructions. On July 25, 2001 the past UL requirement to embed the letters EMT into the surface of the tube was changed to require only durably marking the tube with the letters EMT at a minimum of 1/8 inch (3 mm) high.

1 Council Avenue P.O. Box 608 Wheatland, PA 16161-0608 800.257.8182

www.wheatland.com

Applications

Wheatland Galvanized Steel Electrical Metallic Tubing, National Electrical Code (NEC) 2005 Article 358, can be installed indoors or outdoors, in dry or wet locations, exposed or concealed, in all kinds of atmospheric conditions, and in hazardous locations, when in accordance with the NEC and providing it will not be subject to severe physical damage during and after installation and is properly protected against corrosion. Also, it provides mechanical protection for the conductors while reducing ElectroMagnetic Field (EMF) exposure and shielding against Electro-Magnetic Interference (EMI).

Specifications

Wheatland Galvanized Steel Electrical Metallic Tubing is manufactured in accordance with the latest edition of the following: American National Standards Institute American National Standard for Steel Electrical Metallic Tubing (EMT), ANSI C80.3 Underwriters Laboratories Standard for Electrical Metallic Tubing - Steel, UL 797 National Electrical Code 2005 Article 358 (1999 NEC Article 348) Federal Specification - WW-C-563 The above Federal specification may still be referenced, however the federal government has canceled it and adopted the UL 767 and ANSI C80.3 standard and will no longer maintain a separate standard. Electrical Metallic Tubing was covered under WW-C-563. Additional information on the titles and designations of standards or requirements that have been used for the investigation of products in a specific category can be found in the Underwriters Laboratories Inc., General Information for Electrical Equipment Directory. The UL product category for EMT is FJMX.

Galvanized Steel Electrical Metallic Tubing is an approved equipment grounding conductor under the 2005 NEC Section 250.118(4). The NEC establishes the minimum requirements for a safe electrical installation. Because of the varied environments in which electrical equipment is installed, local amendments are often added. Always consult local codes prior to any installation.

Made in U.S.A.

Certificate Numbers: Wheatland, PA 007172 Chicago, IL 008952 Little Rock, AR 009081

EMT_Spec_Sheet_2005rev.pmd

Wheatland Tube Company

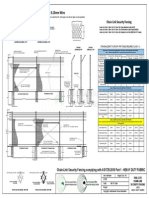

Electrical Metallic Tubing - Steel

WEIGHTS AND DIMENSIONS

Trade Si ze Metri c D esi gnator Wei ght 10 Uni t Lengths lb

1

1 Council Avenue P.O. Box 608 Wheatland, PA 16161-0608 800.257.8182

www.wheatland.com

Outsi de D i ameter(1) i n. 0.706 0.922 1.163 1.510 1.740 2.197 2.875 3.500 4.000 4.500 mm 17.93 23.42 29.54 38.35 44.20 55.80 73.03 88.90 101.60 114.30

Insi de D i ameter(2) i n. 0.622 0.824 1.049 1.380 1.610 2.067 2.731 3.356 3.834 4.334 mm 15.80 20.93 26.64 35.05 40.89 52.50 69.37 85.24 97.38 110.08

Wall Thi ckness(2) i n. .042 .049 .057 .065 .065 .065 .072 .072 .083 .083 mm 1.07 1.25 1.45 1.65 1.65 1.65 1.83 1.83 2.11 2.11

kg 13.6 20.9 30.4 45.8 52.6 67.1 98.0 119.3 158.3 178.3

/2

16 21 27 35 41 53 63 78 91 103

30 46 67 101 116 148 216 263 349 393

/4

1 11/4 11/2 2 21/2 3 31/2 4

Notes : Applicable tolerances

Length: 10 Ft. (3.05 m) +/- 1/4 in. (+/- 6.35 mm) (1) Outside Diameter: 1/2 - 2 +/- 0.005 in. (16 - 53 +/- 0.13mm), 2-1/2 +/- 0.010 in. (63 +/- 0.25 mm), 3 +/- 0.015 in. (78 +/- 0.38 mm) , 3-1/2 - 4 +/- 0.020 in. (91 - 103 +/- 0.51 mm). (2) For information only, not a UL 797 requirement.

PACKAGING

Trade Size Metric Designator Bundle Tape Color Quantity Per Bundle F eet

1

Quantity Per Lift P i e ce s ----------120 61 51 37 30 Bundles 70 50 30 40 30 ----------F eet 7000 5000 3000 2000 1500 1200 610 510 370 300 Meters 2134 1524 914 610 457 366 186 155 113 91

Weight Per Lift Pounds 2100 2300 2010 2020 1740 1776 1318 1341 1291 1179 Kilograms 952.6 1043.3 911.7 916.3 789.3 805.6 597.7 608.4 585.7 534.8

Volume Per Lift Cu. Ft. 31.7 36.1 36.5 38.2 37.9 46.7 41.5 48.9 48.6 50.0 Cu. m 0.9 1.0 1.0 1.1 1.1 1.3 1.2 1.4 1.4 1.4

Meters 30.5 30.5 30.5 15.2 15.2 -----------

/2

16 21 27 35 41 53 63 78 91 103

Black Red Blue Red Black -----------

100 100 100 50 50 -----------

/4

1 11/4 11/2 2 21/2 3 31/2 4

The quantity per Lift conforms to the National Electrical Manufacturers Association Standards Publication RN-2 Packaging of Master Bundles for Steel Rigid Conduit, Intermediate Metal Conduit (IMC), and Electrical Metallic Tubing.

EMT_Spec_Sheet_2005rev.pmd

You might also like

- Anclajes Red HeadDocument8 pagesAnclajes Red HeadLeonardo AvilaNo ratings yet

- Audible Noise ReductionDocument4 pagesAudible Noise ReductionGaurav SharmaNo ratings yet

- Siemens Sentron BuswayDocument2 pagesSiemens Sentron Buswayduyan1987No ratings yet

- Letter From AlantekDocument1 pageLetter From AlantekThuận Trần Chu100% (1)

- M50 enDocument338 pagesM50 entomwilkinsNo ratings yet

- Metal Conduits and ConnectorsDocument28 pagesMetal Conduits and ConnectorskingoglobalNo ratings yet

- Abb IsolatorsDocument24 pagesAbb IsolatorsAnoop KvNo ratings yet

- CoC 100850996CRT-001i PDFDocument1 pageCoC 100850996CRT-001i PDFAnderson Joel Navarro YarlequeNo ratings yet

- Resistors Module 02Document17 pagesResistors Module 02ubaidNo ratings yet

- Hi Flex Flexible Conduit Systems BrochureDocument24 pagesHi Flex Flexible Conduit Systems BrochureMariano SanchezNo ratings yet

- Term Paper-Sheet Metal WeldingDocument6 pagesTerm Paper-Sheet Metal Welding11gargdinesh7No ratings yet

- OFFSHORE CABLES CATALOGUEDocument88 pagesOFFSHORE CABLES CATALOGUEErstendrain EngNo ratings yet

- Strand Make-Up According To DIN VDE 0295, IEC 60228 and HD 383Document1 pageStrand Make-Up According To DIN VDE 0295, IEC 60228 and HD 383rocketvtNo ratings yet

- Guide to Cable Gland Types and InstallationDocument8 pagesGuide to Cable Gland Types and InstallationHimdad TahirNo ratings yet

- Lenton PlusDocument2 pagesLenton PlusAndrei PantuNo ratings yet

- PGE Tech GPT PDFDocument2 pagesPGE Tech GPT PDFAnonymous 1ykzuaxWgYNo ratings yet

- Trefoil and Single Cable Cleats Type SmartcleatDocument12 pagesTrefoil and Single Cable Cleats Type SmartcleatfndprojectNo ratings yet

- Aec Q100-001CDocument14 pagesAec Q100-001CelectronarutoNo ratings yet

- Water Blocking Tendencies in Underwater CablesDocument10 pagesWater Blocking Tendencies in Underwater Cablesrasheed313No ratings yet

- (3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2Document3 pages(3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2ErwinNo ratings yet

- 057521Document20 pages057521M.Senthil VelavanNo ratings yet

- INTERFLEX Catalogue (Conduits and Fittings)Document8 pagesINTERFLEX Catalogue (Conduits and Fittings)cherif yahyaouiNo ratings yet

- Burndy Tool Cross ReferenceDocument28 pagesBurndy Tool Cross Referencerayyan2007No ratings yet

- Product Catalogo RIBE DESBLOQDocument204 pagesProduct Catalogo RIBE DESBLOQDar Win100% (1)

- M&M Resources International Inc. guide to Baosteel cold rolled grain oriented electrical steelDocument12 pagesM&M Resources International Inc. guide to Baosteel cold rolled grain oriented electrical steeldarkonikolic78No ratings yet

- Types of Materials for Marine and Offshore CablesDocument55 pagesTypes of Materials for Marine and Offshore Cablesandy175No ratings yet

- Gtacsr GztacsrDocument1 pageGtacsr GztacsrrooneytuNo ratings yet

- High Conductive High Galvanized Round Steel WireDocument2 pagesHigh Conductive High Galvanized Round Steel WirequycoctuNo ratings yet

- Entraco To Glenair Cross Reference: MIL-PRF-24758ADocument6 pagesEntraco To Glenair Cross Reference: MIL-PRF-24758AJoseph BernardNo ratings yet

- Category 3 copper cable specificationsDocument45 pagesCategory 3 copper cable specificationsArman Ul NasarNo ratings yet

- Magnetic Lock - Single (EM-NH500M)Document2 pagesMagnetic Lock - Single (EM-NH500M)Usman ZouqueNo ratings yet

- LFH-40 Understanding Low Smoke and Halogen Free CablesDocument1 pageLFH-40 Understanding Low Smoke and Halogen Free CablesArdi Do0% (1)

- CP Criteria 01Document15 pagesCP Criteria 01Sheik DawoodNo ratings yet

- Alantek Coaxial CatalogDocument24 pagesAlantek Coaxial CatalogThuận Trần ChuNo ratings yet

- Bomba Flygt 3080caracteristicasDocument2 pagesBomba Flygt 3080caracteristicasOtoniel Cardenas100% (1)

- Hubbell - Connector Theory - Failure Modes & Practical ApplicationsDocument30 pagesHubbell - Connector Theory - Failure Modes & Practical Applicationssulemankhalid100% (1)

- Jurnal Dowel PDFDocument5 pagesJurnal Dowel PDFLukmanHakimNo ratings yet

- Mar Win SteamDocument33 pagesMar Win SteamChristopher RequintoNo ratings yet

- Hot Dip Galvanizing of Sheet Metal-SpangleDocument6 pagesHot Dip Galvanizing of Sheet Metal-SpangleAgustine SetiawanNo ratings yet

- TDDocument4 pagesTDJaime Arellano HuertaNo ratings yet

- Heavy Duty Fabric FencingDocument1 pageHeavy Duty Fabric FencingasotozuazuaNo ratings yet

- Fro Bro Vs247317 EngDocument4 pagesFro Bro Vs247317 EngvonipkoNo ratings yet

- Cross ArmsDocument46 pagesCross Armshalel111No ratings yet

- Insulated and Non-Insulated Cable ConnectorsDocument24 pagesInsulated and Non-Insulated Cable ConnectorskingoglobalNo ratings yet

- Preheat Calculation 1 PDFDocument3 pagesPreheat Calculation 1 PDFravi00098No ratings yet

- 1.10. Grades: Process Piping Fundamentals, Codes and Standards - Module 1Document5 pages1.10. Grades: Process Piping Fundamentals, Codes and Standards - Module 1Raakze MoviNo ratings yet

- Cleveland CablesDocument144 pagesCleveland CablesPhil PhilipNo ratings yet

- Threaded Accessories: MaterialsDocument22 pagesThreaded Accessories: MaterialsdzungNo ratings yet

- En TM 1000 4transmancovinsideDocument33 pagesEn TM 1000 4transmancovinsideAbhinav SinhaNo ratings yet

- Rotary JointDocument7 pagesRotary JointGlobe Star Engineers Pvt LtdNo ratings yet

- 1LCA000003-LTE SinglePh Overhead 10kVA 167kVA Rev01Document4 pages1LCA000003-LTE SinglePh Overhead 10kVA 167kVA Rev01thapa786mNo ratings yet

- 7SL87 Catalog Sip5 PDFDocument8 pages7SL87 Catalog Sip5 PDFPontasNo ratings yet

- ESAB Consumable PDFDocument165 pagesESAB Consumable PDFbond8031No ratings yet

- Copper-Clad Aluminum Bar For Electrical Purposes (Bus Bar)Document5 pagesCopper-Clad Aluminum Bar For Electrical Purposes (Bus Bar)Tuanbk NguyenNo ratings yet

- Electrode Converted Into TextDocument14 pagesElectrode Converted Into TextNeha NimbarkNo ratings yet

- Powder Extinguishers and Fire Safety Equipment GuideDocument19 pagesPowder Extinguishers and Fire Safety Equipment GuideRama Lakshmi Saradhi100% (1)

- Optical Con Field Assembly - Technical Info v1.0Document14 pagesOptical Con Field Assembly - Technical Info v1.0Mariano AcostaNo ratings yet

- AWG Catalog PDFDocument412 pagesAWG Catalog PDFgerrzen64No ratings yet

- Wheatland EMT Spec Sheet 2008Document2 pagesWheatland EMT Spec Sheet 2008abd mohamedNo ratings yet

- Cat Republic Conduit EMTDocument2 pagesCat Republic Conduit EMTDave ChecaNo ratings yet

- A Roadmap Towards A Resilient Sudan-Musadag El ZeinDocument18 pagesA Roadmap Towards A Resilient Sudan-Musadag El ZeinYousif_AbdalhalimNo ratings yet

- R-L French Ruled LetterDocument1 pageR-L French Ruled LetterYousif_AbdalhalimNo ratings yet

- PES 2020 Boots Assignment Tool 3.0 by MFZ69Document1 pagePES 2020 Boots Assignment Tool 3.0 by MFZ69Yousif_AbdalhalimNo ratings yet

- Cooling Load CalculationDocument14 pagesCooling Load CalculationVũ Hằng PhươngNo ratings yet

- Part Number: YE00819: Classic Original ClassicDocument2 pagesPart Number: YE00819: Classic Original ClassicYousif_AbdalhalimNo ratings yet

- Academic Calendar Year 2019-2020Document1 pageAcademic Calendar Year 2019-2020Yousif_AbdalhalimNo ratings yet

- 8471 TechdataDocument3 pages8471 TechdataYousif_AbdalhalimNo ratings yet

- How To Convert AWG To MM: Wire Diameter CalculationDocument2 pagesHow To Convert AWG To MM: Wire Diameter CalculationYousif_Abdalhalim0% (1)

- BS 7671 - British StandardDocument4 pagesBS 7671 - British StandardYousif_AbdalhalimNo ratings yet

- Harmonised cable colours guideDocument2 pagesHarmonised cable colours guideYousif_AbdalhalimNo ratings yet

- VirtualBox VM SettingsDocument1 pageVirtualBox VM SettingsAAC TridayaNo ratings yet

- Voltage Drop CalculationsDocument8 pagesVoltage Drop CalculationsYousif_AbdalhalimNo ratings yet

- Harmonised Cable Core ColoursDocument2 pagesHarmonised Cable Core ColoursYousif_AbdalhalimNo ratings yet

- Voltage Drop CalculationsDocument8 pagesVoltage Drop CalculationsYousif_AbdalhalimNo ratings yet

- Thread data and cable carrying capacity metric standardsDocument3 pagesThread data and cable carrying capacity metric standardsYousif_AbdalhalimNo ratings yet

- SC 2Document1 pageSC 2Yousif_AbdalhalimNo ratings yet

- How to calculate conduit fillDocument2 pagesHow to calculate conduit fillYousif_AbdalhalimNo ratings yet

- Table 4B1Document1 pageTable 4B1Yousif_AbdalhalimNo ratings yet

- Network FixDocument1 pageNetwork FixYousif_AbdalhalimNo ratings yet

- Generator Earthing and Stator Earth Fault ProtectionDocument9 pagesGenerator Earthing and Stator Earth Fault ProtectionYousif_AbdalhalimNo ratings yet

- Bonding CablesDocument2 pagesBonding CablesYousif_AbdalhalimNo ratings yet

- Voltage Drop FormulasDocument1 pageVoltage Drop FormulasSemaj EelNo ratings yet

- Short-Circuit CaculationsDocument10 pagesShort-Circuit CaculationsYousif_AbdalhalimNo ratings yet

- Asynchronous Motor Electrical Data ChartDocument2 pagesAsynchronous Motor Electrical Data ChartYousif_AbdalhalimNo ratings yet

- Demand Factor-Diversity Factor-Utilization Factor-Load FactorDocument13 pagesDemand Factor-Diversity Factor-Utilization Factor-Load FactorYousif_Abdalhalim100% (1)

- Designing Conduit Runs EIA - TIA 569 vs. NECDocument6 pagesDesigning Conduit Runs EIA - TIA 569 vs. NECYousif_AbdalhalimNo ratings yet

- 8 - Voltage Drop EquationsDocument5 pages8 - Voltage Drop EquationsRichard GriffithNo ratings yet

- Etap 16 Readme PDFDocument142 pagesEtap 16 Readme PDFkra_amNo ratings yet

- An Example How To Calculate Voltage Drop and Size of Electrical CableDocument4 pagesAn Example How To Calculate Voltage Drop and Size of Electrical CableYousif_AbdalhalimNo ratings yet

- Thumb Rule 13Document2 pagesThumb Rule 13Yousif_AbdalhalimNo ratings yet

- CuegisDocument2 pagesCuegisTrishaNo ratings yet

- Lesson Plan Earth & SpaceDocument5 pagesLesson Plan Earth & SpaceSol Vega PagdangananNo ratings yet

- Viviana Rodriguez: Education The University of Texas at El Paso (UTEP)Document1 pageViviana Rodriguez: Education The University of Texas at El Paso (UTEP)api-340240168No ratings yet

- Pakage PAU (Fruits)Document70 pagesPakage PAU (Fruits)Gary Bhullar57% (7)

- Pantone and K100 Reverse White MedicineDocument16 pagesPantone and K100 Reverse White MedicinepaanarNo ratings yet

- Applied SciencesDocument25 pagesApplied SciencesMario BarbarossaNo ratings yet

- Aluminium FOil SearchDocument8 pagesAluminium FOil SearchAtul KumarNo ratings yet

- Aditi Pant Internship ReportDocument14 pagesAditi Pant Internship ReportDR.B.REVATHYNo ratings yet

- Isaac Asimov - "Nightfall"Document20 pagesIsaac Asimov - "Nightfall"Aditya Sharma100% (1)

- Gild PitchDocument19 pagesGild PitchtejabharathNo ratings yet

- Teaching and Learning in the Multigrade ClassroomDocument18 pagesTeaching and Learning in the Multigrade ClassroomMasitah Binti TaibNo ratings yet

- Name: Chakshu Purohit Course: BBA LLB Subject: Legal Research and Methodology Submitted To: Utkarsh MishraDocument5 pagesName: Chakshu Purohit Course: BBA LLB Subject: Legal Research and Methodology Submitted To: Utkarsh Mishrachakshu purohitNo ratings yet

- UNIT- 5 IRSDocument78 pagesUNIT- 5 IRSganeshjaggineni1927No ratings yet

- List of Psychotropic Drugs Under International ControlDocument32 pagesList of Psychotropic Drugs Under International ControlRadhakrishana DuddellaNo ratings yet

- The Standard 09.05.2014Document96 pagesThe Standard 09.05.2014Zachary Monroe100% (1)

- Attribute Achievement FormDocument15 pagesAttribute Achievement FormMiguel MenesesNo ratings yet

- Chapter 4 and 5 - For StudentsDocument6 pagesChapter 4 and 5 - For Studentsdesada testNo ratings yet

- Research Chapter 1Document7 pagesResearch Chapter 1Aryando Mocali TampubolonNo ratings yet

- ADD MATH ProjectDocument13 pagesADD MATH Projectmegazat27No ratings yet

- Coriolis - Atlas CompendiumDocument62 pagesCoriolis - Atlas CompendiumSquamata100% (2)

- Asset Valuation: Debt Investments: Analysis and Valuation: 1 2 N M 1 2 N MDocument23 pagesAsset Valuation: Debt Investments: Analysis and Valuation: 1 2 N M 1 2 N MSirSmirkNo ratings yet

- DRUG LISTDocument45 pagesDRUG LISTAmitKumarNo ratings yet

- Froyen06-The Keynesian System I - The Role of Aggregate DemandDocument40 pagesFroyen06-The Keynesian System I - The Role of Aggregate DemandUditi BiswasNo ratings yet

- 6th GATEDocument33 pages6th GATESamejiel Aseviel LajesielNo ratings yet

- Motor Operated ValveDocument6 pagesMotor Operated ValveYosses Sang NahkodaNo ratings yet

- Laptop repair messageDocument3 pagesLaptop repair messagePonpes Manbaul MaarifNo ratings yet

- Flexural Analysis of Beams (Part 2)Document7 pagesFlexural Analysis of Beams (Part 2)Johnnette Nafuerza AggabaoNo ratings yet

- Vital StatisticsDocument35 pagesVital StatisticsRadha100% (1)

- Ôn tập và kiểm tra học kì Tiếng anh 6 ĐÁP ÁNDocument143 pagesÔn tập và kiểm tra học kì Tiếng anh 6 ĐÁP ÁNThùy TinaNo ratings yet

- Adjective: the girl is beautifulDocument15 pagesAdjective: the girl is beautifulIn'am TraboulsiNo ratings yet