Professional Documents

Culture Documents

Daido Hydrodynamic BRG Material PDF

Uploaded by

MachineryengOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daido Hydrodynamic BRG Material PDF

Uploaded by

MachineryengCopyright:

Available Formats

Chapter 2

Typical bearing materials

Many kinds of bearing materials with a variety of the characteristics listed in tables 3-1 and 3-2 have been developed for individual applications and purposes.

Characteristics of bearing materials

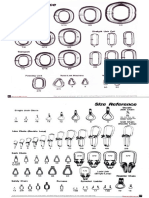

Figure 3-2 shows a comparison of bearing material characteristics. Nine representative materials were selected and each characteristic evaluated, taking the highest rank to be five points.

Material W87S A20 A40 A21X A10H P10/C/A4ZS P4/N/L17 P8/N/K22 P2H/N/K22 Fatigue resistance 1 2 3 4 5 Wear resistance 1 2 3 4 5 Anti-seizure 2 3 4 5 Conformability 1 2 3 4 5 Anti-corrosion 1 2 3 4 5

Note: C and N represent Cu and Ni respectively. Wear resistance with overlay indicates evaluation results for alloy. Figure 3-2 Characteristics of bearing materials

23

Chapter 2

Table 3-1 Typical bearing material list

Material

DAIDO's product name

Cu

Major chemical components (weight %) Sn Pb Sb Al Zn Si In Others 10 5 23 23 17 1 20 40 12 12 10 Traces Traces Traces 10 Traces 9 Traces 9 6 9 9 1.7 1.7 Traces Traces Traces 0.3 Traces 0.3 Traces Traces 2.5 2.5 2.5 4 6

Characteristics

Copper alloy L10

Traces 10 Traces 11 Traces 1.5 Traces Traces 1.2 1.0 1.0 0.7 0.7 1.5 4 4 4 3 3

BG1K* Copper alloy K22 (overlay required) L23

Used for the thrust metal of the piston pin bush and turbo charger. Material for piston pins subject to high Gr,P,Ni temperature and heavy specific loads Generally used for the con'rod bearing and main bearing with a P8/P9 overlay applied. L23 is also used for bushes without an overlay. Applying a P10 overlay ensures high fatigue strength and excellent anti-corrosion, making it ideal for bearings in diesel engines. General aluminum material Excellent anti-seizure and conformability High fatigue strength Ensures conformability equivalent to that of A17X and higher fatigue strength. Pb-free material for high specific load, developed by improving the fatigue strength of A21X General white metal used in general industries. Stronger than W90. Reinforced white metal used for bearings in Cd,Cr low-speed engines. General overlay material Ensures excellent conformability, and improves anti-seizure and wear resistance in high-speed and heavy-load environments. General overlay materials for copper alloy, with excellent wear resistance 12.5 12.5 Overlay for high specific load bearings, with excellent fatigue strength Developed by adding particles to P4 to provide excellent fatigue strength and wear resistance. Improves conformability and uneven contact between the bearing and shaft in aluminum alloy bearings. Excellent anti-corrosion and anti-cavitation. Resin overlay for dry turning of main bearings in low-seed engines. Employs a sintering layer of copper alloy in the middle layer to attach the backsteel. Ensures high temperature resistance, making it highly suitable for use in boundary environments.

L17 Aluminum alloy (overlay required) A4ZS* Aluminum alloy A20 A40 A17X* A21X* A10H W90 Tin alloy (white metal) W87 W87S* Overlay P10 P9 P8 P4* P4Z P1* P2H DLH2 Resin DTK01 DTK07

2 2 2

10 Traces 10 Traces 10 Traces 100

Traces

Binder + PTFE + PTFE + CF + PTFE +

* DAIDO's patented products Note: Materials listed in this table are the current bimetal materials most widely used in the shipping and general industries. Please contact us for solid metals, resin and surface modification materials not listed above.

24

You might also like

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- TREMEC TR-6070 Transmission: 7-Speed RWD Manual TransmissionDocument2 pagesTREMEC TR-6070 Transmission: 7-Speed RWD Manual TransmissionAngelNo ratings yet

- Project Street Rod: The Step-by-step Restoration of a Popular Vintage CarFrom EverandProject Street Rod: The Step-by-step Restoration of a Popular Vintage CarNo ratings yet

- 199R9934 3rev2 PDFDocument16 pages199R9934 3rev2 PDFbatman2054No ratings yet

- Testing agricultural trailersDocument9 pagesTesting agricultural trailersEdsel Jay RaperNo ratings yet

- Melling CatalogDocument36 pagesMelling CatalogpdpatchNo ratings yet

- PutcoProductCatalog-2014 v38CDocument40 pagesPutcoProductCatalog-2014 v38CKPNo ratings yet

- Installation Instructions TH700-R4 (4L60) TranskitDocument19 pagesInstallation Instructions TH700-R4 (4L60) TranskitEddy QueroNo ratings yet

- 615Document32 pages615ccbulgariaNo ratings yet

- IQ3 Haltech LD Manual v2 PDFDocument92 pagesIQ3 Haltech LD Manual v2 PDFEdwinNo ratings yet

- TH400 Transmission Installation Guide - Case Lengths, Mods, Lines, Driveshaft FitmentDocument5 pagesTH400 Transmission Installation Guide - Case Lengths, Mods, Lines, Driveshaft Fitmentiradanke100% (1)

- 2017 Catalog Compressed PDFDocument140 pages2017 Catalog Compressed PDFDaniel DonosoNo ratings yet

- Chev/GMC Truck Reproduction Parts Marketing GuideDocument168 pagesChev/GMC Truck Reproduction Parts Marketing GuideDerrick Hutchinson0% (1)

- Fiero AlignmentDocument4 pagesFiero AlignmentRonen MarkoNo ratings yet

- Bosch REPLACEMENT ALTERNATOR STATORSDocument23 pagesBosch REPLACEMENT ALTERNATOR STATORSLorenzo TorresNo ratings yet

- Section 1Document10 pagesSection 1Engine Tuning UpNo ratings yet

- Adjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersDocument13 pagesAdjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersJ.d. LangleyNo ratings yet

- Camaro High Performance Suspension TuningDocument5 pagesCamaro High Performance Suspension TuningSarawoot Watechagit100% (1)

- Vin Plate Decoding InformationDocument642 pagesVin Plate Decoding InformationTatiana BernalNo ratings yet

- Specification Application Metric English: Engine Mechanical Specifications Y Car - LS1Document6 pagesSpecification Application Metric English: Engine Mechanical Specifications Y Car - LS1Jean Paul BésNo ratings yet

- 3rd q94r-n PDFDocument7 pages3rd q94r-n PDFbelchior alvaro100% (1)

- Volt Sandy BlogsDocument9 pagesVolt Sandy BlogskrivasscribdNo ratings yet

- 2010 Ginn Motor Company HHR Atlanta GADocument8 pages2010 Ginn Motor Company HHR Atlanta GAatlantachevroletNo ratings yet

- Haltech f9v5 ManualDocument99 pagesHaltech f9v5 ManualboxyhenricNo ratings yet

- CompleteCatalog PDFDocument116 pagesCompleteCatalog PDFgume pesaNo ratings yet

- Brembo Racing Catalog 2012Document132 pagesBrembo Racing Catalog 2012jplondonNo ratings yet

- 2009 Mopar Perfomance PDFDocument351 pages2009 Mopar Perfomance PDFmacNo ratings yet

- Driveshaft AngleDocument10 pagesDriveshaft AnglefrazNo ratings yet

- 2005mustang SpecsDocument37 pages2005mustang SpecsTetsunari KodaNo ratings yet

- 750 Street Demon™: Part Numbers: 1903, 1904, & 1905Document20 pages750 Street Demon™: Part Numbers: 1903, 1904, & 1905private 2No ratings yet

- Transfer Case Catalog 2007Document51 pagesTransfer Case Catalog 2007davidNo ratings yet

- Brake QuipDocument100 pagesBrake QuipCentral Hydraulics100% (1)

- 24L FourDocument28 pages24L FourIqbal NugrohoNo ratings yet

- Holley 1909 Carb ManualDocument9 pagesHolley 1909 Carb ManualALMOST610No ratings yet

- Lunati CatalogDocument302 pagesLunati Catalogbmzero100% (5)

- The Dodge Viper 8.4 L V10Document6 pagesThe Dodge Viper 8.4 L V10znamNo ratings yet

- 350-HO Long Block SpecsDocument30 pages350-HO Long Block SpecsClif CunninghamNo ratings yet

- V2 3 6 Final Gear and Differential GearDocument44 pagesV2 3 6 Final Gear and Differential GearDwy Bagus NNo ratings yet

- Valvetrain Feature ETM107 Mechadyne TechnologiesDocument4 pagesValvetrain Feature ETM107 Mechadyne Technologiesseva0No ratings yet

- DIY sex machine guideDocument6 pagesDIY sex machine guideMikeNo ratings yet

- 2006 Big BlockDocument1 page2006 Big BlockMohannad Adnan ShariefNo ratings yet

- 199 R10013 RevDocument8 pages199 R10013 RevJanko ArtukovićNo ratings yet

- Twin Turbo Power GuideDocument24 pagesTwin Turbo Power GuideawalsumNo ratings yet

- 1323Document75 pages1323Werner SchulzNo ratings yet

- Catalogo Bushing Stemco para Kenworth PDFDocument7 pagesCatalogo Bushing Stemco para Kenworth PDFJuan Carlos FuentesNo ratings yet

- Catalogo WisecoDocument35 pagesCatalogo WisecobrunnomaiaNo ratings yet

- Borgeson Steering JointsDocument29 pagesBorgeson Steering JointsKerry Murray100% (1)

- Catalogo EBC 2011Document524 pagesCatalogo EBC 2011Diego Solano ArayaNo ratings yet

- Front Drive AxleDocument19 pagesFront Drive AxleGeraldo Pozos VazquezNo ratings yet

- Rearend Gear GuideDocument18 pagesRearend Gear GuideJam BabNo ratings yet

- Reverse Engineering: AGMA Technical PaperDocument9 pagesReverse Engineering: AGMA Technical PaperSanketNo ratings yet

- TH400 Dissassembly TechnicalDocument29 pagesTH400 Dissassembly TechnicalmateoNo ratings yet

- AMC IgnitiionModificationDocument5 pagesAMC IgnitiionModificationFred DeRoosNo ratings yet

- Melling Performance Catalog PDFDocument237 pagesMelling Performance Catalog PDFLuis Ramón Argüello RealNo ratings yet

- 904 RebuidDocument7 pages904 RebuidDaniel WildNo ratings yet

- Installation Manual: For #60250 2003-2005 Cummins 5.9L Common Rail DieselDocument29 pagesInstallation Manual: For #60250 2003-2005 Cummins 5.9L Common Rail Dieselthanhhai31No ratings yet

- 199r10487 1rev6Document12 pages199r10487 1rev6Alfonso JaureguiNo ratings yet

- Suspension Rear CAVALIERDocument4 pagesSuspension Rear CAVALIERedwin ortizNo ratings yet

- Lip Seal Installation PDFDocument11 pagesLip Seal Installation PDFMachineryengNo ratings yet

- Compressor MountingDocument41 pagesCompressor MountingjmacarroNo ratings yet

- Manual Best Management PortsDocument156 pagesManual Best Management PortsAchraf DouiriNo ratings yet

- Seal Design GuideDocument119 pagesSeal Design GuideaytepeNo ratings yet

- BORSIG ZM Compression - Innovative Solutions for Process Gas CompressionDocument16 pagesBORSIG ZM Compression - Innovative Solutions for Process Gas CompressionMachineryengNo ratings yet

- Hsg253 The Safe Isolation of Plant and EquipmentDocument81 pagesHsg253 The Safe Isolation of Plant and EquipmentRichard HollidayNo ratings yet

- ESA Best Available Techniques Issue 1Document4 pagesESA Best Available Techniques Issue 1vprochockyNo ratings yet

- JC Gasket CranfoilDocument2 pagesJC Gasket CranfoilMachineryengNo ratings yet

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDocument25 pagesHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- SOP Number Insert Number: Standard Operating ProcedureDocument2 pagesSOP Number Insert Number: Standard Operating ProcedureLawNo ratings yet

- Borsig BZM - 2016 - EngDocument84 pagesBorsig BZM - 2016 - EngMachineryengNo ratings yet

- SOP Templates 03Document1 pageSOP Templates 03MachineryengNo ratings yet

- Steam TurbinesDocument8 pagesSteam Turbinesspalaniyandi100% (1)

- Norsok ST 2001Document131 pagesNorsok ST 2001mamounsdNo ratings yet

- Seal Design For High Pressure Offshore-Morton & EvansDocument10 pagesSeal Design For High Pressure Offshore-Morton & EvansMachineryengNo ratings yet

- Pit Ot Tube Pump TechnologyDocument12 pagesPit Ot Tube Pump TechnologymariasofiarossiNo ratings yet

- Api 617 CameronDocument31 pagesApi 617 CameronMachineryengNo ratings yet

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDocument25 pagesHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- UtilityDocument8 pagesUtilityAmit JainNo ratings yet

- Creating A World That Doesnt BreakdownDocument23 pagesCreating A World That Doesnt BreakdownmersiumNo ratings yet

- Compressor Performance Test Procedure Shaybah Rev.2 BorsigDocument23 pagesCompressor Performance Test Procedure Shaybah Rev.2 BorsigMachineryengNo ratings yet

- Compressor Turbo-Air API a4-IRDocument12 pagesCompressor Turbo-Air API a4-IRMachineryengNo ratings yet

- BORSIG Valve PresentationDocument18 pagesBORSIG Valve PresentationMachineryengNo ratings yet

- Lifts and Hoists Maintenance Tasks PDFDocument19 pagesLifts and Hoists Maintenance Tasks PDFMachineryengNo ratings yet

- Burgmann Quick Guide To Identifying Mechanical Seal FailuresDocument1 pageBurgmann Quick Guide To Identifying Mechanical Seal FailuresakabbaraNo ratings yet

- Lifiting Chain Size Referance PDFDocument1 pageLifiting Chain Size Referance PDFMachineryengNo ratings yet

- SVS.435 Steam Turbine Control UpgradesDocument4 pagesSVS.435 Steam Turbine Control UpgradesMachineryengNo ratings yet

- Perf Improv To Aches Rev 0Document16 pagesPerf Improv To Aches Rev 0Poncho RmzNo ratings yet

- Selection of Material Nace - H2S - Technical Paper PDFDocument21 pagesSelection of Material Nace - H2S - Technical Paper PDFajaysharma_1009No ratings yet

- GeneralCable Exzhellent XXIDocument2 pagesGeneralCable Exzhellent XXIDaniel Hermida VaqueroNo ratings yet

- Review: Electrolyte Additives For Lithium Ion Battery Electrodes: Progress and PerspectivesDocument34 pagesReview: Electrolyte Additives For Lithium Ion Battery Electrodes: Progress and PerspectivesMichael LesaNo ratings yet

- Free Knitting Patterns - Leaves Stitch Knitting PatternDocument3 pagesFree Knitting Patterns - Leaves Stitch Knitting PatternN CNo ratings yet

- Chemical Bonding Agents and MortarsDocument14 pagesChemical Bonding Agents and MortarsakurilNo ratings yet

- The Technology of Fire: An IntroductionDocument28 pagesThe Technology of Fire: An IntroductionFEI RIENo ratings yet

- Catalyst Acid-Base Properties Impact Glycerol DehydrationDocument7 pagesCatalyst Acid-Base Properties Impact Glycerol DehydrationnayarapradoNo ratings yet

- WMM Moisture Correction SheetDocument34 pagesWMM Moisture Correction SheetQuality JamNo ratings yet

- Halogen and Noble GasesDocument33 pagesHalogen and Noble GasesYen ZaneNo ratings yet

- MaterialsDocument30 pagesMaterialshorascanmanNo ratings yet

- Technical Guidelines for Optimizing Shot Tip LifeDocument25 pagesTechnical Guidelines for Optimizing Shot Tip Lifelucho0314No ratings yet

- Sus B - 5Document1 pageSus B - 5Partha Sarathi GhoshNo ratings yet

- Evaluating Cu-W Composite Powder Metallurgy ProcessesDocument24 pagesEvaluating Cu-W Composite Powder Metallurgy Processesmuthu kumarNo ratings yet

- Sikalite Powdered Waterproofing AdmixtureDocument2 pagesSikalite Powdered Waterproofing AdmixtureNathàn Ocày100% (1)

- Blasting Painting Procedure (002) - MFAADocument11 pagesBlasting Painting Procedure (002) - MFAAZamri AhmadNo ratings yet

- Metals: Industrial Recycling of Lithium-Ion Batteries-A Critical Review of Metallurgical Process RoutesDocument29 pagesMetals: Industrial Recycling of Lithium-Ion Batteries-A Critical Review of Metallurgical Process RoutesGaurav VermaNo ratings yet

- 10.1007@978 981 15 3669 4Document388 pages10.1007@978 981 15 3669 4Muhammad Abdur RashidNo ratings yet

- Starmedix Suture CatalogueDocument8 pagesStarmedix Suture Cataloguedr_abodNo ratings yet

- Fluid Phase Equilibria, 87 (1993) 133-152Document20 pagesFluid Phase Equilibria, 87 (1993) 133-152Gaurav KunduNo ratings yet

- Data Sheet: Valid From: 5/7/21Document2 pagesData Sheet: Valid From: 5/7/21Omar GuillenNo ratings yet

- Floor hardener for heavy traffic areasDocument2 pagesFloor hardener for heavy traffic areasMahmoudNo ratings yet

- PVC (Eng)Document11 pagesPVC (Eng)Imanol TuerosNo ratings yet

- Sugerido Exhibicion Century SCZDocument98 pagesSugerido Exhibicion Century SCZYanel Cuellar FloresNo ratings yet

- Lec 10 Week (7) (Water Distribution System)Document27 pagesLec 10 Week (7) (Water Distribution System)Ahmad RazaNo ratings yet

- Astm A519Document14 pagesAstm A519PrakashNo ratings yet

- Title: Project Report On Polyester Webbing: Subject: Project Management in EngineeringDocument6 pagesTitle: Project Report On Polyester Webbing: Subject: Project Management in EngineeringShahbaz ahmad100% (1)

- Blue-Flame Gas Stove: Safety InstructionsDocument11 pagesBlue-Flame Gas Stove: Safety Instructionsi4004No ratings yet

- Lin Cot 2005Document9 pagesLin Cot 2005londemonNo ratings yet

- CHE3723 - Safety in Process Plant Design: Lecturer: Eunice Phang S.WDocument1 pageCHE3723 - Safety in Process Plant Design: Lecturer: Eunice Phang S.WRafiHunJianNo ratings yet

- Diamond Like CoatingsDocument24 pagesDiamond Like CoatingscecilchifticaNo ratings yet

- OringDocument140 pagesOringJUAN PABLO CORTES FLORESNo ratings yet