Professional Documents

Culture Documents

Hydrogen Production - Gaps and Priorities

Uploaded by

KVVCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrogen Production - Gaps and Priorities

Uploaded by

KVVCopyright:

Available Formats

Hydrogen Production - Gaps and Priorities

Trygve Riis(1) and Elisabet F. Hagen(2) Preben J. S. Vie (3) and ystein Ulleberg (3) (Corresponding authors)

Abstract This paper summarises the main issues related to hydrogen production. The technologies discussed are reforming of natural gas, gasification of coal and biomass, and splitting of water by water -electrolysis, photoelectrolysis, photo-biological production and high temperature decomposition. For all hydrogen production processes there is a need for significant improvement in plant efficiencies, reduced capital costs, and enhanced reliability and operating flexibility. For the current- and near-term, water electrolysis and small -scale natural gas reformers are recommended. Water electrolysis is a proven technology that can be used in the early phases of building a hydrogen infrastructure for the transport sector. Small-scale natural gas reformers have only limited proven and commercial availability, but several units are being tested in demonstration projects. In the medium to longterm, hydrogen production based on centralised fossil fuel based production with capture and storage of CO2 is recommended. The capture of CO2 for storage purposes is not yet technically and commercially proven, and requires further R&D on absorption or separation processes and process operation. The other processes for hydrogen production are further away from commercialisation and need additional R&D. The production of hydrogen from biomass needs additional focus on the preparation and logistics of the feed. The production will probably only be economical at a larger scale. Photo -electrolysis is at an early stage of development and material cost and practical issues have yet to be solved. The photo -biological processes are at a very early stage of the development with only low conversion efficiencies obtained so far. High temperature processes need further materials development, focusing on high temperature membranes and heat exchangers, for example.

1. INTRODUCTION

Hydrogen can be produced from a variety of feedstocks; from fossil resources such as natural gas and coal, and from renewable resources such as biomass and water with input from renewable energy sources (e.g. sunlight, wind, wave or hydro-power). A variety of process technologies can be used, including chemical, biolo gical, electrolytic, photolytic and thermo-chemical. Each technology is in a different stage of development, and each offers unique opportunities, benefits and challenges. Local availability of feedstock, maturity of technology, market applications and demand, policy issues and costs will influence the choice and timing of the various options for hydrogen production. An overview of the various feedstocks and process technologies is presented in Figure 1.

1 2

The Research Council of Norway, PO Box 2700, St. Hanshaugen NO0131 Oslo, NORWAY Norsk Hydro ASA, NO-0246 Oslo, NORWAY 3 Institute for Energy Technology, PO Box 40, NO2027 Kjeller, NORWAY

IEA Hydrogen Implementing Agreement (HIA) 1 of 11 HIA_HCG_Production_2005-03-15_rev1_final.doc

Hydrogen Production Gaps and Priorities

Riis et al.

Gas: Natural gas or bio -gas are hydrogen sources with steam reforming or partial oxidation

Oil: Hydrogen is produced with steam reforming or partial oxidation from fossil or renewable oils

Algae: Methods for utilizing the photo-synthesis for hydrogen production

H2

Coal: With gasification technology hydrogen may be produced from coal Alcohols like ethanol and methanol derived from gas or biomass are rich on hydrogen and may be reformed to hydrogen

Wood: Pyrolysis technology for hydrogen from biomass Power: Water electrolysis from renewable sources

Figure 1. Some feedstock and process alternatives (Source: Hydro) Several technologies are already available in the marketplace for industrial production of hydrogen. The first commercial technology, dating from the late 1920s, was electrolysis of water producing pure hydrogen. In the 1960s the industrial production of hydrogen shifted slowly towards a fossil based feedstock, which is the main source for hydrogen production today. In Figure 2 a future hydrogen pathway is illus trated. Large-scale hydrogen production is probable on the longer time scale. In the current and medium term the production options for hydrogen are first based on distributed hydrogen production from electrolysis of water and reforming of natural gas and coal. Larger centralised hydrogen production plants are more likely to be introduced at a later stage. These plants will probably be based on biomass or fossil fuels with CO2-capture and storage.

Hydrogen economy" (2030+) 3. As 2 Electrolysis from Renewables and nuclear becomes Building important infrastructure" (2015-2030+) 2. As 1 + more centralised carbon based production Building market" (2003-2015) 1. Decentralised electrolysis, small scale SMR, tanked hydrogen

Turnover profit

Time Figure 2. Main hydrogen pathwa ys - the long term perspective. (Source: Hydro)

IEA Hydrogen Implementing Agreement (HIA)

2 of 11 HIA_HCG_Production_2005-03-15_rev1_final.doc

Hydrogen Production Gaps and Priorities

Riis et al.

The IEA Hydrogen Implementing Agreement (HIA) focuses on the following hydrogen production activities: H2 from fossil energy sources o Large scale with CO2 capture and storage (in collaboration with the IEA G reen House Gas Implementing Agreement programme - GHG) o Small scale distributed generation H2 from biomass Photo-electrolysis (Photolysis) Photo-biological hydrogen production (Biophotolysis) A new activity planned within HIA is high temperature production of hydrogen. This paper aims at providing an overview of the most important issues regarding production of hydrogen, needs for research and development (gaps), and priorities for further development and use. This overview is not, however, all-inclusive, and detailed descriptions of processes and R&D needs should be sought in specialist papers discussing each technology in detail.

2. HYDROGEN FROM FOSSIL FUELS

Hydrogen can be produced from most fossil fuels. The complexity of the processes varies, and in this chapter hydrogen production from natural gas and coal is briefly discussed. Since carbon dioxide is produced as a byproduct, the CO2 should be captured to ensure a sustainable (zero-emission) process. The feasibility of the processes will vary with respect to a centralised or distributed production plant.

2.1.

Production from Natural Gas

Hydrogen can currently be produced from natural gas from three different chemical processes: 1. Steam reforming (SMR Steam Methane Reforming) 2. Partial oxidation (POX) 3. Autothermal reforming (ATR) Several new production concepts have been developed but none of them are close to commercialisation. Steam reforming involves the endothermic conversion of methane and water vapour to hydrogen and carbon monoxide (2.1) . The heat is often supplied from combustion of some of the methane feed-gas. The typical temperatures and pressures for the process are 700 to 850 C and 3 to 25 bar. The product gas contains approximately 12 % CO, which can be further converted to CO2 and H 2 through the water gas shift reaction (2.2). CH4 + H 2O + heat CO + 3 H2 CO + H2O CO2 + H2 + heat (2.1) (2.2)

Partial oxidation of natural gas is the process where hydrogen is produced through a partial combustion of methane with oxygen gas to carbon monoxide and hydrogen (2.3). In this process heat is produced (exothermic) and a more compact design is possible since there is no need for external heating of the reactor. The CO produced is further converted to H2 as described in equation (2.2).. CH4 + O2 CO + 2 H2 + hear (2.3)

Autothermal reforming is a combination of both steam reforming (2.1) and partial oxidation (2.3). The total reaction is exothermic, producing heat. The outlet temperature from the reactor is in the range 950 to 1100 C, and the gas pressure can be as high as 100 bar. The CO produced is converted to H2 as described previously (2.2). The need to purify the gases adds significantly to plant costs and reduces the total efficiency. Each technology has certain benefits and challenges, which are summarised in

IEA Hydrogen Implementing Agreement (HIA)

3 of 11 HIA_HCG_Production_2005-03-15_rev1_final.doc

Hydrogen Production Gaps and Priorities

Riis et al.

Table 1.

Table 1. Comparison of technologies for H2 production from natural gas Technology SMR ATR or POX Benefits Efficiency Size Emissions Costs for small units Costs for large units Simple system Challenges Complex system Sensitive to NG qualities Efficiency H2 quality Emissions/flaring

2.2.

Production from Coal

Hydrogen can be produced from coal through a variety of gasification processes (e.g. fixed bed, fluidised bed or entrained flow). In practice, high temperature entrained flow processes are favoured to maximise carbon conversion to gas, avoiding the formation of significant amounts of char, tars and phenols. A typical reaction for the process is given in equation (2.4) below where carbon is converted to carbon monoxide and hydrogen. This reaction is endothermic and additional heat is required similar to the steam methane reforming. The CO is further converted to CO2 and H2 through the water-gas shift reaction (equation (2.2)). This process is commercially mature, but is more complex compared to production of hydrogen from natural gas. The cost of hydrogen is also higher. But coal is plentiful in many parts of the world and will probably be used as an energy source anyway. It is worth developing technologies to convert it to clean technologies. C(S) + H2 O + heat CO + H2

(2.4)

2.3.

Capture and Storage of CO2

Carbon dioxide is a major exhaust in all production of hydrogen from fossil fuels. The amount of CO2 will vary with respect to the hydrogen content of the feedstock. To obtain a sustainable (zero emission) production of hydrogen the CO2 should be captured and stored. This process is known as de -carbonisation. There are three different options to capture CO2 in a combustion process. 1. Post-combustion. The CO 2 can be removed from the exhaust gas of the combustion process in a conventional steam turbine or CCGT (combined cycle gas turbine) power plant. This is done using e.g. the amine process. The exhaust gas will contain large amounts of nitrogen and some amounts of nitrogen oxides in addition to water vapour, CO 2 and CO. 2. Pre-combustion. In this process CO2 is captured when producing hydrogen through any of the processes discussed above (section 2.1). 3. Oxyfuel-combustion. The fossil fuel is here converted to heat in a combustion process in a conventional steam turbine or CCGT power plant. This is done with pure oxygen as an oxidiser. Mostly CO2 and water vapour are produced in the exhaust or flue gases, and CO2 can be easily separated through condensing the water vapour. The post combustion and oxy -fuel combustion systems involve producing electricity in near-conventional steam and CCGT power plants. The electricity produced is then used for electrolysis of water. Because of the need to capture the CO2 for an energy conversion process of relatively low efficiency, and then using the electricity to electrolyse water, the overall efficiency of fuel to hydrogen would be not more than 30%.

IEA Hydrogen Implementing Agreement (HIA)

4 of 12 HIA_HCG_Production_2005-03-15_rev1_final.doc

Hydrogen Production Gaps and Priorities

Riis et al.

The captured CO2 can be stored in geological formations like oil and gas fields, for example, as well as in aquifers 4. The feasibility and proof of a permanent CO2 storage are critical to the success of de -carbonisation. The choice of the transportation system for the CO2 (pipeline, ship or combined) will largely depend both on the site chosen for the production plant and the site chosen for storage.

3. HYDROGEN FROM SPLITTING OF WATER

Hydrogen can be produced from splitting of water through various processes. This paper briefly discusses water electrolysis, photo-electrolysis, photo -biological production and high temperature water decomposition.

3.1.

Water Electrolysis

Water electrolysis is the process where water is split into hydrogen and oxygen through the application of electrical energy; see equation (3.1). The total energy demand for water electrolysis is increasing slightly with temperature, while the electrical energy demand decreases. A high-temperature electrolysis process might therefore be favourable when high temperature heat is available as waste heat from other processes. This is especially important globally as most of the electricity produced is based on fossil energy sources with relatively low efficiencies. The future potential cost for electrolytic hydrogen is presented in Figure 3, where the possibility to considerably reduce the production cost can be observed. H2O + electricity H2 + O

2

(3.1)

Levelized Hydrogen Cost

5.00 4.00 3.00 2.00 1.00 0.00 Today Small Plant Today Large Plant Future Continuous Future Off-Peak

Cost per kg H ($US)

O&M Electricity Capital Cost

Figure 3. Future potential for cost of electrolytic hydrogen (source: US DoE)

3.1.1. Alkaline Electrolysis

Alkaline electrolysers use an aqueous KOH solution (caustic) as an electrolyte that usually circulates through the electrolytic cells. Alkaline electrolysers are suited for stationary applications and are available at operating pressures up to 25 bar. Alkaline electrolysis is a mature technology allowing unmanned remote operation with significant operating experience in industrial applications. The following reactions take place inside the alkaline electrolysis cell:

Porous water-filled layer in the earth strata

5 of 12 HIA_HCG_Production_2005-03-15_rev1_final.doc

IEA Hydrogen Implementing Agreement (HIA)

Hydrogen Production Gaps and Priorities

Riis et al.

Electrolyte: Cathode: Anode: Sum:

4 H2O 4 H+ + 4 OH4 H + 4e 2 H2

+ -

(3.1) (3.2)

-

4 OH O2 + 2 H2O + 4 e

-

(3.3) (3.4)

2 H2O O2 + 2H2

Commercial electrolysers usually consist of a number of electrolytic cells arranged in a cell stack. Alkaline electrolysers typically contain the main components shown in Figure 4. The major R&D challenges for the future are the design and manufacturing of electrolyser equipment at lower costs with higher energy efficiency and large turn down ratios.

O2

KOH Electricity Transformer/ Rectifier O2/KOH Gas separator Electrolytic cell block H2/KOH Gas separator Deoxidiser Dryer H2

Water

Dioniser/ Reverse Osmosis

KOH

Figure 4. Process diagram of alkaline electrolysis.

3.1.2. Polymer Electrolyte Membrane (PEM) Electrolysis

The principle of PEM electrolysis is presented in equations (3.6) and (3.7). PEM electrolysers require no liquid electrolyte, which simplifies the design significantly. The electrolyte is an acidic polymer membrane. PEM electrolysers can potentially be designed for operating pressures up to several hundred bar, and are suited for both stationary and mobile applications. The main drawback of this technology is the limited lifetime of the membranes. The major advantages of PEM over alkaline electrolysers are higher turndown ratio5, increased safety due to absence of KOH electrolyte, more compact design due to higher current densities and higher operating pressures. anode: H2O O 2 + 2 H+ + 2 e cathode: 2 H+ + 2 e - H2 (3.6) (3.7)

The PEM electrolysers currently available are not as mature as alkaline electrolysers with relatively high cost, low capacity, poor efficiency and short lifetime. It is expected that the performance of PEM electrolysers can be improved significantly by material development and cell stack design.

3.1.3. High Temperature Electrolysis

High temperature electrolysis is based on technology from high temperature fuel cells. The electrical energy needed to split water at 1000 C is reduced considerably compared to hydrogen production at 100 C. This means that a high temperature electrolyser can operate at significantly higher overall process efficiencies than regular low temperature electrolysers. A typical technology is the Solid Oxide Electrolyser Cell (SOEC). This electrolyser is based on the Solid Oxide Fuel Cell (SOFC), which normally operates at 700 to 1000 C. At these temp eratures the electrode reactions are

5

Operating ratio of part load to full load.

6 of 12 HIA_HCG_Production_2005-03-15_rev1_final.doc

IEA Hydrogen Implementing Agreement (HIA)

Hydrogen Production Gaps and Priorities

Riis et al.

more reversible, and the fuel cell reaction can more easily be reversed to an electrolysis reaction. Attempts are currently underway to develop systems in which some of the electricity consumed by the electrolyser can be replaced with available heat from e.g. geothermal, solar or natural gas, thus reducing the consumption of electricity significantly. For the SOEC the main R&D needs relate to materials development and thermo-mechanical stress within the functional ceramic materials, similar to the main challenges for the SOFC.

3.2.

Photo-electrolysis (Photolysis)

Photovoltaic (PV) systems coupled to electrolysers are commercially available. The systems offer some flexibility, as the output can be electricity from photovoltaic cells or hydrogen from the electrolyser. Direct photoelectrolysis represents an advanced alternative to a PV/electrolysis system by combining both processes in a single apparatus; see principle in Figure 5. Photo-electrolysis of water is the process whereby light is used to directly split water into hydrogen and oxygen. Such systems offer great potential for cost reduction of electrolytic hydrogen compared with conventional two -step technologies.

Oxygen Incident solar radiation Hydrogen

Sensitized glass surfaces

Electrolyte Water

Figure 5. Principle of Photo-electrolytic cell (source: Hydrogen Solar Production Company Inc.) Fundamental and applied R&D efforts in relation to photo-electrochemical cell (PEC) materials science and systems engineering are currently being undertaken worldwide, with at least 13 OECD countries maintaining PECrelated R&D projects and/or entire programs. The IEA-HIA coordinates and manages a significant part of these R&D efforts in a collaborative, task-shared Annex. Four major PEC concept areas are being studied, comprising two-photon tandem systems, monolithic multi-junction systems, dual-bed redox systems, and one -pot / two -step systems. While the first two concepts employ thin-film-on-glass devices immersed in water, the latter two concepts are based on the application of photosensitive powder catalysts suspended in water. Various laboratory-scale PEC devices have been developed over the past couple of years, thus far demonstrating solar-tohydrogen conversion efficiencies of up to 16%. The key challenges to advance PEC cell innovation toward the market concern the progress in material science and engineering. The development of highly efficient (performance), corrosion-resistant (longevity) photoelectrode materials and their processing technologies are most important, paving the path toward smart system integration as well as engineering. Since no ideal photo-electrode material for water splitting exists commercially, tailored materials have to be engineered. Combinatorial chemistry approaches offer fast-tracking experimental options for the associated necessary material screening, while modelling capabilities of photooxidation based on quantum transition theory should be developed. Most importantly, fundamental research on semiconductor doping for bandgap shifting and surface chemistry modification is required, including studies on the associated effects on surface as well as bulk semi -conducting properties. Corrosion and photo -corrosion resistance concern further significant R&D challenges to be addressed with most of the promising material options at hand. Both current-matching between anode and cathode and ohmic resistance minimisation require considerable systems design as well as sophisticated engineering solutions. Optimization of fluid dynamics (ma ss and energy transfer) and gas collection and handling (operational safety) will demand major conceptual and application specific R&D attention.

IEA Hydrogen Implementing Agreement (HIA)

7 of 12 HIA_HCG_Production_2005-03-15_rev1_final.doc

Hydrogen Production Gaps and Priorities

Riis et al.

3.3.

Photo-biological production (Biophotolysis)

Photo-biological production of hydrogen is based on two steps, pho tosynthesis (3.8) and hydrogen production catalysed by hydrogenases (3.9) in e.g., green algae and cyanobacteria. Long-term basic and applied research is needed, but if successful a long-term solution for renewable hydrogen production will result. It is of vital importance to understand the natural processes and the genetic regulations of H 2 production. One should construct improved cells by metabolic and genetic engineering, and demonstrate the process in larger bioreactors. Another option is to reproduce the two steps using artificial photosynthesis.

Photosynthesis: 2 H2 O 4 H+ + 4 e- + O 2 Hydrogen Production: 4 H+ + 4 e - 2 H2

(3.8) (3.9)

Figure 6. Principle of photo-biological hydrogen production

3.4.

High temperature Decomposition

High temperature splitting of water occurs at ca. 3000 C. At this temperature 10% of the water is decomposed and the remaining 90% can be recycled. To reduce the temperature other processes for high temperature splitting of water have been suggested: Thermo-chemical cycles Hybrid systems coupling thermal decomposition and electrolytic decomposition Direct catalytic decomposition of water with separation with a ceramic membrane (thermo -physic cycle) Plasma -chemical decomposition of water in a double stage CO2 cycle. For these processes efficiencies above 50 % can be expected and this could possibly lead to a major decrease of hydrogen production costs. The main technical issues for these high temperature processes are materials developments due to the need for corrosion resistance at high temperatures, high temperature membrane and separation processes, heat exchangers, and heat storage medium development. Generally speaking, design aspects, safety issues, and coupling issues with heat sou rces are important and new matters for high temperature processes. Thermo-chemical water splitting Thermo-chemical water splitting is the conversion of water into hydrogen and oxygen by a series of thermally driven chemical reactions. Thermo-chemical water-splitting cycles have been known for the past 35 years. They were extensively studied in the late 1970s and 80s, but have been of little interest in the past 10 years. While there is no question about the technical feasibility and the potential for high efficiency, cycles with proven low cost and high efficiency have yet to be developed commercially. An example of a thermo-chemical process is the

IEA Hydrogen Implementing Agreement (HIA) 8 of 12 HIA_HCG_Production_2005-03-15_rev1_final.doc

Hydrogen Production Gaps and Priorities

Riis et al.

iodine/sulphur cycle, see equations (3.10), (3.11) and (3.12), and, and Figure 7. For this process the research and development needs are to capture the thermally split H 2 and avoid side reactions and the use of noxious substances. The corrosion problems associated with the handling of such materials are likely to be extremely serious.

(850 C): H2 SO4 SO 2 + H2 O + O 2 (120 C): I 2 + SO2 + 2 H2 O H2 SO4 + 2 HI (450 C): 2 HI I2 + H2 SUM: H2 O H2 + O

2

(3.10) (3.11) (3.12)

Hydrogen Hydrogen

H2

Nuclear or Solar Nuclear Nuclear Heat HeatHeat

400 400C C 900 900C C

Oxygen Oxygen

1 1O O2 2 2 2 1 1 O2 2 2 2O + + + S SO O +H H2 O O 2 2 2

H2 2 + + II2 2

2HI 2HI

Rejected Rejected Rejected Heat 100C Heat Heat100 100 100C C C

2H 2HII + + H H2 S SO O 2 4 4

H H22S SO O 4 4

II (Iodine) (Iodine) Circulation

II2 2

II22 + + H + S +H H22 O O+ SO O +H 2 2O 2 2O H H2 O O 2

S (Sulfur) Circulation

SO SO 2 2

+ + H H22O O

Water Water Water

Figure 7. Principle drawing of Iodine/sulfur thermo-chemical process

4. BIOMASS TO HYDROGEN

In biomass conversion processes a hydrogen containing gas is normally produced similar to the gasification of coal, see e.g. equation (2.4). However, no commercial plants exist to produce hydrogen from biomass. Currently, the pathways followed are steam gasification (direct or indirect), entrained flow gasification, and more advanced concepts such as gasification in supercritical water, application of thermo-chemical cycles, or the conversion of intermediates (e.g. ethanol, bio-oil or torrified wood). None of the concepts have reached a demonstration phase for hydrogen production. Biomass gasification is an R&D area shared between H2 production and biofuels production. Gasification (and pyrolysis) is considered the most promising medium term technology for commercialisation of H 2-production from biomass. A typical flow sheet for production of hydrogen from biomass is presented in Figure 8. Energetically drying of biomass might not be justifiable; therefore other pathways based on wet biomass are sought as well. Biomass feedstocks are unrefined products with inconsistent quality and poor quality control. The production methods vary according to crop type, location and climatic variations. Erratic fuels have contributed to the difficulties in technological innovation: less homogenous and low quality fuels need more sophisticated conversion systems. There is a need to rationalise the production and preparation of fuel to produce more consistent, higher quality fuels (described by standards). Larger scale systems tend to be suitable for lower quality cheaper fuels and smaller plants tend to require higher fuel quality and better fuel homogeneity. A better understanding of this relationship and the specific tolerances that each technology can accommodate is needed.

IEA Hydrogen Implementing Agreement (HIA)

9 of 12 HIA_HCG_Production_2005-03-15_rev1_final.doc

Hydrogen Production Gaps and Priorities

Riis et al.

Figure 8. Generic flow sheet for methanol, hydrogen or FT diesel production via biomass gasification (Source: CIRAD Forestry Department/HIA annex 16 subtask B) Several developments are needed to improve the economics of production processes and logistics of the biomass feedstock: Feed preparation - Identify the characteristics of feedstocks that will allow the technologies to develop Gasification of biomass. This is not specific for hydrogen; but is followed-up in relation to general biomass and renewables pathways and research Raw gas handling and clean-up Interface issues and system integration. One should also investigate on the relationship between production scale a nd fuel quality requirements and tolerances that can be accommodated for the respective technologies

5. CENTRALISED HYDROGEN PRODUCTION

Large-scale, industrial hydrogen production from all fossil energy sources can be considered a commercial technology for i ndustrial purposes, though not yet for utilities. Hydrogen production at a large scale has the potential for relatively low unit costs, although the hydrogen production cost from natural gas in medium sized plants may be reduced towards the cost of large-s cale production. An important challenge is to decarbonise the hydrogen production. CO2 capture and storage options are not fully technically and commercially proven and require R&D on absorption or separation processes and process line-up, and acceptance for CO2 storage. It is also important to increase the plant efficiency, reduce the capital costs and enhance the reliability and operating flexibility. A principle sketch of hydrogen distribution from natural gas based centralised hydrogen production plant is presented in Figure 9. Further R&D is particularly needed on hydrogen purification, to produce H2 suitable for fuel cells - and on gas separation, for the separation of hydrogen or CO2 from gas mixtures. This involves developme nt of catalysts, adsorption materials and gas separation membranes for the production and purification of hydrogen. Hydrogen and power can be co-produced in a combined cycle in an integrated gasification and combined cycle (IGCC) plant. The IGCC plant is the most advanced and efficient solution where the carbon in the fuel is removed, and hydrogen is produced in a pre -combustion process. An important challenge for centralised hydrogen production is the requirement for large market demand and the construction of a new infrastructure for hydrogen transmission and distribution and CO2-pipeline to storage. In the future, centralised hydrogen production from high temperature processes based on renewable energy and waste heat can also be an option for enhancing the sustainability and removing the need for capture and storage of CO2.

IEA Hydrogen Implementing Agreement (HIA)

10 of 12 HIA_HCG_Production_2005-03-15_rev1_final.doc

Hydrogen Production Gaps and Priorities

Riis et al.

Figure 9. Principle sketch for large scale centralised hydrogen production with CO2 capture.

6. DISTRIBUTED HYDROGEN PRODUCTION

Distributed hydrogen production can be based on both water electrolysis and the natural gas processes discussed above. The benefit would be a reduced need for transportation of hydrogen fuel, and hence a smaller need for hydrogen infrastructure. Distributed production will also utilise existing infrastructure such as water and electric power or natural gas. However, the production costs for smaller capacities will be higher, and the efficiencies of the production will probably be lower than for centralised plants. In addition, carbon capture and sequestration would be more difficult and costly from small fossil-fuelled plants, and there might be safety issues for public use. Also, it is unlikely that CO2 from fossil fuels will be captured and stored when hydrogen is produced from distributed reformers. The R&D needs for distributed hydrogen production is summarised in Table 2. Small-scale reformers will enable the use of existing natural gas pipelines for production of hydrogen at the site of the consumer. Such reformers therefore represent an important technology for the transition to large hydrogen supply. The availability of commercial reformers is limited and most reformers are currently at an R&D stage. Further development and R&D is essential to meet the customer requirements. Table 2. Overview of R&D needs for distributed hydrogen production systems R&D Needs Minimise cost Minimise foot-print and height Minimise CO2 and other emissions Develop user friendly, automised plants Improve the reliability and durability of operation Optimise the service, training and maintenance program Develop safety, standards and certification Increase the system energy efficiency Ensure hydrogen gas quality gas quality requirements is met by current technology H2 from Natural Gas x x x x x x x x x H2 from water electrolysis x x x x x x x

IEA Hydrogen Implementing Agreement (HIA)

11 of 12 HIA_HCG_Production_2005-03-15_rev1_final.doc

Hydrogen Production Gaps and Priorities

Riis et al.

Some of theses gaps are challenging and require more effort by the technology developers and suppliers. The technology achievements in the last three years have been remarkable and the technology gaps have been reduced significantly. The compactness (foot-print and height) is an especially important market requirement. The suppliers have significantly reduced the foot-print and height. The optimum system for the future would be an underground system that requires a space of 10x3x3 meters for a capacity of 500 - 700 Nm/hour. The target is within reach with some additional R&D effort. The use of space for hydrogen production is a disadvantage for the technology compared to conventional trucked in systems for gasoline/diesel or hydrogen. Minimising foot print and visibility has been an important R&D priority. Also, codes and standards for hydrogen production and storage will need to be revised to permit the use of enclosed or underground spaces, at least in some countries.

7. CONCLUSIONS AND RECOMMENDATIONS

This paper has provided an overview of the main issues (possibilities and gaps) for hydrogen production from water splitting and fossil/hydrocarbon fuels . For all hydrogen production processes there is a need for significant improvement in plant efficiencies, reduced capital costs, and enhanced reliability and operating flexibility. The commercial target for hydrogen production costs is 0.30 USD/kg H2, corresponding to an energy price for gasoline of 2.5 USD/GJ in a competitive market. The hydrogen producing technologies have at best only 2-3 times higher production costs. Distributed hydrogen production based on reforming is often competitive with electrolysis, where reforming costs 16-29 USD/GJ and electrolysis costs 20-40 USD/GJ, depending on investment and energy costs. In large-scale production plants based on natural gas production cost is 5-8 USD/GJ. Distributed hydrogen production can be competitive with centrally produced hydrogen (large -scale natural gas reforming) depending on the transportation distance, e.g. transportation of compressed hydrogen gas for 100 miles will add 15 20 USD/GJ to the cost. In the current and near -term, water electrolysis and small-scale natural gas reformers are suitable. Water electrolysis is a proven technology that can be used in the early phases of building a hydrogen infrastructure for the transport sector. Small-scale natural gas reformers have only limited proven and commercial availability, but several units are being tested in demonstration projects. In the medium to long -term, hydrogen production based on centralised fossil fuel based production with capture and storage of CO2 is feasible. The capture of CO 2 for storage purposes is not yet - technically and commercially proven and requires further R&D on absorption or separation processes and process line-up. The other processes for hydrogen production are further away from commercialisation and need additional R&D. The production of hydrogen from biomass needs additional focus on the preparation and logistics of the feed. The production will probably only be economical at large scale. The photo-electrolysis is at an early stage of development and material cost and practical issues have to be solved. The photo -biological processes are at a very early stage of development with so far low conversion efficiencies obtained. High temperature processes need further materials development, focusing on e.g. high temperature membranes and heat exchangers.

8. ACKNOWLEDGEMENTS

We thank the IEA HIA Task 16, Experts and the Executive Committee, and IEA Bioenergy Thermal Gasification task for their contribution. We specifically would like to acknowledge Dr. Suresh Babu and Paul Lucchese. We will also thank the Research Council of Norway for financial support.

IEA Hydrogen Implementing Agreement (HIA)

12 of 12 HIA_HCG_Production_2005-03-15_rev1_final.doc

You might also like

- Wind in DenmarkDocument10 pagesWind in DenmarkKVVNo ratings yet

- Black PV ModuleDocument2 pagesBlack PV ModuleKVVNo ratings yet

- Simulation of Grid-Connected Photovoltaic SystemDocument7 pagesSimulation of Grid-Connected Photovoltaic SystemKVVNo ratings yet

- Characterizations of Solar PVDocument15 pagesCharacterizations of Solar PVKVVNo ratings yet

- Generator ExcitationDocument4 pagesGenerator ExcitationKVVNo ratings yet

- Active and Passive NetworksDocument14 pagesActive and Passive NetworksKVVNo ratings yet

- Land-Use Requirements of Modern Wind Power PlantsDocument46 pagesLand-Use Requirements of Modern Wind Power PlantsKVVNo ratings yet

- GE ExciterDocument8 pagesGE ExciterKVVNo ratings yet

- Generator & Exciter BasicDocument8 pagesGenerator & Exciter Basictowfiqeee100% (1)

- Super CapacitorsDocument23 pagesSuper CapacitorsKVVNo ratings yet

- Frequency Response StudyDocument114 pagesFrequency Response StudyKVVNo ratings yet

- Solar CellDocument5 pagesSolar CellpurushothamkrNo ratings yet

- Impacts of Wind FarmsDocument20 pagesImpacts of Wind FarmsKVVNo ratings yet

- IecWP Energystorage LR enDocument92 pagesIecWP Energystorage LR enBaneeIshaqueKNo ratings yet

- Turbines and GoverningDocument31 pagesTurbines and GoverningKVV100% (2)

- Mathematical Modeling of Gas TurbineDocument7 pagesMathematical Modeling of Gas TurbineKVVNo ratings yet

- Heat Recovery Steam Generators Optimized For Any ApplicationDocument7 pagesHeat Recovery Steam Generators Optimized For Any ApplicationKVVNo ratings yet

- Power Quality Impact of A Small Wind SystemsDocument4 pagesPower Quality Impact of A Small Wind SystemsKVVNo ratings yet

- Excitation SystemDocument13 pagesExcitation SystemKVVNo ratings yet

- Excitation GE 2100Document21 pagesExcitation GE 2100KVV100% (2)

- GT13E2 Gas Turbine (In Russia and CIS Countries)Document24 pagesGT13E2 Gas Turbine (In Russia and CIS Countries)hoangpalestine100% (1)

- D Series Combined Cycle Steam TurbineDocument16 pagesD Series Combined Cycle Steam TurbineKVV50% (2)

- D Series Combined Cycle Steam TurbineDocument16 pagesD Series Combined Cycle Steam TurbineKVV50% (2)

- Soalr PV InfoDocument12 pagesSoalr PV InfoKVVNo ratings yet

- GE Gas TurbineDocument24 pagesGE Gas TurbineIwan Surachwanto0% (1)

- ABB REL 316 4 Numerical Line ProtectionDocument44 pagesABB REL 316 4 Numerical Line Protectiontin_gabby4876100% (2)

- Load Commutated InverterDocument26 pagesLoad Commutated InverterKVVNo ratings yet

- D Series Combined Cycle Steam TurbineDocument16 pagesD Series Combined Cycle Steam TurbineKVV50% (2)

- GE Generators OverviewDocument16 pagesGE Generators OverviewKVVNo ratings yet

- 400kV OHL Protection enDocument44 pages400kV OHL Protection enNikola MugosaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Basic Principles and Operation of A TransformerDocument28 pagesBasic Principles and Operation of A Transformershaggy_harteNo ratings yet

- Work and PowerDocument26 pagesWork and Powernicka castilloNo ratings yet

- PPE Question Bank Covers Thermal, Hydro, Nuclear PowerDocument7 pagesPPE Question Bank Covers Thermal, Hydro, Nuclear PowerKanagaraj Chelladurai100% (1)

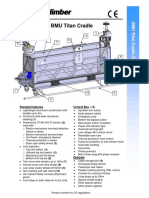

- BMU Titan Cradle: Standard Features Control BoxDocument2 pagesBMU Titan Cradle: Standard Features Control BoxKashyapNo ratings yet

- Instructions for use and installation of a washing machineDocument16 pagesInstructions for use and installation of a washing machineVale MocanuNo ratings yet

- Pureit Advanced Ro MF Manual PDFDocument18 pagesPureit Advanced Ro MF Manual PDFSaurabh MishraNo ratings yet

- To Access The Fuel Oil Management Plan Sample TemplateDocument35 pagesTo Access The Fuel Oil Management Plan Sample TemplateΦοίβος ΖούκηςNo ratings yet

- HYpact Compact HybridDocument24 pagesHYpact Compact HybridMateo Alvez100% (1)

- Analisis Comparativo Cat® 992G Vs - Cat 993KDocument14 pagesAnalisis Comparativo Cat® 992G Vs - Cat 993KMónica Rada Urbina100% (1)

- Design and Implementation of IOT Based Monitoring System For Solar TreeDocument26 pagesDesign and Implementation of IOT Based Monitoring System For Solar TreeDhanraj GuptaNo ratings yet

- Assignment-Research 2-MJD-MALLARIDocument9 pagesAssignment-Research 2-MJD-MALLARIMark MallariNo ratings yet

- Complex Fluid For Olga 5Document10 pagesComplex Fluid For Olga 5angry_granNo ratings yet

- Tata Motors Company ProfileDocument11 pagesTata Motors Company ProfileSiva Krishna Reddy NallamilliNo ratings yet

- IR CompressorDocument30 pagesIR CompressorkingofngayeNo ratings yet

- Fire Safety Procedures: Prevention, Equipment & AlarmsDocument11 pagesFire Safety Procedures: Prevention, Equipment & AlarmsCyrus SantosNo ratings yet

- BIOGAS 5000 Operating ManualDocument107 pagesBIOGAS 5000 Operating ManualmjsampaioNo ratings yet

- M4110 Leakage Reactance InterfaceDocument2 pagesM4110 Leakage Reactance InterfaceGuru MishraNo ratings yet

- Mercury 02l STDDocument2 pagesMercury 02l STDNoursine NoursineNo ratings yet

- Bobcat Battery Reference GuideDocument2 pagesBobcat Battery Reference GuideFrancisco Godoy Kutzbach67% (3)

- Eastern Visayas State University-Ormoc City CampusDocument3 pagesEastern Visayas State University-Ormoc City Campuskhellian villameroNo ratings yet

- ThermodynamicsDocument341 pagesThermodynamicsjonathan2788100% (4)

- General Science: 1. Introduction and Role of ScienceDocument2 pagesGeneral Science: 1. Introduction and Role of ScienceCh Shakeel Ahmed MayoNo ratings yet

- Problems PDFDocument246 pagesProblems PDFJasdeep singhNo ratings yet

- TP48200A-HD15A6 & HD15A7 & HD15A8 & HD15A9 & HT15A5 & HT15A6 & DX15A1 & HX15A1 V500R001 User Manual 01 PDFDocument116 pagesTP48200A-HD15A6 & HD15A7 & HD15A8 & HD15A9 & HT15A5 & HT15A6 & DX15A1 & HX15A1 V500R001 User Manual 01 PDFEla TorquataNo ratings yet

- Igcse: Definitions & Concepts of ElectricityDocument4 pagesIgcse: Definitions & Concepts of ElectricityMusdq ChowdhuryNo ratings yet

- Green ConcreteDocument22 pagesGreen ConcreteQseem Khan100% (1)

- ABB String Inverters: PVS-50/60-TLDocument4 pagesABB String Inverters: PVS-50/60-TLBianca OlaruNo ratings yet

- Lorentz Ps ManualDocument72 pagesLorentz Ps ManualJohn KiokoNo ratings yet

- Information Sheets 6.1.4Document12 pagesInformation Sheets 6.1.4api-196541959No ratings yet

- A Methodology To Determine Transient Recovery Voltage in Short-Line FaultDocument7 pagesA Methodology To Determine Transient Recovery Voltage in Short-Line FaultLeonardo CamargoNo ratings yet