Professional Documents

Culture Documents

Ist Gear Ist Ratio

Uploaded by

Harshvardhan MishraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ist Gear Ist Ratio

Uploaded by

Harshvardhan MishraCopyright:

Available Formats

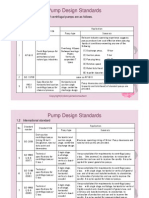

Spur gearing, gearing [mm/ISO] Spur gearing, HelicalHelical gearing [mm/ISO] i ii Check lines:10.

0; Project information Date 06/06/2012 Pinion Gear Project No. 111-111

Author John Doe File name Gear1_02.xls Project Name Spur Gear Basic Info

Spur gearing: Beta=0; mn=2.75; b1=35; b2=34; z1=18; z2=45; n1=9000; n2=3600; i=2.5; P=51.76 [kW] Project Notes Comments

? 1.0 Options of basic input parameters 1.1 Transferred power 1.2 Speed (Pinion / Gear) 1.3 Torsional moment (Pinion / Gear) 1.4 Transmission ratio / from table 1.5 Actual transmission ratio / deviation 2.0 2.0 Material identification according standard : 2.1 Material of the pinion : 2.2 Material of the gear : 2.3 Loading of the gearbox, driving machine - examples 2.4 Loading of gearbox, driven machine - examples 2.5 Type of gearing mounting 2.6 Accuracy grade - ISO1328 |Ra max|v max 2.7 Coefficient of one-off overloading 2.8 Desired service life 2.9 Coefficient of safety (contact/bend) 2.10 Automatic design 3.0

Input section Pw [kW] n [/min] Mk [Nm] i i

ANSI F...Alloy structural steel Gr. 4340 (A322-82) (Rm=965 MPa) face hardened F...Alloy structural steel Gr. 4340 (A322-82) (Rm=965 MPa) face hardened A...Continuous A...Continuous Double-sided symmetrically supported gearing - type 1 4....(Ra max.= 0.4 / v max.= 60)

51.764 9000.0 54.93 2.50 2.50

51.403 3600.0 136.36 0.00% [/min] [Nm]

Options of material, loading conditions, operational and production parameters

KAS Lh SH / SF 1.30

2.00 1250 1.60 [h]

Parameters of the cutting tool and tooth profile

1. DIN 867 (a=20deg, ha0=1.25, hf0=1.0, ra0=0.38, d0=0, anp=0deg, ca=0.25)

3.1 Standardized tool 3.2 Addendum of tool 3.3 Dedendum of tool 3.4 Fillet radius of tool 3.5 Root fillet radius of tool 3.6 Chamfer of root 3.7 Chamfer of root 3.8 Protuberance hight 3.9 Protuberance angle 3.10 Min. unit head clearance 3.11 Unit head clearance

4.00 3.00 2.00 1.00 0.00 -6.00 -4.00 -2.00 -1.00 -2.00 -3.00 -4.00 0.00 2.00

ha0* hf0* ra0* rf0* cha* chb*

1.250 1.000 0.380 0.000 0.000 0.000 0.000 0.000 0.2500 0.2500

1.250 1.000 0.380 0.000 0.000 0.000 0.000 0.000 0.2500 0.2500

[modul] [modul] [modul] [modul] [modul] [modul] [modul] [] [modul] [modul]

d0* anp

ca*min ca*

4.00

6.00

-4.00

4.0

Design of a module and geometry of toothing

4.1 Number of teeth Pinion / Gear 4.2 Normal pressure angle 4.3 Base helix angle 4.4 Setting of the ratio of the width of the pinion to its diameter 4.5 The ratio of the pinion width to its diameter 4.6 Module / Standardized value 4.7 Reference diameter Pinion / Gear 4.8 Recommended width of gearing 4.9 Face width (Pinion / Gear) 4.10 Working face width 4.11 The ratio of the pinion width to its diameter 4.12 Working center distance 4.13 Approximate weight of the gearing 4.14 Minimum coefficient of safety

18 20 0 0.7 2.75 49.50 35.00 34 0.71 86.625 3.698 1.30

45 [] [] < 1.1 [mm] 123.75 34.00 < 1.1 [mm] [kg] 3.08 [mm] [mm] [mm] [mm]

a

b

y d / max

mn d1/d2 b1/b2 bw

29.2 - 54.5

y d / max

aw m SH / SF

80 60 40 20 0 -50 -20 0 -40 -60 -80

50

100

150

200

250

4.15 Normal backlash 4.16 - Recommended min. | max. value 4.17 - Selected normal backlash 5.0 Correction of toothing (Addendum modification) -0.222 -0.056 0.259 x Sx 0.0000 0.0000 1.6328 0.6817 -6.9524 0.5924 9.8725 1.30 3.08 1.50 3.36 0

6.0 5.0 4.0 3.0 2.0 1.0 0.0

0.056 jn 0.0000

0.223

[mm] [mm]

5.1 Types 5.2 - Permissible undercutting of teeth (min. value) 5.3 - Preventing undercutting of teeth (min. value) 5.4 - Prevents tapering of teeth (min. value) 5.5 Pinion addendum modification coefficient setting 5.6 Addendum modification coefficient Pinion / Gear 5.7 Sum of addendum modification coefficients | min. value 5.8 Transverse / Total contact ratio 5.9 Unit tooth thickness on the tip diameter 5.10 Specific sliding on tooth root 5.11 Specific sliding on tooth tip 5.12 Sum of all specific slidings 5.13 Safety coefficient for surface durability 5.14 Safety coefficient for bending durability 5.15 Display of tooth and tool turn for:

0 -1 -2 -3 -4 -5 -6 -7 7 6 5 4 3 2 1 0 Gear

-0.689 -0.622 -1.488 0.0000 > -1.29 1.6328 0.7688 -1.4535 0.8743

S= S= S=

-0.911 -0.678 -1.230 [modul] [modul]

ea/eg

sa*

JA1/JE2 JE1/JA2 Sum|J|

SH SF

[]

0.0 8 6 4 2 0 -2 -4 -6 -8 -2.0 -1.0 -2.0 -3.0 -4.0 -5.0 0.0 2.0 4.0 6.0 8.0 10.0

Results section 6.0 Basic dimensions of gearing

6.1 Number of teeth Pinion / Gear 6.2 Face width (Pinion / Gear) 6.3 Normal module 6.4 Transverse module 6.5 Circular pitch 6.6 Transverse circular pitch 6.7 Base circular pitch 6.8 Center distance (pitch) 6.9 Center distance (production) 6.10 Center distance (working) 6.11 Pressure angle 6.12 Transverse pressure angle 6.13 Pressure angle at the pitch cylinder 6.14 Transverse pressure angle at the pitch cylinder 6.15 Helix angle 6.16 Base helix angle 6.17 Tip diameter 6.18 Reference diameter 6.19 Base diameter 6.20 Root diameter 6.21 Operating pitch diameter 6.22 Addendum 6.23 Dedendum 6.24 Tooth thickness on the tip diameter 6.25 Tooth thickness on the tip diameter 6.26 Tooth thickness on the pitch diameter 6.27 Tooth thickness on the pitch diameter 6.28 Tooth thickness on the root diameter 6.29 Unit tooth thickness on the tip diameter 6.30 Unit correction 6.31 Total unit correction 6.32 Addendum modification coefficient 7.0 Supplemental parameters of gearing 7.1 Number of teeth 7.2 Virtual number of teeth of a helical gear Minimum number of teeth: 7.3 7.4 7.5 8.0 - Permissible undercutting - Without undercutting - Without tapering Qualitative indices of gearing

z b mn mt p pt ptb a av aw

18 35 2.75 2.7500 8.639 8.639 8.118 86.6250 86.6250 86.6250 20.00 20.0000 20.0000 20.0000 0.00 0.0000 55.0000 49.5000 46.5148 42.6250 49.5000 2.7500 3.4375 1.8746 1.8746 4.3197 4.3197 4.3550 0.6817 0.0000 0.0000 0.0000 18 18.000 14 17 22

45 34 [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [] [] [] [] [] [] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [modul] [modul] [modul] 0.0000 45 45.000 14 17 22 [modul] 129.2500 123.7500 116.2870 116.8750 123.7500 2.7500 3.4375 2.1142 2.1142 4.3197 4.3197 5.8217 0.7688

a at awn awt

b bb da d db df dw ha hf sna sta sn st sb sa* dY x1+x2 x z zn zmin1 zmin2 zmin3

8.1 Transverse contact ratio / overlap ratio 8.2 Total contact ratio 8.3 Coefficient of gear unloading 8.4 Resonance speed 8.5 Resonance ratio 8.6 Approximate weight of the gearing 8.7 Efficiency of the gearing 8.8 Recomended lubricant viscosity 9.0 Coefficients for safety calculation Common for the gearing 9.1 Stiffness of a tooth pair 9.2 Meshing stiffness per unit face width 9.4 Application factor 9.5 Dynamic factor 9.6 Number of cycles For pitting safety calculation 9.7 Face load factor (contact stress) 9.8 Transverse load factor (contact stress) 9.9 Total factor of additional loads 9.10 Elasticity factor 9.11 Zone factor 9.12 Helix angle factor 9.13 Contact ratio factor 9.14 Work hardening factor 9.15 Lubricant factor 9.16 Peripheral speed factor 9.17 Roughness factor affecting surface durability 9.18 Life factor for contact stress 9.19 Single pair tooth contact factor For bending safety calculation 9.20 Face load factor (root stress) 9.21 Transverse load factor (root stress) 9.22 Total factor of additional loads 9.23 Helix angle factor 9.24 Contact ratio factor 9.25 Notch sensitivity factor 9.26 Size factor 9.27 Tooth-root surface factor 9.28 Alternating load factor 9.29 Production technology factor 9.30 Life factor for bending stress 9.31 Form factor (bending) 9.32 Stress correction factor 9.33 Tip factor, equal (YFa YSa) 10.0 Safety coefficients 10.1 Safety coefficient for surface durability 10.2 Safety coefficient for bending durability 10.3 Safety in contact in one-time overloading 10.4 Safety in bending in one-time overloading 10.5 Variability coefficient for calculation of probability of a failure 10.6 Probability of a failure 10.7 Nominal contact stress 10.8 Contact stress 10.9 Pitting stress limit 10.10 Permissible contact stress 10.11 Nominal tooth-root stress 10.12 Tooth-root stress 10.13 Tooth-root stress limit 10.14 Permissible bending stress

ea | eb eg

Cdi/df nE1 N m m v50

1.6328 1.6328 0.00

0.0000 0.00

25938.02 0.35 3.6982 99.30% 74 74

[ /min] [kg] [mm2/sec]

c'

11.673 17.213 1.000 1.227 6.75E+08 2.70E+08

cg

KA KV NK KHb KHa KH ZE ZH Zbeta Zeps ZW ZL ZV ZR ZN ZB/ZD KFb KFa KF Ybeta Yeps Ydelta YX YR YA YT YN YFa YSa YFS SH SF SHst SFst vH/vF P SigmaH0 SigmaH SigmaHG SigmaHP SigmaF0 SigmaF SigmaFG SigmaFP 778.44 0.850 3.139 1.505 4.723 1.30 3.08 2.18 4.65 0.08 0.989 1.000 0.987 0.977 1.028 1.020 0.850 1.088

1.007 1.267 1.567 189.81 2.495 1.000 0.888 1.000 0.977 1.028 1.020 0.905 1.000 1.007 1.987 2.455 1.000 0.709 0.995 1.000 0.987 1.000 1.000 0.850 2.568 1.650 4.238 1.50 3.36 2.37 5.03 0.1 1.51 571.48 715.31 1075.94 827.65 71.35 175.16 588.11 367.57 1010.05 776.96 77.24 189.64 584.86 365.54 [%] [MPa] [MPa] [MPa] [MPa] [MPa] [MPa] [MPa] [MPa]

n=; YN=0.85 Automatic n=; ZN=0.85 Mineral oil

11.0

Check dimensions of gearing zw zw W dt dt M 3 3 20.9892 4.8125 4.8125 56.2589 6 6 46.3842 4.8125 4.8125 130.5638 [mm] [mm] [mm] [mm]

11.1 Number of measured teeth 11.2 Number of measured teeth 11.3 Chordal dimension 11.4 Pin/Ball diameter 11.5 Pin/Ball diameter 11.6 Dimension over pins/balls 12.0 Force conditions (forces acting on the toothing)

12.1 Tangential force 12.2 Normal force 12.3 Axial force 12.4 Radial force 12.5 Bending moment 12.6 Peripheral speed on the pitch diameter 12.7 Specific load / Unit load 13.0 Parameters of the chosen material 13.1 Density 13.2 Young's Modulus (Modulus of Elasticity) 13.3 Tensile Strength, Ultimate 13.4 Tensile Strength, Yield 13.5 Poison's Ratio 13.6 Contact Fatigue Limit 13.7 Bending Fatigue Limit 13.8 Tooth Hardness - Side 13.9 Tooth Hardness - Core 13.10 Base Number of Load Cycles in Contact 13.11 Wohler Curve Exponent for Contact 13.12 Base Number of Load Cycles in Bend 13.13 Wohler Curve Exponent for Bend 14.0 Calculation of gearing for the given axis distance

Ft Fn Fa Fr Mo v | vmax wt | wt* Ro E Rm Rp0.2 SHlim SFlim VHV JHV NHlim qH NFlim qF Additions section 0.00 23.33 65.27 7870 206 965 750 0.3 1160 705 600 300

2219.28 2361.71 0.00 807.75 0.00 < 60 23.74 7870 206 965 750 0.3 1160 705 600 300 1.00E+08 10 3.00E+06 9

[N] [N] [N] [N] [Nm] [m/s] [N/mm | MPa] [kg/m^3] [GPa] [MPa] [MPa] [MPa] [MPa] [HV] [HV]

1.00E+08 10 3.00E+06 9

14.1 Required axis distance / Standardized 14.2 List of solutions 14.3 Combination of the teeth number 14.4 Number of teeth Pinion / Gear 14.5 Transmission ratio / Deviation 14.6 A. Change of the addendum modification 14.7 Base helix angle 14.8 Total unit correction 14.9 Distribution of correction 14.10 Type of distribution of corrections to the pinion and gear 14.11 Press the button for transmitting values in to calculation 14.12 B. By a change of the helix angle 14.13 Base helix angle 14.14 Total unit correction 14.15 Press the button for transmitting values in to calculation 15.0 Power, warming-up, gearbox surface 15.1 Ambient air temperature 15.2 Maximum oil temperature 15.3 Coefficient of heat dissipation 15.4 Power losses

aw [mm] ID. z1/z2 i b Sum x x

250 z1 51 2.5294 0.0000 0.94259

According to Meritt

86.63 z2 i 129 1.16% [] [modul] [modul] b Sum X

5. | 51 | 129 | 2.529 | 8.110 | 0.9426

0.7132

0.2294

b Sum x

8.1096 0.0000

[] [modul]

20.00 60.00 10.00 0.36

[C] [C] [W/m2/K] [kW]

15.5 Gearbox surface (min.) 16.0 16.1 16.2 17.0 Preliminary design of shaft diameters (steel) Recommended shaft diameter for: - Main power-transmitting shafts - Small, short shafts Approximate module calculation from the existing gear z da u b mn DA DB 46.51 36.15

0.90

[m2]

62.96 48.93 20 33.50 0.00 10.00 1.50

[mm] [mm]

17.1 Number of teeth 17.2 Tip diameter 17.3 Distance between teeth edges 17.4 Helix angle 17.5 Module of tooth 18.0 19.0 Auxiliary calculations Graphical output, CAD systems

DXF File Automatic Pinion

[mm] [mm] [] [mm]

19.1 2D drawing output to: 19.2 2D Drawing scale 19.3 Detail:

a [] 19.4 Detailed drawing of tooth and wheel 19.5 Number of drawn teeth 19.6 Number of points of tooth tip 19.7 Number of points of tooth flank 19.8 Rolling (turning) of a tool between the bite 19.9 Number of tooth copies in the picture of engagement check 19.10 Text description (Information for BOM) Row 1 (BOM attribute 1) Row 2 (BOM attribute 2) Row 3 (BOM attribute 3) Row 1 (BOM attribute 1) Row 2 (BOM attribute 2) Row 3 (BOM attribute 3) 19.11 Table of parameters

Table of pinion parameters

30 3 5 30 0.5 20 Pinion Spur gear - Pinion []

b [] a [modul]

30 1

Drawing without axes

z1=18, mn=2.75, beta=0 Material: Gr. 4340 (A322-82) Gear Spur gear - Gear z2=45, mn=2.75, beta=0 Material: Gr. 4340 (A322-82)

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Nevada Reply BriefDocument36 pagesNevada Reply BriefBasseemNo ratings yet

- Safety in Manufacturing: Ergonomics: Awkward PosturesDocument2 pagesSafety in Manufacturing: Ergonomics: Awkward PosturesprashanthNo ratings yet

- Demoversion IWE 2011Document47 pagesDemoversion IWE 2011Burag HamparyanNo ratings yet

- Steel Flanges Ansi Stnd1Document36 pagesSteel Flanges Ansi Stnd1Harshvardhan MishraNo ratings yet

- Tech Drilling DrillSystRigWellDocument53 pagesTech Drilling DrillSystRigWellHarshvardhan MishraNo ratings yet

- API Tank DesignDocument189 pagesAPI Tank DesignDD3NZ91% (11)

- Delem: Installation Manual V3Document73 pagesDelem: Installation Manual V3Marcus ChuaNo ratings yet

- Pump Standards ComparisonDocument4 pagesPump Standards ComparisonAnish Dani50% (2)

- BIM and AM to digitally transform critical water utility assetsDocument20 pagesBIM and AM to digitally transform critical water utility assetsJUAN EYAEL MEDRANO CARRILONo ratings yet

- Committt CDocument15 pagesCommittt CHarshvardhan MishraNo ratings yet

- Data Sheet Helix VE 5205-4-16 E KS 2GDocument1 pageData Sheet Helix VE 5205-4-16 E KS 2GHarshvardhan MishraNo ratings yet

- Planet CatalogueDocument8 pagesPlanet CatalogueHarshvardhan MishraNo ratings yet

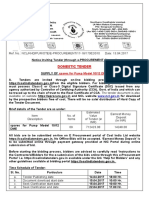

- Executive Engineer Satna (M.P.) NIT No.21 Dated 27.09.2017: 14.75 Lakh 29500Document2 pagesExecutive Engineer Satna (M.P.) NIT No.21 Dated 27.09.2017: 14.75 Lakh 29500Harshvardhan MishraNo ratings yet

- Tendernotice 1 PDFDocument56 pagesTendernotice 1 PDFHarshvardhan Mishra100% (1)

- Tender DocumentDocument70 pagesTender DocumentHarshvardhan MishraNo ratings yet

- Physical Completion Certificate: (See Clause 34 of Section 3-GCC)Document2 pagesPhysical Completion Certificate: (See Clause 34 of Section 3-GCC)Harshvardhan MishraNo ratings yet

- Cement Brochure-PDF FormatDocument6 pagesCement Brochure-PDF FormatHarshvardhan MishraNo ratings yet

- VxcasdasdDocument66 pagesVxcasdasdHarshvardhan MishraNo ratings yet

- V2/2G 10 TO 12 Inch Sudden Loss Pipe 90 (K) First 3 Metre Loss Check Valve LOSS Gate Vlve 0.229306 0.093364 0.9 0.1m 0.3 2.2Document2 pagesV2/2G 10 TO 12 Inch Sudden Loss Pipe 90 (K) First 3 Metre Loss Check Valve LOSS Gate Vlve 0.229306 0.093364 0.9 0.1m 0.3 2.2Harshvardhan MishraNo ratings yet

- EstimateDocument3 pagesEstimateHarshvardhan MishraNo ratings yet

- Water Management 2013 Low ResDocument13 pagesWater Management 2013 Low ResHarshvardhan MishraNo ratings yet

- ISO 9001 Changes SummaryDocument44 pagesISO 9001 Changes Summaryselva.uae8207No ratings yet

- Tendernotice 1Document56 pagesTendernotice 1Harshvardhan MishraNo ratings yet

- Effectiveness of QMSDocument58 pagesEffectiveness of QMSHarshvardhan MishraNo ratings yet

- Submersible Pump SetsDocument193 pagesSubmersible Pump Setskalicharan1350% (2)

- Culture Complete Notes MrunalDocument51 pagesCulture Complete Notes Mrunalamarsinha198767% (6)

- k220ls SparepartsDocument28 pagesk220ls SparepartsHarshvardhan MishraNo ratings yet

- ISO9001Implementation GuidanceDocument7 pagesISO9001Implementation GuidanceNabilahNo ratings yet

- Social Services PDFDocument109 pagesSocial Services PDFHarshvardhan MishraNo ratings yet

- 0 B 4 C 6 F 3 e 8 F 155 F 58 D 114 Ed 7528 F 232Document16 pages0 B 4 C 6 F 3 e 8 F 155 F 58 D 114 Ed 7528 F 232Harshvardhan MishraNo ratings yet

- Safety CornernmmDocument4 pagesSafety CornernmmHarshvardhan MishraNo ratings yet

- India ChinaDocument10 pagesIndia ChinaAmit KumarNo ratings yet

- Detailed engineering drawing bill of materialsDocument1 pageDetailed engineering drawing bill of materialsHarshvardhan MishraNo ratings yet

- (NCERT) Principles of Geography XI (Old Edition) Part 2Document157 pages(NCERT) Principles of Geography XI (Old Edition) Part 2Jilu Easow Raju67% (3)

- Grid Xtreme VR Data Sheet enDocument3 pagesGrid Xtreme VR Data Sheet enlong bạchNo ratings yet

- Banaue Rice Terraces - The Eighth WonderDocument2 pagesBanaue Rice Terraces - The Eighth Wonderokloy sanchezNo ratings yet

- Shenzhen Gooky Technology Co.,Ltd.: Laptop Price ListDocument1 pageShenzhen Gooky Technology Co.,Ltd.: Laptop Price ListOusman KabaNo ratings yet

- The New Breed of Rally BDA: Motor SportDocument8 pagesThe New Breed of Rally BDA: Motor SportHarold MorleyNo ratings yet

- DMT80600L104 21WTR Datasheet DATASHEETDocument3 pagesDMT80600L104 21WTR Datasheet DATASHEETtnenNo ratings yet

- Market & Industry Analysis CheckDocument2 pagesMarket & Industry Analysis CheckAndhika FarrasNo ratings yet

- SQL DBA Mod 1 IntroDocument27 pagesSQL DBA Mod 1 IntroDivyaNo ratings yet

- MTD Microwave Techniques and Devices TEXTDocument551 pagesMTD Microwave Techniques and Devices TEXTARAVINDNo ratings yet

- VectorsDocument9 pagesVectorsdam_allen85No ratings yet

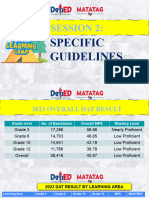

- FINAL Session 3 Specific GuidelinesDocument54 pagesFINAL Session 3 Specific GuidelinesBovelyn Autida-masingNo ratings yet

- Panameterics GF 868 Flare Gas Meter PDFDocument8 pagesPanameterics GF 868 Flare Gas Meter PDFDaniel DamboNo ratings yet

- Caf 8 Aud Spring 2022Document3 pagesCaf 8 Aud Spring 2022Huma BashirNo ratings yet

- Whitmore EZ-Switch LubricantDocument1 pageWhitmore EZ-Switch LubricantDon HowardNo ratings yet

- Bataan Peninsula State University - Balanga Campus: Certificate of RegistrationDocument1 pageBataan Peninsula State University - Balanga Campus: Certificate of RegistrationMichael PeraltaNo ratings yet

- Kooltherm PipeDocument8 pagesKooltherm Pipenaseema1No ratings yet

- ZirakDocument4 pagesZiraktaibzirakchamkani81No ratings yet

- Power Efficiency Diagnostics ReportDocument16 pagesPower Efficiency Diagnostics Reportranscrib300No ratings yet

- Convert MS Word Documents to LinuxDocument16 pagesConvert MS Word Documents to Linux8043 Nitish MittalNo ratings yet

- Ceoeg-Cebqn Rev0Document3 pagesCeoeg-Cebqn Rev0jbarbosaNo ratings yet

- Common Size Statement: A Technique of Financial Analysis: June 2019Document8 pagesCommon Size Statement: A Technique of Financial Analysis: June 2019safa haddadNo ratings yet

- November 2022 Examination: Indian Institution of Industrial Engineering Internal Assignment For IIIE StudentsDocument19 pagesNovember 2022 Examination: Indian Institution of Industrial Engineering Internal Assignment For IIIE Studentssatish gordeNo ratings yet

- PrefaceDocument16 pagesPrefaceNavaneeth RameshNo ratings yet

- A Study On Capital BudgetingDocument2 pagesA Study On Capital BudgetingANKIT SINGHNo ratings yet

- T. Herndon, M. Asch, R. Pollin - Does High Public Debt Consistently Stifle Economic Growth. A Critique of Reinhart and RogoffDocument26 pagesT. Herndon, M. Asch, R. Pollin - Does High Public Debt Consistently Stifle Economic Growth. A Critique of Reinhart and RogoffDemocracia real YANo ratings yet

- Product Models Comparison: Fortigate 1100E Fortigate 1800FDocument1 pageProduct Models Comparison: Fortigate 1100E Fortigate 1800FAbdullah AmerNo ratings yet