Professional Documents

Culture Documents

10-1 Pump Calibration 390MJ 950MJ PDF

Uploaded by

GREGWEILEROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10-1 Pump Calibration 390MJ 950MJ PDF

Uploaded by

GREGWEILERCopyright:

Available Formats

10.01.

01 PUMP CALIBRATION MID SIZE MACHINE 390MJ THRU 950MJ

SOL-VF (VOLUME) ADJUSTMENT

WARNING! THIS PROCEDURE SHOULD BE PERFORMED BY QUALIFIED PERSONNEL ONLY. 1. Insure that the barrel heaters are up to the proper temperature for the material in the barrel.

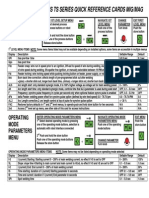

2. Connect AMP1 and VF to the ammeters connectors, J3 and CON D8, equipped inside the electrical control cabinet. 3. Turn OFF the Closed Loop Control. Go to screen 13F Push the upper case letters button, the LED will illuminate. Enter the key word OPTIONDA and press the enter key. Go to address No. 103 INJECTION SPEED CLOSED LOOP CONTROL and enter 00 Go to address No. 112 INJECTION PRESSURE CLOSED LOOP CONTROL and enter 00 Turn the Main Power OFF and then ON. Clear the Low Temp Alarm by turning all the manual switches to the right and the back too neutral with pump off. Activate LS16 (carriage forward) with a coin or piece of metal. The LED on the switch will illuminate. Note: LS15A (carriage back) should not be made. Push the Pump Stop Button. Turn ON the NFB for M1 only (Leave the NFB for M2 OFF) SELECT THE MEASURE MODE (the purpose of this function is to measure 20mm and150mm of stroke): Go to screen 13F and input the Keyword OPSWITCH. Select 4 (measure) in the address Adjustment. Set the data on injection screen 6-a as shown below 1

STEP 1 2 3 4 5 6

4. 5. the 6.

7. 8. 9.

10.

V->P switch

( 1:posn

POSN

2: time

> > > > > >

3:press)

SPEED **.* **.* 20.0 10.0 10.0 10.0 99.00 1.0 slope TP sec 0.00 0.00 0.00 0.00s VI% PRESSURE PH % 99.9 99.9 50.0 10.0 10.0 10.0 VOID TL sec

INJECTION

V->P SWITCH STEP PRESSURE CURE TIM 1 2 3

LI mm 372.0 300.0 ***.* 100.0 20.0 10.0 TIME TA sec POSN LS6 mm PRESS PHL psi time TB sec 0.00 0.00 0.00 TC SEC

PRESSURE 0.0 0.0 0.0

PL %

10.01.02 PUMP CALIBRATION MID SIZE MACHINE 390MJ THRU 950MJ

SOL-VF (VOLUME) ADJUSTMENT

12. Adjust the SPAN and NULL of the AMP1 Amplifier, for the correct machine size, according to the following table (A) and the Injection time displayed in Screen 6A TABLE (A) SET THE DESIGNATED DATA IN THE VI1 AND VI2. SET 280.0 IN LI3 WHEN YOU ADJUST NULL AND SET 150.0 IN LI3 WHEN YOU ADJUST SPAN. Adjust the null and span of AMP1 as shown in the table below. Repeat this procedure a couple of times.

NULL/SPAN SET POINT AMP/VOLUME INJECTION UNIT 390MJ-40 -60 -40 500MJ-60 -80 -60 610MJ-80 -110 -80 720MJ-110 -160 -110 950MJ-160 -240 -160 1200MJ-240 -340 MEASURING POINT NULL (20mm) AMP1/VR 5 RANGE OF AMPERAGE INJ. TIME mA SEC < REFER. > 3.20-3.27 4.08-4.16 2.76-2.82 3.52-3.59 4.60-4.69 2.61-2.66 3.41-3.48 4.35-4.43 2.51-2.56 3.19-3.25 4.33-4.41 2.63-2.68 3.56-3.63 4.63-4.72 3.56-3.63 4.63-4.72 6.44-6.57 SCREEN 6-A 250 250 260 260 260 270 270 270 275 275 275 290 290 290 290 290 290 NO. 1 SPAN L13=150.0 SET DATA VI1 & VI2 % 99.9 99.9 99.9 99.9 99.9 63.0 63.0 63.0 46.0 46.0 46.0 43.0 43.0 43.0 43.0 43.0 43.0 (150mm) AMP1/VR4 RANGE OF AMPERAGE INJ. TIME mA SEC < REFER. > 1.18-1.21 1.50-1.55 1.02-1.05 1.30-1.33 1.69-1.74 1.52-1.57 1.99-2.05 2.54-2.61 2.00-2.06 2.55-2.63 3.46-3.56 2.25-2.31 3.05-3.14 3.96-4.07 3.05-3.14 3.96-4.07 5.50-5.67 SCREEN -6-A 670 670 780 780 780 650 650 650 650 650 650 780 780 780 780 780 780 NO. 1

LI3-280.0 SET DATA V11 & V12 % 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5

NOTE: *610 MJ*: There are some 610 MJ machines in the US that have the Screw rotation speed up option J608AAA001, J608AAA002, J608AAA003, J608AAA004, J608AAA005. These machines have larger Ppumps and special software.

10.01.03 PUMP CALIBRATION MID SIZE MACHINE 390MJ THRU 950MJ

SOL-VF (VOLUME) ADJUSTMENT

13. CHECK OF MAXIMUM INJECTION SPEED USING PUMP M2: Turn OFF Pumps Turn ON NFB for the M2 motor. Set Injection Speed for 99.9 % at VI1 and VI2. Push Pump Start button Check the actual injection time displayed on screen 6A. It should be between the lower and upper values as in the table below.

SET POINT MACHINE MODEL LI3=150.0 DISTANCE OF LI2-LI3=150MM SET DATA RANGE OF V11 & V12 INJ. TIME % SEC

AMPERAGE mA < REFER. >

390MJ-40 -60 -40 500MJ-60 -80 -60 610MJ-80 -110 -80 720MJ-110 -160 -110 950MJ-160 -240 -160 1200MJ-240 -340

99.9 99.9 99.9 99.9 99.9 99.9 99.9 99.9 99.9 99.9 99.9 99.9

0.94-0.98 1.22-1.29 1.56-1.64 0.90-0.94 1.14-1.20 1.55-1.62 0.94-0.99 1.27-1.34 1.66-1.74 1.27-1.34 1.66-1.74 2.30-2.42

14.

Reset the Measure Mode Go to Screen 13F and input the key word OPSWITCH. Enter 0 (normal) in the adjustment address. Turn ON the Closed Loop Control Go to screen 13F Push the upper case letters button, the LED will illuminate. Enter the key word OPTIONDA and press the enter key. Go to address No. 103 INJECTION SPEED CLOSED LOOP CONTROL and enter FF Go to address No. 112 INJECTION PRESSURE CLOSED LOOP CONTROL and enter FF

15.

10.01.04 PUMP CALIBRATION MID SIZE MACHINE 390MJ THRU 950MJ

SOL-VP (PRESSURE) ADJUSTMENT

1. 2. 3. Insure that the barrel heaters are up to the proper temperature for the material in the barrel. Connect AMP1 to the ammeters equipped inside the electrical control cabinet. Confirm the Actual Injection Pressure displayed in Screen 6A is 0 with the Pump OFF. If the displayed value is not 0 adjust the Pressure Sensor Amplifier. Turn OFF the Closed Loop Control. Go to screen 13F Push the upper case letters button, the LED will illuminate. Enter the key word OPTIONDA and press the enter key. Go to address No. 103 INJECTION SPEED CLOSED LOOP CONTROL and enter 00 Go to address No. 112 INJECTION PRESSURE CLOSED LOOP CONTROL and enter 00 Turn the Main Power OFF and then ON. Clear the Low Temp Alarm by turning all the manual switches to the right and the back too neutral with pump off. Activate LS16 with a coin or piece of metal. The LED on the switch will illuminate. Note: LS15A should not be made. In the Injection Screen 6A at the address V-> P switch enter a 1 for (position). At the address for time TA sec, enter 0.0. At the address for posn LS6 mm, enter 1.0 mm. At the addresses for injection speed VI1 ~ VI6 enter 20%. Adjust the SPAN and NULL of the AMP1 AMPLIFIER using the table below for the correct injection unit size, during the Injection Holding phase. NOTE: The milliamp readings are approximate use the actual hydraulic pressure reading.

NULL/SPAN Amp & Volume No. Hold Pressure set

4.

5. 6. the 7.

8.

9.

Injection Pressure

display (psi)

40 HD 60 HD 80 HD 110 HD 160 HD 240 HD 5150 70 5150 70 5150 70 5180 70 5160 70 5130 70

NULL VR10 ON AMP1 PL3 = 20% Hydraulic Pressure kg/cm psi

34 34 34 34 34 34 483 483 483 483 483 483

Amperage (mA)

100 100 100 100 100 100

Injection Pressure

display (psi)

25740 + 250 25740 + 250 25740 + 250 25880 + 250 25810 + 250 25670 + 250

SPAN VR9 ON AMP1 PL3 = 99.9% Hydraulic Pressure kg/cm psi

170 170 170 170 170 170 2417 2417 2417 2417 2417 2417

Amperage (mA)

600 600 600 600 600 600

10. 11.

Adjust the CRT readout with the Span and Null on the MIU / DIU board. Turn ON the Closed Loop Control Go to screen 13F Push the upper case letters button, the LED will illuminate. Enter the key word OPTIONDA and press the enter key. Go to address No. 103 INJECTION SPEED CLOSED LOOP CONTROL and enter FF Go to address No. 112 INJECTION PRESSURE CLOSED LOOP CONTROL and enter FF

10.01.05 PUMP CALIBRATION MID SIZE MACHINE 390MJ THRU 950MJ

SOL-SP (BACK PRESSURE) ADJUSTMENT

1. 2. 3. Insure that the barrel heaters are up to the proper temperature for the material in the barrel. Connect AMP2 to the ammeters equipped inside the electrical control cabinet. Confirm that the Actual Injection Pressure display, in screen 6A, reads 0 with the Pumps turned OFF. If the displayed value is not 0 adjust the Pressure Sensor Amplifier. Move the screw completely forward. Disconnect Y362 (SOL-SR) (Screw Rotate) from the terminal in the lower control cabinet and isolate it electrical tape. Jumper between Y356 (SOL-IF) and DOS. Turn the manual selector switch for Screw Rotate to run and adjust the SPAN and NULL of the AMP2 AMPLIFIER for the proper Injection unit size according to the table below. NOTE: When you change the Back Pressure set up value, you have to return the manual switch for rotate to the neutral position and back again to realize the change. Input the values for screw rotate according to the table below. The screw should not rotate for this check. DO NOT readjust the Span and Null of the MIU / DIU to calibrate the CRT. This is done when calibrating VP.

NULL / SPAN Amp & Volume No. Back Pressure Setting Injection Unit Size Screw Speed Setting % INJECTION PRESSURE (PSI)

4. 5. with 6. 7.

screw

NULL VR5 on AMP2 BPB1 ~ BPB3 = 5%

HYDRAULIC PRESSURE kg/cm (PSI) AMPERAGE (mA) INJECTION PRESSURE (PSI)

SPAN VR4 on AMP2 BPB1 ~ BPB3 = 99%

HYDRAULIC PRESSURE kg/cm (PSI) AMPERAGE (mA)

40 HD 60 HD 80 HD 110 HD 160 HD 240 HD

5.0 4.0 3.0 3.0 2.0 2.0

249 20 249 20 249 20 249 20 249 20 249 20 8.

1.6 1.6 1.6 1.6 1.6 1.6

23 23 23 23 23 23

130 130 130 130 130 130

4980 + 50 4980 + 50 4980 + 50 4980 + 50 4980 + 50 4980 + 50

33 33 33 33 33 33

469 469 469 469 469 469

675 675 675 675 675 675

Remove the jumper between Y356 and DOS and connect Y362 as before.

10.01.06 PUMP CALIBRATION MID SIZE MACHINE 390MJ THRU 950MJ

SOL-CP (CLAMP PRESSURE) ADJUSTMENT

1. PROPORTIONAL RELIEF VALVE CP CLAMP PRESSURE CONTROL VALVE a) Install a pressure gauge in CP-1. a) Adjust the SPAN and NULL of AMP2 as shown below on clamp pressure. Set "clamp force % and check the display "clamp force ton" on the screen 4- A. Adjustment should be repeated a few times. NOTE: When you change the clamp pressure setting value,, you have to turn off the clamp switch, then turn it back on again to see a new reading. Remember you should adjust the SPAN first and then the NULL. NULL / SPAN SET POINT AMP / POT CLAMP 390MJ 500MJ 610MJ 720MJ 950MJ 1200MJ ALLOWANCE TEST POINT NULL CLAMP FORCE = 50% AMP2/VR10 HYD. CLAMP AMPERAGE PRESSURE FORCE ma PSI US ton < REFER. > 1152 193 440 1152 248 440 1152 303 440 1152 358 445 1152 468 445 1152 579 445 14 2 CP-1 SCREEN 4-A NO.2 AMPMETER SPAN CLAMP FORCE = 99.9% AMP2/VR9 HYD. CLAMP PRESSURE FORCE PSI PSI 2304 386 2304 496 2304 606 2304 716 2304 937 2304 1157 28 + 2% -0 -1% CP-1 SCREEN 4-A

AMPERAGE ma < REFER. > 795 795 795 805 805 805 805 NO.2 AMPMETER

You might also like

- 1b - Mep 807a Prog and Aalrm CodesDocument24 pages1b - Mep 807a Prog and Aalrm CodesJohn Garnet100% (1)

- MC-2 SERIES OPERATION MANUALDocument21 pagesMC-2 SERIES OPERATION MANUALsergio paulo chavesNo ratings yet

- Manual Calibrado Monitor Excav. 320 330 CATDocument8 pagesManual Calibrado Monitor Excav. 320 330 CAThyromec95% (59)

- Freescale Semiconductor Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedDocument7 pagesFreescale Semiconductor Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedJavier GuzmánNo ratings yet

- Bla Power Pvt. LTD: Woodward 505 Governor Valve / Actuator Calibration &testDocument23 pagesBla Power Pvt. LTD: Woodward 505 Governor Valve / Actuator Calibration &testWilliam Will Controle WoodwardNo ratings yet

- DataKom 116 - USERDocument4 pagesDataKom 116 - USERKhaleel KhanNo ratings yet

- OPERATING INSTRUCTIONS FOR WORKPIECE CATCHER AND BAR FEED OPTIONSDocument25 pagesOPERATING INSTRUCTIONS FOR WORKPIECE CATCHER AND BAR FEED OPTIONSJan Klata50% (2)

- Emotron Shaft Power Monitor m10 Instruction Manual 01-2550-01 r2 EnglishDocument15 pagesEmotron Shaft Power Monitor m10 Instruction Manual 01-2550-01 r2 EnglishDražen GrgasNo ratings yet

- Op Man A210Document13 pagesOp Man A210IsraelitoDelaRosaNo ratings yet

- Furuno SC-50 - 110Document30 pagesFuruno SC-50 - 110etchegarayf100% (1)

- Quick setup and operation guide for Fronius TS series MIG/MAGDocument4 pagesQuick setup and operation guide for Fronius TS series MIG/MAGRobert SmithNo ratings yet

- Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedDocument11 pagesIntegrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and Calibratedsuri_girishNo ratings yet

- Tc-2060 Instruction Manual v0.09Document93 pagesTc-2060 Instruction Manual v0.09Herry SusiloNo ratings yet

- Daikin IOMDocument8 pagesDaikin IOMmahmoud4871No ratings yet

- Manual Válvula MotorizadasDocument8 pagesManual Válvula MotorizadasJosé Felix HernándezNo ratings yet

- Installation and Operation of Jockey Pump ControllersDocument14 pagesInstallation and Operation of Jockey Pump Controllersjulchab100% (1)

- GC Cookbook ManualDocument7 pagesGC Cookbook ManualGani Cahyo HandoyoNo ratings yet

- 19xrt CarrierDocument12 pages19xrt CarrierSuretodoNo ratings yet

- IA NT Operators Guide 02 2009Document8 pagesIA NT Operators Guide 02 2009Marko StubeljNo ratings yet

- Altronics CPU-2000 IOM 08-2002 PDFDocument29 pagesAltronics CPU-2000 IOM 08-2002 PDFSMcNo ratings yet

- Eds3000 Us ManualDocument17 pagesEds3000 Us ManualНикола СтефановићNo ratings yet

- Site Master™: Maintenance Manual Model S251C Antenna and Cable AnalyzerDocument16 pagesSite Master™: Maintenance Manual Model S251C Antenna and Cable AnalyzerBert En Sonya PauwelsNo ratings yet

- Gripper Instructions 1Document10 pagesGripper Instructions 1rubenNo ratings yet

- Fan Motor Speed (Hydraulic and Radiator Cooling) - Test and Adjust PDFDocument3 pagesFan Motor Speed (Hydraulic and Radiator Cooling) - Test and Adjust PDFHarol Ariel Sanchez MezaNo ratings yet

- MPL 15S 36S Genset Control Parameters AlarmsDocument5 pagesMPL 15S 36S Genset Control Parameters AlarmsDragos ComanNo ratings yet

- Relief Valve (Line) - Test and Adjust - Boom Lowering Control ValveDocument9 pagesRelief Valve (Line) - Test and Adjust - Boom Lowering Control ValveR I Santoso100% (1)

- 320B Caterpillar, testing in adjusting relief lineDocument8 pages320B Caterpillar, testing in adjusting relief lineLuisNo ratings yet

- Freescale Semiconductor Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedDocument22 pagesFreescale Semiconductor Integrated Silicon Pressure Sensor On-Chip Signal Conditioned, Temperature Compensated and CalibratedRafanuñez RodriguezNo ratings yet

- DS31590 (SM780055)Document31 pagesDS31590 (SM780055)uhlandeNo ratings yet

- EMX Service ManualDocument24 pagesEMX Service ManualyekukuNo ratings yet

- EC3-611 Rack Controller and ECD-000 Display UnitDocument8 pagesEC3-611 Rack Controller and ECD-000 Display UnitMaria DazaNo ratings yet

- Mcv110 Valve PilotDocument8 pagesMcv110 Valve PilotJose Manuel Bautista Martinez100% (1)

- CM-908S Service ManualDocument58 pagesCM-908S Service ManualCiubotaru ElenaNo ratings yet

- Benshaw Motor StarterDocument228 pagesBenshaw Motor Starterhennry_8307No ratings yet

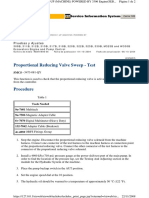

- Proportional Reducing Valve Sweep - Test: Pruebas y AjustesDocument2 pagesProportional Reducing Valve Sweep - Test: Pruebas y AjustesAugusto BellezaNo ratings yet

- CH Digital Temperature Controller Instruction ManualDocument10 pagesCH Digital Temperature Controller Instruction Manualgurguri5691100% (1)

- MPX2010Document12 pagesMPX2010Arni IrenawatiNo ratings yet

- PSHL PressureMatic Operation and Service Manual PDFDocument15 pagesPSHL PressureMatic Operation and Service Manual PDFmareveyNo ratings yet

- Dse5510 Installation InstDocument2 pagesDse5510 Installation Instricardo_dionisi2700No ratings yet

- Vat Pm5 ControllerDocument16 pagesVat Pm5 ControllersigecNo ratings yet

- Panasonic Ct-32,36sx31 CH Bp371, Bp372 SMDocument39 pagesPanasonic Ct-32,36sx31 CH Bp371, Bp372 SMRoberto FloresNo ratings yet

- 01EJ3060.PDF Prueba en BancoDocument3 pages01EJ3060.PDF Prueba en BancoAlex PakitoNo ratings yet

- GLORY Gfb800 - 900 - User ManualDocument37 pagesGLORY Gfb800 - 900 - User ManualFritz Bukowsky50% (2)

- Setting up a temperature controllerDocument3 pagesSetting up a temperature controlleristanbulian100% (1)

- MPX5100Document17 pagesMPX5100Andri PaoNo ratings yet

- Turboexpansor. Manual de Operacion HMIDocument21 pagesTurboexpansor. Manual de Operacion HMICamilo Ernesto Nardez MartinezNo ratings yet

- AirMaster P1ÄÜÆ® Ñ (¿ ®) PDFDocument10 pagesAirMaster P1ÄÜÆ® Ñ (¿ ®) PDFkaduz800% (1)

- MPX200Document8 pagesMPX200Hugo ContrerasNo ratings yet

- Calibration ManualDocument56 pagesCalibration ManualMaxence Kouessi100% (1)

- IM05805023K - XTJP - Op - Manual - RH2 - 06-07-12Document12 pagesIM05805023K - XTJP - Op - Manual - RH2 - 06-07-12melgarcia829No ratings yet

- Relief Valve (Line) - Test and Adjust: Pruebas y AjustesDocument8 pagesRelief Valve (Line) - Test and Adjust: Pruebas y AjustesRonaldo GaleanoNo ratings yet

- BC-8000 Field Calibration Procedure 55 AMPDocument11 pagesBC-8000 Field Calibration Procedure 55 AMP김덕용No ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 14 Case Study Shanghai World Financial CenterDocument6 pages14 Case Study Shanghai World Financial CenterElvin Michaels100% (1)

- Circles and conic sections review problemsDocument9 pagesCircles and conic sections review problemsMaze GomezNo ratings yet

- Considerations On GIN Grouting Method - Lombardi 2011 PDFDocument9 pagesConsiderations On GIN Grouting Method - Lombardi 2011 PDFdavidramirezramirezNo ratings yet

- CA3SN-G Cold Rolled SteeDocument2 pagesCA3SN-G Cold Rolled SteeFaizan QadirNo ratings yet

- Crane - Flow of Fluids Through Valves, Fittings and Pipe (1986) by CraneDocument131 pagesCrane - Flow of Fluids Through Valves, Fittings and Pipe (1986) by CranesnamprogNo ratings yet

- Calculating nominal flexural strength of reinforced concrete beamsDocument7 pagesCalculating nominal flexural strength of reinforced concrete beamsBry RamosNo ratings yet

- Steam Turbines Generators PDFDocument13 pagesSteam Turbines Generators PDFPrince ChaudharyNo ratings yet

- Fenner Keyless DrivesDocument56 pagesFenner Keyless DrivesroytamaltanuNo ratings yet

- Ball and BeamDocument8 pagesBall and BeamIonel MunteanuNo ratings yet

- ELEK Cable HV ReportDocument6 pagesELEK Cable HV ReportJayson PatrickNo ratings yet

- Ballistic Particle Manufacturing (BPM)Document15 pagesBallistic Particle Manufacturing (BPM)Senaka BandaraNo ratings yet

- Electric Motor and Generator GuideDocument4 pagesElectric Motor and Generator GuideEller Jansen AnciroNo ratings yet

- BME Refrigeration and Air ConditioningDocument6 pagesBME Refrigeration and Air ConditioningalysonmicheaalaNo ratings yet

- Product Sheet SYMAP General Information - Rev .0Document8 pagesProduct Sheet SYMAP General Information - Rev .0Keli KeyNo ratings yet

- Introduction To NDTDocument50 pagesIntroduction To NDTSuresh SenanayakeNo ratings yet

- Zeta-Potential Measurements On Micro Bubbles GeneratedDocument9 pagesZeta-Potential Measurements On Micro Bubbles Generatedggg123789No ratings yet

- Kinetic Energy Flywheel Energy StorageDocument13 pagesKinetic Energy Flywheel Energy StorageSarfarazHasanNo ratings yet

- Grasp8 Users Manual PDFDocument95 pagesGrasp8 Users Manual PDFantoniolflacoNo ratings yet

- Design and Manufacturing of Pneumatic Pipe Bending MachineDocument5 pagesDesign and Manufacturing of Pneumatic Pipe Bending MachineSriram MuruganNo ratings yet

- Led Bulbs CatalogueDocument30 pagesLed Bulbs CatalogueleedarsonlightingNo ratings yet

- CRCF BrainstormDocument20 pagesCRCF BrainstormDavid BriggsNo ratings yet

- TDT-172718DE-65F Adjustable Electrical Downtilt AntennaDocument1 pageTDT-172718DE-65F Adjustable Electrical Downtilt AntennaAnonymous ZlPONGNo ratings yet

- Retrofocus lenses – and why they were inventedDocument15 pagesRetrofocus lenses – and why they were inventedseifadiazNo ratings yet

- Pokédex Eon GuardiansDocument495 pagesPokédex Eon GuardianssaacidNo ratings yet

- ORGANISASI SELULER - Struktur Dan Fungsi-2017 PDFDocument58 pagesORGANISASI SELULER - Struktur Dan Fungsi-2017 PDFMantanindah 0206No ratings yet

- BP Chapter 13 - Understanding the Causes of FoxingDocument23 pagesBP Chapter 13 - Understanding the Causes of FoxingSonia KataNo ratings yet

- Great Circle Sailing Notes PDFDocument88 pagesGreat Circle Sailing Notes PDFAsdNo ratings yet

- Anif Jamaluddin: Prodi P.Fisika, PMIPA, FKIP, Universitas Sebelas Maret, SurakartaDocument21 pagesAnif Jamaluddin: Prodi P.Fisika, PMIPA, FKIP, Universitas Sebelas Maret, SurakartaApriyan P ArdhityaNo ratings yet

- Hollow Section Connection Using BoltDocument4 pagesHollow Section Connection Using Boltikanyu79No ratings yet

- CASE STUDY: Advanced Analysis of Reciprocating Engines, Compressors and Gas PipelinesDocument4 pagesCASE STUDY: Advanced Analysis of Reciprocating Engines, Compressors and Gas PipelinesabdulbasitbNo ratings yet