Professional Documents

Culture Documents

Slug Flow

Uploaded by

Marimuthu AyyamperumalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slug Flow

Uploaded by

Marimuthu AyyamperumalCopyright:

Available Formats

Slug Flow

(Sample model : slug.dat)

Slug flow is a phenomenon that occurs under special circumstances of two phase gas-liquid flow. It is the most serious scenario in two phase flow as it involves a moving liquid mass pushed by gases in between. Slugs can also form due to inadvertent collection of liquid in relief lines and low quality steam flow in well collection. Slug flow is not very uniform as the process of formation of slugs is random. This makes it hard to predict slug forces accurately. Slugs characteristics are: Slug speed v : usually 0.5 to 1.0 times the gas velocity Slug length L : The longer, the more conservative Slug fluid density D 2 Slug cylinder area A= 4

r time phase between successive slugs

Slug forces are generated when changes in flow direction occurs as at elbows. The change in momentum causes these forces. The amplitude of the slug force for 90deg elbow is:

Slug Force = AV 2

82

Typical forcing functions on 90-deg and 45-deg elbows are shown below

R seconds to exit the bend and to attain the maximum slug V force AV 2 , where R is the length of the bend. The peak slug force is sustained for L R R seconds. It then drops in seconds. V V

It takes the slug head

At pipe reduction or at orifice locations the characteristics of the slug force history can be different. In this case, the rise time can be assumed zero and the slug impact duration is 2L/V.

83

The slug load is ideally suited for time history analysis in AutoPIPE. You can model the phase between successive impacts on different elbows. Only one TIH file and one THL file need to be entered for each slug. The TIH file profile is shown above. The THL file defines points of application of the TIH file and the direction of load application. It also specifies the time the load will act at each point. A force will be applied at each elbow Near and Far points as shown in the sketch. The TIH file depends on slug length, but the THL does not. THL vary with slug speed. Most of the response to slug flow is primarily caused by low frequency modes that have large modal displacements in the direction of slug loading.

84

Sample Slug Problem

ASME B31.4 Pressure: 1.034 N/mm2 (150 psi) Temperature: 93.3 deg.C (200 F) Slug Length = 3.05 m (10 ft) Fluid density = 800.92 kg/m3 Fluid velocity = 15.24 m/sec (50 ft/sec) Fluid diameter = 304.8mm (12 inches i.e.12STD), Fluid area = 0.072966 m2 (113.098 in2) Fluid Force: AV 2 = 800.92*0.072966*15.242 = 13573 N (3051.33 lbs) 45-deg bends:

R = 1.5*(12/12)*(1.57/2)/50 = 0.024 seconds V L R Td = = 0.176 sec V

Tr=

Tr+Td = 0.2 sec 2Tr+Td = 0.224 sec

90-deg bends:

R = 1.5*1*1.57/50 = 0.047 seconds V L R Td = = 0.153 sec V

Tr=

Tr+Td = 0.2 sec 2Tr+Td = 0.247 sec

85

86

45-deg slug definition

87

90-deg slug definition

88

You might also like

- Measurements in A Pulsating FlowDocument13 pagesMeasurements in A Pulsating Flowusebio64No ratings yet

- Lifting Appliances Guide Oct18Document234 pagesLifting Appliances Guide Oct18Melvin Leong100% (1)

- Acoustic Fatigue Evaluation of Branch ConnectionsDocument8 pagesAcoustic Fatigue Evaluation of Branch ConnectionsShalihan MustafaNo ratings yet

- Dry Gas Rapid Valve OpeningCheckDocument1 pageDry Gas Rapid Valve OpeningCheckDhia SlamaNo ratings yet

- Topic 7 Oil and Gas Pipeline SolutionsDocument17 pagesTopic 7 Oil and Gas Pipeline SolutionsImranMajidli100% (1)

- Examples Applying Fea Results With Caesar II Models Webinar PDFDocument36 pagesExamples Applying Fea Results With Caesar II Models Webinar PDFkorbelNo ratings yet

- Flow Induced Vibration Choke ValvesDocument8 pagesFlow Induced Vibration Choke Valvesharmeeksingh01No ratings yet

- Otc18895 Flow Induced Pulsations in RisersDocument5 pagesOtc18895 Flow Induced Pulsations in Risershamadani100% (1)

- VIV Span EngineeringDocument15 pagesVIV Span EngineeringDianoDeNo ratings yet

- Theoretical External Collapsing Pressure For Pipelines (Method Is Not Per ASME.)Document1 pageTheoretical External Collapsing Pressure For Pipelines (Method Is Not Per ASME.)NakkolopNo ratings yet

- f201508151439617857 PDFDocument6 pagesf201508151439617857 PDFh_alimohamNo ratings yet

- A193B7 MaxTemp AllwbleStress - Portland BoltDocument5 pagesA193B7 MaxTemp AllwbleStress - Portland BoltAnonymous nw5AXJqjdNo ratings yet

- Pipeline Heat Transfer Model Explains Temperature DistributionDocument2 pagesPipeline Heat Transfer Model Explains Temperature DistributionAhmed Rashied100% (1)

- Numerical Analysis of Pipeline Response to Slow LandslidesDocument13 pagesNumerical Analysis of Pipeline Response to Slow LandslidesCurtis PattersonNo ratings yet

- Engineering Failure Analysis: Hossein Ghaednia, Sreekanta Das, Rick Wang, Richard KaniaDocument12 pagesEngineering Failure Analysis: Hossein Ghaednia, Sreekanta Das, Rick Wang, Richard KaniaJennifer Julieth Triana ForeroNo ratings yet

- Hydraulic TransientsDocument58 pagesHydraulic TransientsjulianvillajosNo ratings yet

- 1Document7 pages1sri9987No ratings yet

- Nozzle loading guidelines and reducing methodsDocument2 pagesNozzle loading guidelines and reducing methodsaap1No ratings yet

- Screening Reactor For Water HammerDocument49 pagesScreening Reactor For Water HammerYu GanNo ratings yet

- Cross Country Piping Stress AnalysisDocument8 pagesCross Country Piping Stress Analysisprabu2001No ratings yet

- Schulkes - Slug Frequencies Revisited PDFDocument15 pagesSchulkes - Slug Frequencies Revisited PDFneverwolfNo ratings yet

- Design Code Requiring Surge AnalysisDocument3 pagesDesign Code Requiring Surge AnalysisSharun SureshNo ratings yet

- Skyciv Foundation Design: InputDocument19 pagesSkyciv Foundation Design: InputNaim ZeinounNo ratings yet

- PSV CatalogDocument60 pagesPSV Catalogbuler empatsatuduaNo ratings yet

- Thermal BowingDocument8 pagesThermal BowingA. VenugopalNo ratings yet

- Shell Thickness CalcDocument1 pageShell Thickness CalcDidi KurniadiNo ratings yet

- Understanding Vibration-Induced Pipework FailureDocument3 pagesUnderstanding Vibration-Induced Pipework Failureأصلان أصلانNo ratings yet

- Anayo Ogazi Thesis 2011Document306 pagesAnayo Ogazi Thesis 2011Ton PhichitNo ratings yet

- Paper - Explosion Loading On Equipment From CFD Simulations - ComentadoDocument25 pagesPaper - Explosion Loading On Equipment From CFD Simulations - ComentadorsigorNo ratings yet

- Erosional Velocity CriteriaDocument1 pageErosional Velocity Criteriavijay_jvNo ratings yet

- CS-Guide CalculationDocument27 pagesCS-Guide Calculationduf fuNo ratings yet

- Fitness-For-Service Analysis of Skelp-End Welds in Spiral PipesDocument9 pagesFitness-For-Service Analysis of Skelp-End Welds in Spiral PipesMarcelo Varejão CasarinNo ratings yet

- Expansion Analysis of Offshore PipelineDocument25 pagesExpansion Analysis of Offshore PipelineSAUGAT DUTTANo ratings yet

- Guidelines for the Avoidance of Vibration Induced Fatigue Failure in Process Pipework pdf - Google 搜索 PDFDocument2 pagesGuidelines for the Avoidance of Vibration Induced Fatigue Failure in Process Pipework pdf - Google 搜索 PDFjasonwu11150% (2)

- Pipng Stress Analysis Design Guide: Pagmi Phase I Project PROJECT NO.3235-200Document11 pagesPipng Stress Analysis Design Guide: Pagmi Phase I Project PROJECT NO.3235-200Salma BacharNo ratings yet

- Integrated Training Program / Phase B - Flare Protection Systems Page 1 of 33Document33 pagesIntegrated Training Program / Phase B - Flare Protection Systems Page 1 of 33metasoniko2014No ratings yet

- Two Phase Flow Safety ValveDocument7 pagesTwo Phase Flow Safety Valversingle81No ratings yet

- Effect of Liquid Viscosity On Flow Patterns of Gas-Liquid Two-Phase FlowDocument5 pagesEffect of Liquid Viscosity On Flow Patterns of Gas-Liquid Two-Phase Flowyoupof83No ratings yet

- Static Calculation of Pipeline Free SpansDocument1 pageStatic Calculation of Pipeline Free SpansMannattil Krishna KumarNo ratings yet

- Free Span Rectification by Pipeline Lowering (PL) MethodDocument10 pagesFree Span Rectification by Pipeline Lowering (PL) MethodJangdiniNo ratings yet

- Creeps Analysis of ThermoplasticsDocument7 pagesCreeps Analysis of ThermoplasticsIgor AlarcónNo ratings yet

- DNV 1996Document22 pagesDNV 1996ankeshkatochNo ratings yet

- Design of Helical SpringsDocument14 pagesDesign of Helical SpringsSerdar ArslanNo ratings yet

- BS en Iso 11299-1-2018 - (2019-01-06 - 09-13-21 Am)Document26 pagesBS en Iso 11299-1-2018 - (2019-01-06 - 09-13-21 Am)wodonit136No ratings yet

- Blowdown of Pipelines Carryng Flashing LiquidsDocument10 pagesBlowdown of Pipelines Carryng Flashing LiquidsMilson GomezNo ratings yet

- SEPA15014 MFSTF CV 00 SPC 004 - Specification For Grouting - Rev ADocument15 pagesSEPA15014 MFSTF CV 00 SPC 004 - Specification For Grouting - Rev APruthviraj JuniNo ratings yet

- Understanding Ped For Asme VesselsDocument33 pagesUnderstanding Ped For Asme VesselsRamakrishnan SrinivasanNo ratings yet

- Thermal ExpansionDocument9 pagesThermal Expansionshahid hamzaNo ratings yet

- 9.line Size & Wall ThicknessDocument48 pages9.line Size & Wall ThicknessClark PlúaNo ratings yet

- Pipe Loading - Pipe BridgeDocument3 pagesPipe Loading - Pipe BridgeSrishti Project ConsultantsNo ratings yet

- Samson: Evaluating The Calculation Accu-Racy Provided by The Relevant Noise Prediction Standards For Control ValvesDocument12 pagesSamson: Evaluating The Calculation Accu-Racy Provided by The Relevant Noise Prediction Standards For Control ValvesGopinath GunasekaranNo ratings yet

- Multiphase Flow 1995From EverandMultiphase Flow 1995A. SerizawaNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Phase Equilibria: Basic Principles, Applications, Experimental TechniquesFrom EverandPhase Equilibria: Basic Principles, Applications, Experimental TechniquesNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

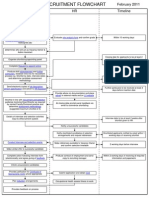

- Recru FlowDocument1 pageRecru FlowharishtokiNo ratings yet

- Reference..... SWOT AnalysisDocument38 pagesReference..... SWOT AnalysismarklesterNo ratings yet

- On Auto CadDocument20 pagesOn Auto CadsidhantNo ratings yet

- ANSI-IsA 5.4 Standard For Loop DiagramsDocument22 pagesANSI-IsA 5.4 Standard For Loop DiagramsharishtokiNo ratings yet

- RFS-CT-2006-00031 - HISTWIN High-Strength Steel Tower For Wind TurbineDocument15 pagesRFS-CT-2006-00031 - HISTWIN High-Strength Steel Tower For Wind TurbineJoemarie MartinezNo ratings yet

- RFS-CT-2006-00031 - HISTWIN High-Strength Steel Tower For Wind TurbineDocument15 pagesRFS-CT-2006-00031 - HISTWIN High-Strength Steel Tower For Wind TurbineJoemarie MartinezNo ratings yet

- Influence of Ring Stiffeners On A Steel Cylindrical Shell: D. Lemák, J. StudničkaDocument8 pagesInfluence of Ring Stiffeners On A Steel Cylindrical Shell: D. Lemák, J. StudničkaOTPIDINo ratings yet

- ANSI-IsA 5.4 Standard For Loop DiagramsDocument22 pagesANSI-IsA 5.4 Standard For Loop DiagramsharishtokiNo ratings yet

- Origami-Car VWDocument9 pagesOrigami-Car VWMohd ZaidanNo ratings yet

- Origami-Car VWDocument9 pagesOrigami-Car VWMohd ZaidanNo ratings yet

- RFS-CT-2006-00031 - HISTWIN High-Strength Steel Tower For Wind TurbineDocument15 pagesRFS-CT-2006-00031 - HISTWIN High-Strength Steel Tower For Wind TurbineJoemarie MartinezNo ratings yet

- ABAQUSDocument33 pagesABAQUSharishtokiNo ratings yet

- Origami-Car VWDocument9 pagesOrigami-Car VWMohd ZaidanNo ratings yet

- Explore The Big Cats PDFDocument65 pagesExplore The Big Cats PDFvarcolacNo ratings yet

- Distribution System Analysis by Tarun GonenDocument1 pageDistribution System Analysis by Tarun GonenharishtokiNo ratings yet

- Time PassDocument1 pageTime PassharishtokiNo ratings yet

- FT InchDocument2 pagesFT InchharishtokiNo ratings yet

- Autopipe 2004 - V8.60 New Features: Mark Upston P.Eng. Plant Cae Manager 1-800-BentleyDocument25 pagesAutopipe 2004 - V8.60 New Features: Mark Upston P.Eng. Plant Cae Manager 1-800-BentleyharishtokiNo ratings yet

- Livia BrochureDocument13 pagesLivia BrochureharishtokiNo ratings yet

- Time PassDocument1 pageTime PassharishtokiNo ratings yet

- Time PassDocument1 pageTime PassharishtokiNo ratings yet