Professional Documents

Culture Documents

Descriere Functionala HVAC+BMS ENG 27.10.2003

Uploaded by

Frinaru CiprianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Descriere Functionala HVAC+BMS ENG 27.10.2003

Uploaded by

Frinaru CiprianCopyright:

Available Formats

CASCADE OFFICE BUILDING

I. FUNCTIONAL DESCRIPTION OF AUTOMATION SYSTEM 1. Boiler Plant

A. Basic Functions In The Manual Operation Mode

All on/off controls for pumps and boilers are available on the power and automation panel of the boiler plant (see TFA1_CT diagram).

B. Basic Functions In The Automatic Operation Mode

The proposed controller for boiler plant automation is pre-programmed and meets the automation requirements. Beside boiler sequence and temperature regulation on individual heating circuits, other functions are provided, such as boiler rotation, detailed time programs for working days, weekend and holidays, hot water temperature correlation with outside temperature and with consumer operating conditions (e.g. air handling units). 1. Temperature Regulation On Individual Heating Circuits The temperature setpoint calculation for the hot water is performed depending on the outside temperature (this is averaged on 1-hour time interval to avoid disturbance errors). The user can select heating diagram parameters for each heating circuit. There is also an individual program control point for every heating circuit, serving for the heating operation validation on the afferent circuit. This point could be used by the dispatcher to stop the heating for service and overhaul works. The heating automatically stops working when the outside temperature exceeds certain limits. There are two such limits available: a short-term average (e.g. one hour) and a long term average (e.g. 3 days). The heating stops working when one of the two limits is exceeded. The heating operation related to the two limits could be schematically represented as follows:

Outsidetem perature Outside tem perature (short term average) Lim it 1 Lim it 2 Outside temperature (long term average)

Heating on

Heatingoff

Heating on

Tim e

Figure 1: Heating on/off diagram

Pag. 1 din 25

CASCADE OFFICE BUILDING The heating diagrams are defined using two parameters establishing the heating diagram slope and the curvature factor (a quicker temperature increase in the proximity of 0C). The temperature of the supplied hot water has also an upper limit. The heating diagram sets are represented in figure 2. The temperature setpoint for the hot water, resulting from this calculation, could be displayed through program points. The program compares the reading of the temperature sensor placed on the hot water supply circuit with the temperature setpoint and shut off/on the three-way control valve accordingly.

Hot wateragent Temperatur temperature nclzire

Temperatur exterioar Outside temperature

Figure 2: Hot water temperature versus outside temperature The heating pump operates continuously as long as the hot water is supplied. The program module managing the heating for individual circuits has also another important role. It sends to the boiler strategy the optimum temperature as evaluated for the boiler supply circuit. These values are collected by the strategy from all the heating circuits and from domestic hot water preparing unit. The maximum value is considered, that is the most disadvantageous condition, thus establishing the exact temperature requirement and saving energy. For example, if circuit 1 needs 55C and circuit 2 needs 56C, the boiler strategy shall supervise a 56C temperature in the boiler supply circuit. The exact establishment of temperature needs provides important savings, as the boilers will not be forced to generate more heat than this exactly determined value. The hot water supply for the heating circuit equipped with heaters and air curtains shall be performed according to a time program and depending on the outside temperature. The hot water supply for the heating circuit equipped with fan coils shall be performed according a time program, and depending on the outside temperature and the hot water control through the three-way valve.

Pag. 2 din 25

CASCADE OFFICE BUILDING 2. Boiler Sequencing The two boilers are started depending on the energy demand needed to achieve the desired temperature in the boilers supply circuit. All the users, e.g. the program modules controlling the users operation (the two heating circuits) evaluate the hot water temperature needed for optimum operation. The maximum demand of all the users is considered as temperature setpoint for boilers sequencing. This value could be incremented by the strategy module to balance the line losses. The functions of the boiler sequencing strategy module are the following: 1. Computing the needed number of boilers to achieve the desired temperature in the supply circuit. 2. Supervising the temperature change rate in the supply circuit, thus performing an anticipating function for the needed number of boilers. 3. Periodically rotating the boilers in the boiler group, thus providing an uniform wearing of these boilers. 4. When both boilers are not required to operate simultaneously, the continuous operation of a single boiler is limited. 5. The three-way valves mounted on boilers will protect them against the cold water penetration and consequently against fracture. The program supervises the number of operating boilers, the number of faulty boilers as well as the operating thermal power.

2. Cooling Plant

C. Basic Functions In The Manual Operation Mode

In this operation mode all the manual procedures for chiller control are available from its interface. The manual controls for on/off switching the chilled water circulation pumps are also available. The pumps are switched on/off using the push buttons on the power and automation panel of the cooling plant (see TFA2_CF+CTA+GG+Elevator+Fire diagram). This panel supplies the following users: Chilled water circulation pumps.

D. Basic Functions In The Automatic Operation Mode

In the automatic operating mode the automation panel switches on/off the chillers and the chilled water circulation pumps according to the time programs. The panel also receives a failure signal from the chiller. The cooling plant is stopped when entering in the winter operation mode.

3. Air Handling Unit

E. Basic Functions In The Manual Operation Mode

In this operation mode the manual controls for switching on/off the fan are available through the push buttons on the panel door. The battery dampers and valves are manually operated (see the TFA2_CF+CTA+GG+Elevator+Fire diagram).

Pag. 3 din 25

CASCADE OFFICE BUILDING The panel supplies the following users: Supply fan Exhaust fan Humidifier

F. Basic Functions In The Automatic Operation Mode

The conditioned air generation should follow several criteria. Therefore the strategy governing the automation process is very important. The strategy objectives are the following: Providing conditioned air at the required parameters; Providing a minimum energy consumption; Protection of the plant when malfunctions or failures appear; Using the plant with an operation duty cycle providing the maximum possible operation life (avoiding the repeated equipment starts and stops, etc.); Permanent supervising of plant parameters and warning the operator for malfunctions or failures. The occupied period is programmable through time programs. This can have two values: Occupied, corresponding to the time period when the building is occupied, and Unoccupied, corresponding to the time period when the building is not occupied. The programming through the time programs ensures energy saving for the time periods when there are no people inside the building. In the Occupied period operating mode the plant generates conditioned air at the preset parameters. The programming of these parameters can also be performed within the time programs. Depending on the outside temperature, the preset temperature value can be adjusted by the controller. This feature allows the establishment of different comfort conditions during the summer and winter without needing the frequent controller adjustment for temperature setpoint change. In the time periods when the building is not occupied, the plant could be in the following operating modes, having the associated values: Night cycle. Even if it is an unoccupied period, a minimum temperature should be maintained. The temperature limits are initially preset, the related parameters being set at 14C and 28C respectively. This feature drastically reduces the fuel consumption because, for example, the energy needed to heat a room totally cooled under 14C during the night is much larger than the necessary energy to maintain the minimum comfort limits. Frost protection operating mode. This operation mode starts independently of occupied or unoccupied period, when the frost protection thermostats generate a starting signal. In such a case, the controller automatically switches on the heating. The controller performs the temperature control by driving the related sequence for dampers and heating and cooling battery valves.

Pag. 4 din 25

CASCADE OFFICE BUILDING

2. BMS Overview

BMS (Building Management System)

The BMS dispatcher assigned to the Cascade office building supervises and controls the following:

TFA1

Boiler Plant

START/STOP boilers controls; boiler 3-way valve control; START/STOP controls for boiler re-circulation pumps; START/STOP controls for heating circulation pumps; outside temperature supervising; supervising the supply temperature for boiler 1; supervising the return temperature for boiler 1; supervising the supply temperature for boiler 2; supervising the return temperature for boiler 2; supervising the general supply temperature; supervising the general return temperature; supervising the fan coil supply circuit temperature; supervising the supply circuit temperature for heaters and air curtains; controlling the 3-way valve on the fan coil heating circuit;

TFA2

Cooling Plant

chiller START/STOP control; chiller pumps START/STOP controls; supervising the chiller operation condition;

Air Handling Unit

START/STOP control for supply fan; START/STOP controls for exhaust fans; humidifier START/STOP control; START/STOP control for supply and exhaust air dampers; supervising the supply air temperature; supervising the exhaust air temperature; supervising the exhaust air humidity; controlling the three-way valves for heating and cooling battery; humidity proportional control; temperature setpoints;

GENERATOR GROUP

supervising the operating condition;

ELEVATORS

supervising the operating condition of elevator 1; supervising the operating condition of elevator 2; elevator failure;

FIRE

supervising the detection system operating status; Pag. 5 din 25

CASCADE OFFICE BUILDING

TFA3

START/STOP controls for smoke exhaust fans (2 pieces); shutter control (4 pieces); START/STOP controls for overpressure air supply fans (3 pieces); supervising the domestic water pressure booster group; fuel level supervising; The BMS dispatcher has the following features:

1.1 Dispatcher Unit The dispatcher unit, referred to as BMS in the following, performs the following general functions: Network management Operator interfacing Display system in the graphic mode Data acquisition system and event history Alarm management Supervising Report generation

Hardware Specifications The hardware BMS dispatcher components should meet the following minimum requirements: Intel Pentium Processor (or more advanced) Video Super VGA card providing a 1024 x 768 pixel resolution and 256 colours (2 MB RAM video) Minimum 32 MB RAM 1.2 GB Hard Disk I/O Interface with 8 RS-232 ports Minimum 8x speed CD-ROM drive Mouse port and mouse 1.44 MB floppy-disk drive Epson or Hewlett Packard printer Super VGA non-interlaced monitor having a 1024 x 768 pixel resolution and a minimum refreshing frequency of 70 Hz

Software Specifications

Pag. 6 din 25

CASCADE OFFICE BUILDING The BMS system is based on the multi-tasking and multi-user Windows NT/Windows 95 operating system. The standard services provided by the operation system include: Multi-tasking and multi-user support TCP/IP network support Data exchange capability with OBDC data bases Full integration in the Microsoft Windows Network Remote connection via WAN or PSTN (dial-up)

1.2 Data control and acquisition The BMS system includes capabilities for data control and acquisition using standard software drivers that need no individual implementing operations. The entire system configuration is accessible during the data acquisition or the use of other communication channels. The BMS nodes do not need restarts for implementing the data base changes. Additionally, the on-line performed data base changes instantaneously apply to the system without needing another network operation system (such as NetWare, LAN Manager, Banyan Vines). Configuration The communication driver can be set up on-line by the users by entering an access code. The parameters that can be changed are the following: Device type Communication port Channel name (up to 6 ASCII characters) Bit-rate and parity (for RS-232 or RS-422) Communication Time out Check sum (CRC_16) Data bit number Stop bit number Marginal communications barometer limit Failed communications barometer limit

Communications BMS develops a communication system compatible to: RS-232 RS-422/485 Ethernet, TCP/IP Pag. 7 din 25

CASCADE OFFICE BUILDING C-Bus communication networks, etc.

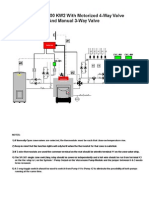

Supervising

Boiler plant

Cooling plant+Air handling unit+Generator set+Elevators+Fire

Exhaust shutters smoke/garage noxa

Electric generator set

Normal exhaust fans

Smoke exhaust fans

Water pressure booster group supervising

CLU tank level supervising

Cooling plant

Boiler plant

Cooling plant, air handling unit, generator set, elevators, fire

Supervising

Heating, ventilation, conditioned air

1.3 Data acquisition

The system performs the data acquisition using one of the two following methods: Periodical scanning Exception report The system provides minimum 9 scanning time intervals between 1 and 900 seconds. To reduce as most as possible the communication traffic, the system automatically locks the data demand using adjacent addresses and scanning intervals to generate data packages, thus optimising the traffic for a preset demand. There are also utility functions allowing data package assigning check for every scanning time interval as well as compiling grouping statistics concerning the communication channel load. When the subsystems allow, the RBE protocols (exception report) can be used to reduce the system load. If necessary, the two methods could be alternately used, providing a correct and optimum data acquisition. 1.4 Controller Communication

The operator commands are sent to controllers using a communication technique, which secure the data integrity. When the operator doesnt receive a reception notification after a command initiation, which means the command was erroneously transmitted, the operator is Pag. 8 din 25

Fire detection system status

Air handling unit

Elevators

CASCADE OFFICE BUILDING informed by an alarm, presettable by the user according to his/her needs. A deliver of an notification message could optionally be associated to each individual point. This message will ask for a supervising confirmation of the operator action before sending the entered value to the controller. 1.5 System Data Base

The system develops a real-time data base, including acquired data from analogue, digital or logic inputs. This data base can be set up by the user without needing other programming actions and without interrupting the system operation. This data base provides an information history concerning events or analogue, digital or logic inputs. This information is accessible in a similar way to other basic system functions, such as displays, reports, supervising, etc.

Data Base Setup The data base setup is accessible to the user through a password even the system is on-line. The setup needs no other programming, compiling or linking operations and doesnt need the system stop or restart. The event and data history remains unaffected by the data base setup change. Data entering is possible using the following methods, depending on operator knowledge about the system: Using the Fill in the blanks setup Using the data editor Using the operator interface

The first setup method allows the data base use without knowing in detail its changing process. The system provides a permanent help window allowing the inexperienced users to set-up this data base. The user can also use as model a point already stored in the data base. A new point storing could be performed by changing the parameters, which are different from on point to another only (such as name, descriptor and address). For experienced operators, a quick way to handle the data base is possible by using a text editor and the ASCII files with setup recordings. If necessary, the data base can be generated off-line and loaded when it is needed. The system is also provided with an access password allowing a remote data base change using a modem, thus providing the possibility of maintenance and failure analyses from a specialised remote engineering centre. Data Base Structure The real-time data base allows data storage using the following structures: Analog point structures Status type point structures Data history structures Accumulator type point structures User defined structures Pag. 9 din 25

CASCADE OFFICE BUILDING Event structures

Every mentioned structure can be compressed in such a way that it can be associated to a single complex type point having associated parameters referred to by using a single terminology. Every structure is accessible using subsystems such graphic operator interface, report generating system or application interface, having a point.parameter type format, without needing to know the internal storing process. The system can keep frequent asked data base segments in a quick access zone (memory resident information), the other segments being placed on hard disk. The memory resident data can be permanently saved on hard disk to avoid data loss in case of power failure. Data base backup is possible with the on-line system, including History backup. The backup copy can be stored on floppy disk or magnetic tape where it is possible. 1. Analog point structure The analog data is stored in structures having the following parameters: Point name Process variable (PV) Output (OP) Up to 4 operator-definable inputs Scanning time interval Alarm flag Alarm status 0% & 100% range PV Clamp Flag Dead band alarm Dead band control Normal mode Upper limit SP Lower limit OP 2. Status point structure The status (digital) information is stored in the data base in a point.status type structure. The status type point processes the 1-3 bit digital inputs allowing 8 possible statuses. The status point is a structure including the following parameters: Point name Process variable Mode Scanning time interval Alarm flag Point description Output Scanning status Scanning address Alarm priority Point description Setpoint (SP) Mode (MD) Scanning status Scanning address Alarm status Associated display Operator control level Measuring units Dead band movement Control interruption Up to 4 alarm types Upper limit SP Lower limit OP

Pag. 10 din 25

CASCADE OFFICE BUILDING Re-alarming status Input width Output width Control error alarm priority Normal mode Associated display Operator control level Output pulse width Interruption control

3. Accumulator type structure The data associated with pulse type inputs is stored in accumulator type point structures which will automatically supervise the operating instruments. The accumulator type point is a structure including the following parameters: Point name Process variable Raw counts Measuring factor Scanning time interval Alarm flag 0% & 100% range Operator control level Up to 4 alarm types 4. History data structure The system point History is configurable due to the point definition. The history is provided for instantaneous or discrete values, having the acquisition rate between 5 seconds and 24 hours. After being saved in the history data base, the point is available through POINT.PARAMETER, in combination with a method to locate a certain searched value. The graphic operator interface, supervising system, report-generating system and the application interface have access to History. A History point change is on-line possible without losing prior collected data. 5. Event data structure The system generates a log including the following event-related information: Alarms Processed alarms Reset to normal Operator control commands Operator password and security level changes On-line data base changes Communication alarms Pag. 11 din 25 Point description Rollover value Scaling value Scanning status Scanning address Alarm status Associated display Measuring units

CASCADE OFFICE BUILDING System restart messages The standard displays are created in such a way that they show the log page including the most recent event in the upper area of the screen. The following pages include the events in the descending order of the occurrence moment. The sorting of log data is possible by using a standard report, which could be set up with the filling-in-the-blanks method. No special related coding is provided. The event data base includes the following information: Occurrence time and date Point name Event type Alarm priority Point description Measuring units

The data base is accessible from other subsystems too, such as operator interface, report generating system or application interface. It is also possible to get an event file completely filling the available space on the hard disk. Depending on the available hard disk space, the file can store up to 1,000,000 (one million) events, having 200,000 events defined by the basic system. The file stores the events in a current buffer. When the file becomes completely filled, an alarm is generated to warn the operator to save the file on an external support. The events will be transferred in an archive to allow saving new events in the buffer. Another memory zone could be provided to keep this archive ready for transfer on an external support. The operators have the possibility to restore the archives using the operator interface and the dedicated displays. The event file is compatible with the report generating system. The system automatically recalls a recorded file when a report needing data covered by this file is requested. The operator can restore archives and to review or print them from the workstation.

6. User definable data structure To cover all data types that could be used in such applications, the system provides the possibility to create a data base which can be defined by the user and can be completely integrated in the system. This data base can be accessed through: User graphics System report Application programs Network application using API network interfaces

Pag. 12 din 25

CASCADE OFFICE BUILDING

Data processing algorithms Beside standard process functions, the system allows additional processing by using standard algorithms attachable to an analog, status or accumulator type point. The main functions provided by these algorithms are the following: Arithmetic calculation Boolean calculation Max/min values Integration calculation Calculation of total operating hours Alarm group locking Report request Application request

Archiving Data History The system allows history archiving to perform a continuous supervising of system evolution. The archived data can be stored on hard disk or saved on an external support (floppy disk, magnetic tape, etc.). The number of the archives stored by the system depends on the hard disk size. The system allows the user to define specific history saving intervals to avoid unnecessary saving operations. The history archiving could be activated in one of the following methods: By operator request According to a periodical schedule

On the event occurrences After being archived, the data is available for re-evaluation using the system utilities combined with on-line archives or other history data. 1.6 Operator Interface

The operator interface was created to ensure efficient system communication, data transfers and abnormal operation case handling. It is conceived as a pyramidal graphic structure with operating windows. The operator interface is interactive and entirely based on graphic symbols and icons. The interface operation is based on working windows and meets the Windows standard conventions to reduce at most as possible the operator training. Specifically, the command bars, icons and cascaded menus are accessible on each display to allow easy access to basic Pag. 13 din 25

CASCADE OFFICE BUILDING functions. Similarly, certain functions are accessible through a standard button set, this feature implying no specific configuration. More than 500 user displays can be provided. These displays will be set up by using the Integrated Display Building functions available on the workstation.

Operator Interface Features The system offers an operator interface under Windows environment having the minimum performance presented below. For the following functions no user coding or programmes are needed: Window resizing, zoom in, zoom out Dedicated buttons to open menus including: - Associated display - Alarm content - Alarm handling menu - Forward/Back display sequence - Re-entering the previous display (minimum 8) - Graphic call-up - Supervising call-up - Group call-up - Service input/output command - Point details The alarm zone displays the highest priority alarm and the most recent (the oldest) nonhandled alarm Zone for displaying system internal date and time Current access level Station number Alarm reporting Communication error reporting Data marking and entering devices

The operator interface allows to simultaneously use the mouse and the keyboard. The fixed menus and the dedicated keys simplify the operation. The operator interface allows using touch-screen systems to mark and enter commands. The operator interface uses command bars for common operations. It also allows to open/close cascade-type menus and windows. Operator Interface Functions The operator interface develops the following functions: Field equipment display and control Alarm acknowledgement depending on their priority Report printing Pag. 14 din 25

CASCADE OFFICE BUILDING Event archiving and handling Password change On-line generation of data base and graphic display Supervising the data sent on communication channels System parameter setup

The computer allows the simultaneous display of several work zones. Each work zone allows the operator to choose between the following working methods: Master operating mode: The operator has normal access to the system Maintenance and engineering mode: System setup and application programming Graphic development mode: Graphic application development using the Graphics Display Building package All the working modes allow simultaneously displaying and operating several work windows on the screen. The access to these operation modes can be limited through password. Security Levels The system accepts 6 security levels. The allowed functions on each level are as follows: Level 1: Level 2: Level 3: Level 4: Sign-Off mode - Viewing the start-up screen It allows using the functions of previous level plus operator possibility to receive occurred alarms. This level is specific to inexperienced operators. It allows using the functions of previous levels plus operator possibility to use simple functions, such as enable/disable, etc. It allows using the functions of levels 1-3 plus access to time programs, periphery system assigning, point measuring parameter change, reports and relatively complete use of standard display configuration. It is specific for the operating engineer. It allows using the functions of levels 1-4 plus access to functions such as building and connection displays, assigning functions to buttons, etc. It is reserved to the operational supervisor. The highest access level. It allows unlimited access to all the system work stations. It is reserved to the operational manager.

Level 5:

Level 6:

Sign-On/Sign-Off The operator can switch the system in the sign-on status if the ID and access password were correctly entered (both up to 6 characters). After entering incorrect passwords three times in succession, the workstation is locked during a preset time interval, which can be set by the system setup. Other workstation or central computer will not be affected. The operators can login with single or multi-user passwords. The single-user passwords allow a single operator to switch a single workstation in the sign-on status, but the multi-user passwords are usually entered by operators at high security levels, which need to simultaneously switch several workstations in the sign-on status. A password and specific Pag. 15 din 25

CASCADE OFFICE BUILDING enabled operating zones can be defined for each operator. Switching to the sign-off status is performed using the related command having the same name. A keyboard interruption is also provided, so that the operator is automatically switched off after a preset inactivity time interval. An automatic screen switch-off can optionally be set up to protect certain information if necessary. 7. Zone assigning Specific zones in the district heating system can be assigned to each operator with related control and supervising responsibilities. A zone will be defined as a logical entity including a system point set. Physically, this zone will be a part from the ventilation/air conditioning system. An operator can see and operate the points in the assigned zone only. 8. Password authentication Each password shall be an alphanumeric character string having up to 6 characters but not less than 5 characters. The system allows the operator to change his/her password without restrictions. When changing the password, the new password must be different from the last ten ones previously entered in the last three months. Otherwise the system will not allow entering a new password. 1.7 Time Programs

The system provides a storing capacity of at least 1,000 time programs. The time programs allow the control of system points at preset times. All the time programs can be set up through the workstations. Each program includes: Date Time Point name Point parameter Required value Programming type

Minimum types of time programs: One shot it will be run once and afterwards it will be deleted Daily it will be run every day Working days it will be run from Monday to Friday Weekend it will be run every Saturday and Sunday Holiday it will be run in holidays Special days it will be run on special days (for example on Mondays)

When the control devices have internal time programs, BMS can download, change, display or forward these programs. Pag. 16 din 25

CASCADE OFFICE BUILDING

1.8 Standard display systems

The following displays could be included as system components: Alarm content Event content Point Detail Template displays Trend Set Template displays Group Control and Group Trend Template displays Communication statuses System statuses Scratch-pad display

The Trend and Group displays setup needs entering the point name only. The other displays need no setup. 9. Managing displays The system provides the following full-screen displays: Master menu Report summary Alarm summary Event summary Display summary System parameter setup Work station setup Zone assigning Time period assigning Holiday assigning History assigning Button assigning Operator defining Operator message board Events and recovering archive Time periods and setup summary Point Detail for each configured point Pag. 17 din 25

CASCADE OFFICE BUILDING

Display Systems The system setup is displayed on the screen using the Graphic Display Building editor. The Graphic Display Building editor can operate both in the operator interface window of the BMS server and if connected to the workstations. Each program sequence is displayed through static and dynamic objects. Each operation of the WYSIWYG (What You See Is What You Get) editor displays the performed action exactly to the used workstation. Usually the static objects created with the Graphic Display Building editor are not associated with dynamic objects. The static objects could include static text, rectangles, circular arcs and circles. Anyway, there is the possibility to animate the static objects, thus resulting dynamic characteristics. For example, a tank could be drawn and animated, and its filling level could be read in a basic file. The dynamic objects can be attached to the BMS system data bases. Any information in data base can be displayed when requested by the operator, being sorted by the changing order in the data base and by the control system performance. The dynamic objects can include dynamic text, driving buttons, indicators, maps, validation boxes and scroll bars. It is possible to include the displayed static and dynamic objects in a single screen. The displayed objects can be handled through pointing, keying and dragging using the editor. They can also be moved, resized, copied, grouped, aligned and superposed using the same editor. It is also possible to copy and mark objects as well as to switch or change the displays. The Graphic Display Building editor provides the following features: Displaying the system step by step diagram Point and key operation Clipboard Placing the objects on standard co-ordinates Graduated lines Colour palette and lines Dialogue boxes to define the object details Drafting and paging the building diagram Help Importing drawings and graphics generated in standard Windows Metafiles and Bitmap files Standard diagram library 3-D effects including outlining, rotation and line change

Pag. 18 din 25

CASCADE OFFICE BUILDING 1.9 Alarm Management

The system can detect a large alarm range and it has management features to quickly and precisely detect and acknowledge all the process abnormal operating conditions.

Alarm Types The system can detect the following alarm types: PV HI PV LOW PV HI HI PV LOW LOW Hi Deviation Low Deviation Change speed System alarms Invalidated data Faulty transmission

For any four of these alarms an individual analog or accumulator type point can be defined as part of the process setup points. Alarm Priorities The system recognises four alarm priority levels as follows: Urgent High Low Journal

Each point-described alarm is included in one of these categories. The alarms having Urgent, High and Low priority can be displayed in the system alarm list. Only the Journal priority alarm is sent to the system alarm printer and it is recorded in the event data base. Any alarm type can be configured with sound warning. If configured, the sound warning appears at the workstation and optionally, through an additional contact, it can enable an external sound warning system. An operator-driven push button is recommended to shut-off the sound alarm. Should the failure not be cleared, the alarm and the sound alarm system restart. The system can re-enable the sound alarm after a preset time interval if the operator doesnt remove the detected failure. Pag. 19 din 25

CASCADE OFFICE BUILDING Alarm Processing The automatic attachment of a point at the occurrence of each alarm changes the system influence on performance in the following manner: If the alarm is cleared during the preset time, the point name, alarm type, alarm priority, point description, new value and development company will be recorded in the event data base The virtual point attached to the alarm can be displayed in red colour (steady or flashing) when this point is used If the alarm source is unknown the Low, High and Urgent alarm list should be analysed Sound alarm enabling (if configured) Alarm indicator flashes.

Additionally, the operator interface alarm zone displays the last (optionally the oldest) alarm, the priority level and the non-handled system alarms.

Alarm Handling To perform an efficient handling of system alarms, the following methods are available: Selecting any point parameter in the system diagram and assigning a recognising push button Dividing alarms in system alarming zones and pushing the assigned recognising button Dividing alarms in displayed alarm lists and pushing the assigned recognising button A paging of the displayed alarm list is performed to improve performance.

To allow the operator a better recognising, the flashing indicator will be steady lit and PV will remain red as preset. The alarm handling will be thus performed by operator-led or station-led identification in the event data base. The point must be switched off the alarm status before being handled by the operator, the alarm being described by reverse video displaying and reentering in the specification list for operator-recognised alarms. It is very easy for the server-connected controller to confirm to the operator the recognition of critical alarm conditions before taking an action.

Pag. 20 din 25

CASCADE OFFICE BUILDING

Alarm reporting The alarms can be reported as follows: Alarm message displayed on the operating interface alarm line. Alarm message in the displayed alarm list. Sound warning (if PC Speaker or sound card is used)

Alarm messages written on the alarm printer The alarms can be reported on station if there is no a permanent supervising operator. These features are operational if the workstations are permanently connected to the network and computer and if the workstation software is running and remains connected to the network. Non-reporting alarms could be due to the point detail settings.

Special Alarm Line The special alarm line appears on all the displays when there are high priority, new or old (configurable) alarms which were not handled by the system. This line will be deleted when there are no non-handled alarms for the process operator. According to alarms, the graphic display shows the identified point, point type, and special line description. If multiple alarms occur, several status condition changes and sub-segment messages will be displayed, if having highest priority. The displayed sub-segment alarms as well as the information about the previous alarms will be moved in the non-handled alarm list, waiting to be handled by the operator.

Alarm Removing If not listed on printer, the alarms are recorded in the event file to allow a subsequent reporting or archiving. Functional Keys For Alarm Responding The following dedicated functional keys and the corresponding images on the function bar can be recalled as alarm responding functions: ACKNOWLEDGE After moving the cursor on the screen point in alarm and after selecting the point, the operator can handle (read) the alarm by pressing this key. This action can be done by the operator either in the event file or when the messages are listed on the printer. ALARM SUMMARY By pressing this key in any moment, the operator can view on the screen all the currently active alarms. The alarm messages can be coloured according to priorities. The operator can view the alarms according to priorities too. It is possible to handle alarms from the current display or from an associated display defined for the related point. ASSOCIATED DISPLAY After moving the cursor on the screen point and after selecting the point, by pressing this key, the operator gets an application on a display associated to this alarm. Pag. 21 din 25

CASCADE OFFICE BUILDING 1.10 Supervising

The system provides supervising capabilities using the following functions: Real-time supervising Time supervising Archiving Table supervising Window supervising Measuring or percentage units Displayed cursor for data supervising Supervising comparisons between archived, real-time and history data (for example this year and last year). Comparisons between equally time-spaced recordings of a certain point or between different points are possible. Supervising the disconnection through the on/off method The independent Y-axis by points, multi-plot supervising. It is possible to display the Y-axis for each point by supervising, simply selecting the point with the mouse or the keyboard. Copying the current and displayed window, having the supervised data in clipboard for moving them in another window or document.

The supervising setup is simply performed with a Name.Point input for the used configuration. All the supervising configurations are performed on-line, without interrupting the system operation. The data history is not affected by the supervising configuration changes.

Supervising types The system can supervise real-time, history or multi-format archived data, the related formats being previously defined: Simple supervising bar Double supervising bar Triple supervising bar Multi-plot supervising Multi-range supervising Digital supervising X-Y-Plot supervising Plotting the value history for a certain point Plotting the value history for two points Plotting the value history for three points Plotting the value history for up to 8 points Plotting the re-aligned value history for up to 8 points Plotting the digital value history for up to 8 points Graphic comparison between 2 points

For each set of supervised data the operator can set up a number of history samples and displayable ranges. The set up points in the supervising sets can be changed on-line. The operators can read the displayed information in the supervising set for a final check. Using the scroll bars, the supervising sets can be moved before or after data recordings. The supervising sets shall have automatic access to the archived files, without operation setup.

Pag. 22 din 25

CASCADE OFFICE BUILDING 1.11 Reporting

The system includes a report flexible package for an easier generation of reported data. The reports comprise standard pre-established forms for common requirements concerning the alarm (event) reporting and for generating user-configurable reports.

Standard Reports The system includes the following preset reports: Alarm/Event report Operator order report Point order report Alarm duration report Point attribute report Data base reference report

The configuration of these reports can be found by entering the information book. There are several other parameters for a complete report configuration, such as point name, filter information, searching time interval and printer destination. The non-programmed information can specifically be recognised. 10. Alarm/Event report This report will generate a list including all the events, along with type and time specification. 11. Operator order report This report will generate a list including all the operator actions as well as information concerning the operator and operating time period. 12. Point order report This report provides the following information about a specified point or each point included in a specified set: List with displayed numbers defining the point List of algorithm numbers and corresponding blocks defining the point.

List of other reports concerning the related point 13. Report concerning the point attributes It is recommended to get a report concerning the points selected using one of the following criteria: Out-of-service Suppressed alarm Abnormal input levels Operation in manual mode Pag. 23 din 25

CASCADE OFFICE BUILDING Free Format Report Additionally, the configurable report generation allows the user to generate own reports. These reports can be generated on-line. They can have access to any data base and can perform operations to get other derived values. These values can be stored in files or other data bases. The report can include up to 132 columns of unlimited width. The report generator has the following features: Access to all the data bases and to History Access to the user-entered data Arithmetic calculation capability Statistic calculation capability User-defined report format

Report Enabling The reports can be enabled in the following circumstances: Data Export To Other Application The system allows data export to other applications, such those including spreadsheets, using methods such as CSV or copying with direct on-screen marking. The real-time data transfer using Windows 3.x Dynamic Data Exchange (DDE) or Windows95 OBDC can be performed in such a way that the requirements of POINT. PARAMETER be observed. The History is also accessible via DDE or OBDC. Periodical enabling at user-specified time intervals At the operator request Started by events Started by applications

Pag. 24 din 25

CASCADE OFFICE BUILDING

1.12 System Security

The system provides up to 6 security levels ensuring a graduated access to the operating and setup functions. If necessary, each operator can be associated with a profile defined by the following parameters: Security level (1-6) Control level (1-255) Operator ID Unique password

Any action started by the operator can be recorded in the event data base with the operator ID. Moreover, a point operation will not be accepted if the correspondence between the operator profile and the level assigned to the related point is not achieved. A password management mode can be provided. 1.13 LAN Network Integration

BMS Network Server This feature allows using computers with real-time access to BMS system data base and History, using a TCP/IP LAN communication. The access is permitted in the following circumstances: Microsoft DDE applications using DDE or OBDC network software Other BMS systems via Network Node Scanning Applications developed by the user based on Network Application Programming Interface libraries supplied by the BMS provider

SQL Reporting System This system allows the user to get a report using SQL commands for data transfer between BMS data base and a local or remote SQL server, and a relational data base (Sybase for example). Network printing BMS allows the multiple workstations to be screen dumps connected to a printer. The printer must be connected to a parallel port on a sole workstation.

Pag. 25 din 25

You might also like

- RAUPEX Radiant HeatingDocument8 pagesRAUPEX Radiant HeatingFrinaru CiprianNo ratings yet

- N-O Zone ValveDocument1 pageN-O Zone ValveFrinaru CiprianNo ratings yet

- Raupex Heating and Plumbing SystemsDocument8 pagesRaupex Heating and Plumbing SystemsFrinaru CiprianNo ratings yet

- 3-Way Therm Valve Wcon SZDocument1 page3-Way Therm Valve Wcon SZFrinaru CiprianNo ratings yet

- NOX TPA E DescriptionDocument5 pagesNOX TPA E DescriptionFrinaru CiprianNo ratings yet

- Sauter Electronic AG-EnglischDocument7 pagesSauter Electronic AG-EnglischFrinaru CiprianNo ratings yet

- NOX operation and control via PC softwareDocument8 pagesNOX operation and control via PC softwareFrinaru CiprianNo ratings yet

- 2004 Radiant Heating CatalogDocument47 pages2004 Radiant Heating CatalogFrinaru CiprianNo ratings yet

- 4-Way Valve Wcon Delux-SZDocument1 page4-Way Valve Wcon Delux-SZFrinaru CiprianNo ratings yet

- 2-Way Inject Valve Wcon SZDocument1 page2-Way Inject Valve Wcon SZFrinaru CiprianNo ratings yet

- NOX TPA E DescriptionDocument5 pagesNOX TPA E DescriptionFrinaru CiprianNo ratings yet

- NOX Operation 1.4 EDocument28 pagesNOX Operation 1.4 EFrinaru CiprianNo ratings yet

- Vito PlexDocument22 pagesVito PlexFrinaru CiprianNo ratings yet

- NOX operation and control via PC softwareDocument8 pagesNOX operation and control via PC softwareFrinaru CiprianNo ratings yet

- Usage of Picture Monitoring System: - Protection Against Theft - Protection Against DamageDocument11 pagesUsage of Picture Monitoring System: - Protection Against Theft - Protection Against DamageFrinaru CiprianNo ratings yet

- Security Information Management System (SIMS)Document39 pagesSecurity Information Management System (SIMS)Frinaru CiprianNo ratings yet

- SIMS Install V4Document21 pagesSIMS Install V4Frinaru CiprianNo ratings yet

- NOX Systems technical data overview for intrusion detectionDocument2 pagesNOX Systems technical data overview for intrusion detectionFrinaru CiprianNo ratings yet

- Security Information Management System (SIMS)Document41 pagesSecurity Information Management System (SIMS)Frinaru CiprianNo ratings yet

- SIMS Install V4Document21 pagesSIMS Install V4Frinaru CiprianNo ratings yet

- SIMS Install V4Document21 pagesSIMS Install V4Frinaru CiprianNo ratings yet

- Security Information Management System (SIMS)Document39 pagesSecurity Information Management System (SIMS)Frinaru CiprianNo ratings yet

- SIMS Install V4Document21 pagesSIMS Install V4Frinaru CiprianNo ratings yet

- Security Information Management System (SIMS)Document41 pagesSecurity Information Management System (SIMS)Frinaru CiprianNo ratings yet

- FLD E DescriptionDocument2 pagesFLD E DescriptionFrinaru CiprianNo ratings yet

- NOX E DatasheetsDocument12 pagesNOX E DatasheetsFrinaru CiprianNo ratings yet

- NOX E Devicelist LongDocument22 pagesNOX E Devicelist LongFrinaru CiprianNo ratings yet

- NOX E DatasheetsDocument12 pagesNOX E DatasheetsFrinaru CiprianNo ratings yet

- RV AsennusohjeDocument12 pagesRV AsennusohjeFrinaru CiprianNo ratings yet

- RV DatasheetDocument2 pagesRV DatasheetFrinaru CiprianNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Basics Guide: Autodesk Maya 2020Document40 pagesBasics Guide: Autodesk Maya 2020KARTICK PRASADNo ratings yet

- A WR Getting StartedDocument136 pagesA WR Getting StartedSri LakshmiNo ratings yet

- Chapter 4 - User InteractionDocument155 pagesChapter 4 - User InteractionAngela BeatriceNo ratings yet

- Vista 20P - Programming GuideDocument16 pagesVista 20P - Programming GuideIrfan SupuNo ratings yet

- As Built ManagerDocument154 pagesAs Built ManagerAmol KolheNo ratings yet

- Chessmaster® Grandmaster Edition Manual PDFDocument31 pagesChessmaster® Grandmaster Edition Manual PDFjohnlondon125100% (1)

- PICAXE VSM Tutorial - Part 2 InstallationDocument11 pagesPICAXE VSM Tutorial - Part 2 InstallationVDT2420 EmbeddedNo ratings yet

- 51 - Interface With Staad Pro - DocDocument21 pages51 - Interface With Staad Pro - DocFauzankalibataNo ratings yet

- NSFC01-02 SM01A (English)Document57 pagesNSFC01-02 SM01A (English)Madiha Maroof100% (13)

- 05-6193A01A Serial-Telnet SupplementDocument114 pages05-6193A01A Serial-Telnet SupplementJanssen N'GadiNo ratings yet

- Ga 160 VSD: Instruction BookDocument112 pagesGa 160 VSD: Instruction BookserkalemtayeNo ratings yet

- GMS - Getting StartedDocument37 pagesGMS - Getting StartedSorina CrețuNo ratings yet

- Tkuse Creo10000Document2,253 pagesTkuse Creo10000tanytanaya101No ratings yet

- NOKIA 6610 User GuideDocument185 pagesNOKIA 6610 User GuideIjazNo ratings yet

- T24 Induction Business - Navigation R13 v1.0 Sept 13 PDFDocument112 pagesT24 Induction Business - Navigation R13 v1.0 Sept 13 PDFclement100% (1)

- Operation Manual: Flame/Plasma CNC Cutting SystemDocument37 pagesOperation Manual: Flame/Plasma CNC Cutting SystemФусо100% (1)

- Testing QTP NotesDocument38 pagesTesting QTP NotesAbhishekNo ratings yet

- Series SRX: Total StationDocument126 pagesSeries SRX: Total Stationspani20003867No ratings yet

- Ct90302 Remote InstructionsDocument6 pagesCt90302 Remote InstructionsRoberto Murillo AriasNo ratings yet

- SPEED PARK VALET MANAGEMENTDocument14 pagesSPEED PARK VALET MANAGEMENTAbdul RehmanNo ratings yet

- BLT 3012 Hydraulics InfoWorks TutorialDocument13 pagesBLT 3012 Hydraulics InfoWorks TutorialdobridorinNo ratings yet

- SoftX3000 Hardware Description ManualDocument148 pagesSoftX3000 Hardware Description ManualHassaan Shuja50% (2)

- XK3196F1 Weighing Indicator Adjustment Manual: PanelDocument4 pagesXK3196F1 Weighing Indicator Adjustment Manual: PanelJaspreet RoopraiNo ratings yet

- Ads GuideDocument146 pagesAds GuideSudharshan BabuNo ratings yet

- H3000 Series ManualDocument118 pagesH3000 Series ManualNapau CristianNo ratings yet

- Operator's Manual for the AGC Automatic Gen-set ControllerDocument19 pagesOperator's Manual for the AGC Automatic Gen-set ControllerAugusto BellezaNo ratings yet

- 354 267-24 (Heidenhain)Document550 pages354 267-24 (Heidenhain)Nicolae TabircaNo ratings yet

- Hot Notes User GuideDocument13 pagesHot Notes User GuidesumanNo ratings yet

- R-Net OBP ManualDocument43 pagesR-Net OBP ManualKin Fung SoNo ratings yet