Professional Documents

Culture Documents

Table 1. Summary of Contract Required Detection Limits, Holding Times, and Preservation For HEM Oil and Grease and SGT-Hem Non-Polar Material

Uploaded by

prouserdesigner77Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table 1. Summary of Contract Required Detection Limits, Holding Times, and Preservation For HEM Oil and Grease and SGT-Hem Non-Polar Material

Uploaded by

prouserdesigner77Copyright:

Available Formats

N-HEXANE EXTRACTABLE MATERIAL (HEM; OIL AND GREASE) and SILICA GEL TREATED N HEXANE EXTRACTABLE MATERIAL (SGT-HEM;

NON-POLAR MATERIAL) Extraction and Gravimetry

EPA Office of Water Method 1664, Revision A (February 1999)

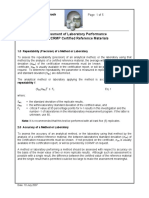

Table 1. Summary of Contract Required Detection Limits, Holding Times, and Preservation for HEM; Oil and Grease and SGT-Hem; Non-polar Material Contract Required Detection Limit (CRDL) 5 mg/L Technical and Contract Holding Times Preservation

Analytical Parameter

N-Hexane Extractable Material (HEM); Oil and Grease Silica Gel Treated N-Hexane Extractable Material (SGT HEM); Non-polar Material

Technical: 28 days from collection; Contract: 26 days from receipt at laboratory Technical: 28 days from collection; Contract: 26 days from receipt at laboratory

pH <2 with HCl or H2SO4; Cool to 2E C 2E C

5 mg/L

pH <2 with HCl or H2SO4; Cool to 2E C 2E C

Data Calculations and Reporting Units: Calculate HEM and SGT-HEM sample results using Equation 5 provided in Section 12.0 of Method 1664A. Report water sample results in concentration units of milligrams per liter (mg/L) HEM and mg/L SGT-HEM. Report HEM and SGT-HEM concentrations that are less than 10 mg/L to 2 significant figures, and HEM and SGT-HEM concentrations that are greater than or equal to 10 mg/L to 3 significant figures. For rounding results, adhere to the following rules: a) If the number following those to be retained down; b) If the number following those to be retained round up; or c) If the number following the last digit to be 5, round down if the digit is even, or round odd. is less than 5, round is greater than 5, retained is equal to up if the digit is

All records of analysis and calculations must be legible and sufficient to recalculate all sample concentrations and QC results. Include an example calculation in the data package.

1664ACRF 1 of 3 Revision 1/21/2000

Table 2.

Summary of Calibration Procedures for HEM; Oil and Grease and SGT-Hem; Non-polar Material by Method 1664A Frequency Daily Acceptance Criteria 10% at 2 mg ( 0.2 mg) 0.5% at 1000 mg ( 5 mg) 10% at 2 mg ( 0.2 mg) 0.5% at 1000 mg ( 5 mg) Corrective Action 1. Recalibrate balance and verify before sample analysis 1. Recalibrate balance and verify before sample analysis 2. Reweigh the batch

Calibration Element Calibrate Analytical Balance at 2 mg and 1000 mg using Class S weights Calibration Verification (CV) at 2 mg and 1000 mg

Daily, after sample analysis

Table 3.

Summary of Internal Quality Control Procedures for HEM; Oil and Grease and SGT-Hem; Non-polar Material by Method 1664A Frequency One per Batch or SDG (1 per 20 samples minimum) Acceptance Criteria < CRDL

a

QC Element Laboratory Method Blank (MB)

Corrective Action 1. Halt analyis, eliminate source of contamination and weigh blank showing no evidence of contamination 3. All samples must be associated with an uncontaminated method blank 1. Flag associated data with an "*"

Duplicate Sample (DUP)

One per batch or SDG

RPD <20% for samples >5X CRDL; CRDL for samples <5X CRDL 25% from expected value Within limits: Avg R 2s e

Matrix Spike (MS)b Ongoing Precision and Recovery (OPR) Standard c, d

One per batch or SDG One per batch or SDG

1. Flag associated data with an "N" 1. Identify and correct the problem. 2. Re-extract sample batch. 3. Repeat OPR

a SDG - Sample Delivery Group - each case of field samples received; or each 20 field samples within a case; or each 14 calendar day period during which field samples in a case are received. b

Spike sample aliquot with the hexadecane/stearic acid spiking solution.

Follow Section 9.3 of Method

1664ACRF 2 of 3 Revision 1/21/2000

1664A for Matrix Spike sample.

c d

Refer to Section 9.6 of Method 1664A.

The OPR standard must be spiked with hexadecane/stearic acid solution prepared from a separate source than the solution used for matrix spikes.

e

Plus or minus 2 standard (s) deviations of the average recovery (R).

Dilute and reanalyze samples with concentrations exceeding the range of the calibration curve. Results for such reanalyses should fall within the mid-range of the calibration curve. Report results and submit documentation for both analyses.

1664ACRF 3 of 3 Revision 1/21/2000

You might also like

- Table 1. Summary of Contract Required Detection Limits, Holding Times, and Preservation For HEM Oil and Grease and SGT-Hem Non-Polar MaterialDocument3 pagesTable 1. Summary of Contract Required Detection Limits, Holding Times, and Preservation For HEM Oil and Grease and SGT-Hem Non-Polar MaterialrasyidridhoNo ratings yet

- Table 1A. Summary of Holding Times and Preservation For Organophosphorus PesticidesDocument4 pagesTable 1A. Summary of Holding Times and Preservation For Organophosphorus PesticidesrizonicoNo ratings yet

- Table 1. Summary of Contract Required Detection Limits, Holding Times, and Preservation For Total Organic Carbon (TOC)Document6 pagesTable 1. Summary of Contract Required Detection Limits, Holding Times, and Preservation For Total Organic Carbon (TOC)Ibnu RhidaNo ratings yet

- Table 1. Summary of Contract Required Detection Limits, Holding Times, and Preservation For Chemical Oxygen Demand (COD)Document4 pagesTable 1. Summary of Contract Required Detection Limits, Holding Times, and Preservation For Chemical Oxygen Demand (COD)Sumeet Kumar SinhaNo ratings yet

- BOD Standard Method 5210 BDocument2 pagesBOD Standard Method 5210 BLUCHY43No ratings yet

- Table 1. Summary of Contract Required Detection Limits, Holding Times, and Preservation For Biochemical Oxygen Demand (BOD)Document2 pagesTable 1. Summary of Contract Required Detection Limits, Holding Times, and Preservation For Biochemical Oxygen Demand (BOD)Syahrul AminNo ratings yet

- OspeDocument29 pagesOspemonday125No ratings yet

- γ-GT Determination Kinetic MethodDocument4 pagesγ-GT Determination Kinetic MethodpixiedustNo ratings yet

- DGA - DGA Gas-In-Oil Standards A Tool - M CyrDocument14 pagesDGA - DGA Gas-In-Oil Standards A Tool - M Cyrganeshrudra100% (1)

- CoA P873870Document3 pagesCoA P873870madalin danilNo ratings yet

- TNTplus Ammonia EPA FormatDocument10 pagesTNTplus Ammonia EPA FormatOudah AliNo ratings yet

- UOP 555-10 Trace Impurities in Benzene by GCDocument11 pagesUOP 555-10 Trace Impurities in Benzene by GCMorteza SepehranNo ratings yet

- TNTplus Ammonia EPA FormatDocument10 pagesTNTplus Ammonia EPA FormatYoyito JaenNo ratings yet

- GcmsDocument3 pagesGcmsRista Susanti100% (1)

- D 6584 - 00 - Rdy1odqDocument5 pagesD 6584 - 00 - Rdy1odqSeven DangNo ratings yet

- Flahive Et al-2007-QSAR & Combinatorial ScienceDocument7 pagesFlahive Et al-2007-QSAR & Combinatorial ScienceEmrah ÇAMNo ratings yet

- Certificate of Analysis for Vitamin A Palmitate CRMDocument6 pagesCertificate of Analysis for Vitamin A Palmitate CRMAnonymous pCIauPOGNo ratings yet

- AgilentDocument8 pagesAgilentratnagiridineshNo ratings yet

- Method 10B - Determination of Carbon Monoxide Emissions From Stationary SourcesDocument8 pagesMethod 10B - Determination of Carbon Monoxide Emissions From Stationary SourcessimonclaudioNo ratings yet

- Hach TKN Method 10242 Final 01102013Document10 pagesHach TKN Method 10242 Final 01102013Oudah AliNo ratings yet

- Lipidocare User GuideDocument89 pagesLipidocare User GuideCarlos Alberto ContrerasqNo ratings yet

- PI e TRIG - 5 11Document2 pagesPI e TRIG - 5 11sovi haswindhaNo ratings yet

- PI e TRIG - 5 11Document2 pagesPI e TRIG - 5 11Salsabila Nur OktavianiNo ratings yet

- D2789Document7 pagesD2789rimi7alNo ratings yet

- PRPP 2013 Crude Oil PropertiesDocument7 pagesPRPP 2013 Crude Oil PropertiesMohamed AlaaNo ratings yet

- AOCS Ce 1d91Document3 pagesAOCS Ce 1d91Lucas de Melo100% (1)

- Nsf-Ansi-Can 61-2020-20210602150943 (100-163)Document64 pagesNsf-Ansi-Can 61-2020-20210602150943 (100-163)QT Trái Tim Của GióNo ratings yet

- Certificate of Analysis: Reference Material - Primary StandardDocument8 pagesCertificate of Analysis: Reference Material - Primary StandardWidya Dwi AriniNo ratings yet

- Ra SP Sulf Leco - 632Document6 pagesRa SP Sulf Leco - 632Febri SandiNo ratings yet

- Lab Policies Triglycerides - Cobas c501 Lab 4455Document4 pagesLab Policies Triglycerides - Cobas c501 Lab 4455Marj MendezNo ratings yet

- Analytical Method Validation Report of Saxagliptin TabletDocument25 pagesAnalytical Method Validation Report of Saxagliptin TabletUmer Al-FaisalNo ratings yet

- RACE KitDocument31 pagesRACE KitManikantan KNo ratings yet

- Lab Policies Hemoglobin A1C - Cobas c501 Lab 4004Document6 pagesLab Policies Hemoglobin A1C - Cobas c501 Lab 4004yosefinNo ratings yet

- USEPA Hach Method 10267Document9 pagesUSEPA Hach Method 10267rezaNo ratings yet

- Cap EiaDocument8 pagesCap EiangathamNo ratings yet

- Creatinine Test Kit Quality ControlsDocument2 pagesCreatinine Test Kit Quality ControlsKOUAME EDYMAIN FRANCISNo ratings yet

- LIPASEDocument4 pagesLIPASEsyufriyadiNo ratings yet

- PI e TRIG - 10 15Document2 pagesPI e TRIG - 10 15labor baiturrahimNo ratings yet

- Environmental and Plant Hygiene Monitoring ProcedureDocument8 pagesEnvironmental and Plant Hygiene Monitoring ProcedureelvinmauyaNo ratings yet

- Clinical Laboratories Point of Care Testing: Rev 2, Ver 1, 6/2013Document22 pagesClinical Laboratories Point of Care Testing: Rev 2, Ver 1, 6/2013Inês PimentaNo ratings yet

- Charged Aerosol Detection for Liquid Chromatography and Related Separation TechniquesFrom EverandCharged Aerosol Detection for Liquid Chromatography and Related Separation TechniquesPaul H. GamacheNo ratings yet

- Determination of α-Amylase Activity Using a Colorimetric MethodDocument1 pageDetermination of α-Amylase Activity Using a Colorimetric MethodMaher100% (1)

- Potenciometria Minoxidil PDFDocument5 pagesPotenciometria Minoxidil PDFJ C Torres FormalabNo ratings yet

- Low Level Measurement of Cadmium in Foods: AA-97 May 1990Document5 pagesLow Level Measurement of Cadmium in Foods: AA-97 May 1990ابزار دقیقNo ratings yet

- Bdox D Met Dioxins Furans Brominated-DioxinsDocument50 pagesBdox D Met Dioxins Furans Brominated-Dioxinssabrina amaralNo ratings yet

- TG 702Document4 pagesTG 702hairiNo ratings yet

- Duval 2005Document7 pagesDuval 2005Daniel LuchoNo ratings yet

- M 12-D I L E F S S: 1.0 Scope and ApplicationDocument14 pagesM 12-D I L E F S S: 1.0 Scope and ApplicationLili YiyoNo ratings yet

- Determination of Disinfectant Imagard ID-401 Residue Post Application On SurfaceDocument7 pagesDetermination of Disinfectant Imagard ID-401 Residue Post Application On SurfaceSurjeet SamantaNo ratings yet

- Creatinine: Quantitative Determination of CreatinineDocument2 pagesCreatinine: Quantitative Determination of CreatinineSamuel GCNo ratings yet

- DMA-80 Tips and TechniquesDocument15 pagesDMA-80 Tips and TechniquesJuan CarlosNo ratings yet

- CreaDocument5 pagesCreaKouame Francis0% (1)

- AAGP2 enDocument3 pagesAAGP2 enLince WijoyoNo ratings yet

- 5c. Acceptance SamplingDocument17 pages5c. Acceptance SamplingSagar ShahNo ratings yet

- Hydrogen Content of Gases by Gas ChromatographyDocument3 pagesHydrogen Content of Gases by Gas ChromatographyDavinNo ratings yet

- 3-MCPD Analysis in Oils by AOCS Cd 29c MethodDocument19 pages3-MCPD Analysis in Oils by AOCS Cd 29c MethodSergio Peralta MolinaNo ratings yet

- En CK (Nac) Baosr6x79 UsDocument3 pagesEn CK (Nac) Baosr6x79 UscarineNo ratings yet

- Materiales de Referencia CCRMP (CANMET)Document5 pagesMateriales de Referencia CCRMP (CANMET)Erick Leonardo Valle MendozaNo ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- A Laboratory Manual of Physical PharmaceuticsFrom EverandA Laboratory Manual of Physical PharmaceuticsRating: 2.5 out of 5 stars2.5/5 (2)

- Numerical Methodes of Exploration Seismology - Margrave - 10Document1 pageNumerical Methodes of Exploration Seismology - Margrave - 10prouserdesigner77No ratings yet

- Numerical Methodes of Exploration Seismology - Margrave - 11Document1 pageNumerical Methodes of Exploration Seismology - Margrave - 11prouserdesigner77No ratings yet

- SPS FormatDocument37 pagesSPS Formatprouserdesigner77No ratings yet

- Hell WeekDocument1 pageHell Weekprouserdesigner77No ratings yet

- PDT-00 2D Survey Processing FlowDocument2 pagesPDT-00 2D Survey Processing Flowprouserdesigner77No ratings yet

- Us20030075626 PDFDocument28 pagesUs20030075626 PDFprouserdesigner77No ratings yet

- IR06121Document42 pagesIR06121prouserdesigner77No ratings yet

- Seismic ProcessingDocument15 pagesSeismic ProcessingAbdelrahman Mossaad0% (1)

- Reg Lement 4Document15 pagesReg Lement 4prouserdesigner77No ratings yet

- 2017 Cisbgf Cleriston Ilovepdf CompressedDocument7 pages2017 Cisbgf Cleriston Ilovepdf Compressedprouserdesigner77No ratings yet

- Computers & Geosciences Volume 33 Issue 7 2007 (Doi 10.1016/j.cageo.2007.03.003) Geoff Bohling - Richard C. Aster, Brian Borchers, Clifford H. Thurber,, Parameter Estimation and Inverse Problems (2Document2 pagesComputers & Geosciences Volume 33 Issue 7 2007 (Doi 10.1016/j.cageo.2007.03.003) Geoff Bohling - Richard C. Aster, Brian Borchers, Clifford H. Thurber,, Parameter Estimation and Inverse Problems (2prouserdesigner77No ratings yet

- TLE 1996 Scalable ParallelDocument4 pagesTLE 1996 Scalable Parallelprouserdesigner77No ratings yet

- Jackson Wood Shaving Mill 16D4Document2 pagesJackson Wood Shaving Mill 16D4prouserdesigner77No ratings yet

- Full Step by Step Tutorial On How To HACK GMail AccountsDocument3 pagesFull Step by Step Tutorial On How To HACK GMail AccountsAditya Thakker90% (10)

- SPS Format.1Document35 pagesSPS Format.1Bayu SaputroNo ratings yet

- Wood Shaving Machine: Skype:olivia910402Document2 pagesWood Shaving Machine: Skype:olivia910402prouserdesigner77No ratings yet

- Specifications: SM600 Wood Shaving MachineDocument1 pageSpecifications: SM600 Wood Shaving Machineprouserdesigner77No ratings yet

- Wis 23Document7 pagesWis 23prouserdesigner77No ratings yet

- SS-24 Shaving MachineDocument1 pageSS-24 Shaving Machineprouserdesigner77No ratings yet

- VMware Linux VM Best PracticeDocument23 pagesVMware Linux VM Best PracticeJuan Carlos CasanovNo ratings yet

- Harmonic Noise Attenuation For Vibroseis Data: G. Dal Moro, P. Scholtz, K. IranpourDocument3 pagesHarmonic Noise Attenuation For Vibroseis Data: G. Dal Moro, P. Scholtz, K. Iranpourprouserdesigner77No ratings yet

- Create UserDocument1 pageCreate Userprouserdesigner77No ratings yet

- Vib CorrDocument2 pagesVib Corrprouserdesigner77No ratings yet

- 3D Geometry Loading in Promax, A Practical Crperl ExampleDocument13 pages3D Geometry Loading in Promax, A Practical Crperl Exampleprouserdesigner77No ratings yet

- Geo ScientistDocument1 pageGeo Scientistprouserdesigner77No ratings yet

- Azanwaeqama PDFDocument35 pagesAzanwaeqama PDFprouserdesigner77No ratings yet

- 2003 55Document18 pages2003 55Ray SeawerNo ratings yet

- Geophy SNR GeophyDocument1 pageGeophy SNR Geophyprouserdesigner77No ratings yet

- PDocument68 pagesPprouserdesigner77No ratings yet

- Sharh Thalathat AlosoolDocument167 pagesSharh Thalathat AlosoolabdulhakimkNo ratings yet

- 9 - NCP Computer Science PGDocument19 pages9 - NCP Computer Science PGM AmbreenNo ratings yet

- SuffrageDocument21 pagesSuffragejecelyn mae BaluroNo ratings yet

- Universal Robina Co. & Bdo Unibank Inc.: Research PaperDocument25 pagesUniversal Robina Co. & Bdo Unibank Inc.: Research PaperSariephine Grace ArasNo ratings yet

- Migration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Document28 pagesMigration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Ajay palNo ratings yet

- Revised Man As A Biological BeingDocument8 pagesRevised Man As A Biological Beingapi-3832208No ratings yet

- Osora Nzeribe ResumeDocument5 pagesOsora Nzeribe ResumeHARSHANo ratings yet

- LGFL Service GuideDocument24 pagesLGFL Service GuideThe Return of the NoiristaNo ratings yet

- 277Document18 pages277Rosy Andrea NicolasNo ratings yet

- BMXNRPDocument60 pagesBMXNRPSivaprasad KcNo ratings yet

- Java MCQ QuestionsDocument11 pagesJava MCQ QuestionsPineappleNo ratings yet

- Done by Akansha Bharti Harshitha K.N. Ishika Sunil Rajput Rashmi NaikDocument12 pagesDone by Akansha Bharti Harshitha K.N. Ishika Sunil Rajput Rashmi NaikRamya BalanNo ratings yet

- Overview for Report Designers in 40 CharactersDocument21 pagesOverview for Report Designers in 40 CharacterskashishNo ratings yet

- Chapter 08Document18 pagesChapter 08soobraNo ratings yet

- Wsi PSDDocument18 pagesWsi PSDДрагиша Небитни ТрифуновићNo ratings yet

- LLM DissertationDocument94 pagesLLM Dissertationjasminjajarefe100% (1)

- Tupperware India's Perception StudyDocument10 pagesTupperware India's Perception StudyAnmol RahangdaleNo ratings yet

- Test SessionDocument2 pagesTest SessionMuhammad Fiaz AslamNo ratings yet

- Palgrave Handbook of Research in Historical Culture and EducationDocument847 pagesPalgrave Handbook of Research in Historical Culture and EducationGonzalo Garcia100% (1)

- Ne 01 20 09 2018Document436 pagesNe 01 20 09 2018VaradrajNo ratings yet

- MKT-case StudyDocument7 pagesMKT-case StudyJoe Thampi KuruppumadhomNo ratings yet

- 99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudDocument6 pages99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudPavankumar PuvvalaNo ratings yet

- Khaton Prayer BookDocument47 pagesKhaton Prayer BookKarma TsheringNo ratings yet

- Technical File D13-MH, MG IMO Tier 11 GLDocument18 pagesTechnical File D13-MH, MG IMO Tier 11 GLsfsdffdsdfsdfsdfNo ratings yet

- Plant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirDocument20 pagesPlant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirSharad KokateNo ratings yet

- Policies and Regulations On EV Charging in India PPT KrishnaDocument9 pagesPolicies and Regulations On EV Charging in India PPT KrishnaSonal ChoudharyNo ratings yet

- Motivations for Leaving Public Accounting FirmsDocument33 pagesMotivations for Leaving Public Accounting Firmsran0786No ratings yet

- C ClutchesDocument131 pagesC ClutchesjonarosNo ratings yet

- PowerhouseDocument10 pagesPowerhouseRanjan DhungelNo ratings yet

- Exam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023Document285 pagesExam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023maniNo ratings yet

- Moderntheater 170210003221 PDFDocument80 pagesModerntheater 170210003221 PDFDycan MikeNo ratings yet